Mx5, Chapter 2

Moderators: timk, Stu, -alex, miata, StanTheMan, greenMachine, ManiacLachy, Daffy, zombie, Andrew, The American, Lokiel

- Okibi

- Speed Racer

- Posts: 10912

- Joined: Thu Aug 21, 2003 11:00 am

- Vehicle: NB SE

- Location: Perth, Western Australia

- Contact:

Re: Mx5, Chapter 2

If you had access to a car like this, would you take it back right away? Neither would I.

-

The American

- Forum Guru

- Posts: 1542

- Joined: Fri Jun 29, 2012 9:23 pm

- Vehicle: NB8B - Turbo

- Location: Brisbane, Qld. Previously Perth WA

- Contact:

Os Giken Diff First Drive

From 8pm to 11:30pm Friday, the new Os Giken diff found its way back into the car.

The old diff mount bushes were removed and replaced with the Energy Suspension poly bushes. Generous use of the supplied lubricant made this much easier.

PPF alignment was set to 66mm with the help of a trolley jack, straight edge and vernier calipers.

The first drive this afternoon wasn't really enough (or the right environment) to test the diff out.

Part-throttle tight u-turns produce lock and inside wheel spin/skip. Light-throttle cornering at intersections produces occasional clonks. Because of the latter, I had to pull over to reassure myself that I'd done the wheel nuts up.

If NVH is your thing, definitely stick with a Torsen!

The diff is tight enough that I almost can't rotate one wheel independently of the other by hand with the car jacked off the ground.

The old diff mount bushes were removed and replaced with the Energy Suspension poly bushes. Generous use of the supplied lubricant made this much easier.

PPF alignment was set to 66mm with the help of a trolley jack, straight edge and vernier calipers.

The first drive this afternoon wasn't really enough (or the right environment) to test the diff out.

Part-throttle tight u-turns produce lock and inside wheel spin/skip. Light-throttle cornering at intersections produces occasional clonks. Because of the latter, I had to pull over to reassure myself that I'd done the wheel nuts up.

If NVH is your thing, definitely stick with a Torsen!

The diff is tight enough that I almost can't rotate one wheel independently of the other by hand with the car jacked off the ground.

- plohl

- Racing Driver

- Posts: 1922

- Joined: Wed Oct 14, 2009 12:13 am

- Vehicle: NA8

- Location: Brisbane

-

The American

- Forum Guru

- Posts: 1542

- Joined: Fri Jun 29, 2012 9:23 pm

- Vehicle: NB8B - Turbo

- Location: Brisbane, Qld. Previously Perth WA

- Contact:

Re: Mx5, Chapter 2

plohl wrote:How does it handle the clutch kicks though?

Ha ha - I don't have the 'knuckles' for that

-

The American

- Forum Guru

- Posts: 1542

- Joined: Fri Jun 29, 2012 9:23 pm

- Vehicle: NB8B - Turbo

- Location: Brisbane, Qld. Previously Perth WA

- Contact:

Re: Mx5, Chapter 2

I took the Os Giken diff for a second drive this afternoon, over Mt Glorious to Northbrook Parkway and return.

Once the diff 'grips' under light load it seems to hold itself partly clamped (unless there's been some firm engine braking), which seems to lead to some chatter if you happen to do a u-turn or tight low speed turn, but otherwise it's mostly invisible. Tight figure-8's don't create chatter until there's some moderate torque in play. Push it a little more than part throttle and it starts to lock and spin the inside wheel to keep pace with the outside.

The inside wheelspin of the Torsen in steep, tight uphill corners is gone - it feels like just grips, and I didn't notice anything that felt like it wanted to 'push'. I'm looking forward to trying it at the Noosa Hillclimb in November.

I think I will have to do another motorkhana with this diff!

Clutch pack diffs are a new experience for me. I was happy with the Mazda Torsen that I thought I had until it became a single spinner. When I pulled it out, I discovered it was an aftermarket 'OBX' helical (essentially a torsen style diff). After I replaced the after market helical with a Mazda Torsen, I researched the failure. I found that the OBX helical diff is known to fail as a result of poor quality Bellville washers that provide preload to the gears that limit the slip. The OBX is also rebuildable. I also read that Mazda torsens used in spec miata racing are known to lose effectiveness for essentially the same reason that my aftermarket unit had failed, and are not so easily rebuilt.

Persistent inside wheelspin and the spectre of failed Torsen diffs, combined are the reason I decided to sell the Mazda LSD and switch to the current diff.

I still have the OBX helical, and have ordered the parts required to rebuild it. I also have a 3.6 open diff into which the OBX helical will be installed once fixed. This may go in the spare parts stash or be for sale soon.

Once the diff 'grips' under light load it seems to hold itself partly clamped (unless there's been some firm engine braking), which seems to lead to some chatter if you happen to do a u-turn or tight low speed turn, but otherwise it's mostly invisible. Tight figure-8's don't create chatter until there's some moderate torque in play. Push it a little more than part throttle and it starts to lock and spin the inside wheel to keep pace with the outside.

The inside wheelspin of the Torsen in steep, tight uphill corners is gone - it feels like just grips, and I didn't notice anything that felt like it wanted to 'push'. I'm looking forward to trying it at the Noosa Hillclimb in November.

I think I will have to do another motorkhana with this diff!

Clutch pack diffs are a new experience for me. I was happy with the Mazda Torsen that I thought I had until it became a single spinner. When I pulled it out, I discovered it was an aftermarket 'OBX' helical (essentially a torsen style diff). After I replaced the after market helical with a Mazda Torsen, I researched the failure. I found that the OBX helical diff is known to fail as a result of poor quality Bellville washers that provide preload to the gears that limit the slip. The OBX is also rebuildable. I also read that Mazda torsens used in spec miata racing are known to lose effectiveness for essentially the same reason that my aftermarket unit had failed, and are not so easily rebuilt.

Persistent inside wheelspin and the spectre of failed Torsen diffs, combined are the reason I decided to sell the Mazda LSD and switch to the current diff.

I still have the OBX helical, and have ordered the parts required to rebuild it. I also have a 3.6 open diff into which the OBX helical will be installed once fixed. This may go in the spare parts stash or be for sale soon.

-

The American

- Forum Guru

- Posts: 1542

- Joined: Fri Jun 29, 2012 9:23 pm

- Vehicle: NB8B - Turbo

- Location: Brisbane, Qld. Previously Perth WA

- Contact:

Bulahdelah Hillclimb 2017

The Bulahdelah Hillclimb was my latest adventure in the White Mouse. It was hot and very windy, which was the cause of the only delays - dry gum leaves blowing across the track and triggering the timing gear! There were no accidents or incidents and the towies had nothing to do - perfect result.

There where 38 cars entered, including a few very serious looking and sounding Mitsubishi and two Mx5's (mine and Patrick's).

Patrick's machine had an issue on the first run and was not running properly and so he called it a day. He's a Bulahdelah local and I had hoped he'd be my time to beat (has more HP, and knows the course).

On the morning of the event and before the drivers briefing I walked the track to pick some lines. Several corners have significant camber changes either mid corner or on corner exit. The first right-hander rotates for approximately 300 degrees and is the place many come unstuck if they apex too early and are still corning when the camber change arrives, unloading the rear and causing a pirouette to the kerb.

The same corner has huge banking on the inside of the turn, and I had decided to apex very early, hug the inside, making the most of the extra grip from the banking, and be positioned to run straight across the camber change. I ran this line for the first three lines and was way off the pace.

For my last run, I attempted a very late apex line that regulars were talking about. As a result, I was able to hold 4th through the corner and all the way to the first chicane, and knocked off 2 seconds. This put me 2nd in class and (I think) 14th outright, and only .38 behind a stripped out Lotus Elise. The car got very light across the camber change - you could feel how a little bit of poor positioning could go very badly.

In all, a very fast and fun course.

One neat feature of the event was their system that sent your time and trap speed across the finish line by SMS to you phone as soon as you crossed the line.

I'm glad I ticked this one off the bucket list. If I did it again, it would only be for a two day event - it was a very long drive for 4 runs. If you're in Sydney or Newcastle, it's definitely worth the trip - I heard the next one is in March 18.

I will post a video soon.

There where 38 cars entered, including a few very serious looking and sounding Mitsubishi and two Mx5's (mine and Patrick's).

Patrick's machine had an issue on the first run and was not running properly and so he called it a day. He's a Bulahdelah local and I had hoped he'd be my time to beat (has more HP, and knows the course).

On the morning of the event and before the drivers briefing I walked the track to pick some lines. Several corners have significant camber changes either mid corner or on corner exit. The first right-hander rotates for approximately 300 degrees and is the place many come unstuck if they apex too early and are still corning when the camber change arrives, unloading the rear and causing a pirouette to the kerb.

The same corner has huge banking on the inside of the turn, and I had decided to apex very early, hug the inside, making the most of the extra grip from the banking, and be positioned to run straight across the camber change. I ran this line for the first three lines and was way off the pace.

For my last run, I attempted a very late apex line that regulars were talking about. As a result, I was able to hold 4th through the corner and all the way to the first chicane, and knocked off 2 seconds. This put me 2nd in class and (I think) 14th outright, and only .38 behind a stripped out Lotus Elise. The car got very light across the camber change - you could feel how a little bit of poor positioning could go very badly.

In all, a very fast and fun course.

One neat feature of the event was their system that sent your time and trap speed across the finish line by SMS to you phone as soon as you crossed the line.

I'm glad I ticked this one off the bucket list. If I did it again, it would only be for a two day event - it was a very long drive for 4 runs. If you're in Sydney or Newcastle, it's definitely worth the trip - I heard the next one is in March 18.

I will post a video soon.

-

The American

- Forum Guru

- Posts: 1542

- Joined: Fri Jun 29, 2012 9:23 pm

- Vehicle: NB8B - Turbo

- Location: Brisbane, Qld. Previously Perth WA

- Contact:

Os Giken - 1st Hillclimb

plohl wrote:How does it handle the clutch kicks though?

The best description I can think of for the new diff compared to the various torsen diffs is that 'it feels like it has plugged a power leak at the rear wheels'.

Once a wheel started spinning with the Torsen, it tended to keep spinning, until the grip available to that wheel caught up with the torque being directed to it. Wheel spin started when one wheel went beyond the limits of its grip.

With the Os Giken, wheel spin happens when the grip available to both tyres is exceeded (probably stating the obvious here, but trying to describe the 'felt' difference).

I could launch the car more quickly with less RPM. The car felt like it had more power off the line. It seems to me that start line power with the Torsen was being sapped in two ways:(1) The torque required to drive the Torsen gears (that through geared resistance deliver power to the wheel with more grip) is lost. (2) To take advantage of all of the grip to both wheels, the Torsen required a certain amount of wheelspin from the wheel with less grip in order to send greater torque to the wheel with more grip, and before the limit of grip could be reached for the wheel with more. Wheelspin = friction = power loss.

By contrast, the Os Giken only requires enough torque to overcome the pressure ring springs acting against the cam before it clamps and locks up.

The seat of pants dyno suggested that less power was required for a quicker launch with the OS Giken. The above is my novice theory to explain why - somebody who knows their diffs, please chime in!

After the launch, the diff became noticeable to me only through the absence of inside wheelspin, and slightly increased tendency to step sideways coming out of the chicanes under power. I've been asked if it wanted to 'push' or understeer - not that I noticed. I'm using fairly sticky rubber, have -4 camber in the front, relatively soft spring rates, and factory ARBs - I find it turns in for me very reliably, and the diff made no perceptible difference to this.

Clutch kicks? Nah!

The clicks and pops from the first few hundred kilometres also seem to have settled down.

-

The American

- Forum Guru

- Posts: 1542

- Joined: Fri Jun 29, 2012 9:23 pm

- Vehicle: NB8B - Turbo

- Location: Brisbane, Qld. Previously Perth WA

- Contact:

-

The American

- Forum Guru

- Posts: 1542

- Joined: Fri Jun 29, 2012 9:23 pm

- Vehicle: NB8B - Turbo

- Location: Brisbane, Qld. Previously Perth WA

- Contact:

OBX LSD

The reason I started down the path towards a clutch-pack diff, was the apparent failure of the 'torsen' that was fitted to my car when I bought it. The diff had begun behaving more like an 'open' and limiting less and less wheelspin. It became most apparent to me that it was 'had it' when a fellow competitor at last year's Noosa Hillclimb sent me this clip of the White Mouse leaving the start line, and doing a very convincing single wheel peal.

On further inspection, it was clear that something inside the diff had come adrift:

As a result it, came out and was replaced with another torsen. At that point I discovered that what I had was actually an OBX helical diff and not a factory Torsen. I also learned that these are prone to failure of the belleville washers and are rebuild-able. The 'slop' visible in the video above seemed likely to be the failure of the bellville washers.

I over the last few weeks, I got around to disassembling the diff center with a view to rebuilding it, with new belleville washers and bolts.

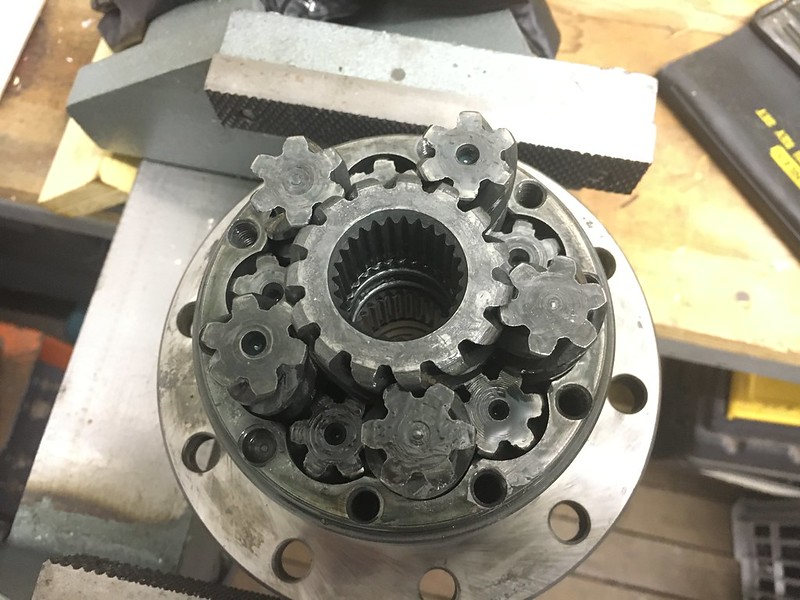

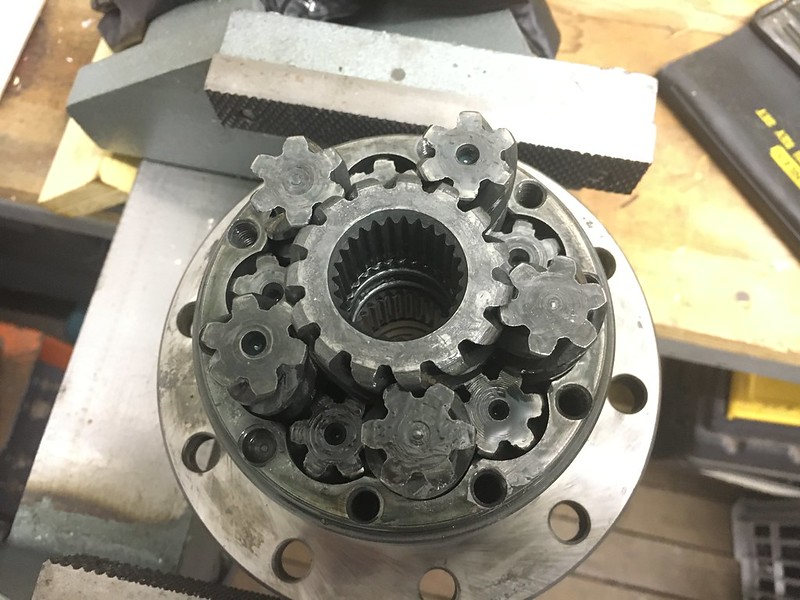

Removing one side of the case reveals a collection of gears:

Between the left hand and right hand center gears, at least 6 washers should be present and be providing preload to the diff: I found only two remaining that looked like this:

The second observation, less obvious, was that the two center gears had been installed in reverse, meaning that under forward load, they would be drawn together rather than being forced into contact with the very stout housing. The result of this is that the belleville washers take the full load and friction of the drive and as a result, fail quickly.

So where did the other 4 washers go to? The got chomped up and powdered:

There is no where for the broken washers to go within the housing except through the gears, and this particular main gear appeared to have done most of the chewing. . I spent a good while cleaning metal powder and flakes of washer out of many places.

. I spent a good while cleaning metal powder and flakes of washer out of many places.

The washers are held within a single case that sits between the central gears, and are sandwiched between two splined washers that are designed to slide in and out of the central case as the washers deflect.

The washers are stacked like so to create the preload spacing that keeps the main gears of the LSD pressed against the housing:

Sitting inside the splined washer, and inside the central housing:

The two halves of the diff go together, located with a single down and clamp on the washers. I used blue Locktight on the bolts and torqued to the recommended 28ft/lbs. Sometime soon, I will get it installed in a spare 3.63 open diff.

On further inspection, it was clear that something inside the diff had come adrift:

As a result it, came out and was replaced with another torsen. At that point I discovered that what I had was actually an OBX helical diff and not a factory Torsen. I also learned that these are prone to failure of the belleville washers and are rebuild-able. The 'slop' visible in the video above seemed likely to be the failure of the bellville washers.

I over the last few weeks, I got around to disassembling the diff center with a view to rebuilding it, with new belleville washers and bolts.

Removing one side of the case reveals a collection of gears:

Between the left hand and right hand center gears, at least 6 washers should be present and be providing preload to the diff: I found only two remaining that looked like this:

The second observation, less obvious, was that the two center gears had been installed in reverse, meaning that under forward load, they would be drawn together rather than being forced into contact with the very stout housing. The result of this is that the belleville washers take the full load and friction of the drive and as a result, fail quickly.

So where did the other 4 washers go to? The got chomped up and powdered:

There is no where for the broken washers to go within the housing except through the gears, and this particular main gear appeared to have done most of the chewing.

The washers are held within a single case that sits between the central gears, and are sandwiched between two splined washers that are designed to slide in and out of the central case as the washers deflect.

The washers are stacked like so to create the preload spacing that keeps the main gears of the LSD pressed against the housing:

Sitting inside the splined washer, and inside the central housing:

The two halves of the diff go together, located with a single down and clamp on the washers. I used blue Locktight on the bolts and torqued to the recommended 28ft/lbs. Sometime soon, I will get it installed in a spare 3.63 open diff.

- Okibi

- Speed Racer

- Posts: 10912

- Joined: Thu Aug 21, 2003 11:00 am

- Vehicle: NB SE

- Location: Perth, Western Australia

- Contact:

Re: Mx5, Chapter 2

Very interesting

If you had access to a car like this, would you take it back right away? Neither would I.

-

The American

- Forum Guru

- Posts: 1542

- Joined: Fri Jun 29, 2012 9:23 pm

- Vehicle: NB8B - Turbo

- Location: Brisbane, Qld. Previously Perth WA

- Contact:

Oil filter relocation and cooler update

Following the install of my oil cooler and filter relocation set up, I was having difficulties with the oil filter jamming onto the Grex filter block. I ended up sacrificing three K&N filters while trying to solve it. It seems that it was the K&N filter that was the problem.

The rubber seal on the filter sits between two metal lips on the filter. The inner and outer on the K&N filter are the same height. The inner lip was fouling ever so slightly on the inner edge of the seal mating surface of the filter block. With a single heat cycle it would jam on and I could not remove it without taking it out of the car and placing the filter in a vice.

The inner void on the filter block measures slightly more than 55mm:

The inner lip of the K&N filter measures slightly more again, allowing it to make contact with the mating surface:

This gave me the idea to compare other filters for clearance, and as a result I switched to a Ryco filter that has an inner lip that sits further into the filter than the outer. It doesn’t appear to make contact except through the compression of the rubber seal, and I can remove by hand with ease.

Half the attraction for the relocation of the filter, was the ability to remove the filter from a vertical mount without a drip, and then reinstall a primed filter. I can finally tick that box!

The rubber seal on the filter sits between two metal lips on the filter. The inner and outer on the K&N filter are the same height. The inner lip was fouling ever so slightly on the inner edge of the seal mating surface of the filter block. With a single heat cycle it would jam on and I could not remove it without taking it out of the car and placing the filter in a vice.

The inner void on the filter block measures slightly more than 55mm:

The inner lip of the K&N filter measures slightly more again, allowing it to make contact with the mating surface:

This gave me the idea to compare other filters for clearance, and as a result I switched to a Ryco filter that has an inner lip that sits further into the filter than the outer. It doesn’t appear to make contact except through the compression of the rubber seal, and I can remove by hand with ease.

Half the attraction for the relocation of the filter, was the ability to remove the filter from a vertical mount without a drip, and then reinstall a primed filter. I can finally tick that box!

-

The American

- Forum Guru

- Posts: 1542

- Joined: Fri Jun 29, 2012 9:23 pm

- Vehicle: NB8B - Turbo

- Location: Brisbane, Qld. Previously Perth WA

- Contact:

SLRV Noosa Hill Climb Summer Challenge 2017

The Noosa Hill Climb Summer Challenge 2017 was my 4th attempt at 'the hill'

After the first three runs, it rained quite heavily and there was no chance of improving on the times set on Saturday morning in the afternoon or the following day. I ended up calling at after the second or run on Sunday and packing up so I could get home to spend the afternoon with my wife and kids.

This was my best attempt in the wet (about 80 seconds):

And this was my third and best attempt in the dry (65.17):

The last three events, I have achieved a 65: 65.19, 65.15 and 65.17. The last two events where I'd hit a low 65 it was on the second day after building up to my best run, first or second run of the afternoon on the Sunday. This time, I managed it on my third run on Saturday morning - i'm confident that I could achieve the illusive sub-65 time. Based on my splits, my 'theoretical' best time is about a 64.5.

When I watch the clips, I can see time that could be saved in lots of the corners, but convincing my brain of this in real time, is proving difficult.

To put that time in context: Kevin Gray in his naturally aspirated NA ran a 65 (with what I assume is a lot less HP). Brock Paine in his NA Silvia managed a 63. The winning car in my class was an LS engined Elphin Streamliner that crossed the line with a 58.

Next year!

After the first three runs, it rained quite heavily and there was no chance of improving on the times set on Saturday morning in the afternoon or the following day. I ended up calling at after the second or run on Sunday and packing up so I could get home to spend the afternoon with my wife and kids.

This was my best attempt in the wet (about 80 seconds):

And this was my third and best attempt in the dry (65.17):

The last three events, I have achieved a 65: 65.19, 65.15 and 65.17. The last two events where I'd hit a low 65 it was on the second day after building up to my best run, first or second run of the afternoon on the Sunday. This time, I managed it on my third run on Saturday morning - i'm confident that I could achieve the illusive sub-65 time. Based on my splits, my 'theoretical' best time is about a 64.5.

When I watch the clips, I can see time that could be saved in lots of the corners, but convincing my brain of this in real time, is proving difficult.

To put that time in context: Kevin Gray in his naturally aspirated NA ran a 65 (with what I assume is a lot less HP). Brock Paine in his NA Silvia managed a 63. The winning car in my class was an LS engined Elphin Streamliner that crossed the line with a 58.

Next year!

-

Magpie

- Speed Racer

- Posts: 7468

- Joined: Fri Feb 11, 2011 12:49 pm

- Vehicle: NA6

- Location: Purga, QLD

Re: Mx5, Chapter 2

Brock’s times at the King of QR are not reflective of Nossa.

-

The American

- Forum Guru

- Posts: 1542

- Joined: Fri Jun 29, 2012 9:23 pm

- Vehicle: NB8B - Turbo

- Location: Brisbane, Qld. Previously Perth WA

- Contact:

-

The American

- Forum Guru

- Posts: 1542

- Joined: Fri Jun 29, 2012 9:23 pm

- Vehicle: NB8B - Turbo

- Location: Brisbane, Qld. Previously Perth WA

- Contact:

Re: Mx5, Chapter 2

This must be close to sitting on the bump stop?

Who is online

Users browsing this forum: No registered users and 7 guests