Your pressure sensor seems OK - DON'T buy any pressure sensor under A$100, they're usually crap Chinese ones.

You will need to configure your ECU to start reading those new inputs too (Hint: Use that linear table shown in your Oil temperature pictures and use the correct table data for your temperature sensor - it's NOT linear and they're NOT all calibrated the same).

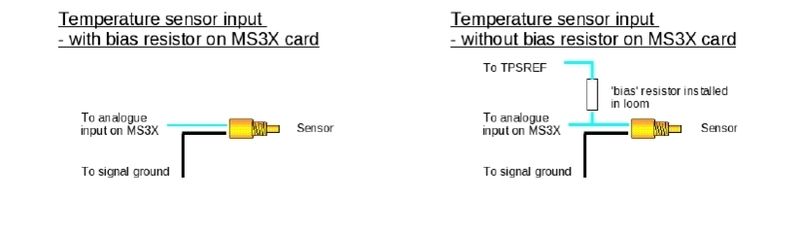

I need to double-check the temperature sensor though for connections but polarity DOESN'T matter for thermistors (I can't remember if you need to connect it to 5V or GND - logic says it should be 5V since GND can be provided by the threading but for some reason I remember it as needing GND).

Vampire clamps on thin wires are a bad idea since they'll eventually break them and you'll end up with 2 sensors that no longer work if you're tapping off an existing sensor.

I have used them to tap power+GND from my power windows for my Wideband O2 heater element since those are VERY thick copper wires - still best NOT to use them anywhere but this was low-risk and I needed to finish the job quickly.

Have a look a Soviet's thread on MT.net, starting at post#1977 on

https://www.miataturbo.net/build-threads-57/soviet-russia-car-build-you-61522/page33/ He uses a proper crimping tool (I bought this same one and it's bloody good) and crimps for specific wire gauges (I've got a bunch of these too).

OEM uses crimps for joining wires so you should too - there's less chance of them breaking (when you solder thin wires, it can make them more susceptible to breaking/snapping at the solder point) Just make sure you insulate them after to avoid shorts.

In my SP23, for the audible reversing sensors, I used the reverse lights for a source of power and GND. I stripped away the insulation where I wanted to tap to, crimped my new wires to those points using the appropriate crimp and taped them up for insulation. This left the original wires intact, was easy to do and looked OK.

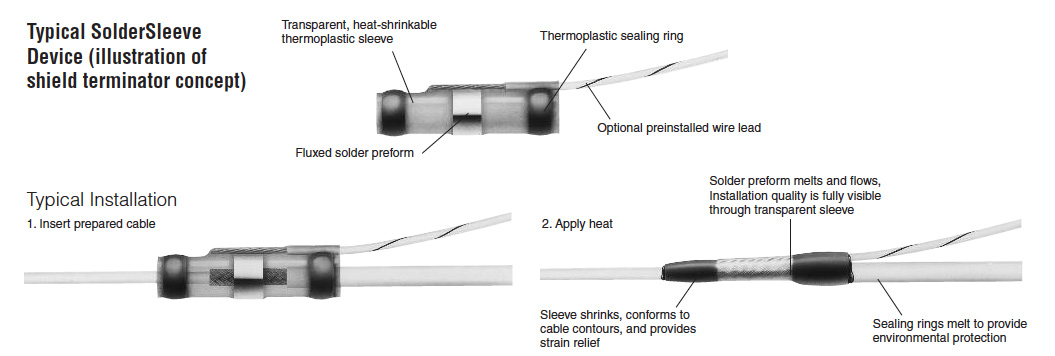

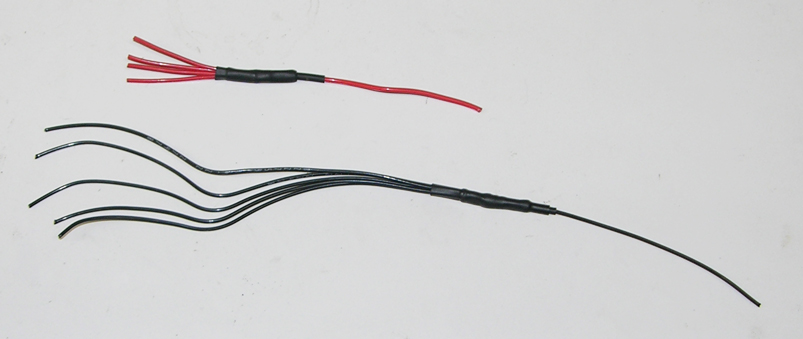

The solder sleeves are a good idea since they provide extra strength around the solder point and insulation - I've used these in places.

Finding small wire crimps can be hard but you can DIY them by cutting the tips off existing spare pins you may have lying around.

Also for small wire pins, get a suitable crimping tool - the Supercheap one used for bullet/spade connectors is way too big and clumsy.