With gearbox finally attached, and most of the ancillaries in place, the engine and gearbox went back in on Monday.

Next jobs on the list:

- Refit tailshaft, PPF and shifter

- Bleed clutch system (has a new flexible line to replace the squiggly hardline)

- Make and fit fuel lines for to and from the fuel rail to the FPR and return line.

- fit radiator and finalise reroute piping

- fit intercooler and fabricate intercooler pipework

- Extend IAT sensor wiring to the new IAT location (exit of intercooler)

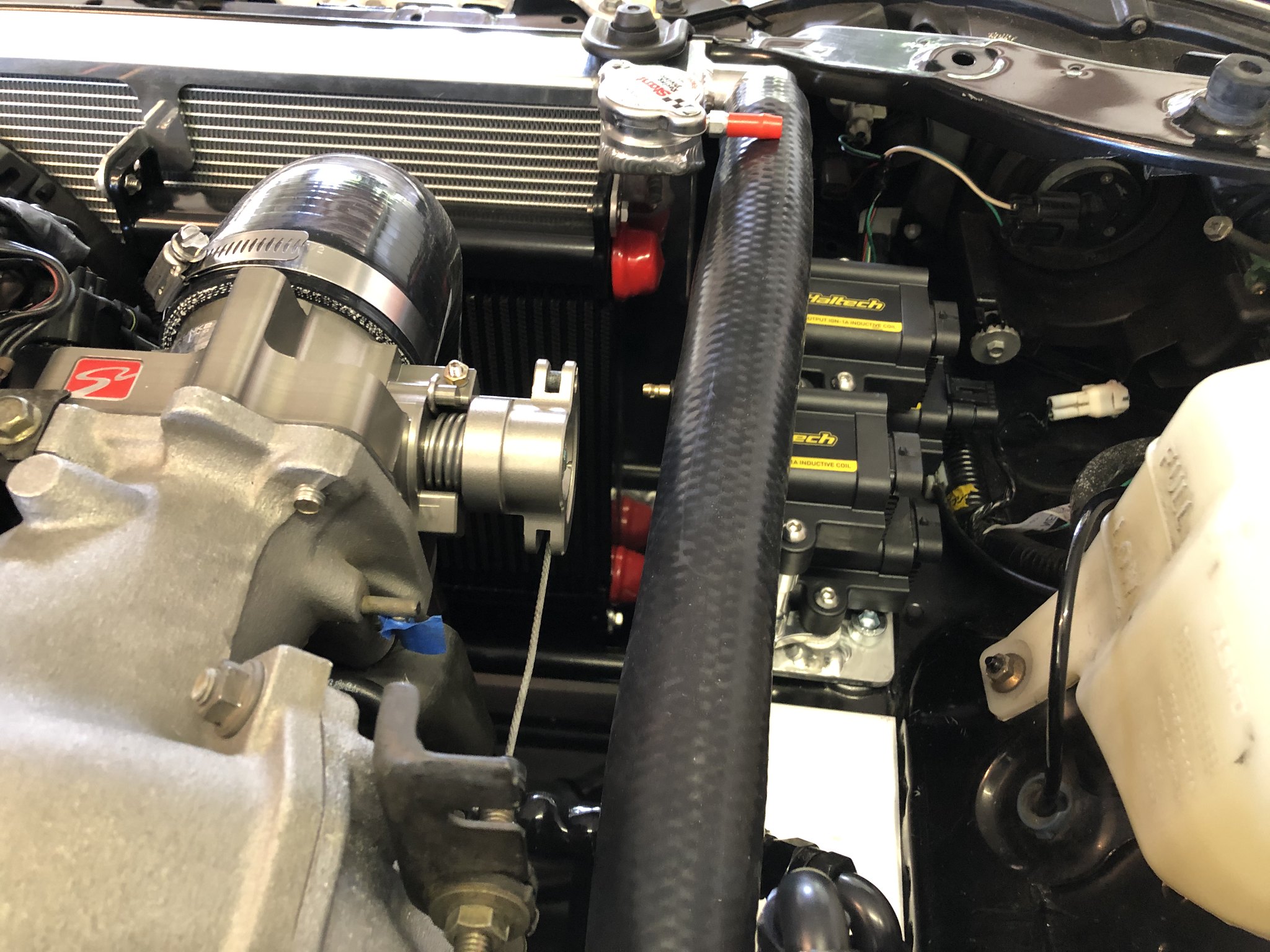

- Mount ignition coils

- Mount oil filter block and make lines

- mount oil cooler and make lines

So many jobs left to do!

[/url]

[/url]