Originally posted by Lokiel, Sun Sep 24, 2017 3:41 pmOriginally posted by Lokiel, Sun Apr 10, 2011 8:26 pm[I'm currently in the process of installing an Adaptronic e440 SE/Mazdaspeed ECU.

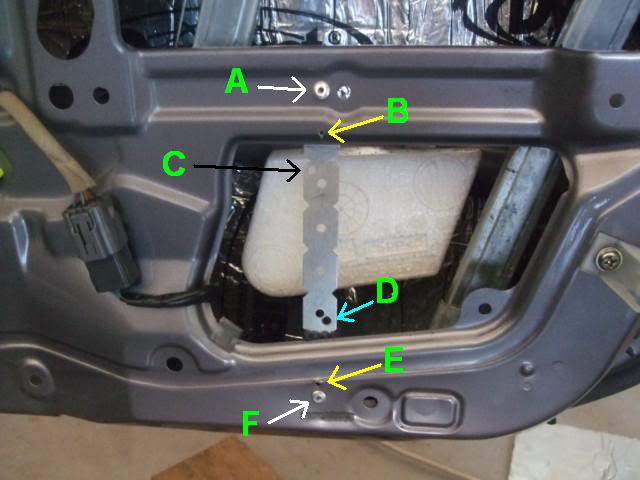

Here's where the ECU is located in RHD cars, the passenger footwell, under the carpet:

The top photo shows the cover plate, the lower shows the ECU under that cover plate.

Note that to remove the cover plate, you'll need to either grind off the lower two outer-most bolts or use your Dremel to cut a slice into them so that you can undo them with a screwdriver.

Those blue wires, "vampire clipped" to the ECU wires, were for my Flyin' Miata O2 Mod - these have now been removed since they are no longer required with the Adaptronic - WHOOPIE!

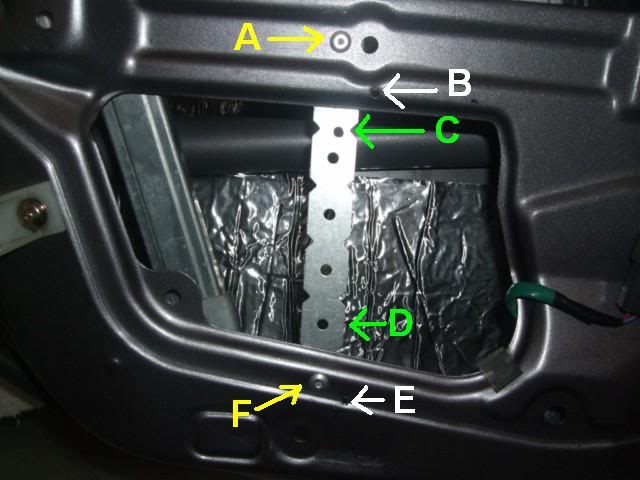

I decided to mount the e440 next to the ECU since it looks like there's plenty of room:

The white harnesses from the OEM ECU were included with the e440 but, as you can see, unfortunately they're about 120mm too short. I spoke to Andy from Adaptronic and he's sending me some longer ones. The Americans need longer harnesses and I suspect most Aussies will too. I really didn't want to lengthen these myself, 4-8 wires is OK, but not 30 or so.

This photo shows how the OEM ECU is mounted against thecover plate:

The bracket on the top left is not actually mounted to the cover plate, it's merely used as a brace for the OEM harness.

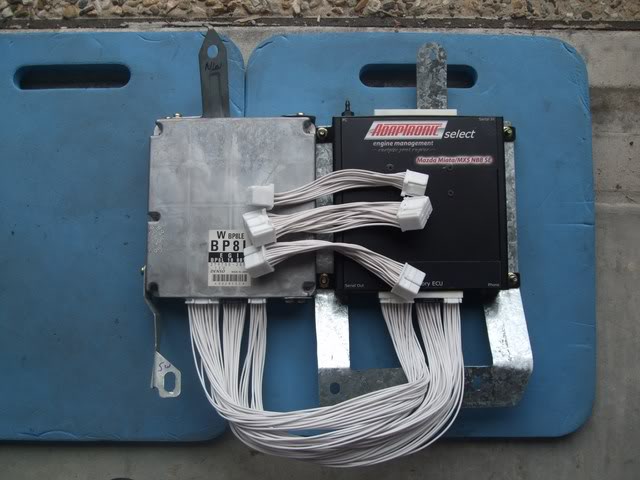

I decided to get rid of the 2 left side brackets and use the new bracket I was making to mount the OEM ECU to. Originally I planned to make the new bracket from aluminium but when I went to Bunnings, I found that the $34 sheet of aluminium I needed only cost $12 in galvanised iron so galvanised iron it was! Here's the new bracket, front and rear view:

I may yet make those interior cutouts even larger, the bracket is strong enough to do so (my original template was made assuming I was using aluminium so I needed more rigidity). I may also "skinny-up" the top bracket too since it's strong enough in galvanised iron.

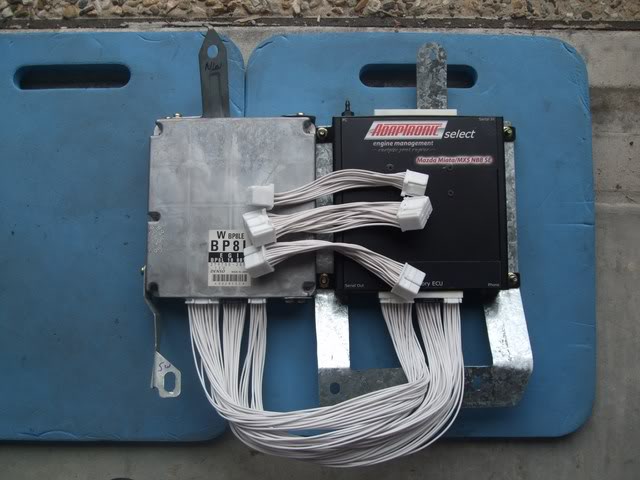

Here's the e440 mounted to the new bracket, followed by the two ECUs mounted, and a rear view:

This is what it looks like with the cover plate installed - everything's nicely tucked behind it:

Top view:

Here you can see where the car's harness plugs into (white socket), the USB port (bottom right of e440) and MAP sensor port (top right of e440). The car's harness will need to be plugged in while the cover plate is off but there is room for it.

Bottom view:

The new harnesses will connect the 2 ECUs.

OEM ECU side view:

This shows the OEM brackets for the OEM ECU.

e440 ECU side view:

Originally posted by bootz, Wed Apr 13, 2011 12:11 pm[

Originally posted by bootz, Wed Apr 13, 2011 12:11 pm[Very neat.

Originally posted by Mr Morlock, Sat Apr 16, 2011 7:05 pm[Interesting- gal sheet for a pressed metal component- does it fail on the edges ( ie corrosion) ? Alu, ss , or metal later plated ( not practical for diy) might stand up longer - but agree prob academic. In the car industry everything is checked for salt spray resistance. Looks a neat job.

Originally posted by bootz, Sat Apr 16, 2011 11:15 pm[Perhaps when you have assessed the changes you can post the effectiveness of the new ECU. I am also interested as to the process that initiated which is quite an expensive mod. Enjoying your thread

Originally posted by Lokiel, Sun Apr 17, 2011 8:28 pm[

Originally posted by Lokiel, Sun Apr 17, 2011 8:28 pm[Mr. Morlock: I must admit I hadn't considered bracket corrosion to be an issue since my passenger side footwell is dry - will keep an occasional eye on that though.

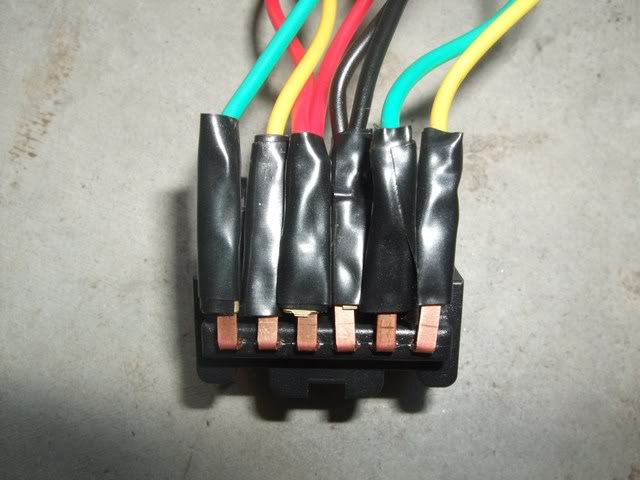

The longer ECU harnesses arrived this week:

These are 3 times longer than the original ones. I also lightened the new bracket by making the 2 inner "windows" larger and the top brace thinner. I also made the two bottom holes "longer" to allow it to be wiggled around a bit when mounting it.

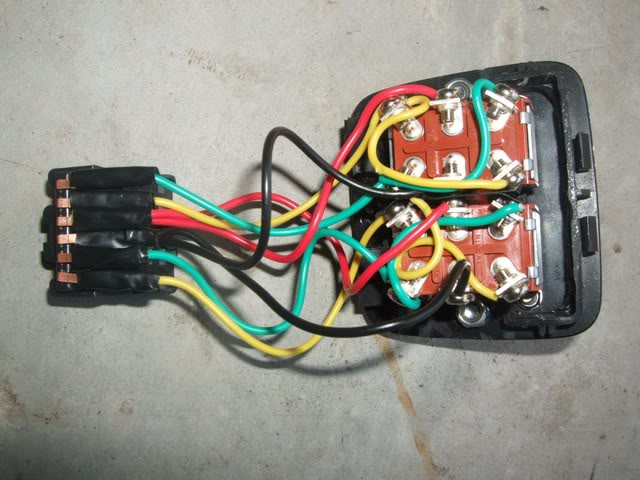

Here's what they look like from a side view with the cover plate mounted on top:

As you can see, there's plenty of room to tuck the extra cable length.

Rear view with the cover plate mounted:

When I mounted this in the footwell, I found that the bottom of the bracket was touching the bottom of the floor so I cut off 10mm from the bottom of it - I didn't want it to scratch through the footwell paint or screech when driving (metal on metal).

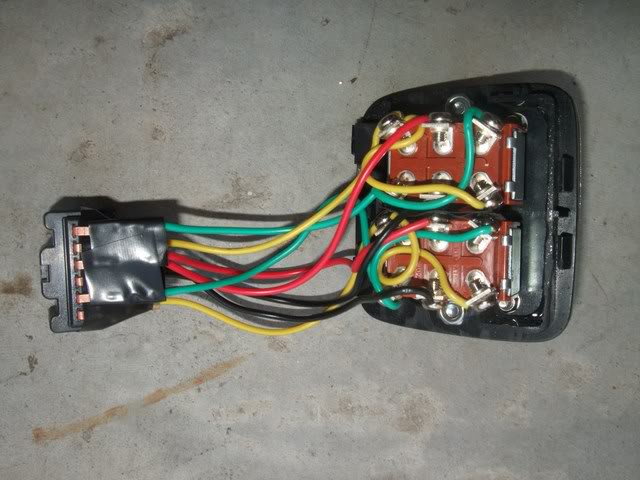

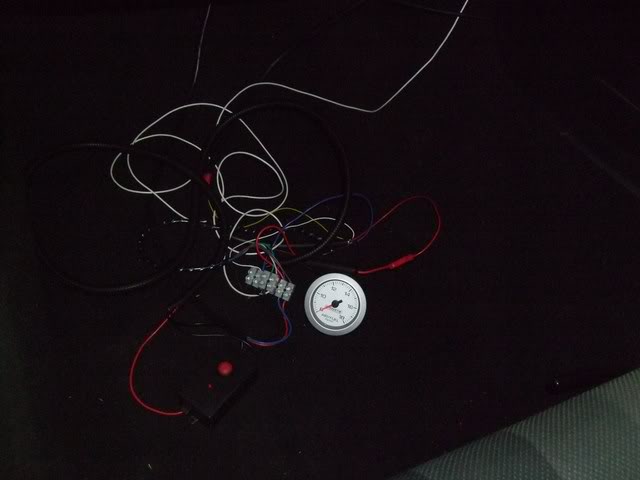

After that minor mod, I mounted it in the footwell. Here's what it looks like fitted, minus the cover plate:

It's pretty awkward getting it in there now since it's so wide. First you need to attach the OEM harness to the e440 ECU, along with the boost hose to the internal MAP sensor and connect the USB cable, otherwise you'll never be able to attach them (unless you're triple-jointed). I zip-tied the USB cable to the MAP sensor's rubber hose which should ensure that it doesn't fall out as easy.

Unfortunately my car has been sitting in the garage too long and the battery is now flat so I couldn't do any tuning today