The Roadster NA Journey Begins

Moderators: timk, Stu, -alex, miata, StanTheMan, greenMachine, ManiacLachy, Daffy, zombie, Andrew, The American, Lokiel

- Steampunk

- Speed Racer

- Posts: 4670

- Joined: Wed Oct 10, 2007 9:16 am

- Vehicle: NA6

- Location: Southside of Breeze-bane

Re: The Roadster NA Journey Begins

Hmmm but what's the remedy? Perhaps get a cheap 2nd hand cam cover, drill out the hole where it mounts, install rubber bung then bond a nutsert/rivnut in that rubber bung?

I guess while your at it, drill out the hole where the sensor body actually sits then pad that out with rubber.

I guess while your at it, drill out the hole where the sensor body actually sits then pad that out with rubber.

-

Magpie

- Speed Racer

- Posts: 7468

- Joined: Fri Feb 11, 2011 12:49 pm

- Vehicle: NA6

- Location: Purga, QLD

Re: The Roadster NA Journey Begins

To help, at least me understand where the problem could be, consider this...

I have these:

This is the OEM

The OEM Cam Angle Sensor is designed to work with the OEM cam wheels. I'm postulating that if there is a difference in what is being detected by the OEM sensor then this MAY be causing the issue. The OEM sensor is a fixed distance from its target and is it probable that the Toda cam wheel target is not an exact duplicate of the OEM.

Again why is this only happening in my build?

I have these:

This is the OEM

The OEM Cam Angle Sensor is designed to work with the OEM cam wheels. I'm postulating that if there is a difference in what is being detected by the OEM sensor then this MAY be causing the issue. The OEM sensor is a fixed distance from its target and is it probable that the Toda cam wheel target is not an exact duplicate of the OEM.

Again why is this only happening in my build?

- MattR

- Racing Driver

- Posts: 1305

- Joined: Wed Feb 25, 2009 11:26 pm

- Vehicle: NA6

- Location: Brisbane

Re: The Roadster NA Journey Begins

Mark I don't think the problem would be the aftermarket cam gears. The sensor is working from cold and until everything is hot and then after some time. As suggested previously, to my way of thinking it sounds like it is degradation of the signal more so due to heat than anything else.

Might sound silly, but have you gotten it to the stage where you get the miss, bring the car in still running and then spray some water on the CAS to cool it down quickly and see what happens then. Also is the breakdown only under load, or if you free rev it as well?

Sounds stupid, but what about trying a temporary rewire for the CAS back to the ECU id that is not too much trouble to swap out and take the wiring as far away from the heat as quickly as possible? What signals are adjacent wires carrying? Could you be getting interference between wires as it gets hotter, or a harness mount or bracket is pinching or rubbing a wire and when cold does not worry the system, but when hot is enough to do interfere with the signal by a short, or is it a bad joint in the wiring, or for left field could it even be a dry joint on the board in the ECU????

If the ECU is getting reference from the crank, as suggested, does it need cam reference as well, other than just a check signal. If this is the case, could not a dummy signal be set up once the sensor falls out of spec? Just putting up some possible, or not so suggestions....

I mainly played with 40 year old Datsun motors with a Haltech F9 computer, hell the race L29 even still had a points distributor until the mid 2000's and then I only swapped it for a modified L28 electronic distributor that had no vacuum advance and the mechanical advance was played with. You reckon you have troubles, try finding:

1. A tuner who can still program a F9, and

2. Finding a laptop that ran Windows XP or earlier and a serial port to plug into the computer.

I did have similar issues on a L18 out to 2.2 litres running twin webers, would run for about 5 laps and then cut out, cool it down waiting to get towed back to the pits and by the time it was back would fire up fun and run. Took us a few meetings to fix the problem, but in the end never really knew as we replaced the ignition system, starting with basics like coil, leads, dizzy and then wiring, which all tested fine in other cars. What was really frustrating was that you worked on it in the shop, did what you could there to test and all seemed fine until you got out on the track. Replace one part and the problem still was there and that was on a relatively simple old school engine.

I feel your pain, and only going through everything methodically and one step at a time will the problem be solved, and it will be a "doh" moment.

Might sound silly, but have you gotten it to the stage where you get the miss, bring the car in still running and then spray some water on the CAS to cool it down quickly and see what happens then. Also is the breakdown only under load, or if you free rev it as well?

Sounds stupid, but what about trying a temporary rewire for the CAS back to the ECU id that is not too much trouble to swap out and take the wiring as far away from the heat as quickly as possible? What signals are adjacent wires carrying? Could you be getting interference between wires as it gets hotter, or a harness mount or bracket is pinching or rubbing a wire and when cold does not worry the system, but when hot is enough to do interfere with the signal by a short, or is it a bad joint in the wiring, or for left field could it even be a dry joint on the board in the ECU????

If the ECU is getting reference from the crank, as suggested, does it need cam reference as well, other than just a check signal. If this is the case, could not a dummy signal be set up once the sensor falls out of spec? Just putting up some possible, or not so suggestions....

I mainly played with 40 year old Datsun motors with a Haltech F9 computer, hell the race L29 even still had a points distributor until the mid 2000's and then I only swapped it for a modified L28 electronic distributor that had no vacuum advance and the mechanical advance was played with. You reckon you have troubles, try finding:

1. A tuner who can still program a F9, and

2. Finding a laptop that ran Windows XP or earlier and a serial port to plug into the computer.

I did have similar issues on a L18 out to 2.2 litres running twin webers, would run for about 5 laps and then cut out, cool it down waiting to get towed back to the pits and by the time it was back would fire up fun and run. Took us a few meetings to fix the problem, but in the end never really knew as we replaced the ignition system, starting with basics like coil, leads, dizzy and then wiring, which all tested fine in other cars. What was really frustrating was that you worked on it in the shop, did what you could there to test and all seemed fine until you got out on the track. Replace one part and the problem still was there and that was on a relatively simple old school engine.

I feel your pain, and only going through everything methodically and one step at a time will the problem be solved, and it will be a "doh" moment.

- mrpham

- Forum sponsor

- Posts: 856

- Joined: Tue Sep 20, 2011 8:42 pm

- Vehicle: NA6

- Location: Brisbane

- Contact:

Re: The Roadster NA Journey Begins

Hey Mark.

I don't have a lot of knowledge in this matter, but I'm also running the same Toda cam gears and factory sensor.

Initially I had heaps of issues, I would pretty much carry a couple spares with me in the car. Thought it was heat, sort of confirmed when it would go away when sensors was swapped out. But I than installed a brand new sensor and things continued as they did before, it would miss at a certain RPM and cause the engine to fumble. When it got worse the engine just stopped completely. The RPM that caused the missing wasn't always the same.

Talking to other Megasquirt users, we thought that it was definitely signal degradation due to heat and the Megasquirt wasn't able to handle it like the factory ECU would. So I was than going to purchase this to help clean the signal up.

http://www.jbperf.com/dual_VR/v2_1.html

But before I did that, someone mentioned that it could be vibration in the connector terminals. I wasn't really optimistic about that idea, but I went and zip-tied the connector to the sensor like below and I haven't had any issues since. Sitting in summer traffic too.

No real proof of the results or how it works

I don't have a lot of knowledge in this matter, but I'm also running the same Toda cam gears and factory sensor.

Initially I had heaps of issues, I would pretty much carry a couple spares with me in the car. Thought it was heat, sort of confirmed when it would go away when sensors was swapped out. But I than installed a brand new sensor and things continued as they did before, it would miss at a certain RPM and cause the engine to fumble. When it got worse the engine just stopped completely. The RPM that caused the missing wasn't always the same.

Talking to other Megasquirt users, we thought that it was definitely signal degradation due to heat and the Megasquirt wasn't able to handle it like the factory ECU would. So I was than going to purchase this to help clean the signal up.

http://www.jbperf.com/dual_VR/v2_1.html

But before I did that, someone mentioned that it could be vibration in the connector terminals. I wasn't really optimistic about that idea, but I went and zip-tied the connector to the sensor like below and I haven't had any issues since. Sitting in summer traffic too.

No real proof of the results or how it works

Current Forum Specials!

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

-

Magpie

- Speed Racer

- Posts: 7468

- Joined: Fri Feb 11, 2011 12:49 pm

- Vehicle: NA6

- Location: Purga, QLD

Re: The Roadster NA Journey Begins

John, appreciate the post! I did try the cable tie option however I only had very large ones so I put it around the plug and not between the wires as in your example. Interestingly a similar suggestion has been made by others that wiring direct to the CAS sensor and epoxy the wires in, same manner as done on V8 supercars and F1's to stop any vibration. However a cable tie would be proof of concept.

Spoke with Jeff at Plus today and he has the Haltech sensor ready to install, however suggested that another ECU be installed to rule out this as a cause. So at Morgan Park I will run another PS1000 and if the issue does not come back I will swap in a failed sensor to see what happens. I will also make sure I have some smaller cable ties to try John's solution. Testing at Morgan Park will decide the next step. Haltech recommends that its sensor be installed 1mm away from the Cam Wheel 'nubs'.

MattR again I'm still a believer of it being a signal degradation that is not being handled the same way as the OEM ECU does.

Here is a video of a Cam Angle Sensor completely failing.

Here is the data:

the 250 mark corresponds with about the 30 sec mark of the video.

Blue is RPM

Red is Miss count (you can see where it starts to increase)

Green is Oil Temp

Yellow is Coolant temp

Light Blue is Air temp (it did not go over 46°c, I need to figure out the logging software to display on the same scale)

Miss EC Day 1 S3 by Eipeip, on Flickr

Miss EC Day 1 S3 by Eipeip, on Flickr

Spoke with Jeff at Plus today and he has the Haltech sensor ready to install, however suggested that another ECU be installed to rule out this as a cause. So at Morgan Park I will run another PS1000 and if the issue does not come back I will swap in a failed sensor to see what happens. I will also make sure I have some smaller cable ties to try John's solution. Testing at Morgan Park will decide the next step. Haltech recommends that its sensor be installed 1mm away from the Cam Wheel 'nubs'.

MattR again I'm still a believer of it being a signal degradation that is not being handled the same way as the OEM ECU does.

Here is a video of a Cam Angle Sensor completely failing.

Here is the data:

the 250 mark corresponds with about the 30 sec mark of the video.

Blue is RPM

Red is Miss count (you can see where it starts to increase)

Green is Oil Temp

Yellow is Coolant temp

Light Blue is Air temp (it did not go over 46°c, I need to figure out the logging software to display on the same scale)

Miss EC Day 1 S3 by Eipeip, on Flickr

Miss EC Day 1 S3 by Eipeip, on Flickr-

toppertee

- Racing Driver

- Posts: 699

- Joined: Mon Jul 11, 2011 4:16 pm

- Vehicle: NA6

- Location: Brisbane

Re: The Roadster NA Journey Begins

IMHO....

From having to deal with this stuff weekly, in my working life....

Glad it's someone else problem.....

From having to deal with this stuff weekly, in my working life....

Glad it's someone else problem.....

- gslender

- Speed Racer

- Posts: 2330

- Joined: Sat Feb 19, 2011 10:49 pm

- Vehicle: NA6

- Location: Brisbane, QLD

Re: The Roadster NA Journey Begins

If the car was mine to play with I'd get a scope on the sensor when it is misbehaving. I'd bet it would be obvious what the issue is in no time. Anything less than that is just guessing.

Sent from my iPad using Tapatalk

Sent from my iPad using Tapatalk

MX5 91 NA6 LE completely stock and loving it!

MX5 92 NA8/ITBs Silver "aka Track Beeotch"

MX5 92 NA8/ITBs Silver "aka Track Beeotch"

-

Magpie

- Speed Racer

- Posts: 7468

- Joined: Fri Feb 11, 2011 12:49 pm

- Vehicle: NA6

- Location: Purga, QLD

Re: The Roadster NA Journey Begins

I have a scope, however it is 240v.

The 'Miss' count says what the problem is! A scope will say what has changed but not why. The issue is a solution!

The 'Miss' count says what the problem is! A scope will say what has changed but not why. The issue is a solution!

- gslender

- Speed Racer

- Posts: 2330

- Joined: Sat Feb 19, 2011 10:49 pm

- Vehicle: NA6

- Location: Brisbane, QLD

Re: The Roadster NA Journey Begins

Magpie wrote:I have a scope, however it is 240v.

The 'Miss' count says what the problem is! A scope will say what has changed but not why. The issue is a solution!

Bollocks. A scope will tell you what the sensor sees at idle and what has changed at 5500 rpm and if they're materially different its the sensor. If not, it's the ecu. Miss count is just the ecu saying it lost sync because what it expected wasn't there. That can be because the ecu is looking for the wrong part of the signal, noise, inverted wiring, wrong pattern, wrong sensor etc.

Scope would also show up any noise on the wiring.

G

Sent from my iPad using Tapatalk

MX5 91 NA6 LE completely stock and loving it!

MX5 92 NA8/ITBs Silver "aka Track Beeotch"

MX5 92 NA8/ITBs Silver "aka Track Beeotch"

-

Magpie

- Speed Racer

- Posts: 7468

- Joined: Fri Feb 11, 2011 12:49 pm

- Vehicle: NA6

- Location: Purga, QLD

Re: The Roadster NA Journey Begins

Agreed G. The 'miss' is not consistent. The video shows a complete failure, this is a rare event. On most occasions the car can be dríven below 5,500 with no issue.

If the fault was predictable then yes scoping would show the difference in signals.

What I should also be logging is "triggers since last home" as this should be a consistant number. Whilst this is not using a scope it will tell what is happening.

If you have a USB type scope and happy to sit in the passengers seat to log what is happening I'll take you for a drive.

I'll post some other videos of a miss that does not result in a complete failure tonight.

If the fault was predictable then yes scoping would show the difference in signals.

What I should also be logging is "triggers since last home" as this should be a consistant number. Whilst this is not using a scope it will tell what is happening.

If you have a USB type scope and happy to sit in the passengers seat to log what is happening I'll take you for a drive.

I'll post some other videos of a miss that does not result in a complete failure tonight.

-

Ice88

- Fast Driver

- Posts: 149

- Joined: Mon Jan 05, 2015 10:31 am

- Vehicle: ND - 2 GT

Re: The Roadster NA Journey Begins

Not sure about on the Haltech PS1000, but the cam isn't actually required for the car to run providing the crank wheel has enough resolution. If running 36 tooth wheel thats more then enough, you won't need the cam wheel unless doing sequential ignition.

Historically speaking Haltech have been horrible with dealing with hall effect sensors. Hence why you used to have to use an RA10 with anything pre PS1000. i.e. E6X etc.

The problem with Hall sensors is that there digital in nature IIRC which produces a digital signal, on/off. No matter the RPM the nature of the signal remains the same i.e. same magnitude etc. The benefit of reluctor is that as the RPM increases so does the amplitude, which is why some say its more reliable. So if the signal is being distorted then its certainly possible that ecu is having troubles.

Couple of things to think about, is the pole face too wide on the cam for the cam wheel posts? The cam wheel posts look a lot narrower then stock which can cause issues. Does swapping to the reluctor sensor help?

EDIT: Found the link in my browser bookmark list finally, andy from adapt uses these on his own cars including his 13b mx5 as they produce a very good clean signal, was going to swap to them myself:

http://uk.farnell.com/honeywell-s-c/1gt ... ?Ntt=gt101

Historically speaking Haltech have been horrible with dealing with hall effect sensors. Hence why you used to have to use an RA10 with anything pre PS1000. i.e. E6X etc.

The problem with Hall sensors is that there digital in nature IIRC which produces a digital signal, on/off. No matter the RPM the nature of the signal remains the same i.e. same magnitude etc. The benefit of reluctor is that as the RPM increases so does the amplitude, which is why some say its more reliable. So if the signal is being distorted then its certainly possible that ecu is having troubles.

Couple of things to think about, is the pole face too wide on the cam for the cam wheel posts? The cam wheel posts look a lot narrower then stock which can cause issues. Does swapping to the reluctor sensor help?

EDIT: Found the link in my browser bookmark list finally, andy from adapt uses these on his own cars including his 13b mx5 as they produce a very good clean signal, was going to swap to them myself:

http://uk.farnell.com/honeywell-s-c/1gt ... ?Ntt=gt101

-

sailaholic

- Speed Racer

- Posts: 3511

- Joined: Thu May 19, 2011 3:38 pm

- Vehicle: NA8

- Location: Brisbane

Re: The Roadster NA Journey Begins

Mark,

I agree with Plus, you've tried 6? new oem sensors, you re wired the signal cables to be shielded. Time to start looking at the other end of the system (ECU). I would have said aftermarket is just as or more likely to have an issue as OEM. You could also look at swapping in some non haltec ECUs. There would be alittle fiddling copying the fuel and ignition tables and various bits and pieces across between sets of software but it really wouldn't be that hard compared to everything else your looking at as well.

Coming good for a while with a new sensor could just be the ECU cooling down while you swap everything over...

That said...low hanging fruit first. Try Johns Ziptie

My experience is if you become fixated at a time like this on what you "know" the problem is, you'll miss the real problem. I thought my ECU was getting too hot and that was causing ignition breakdowns. I had some circumstantial evidence to suggest that. Turned out that the sockets in the stock loom were stretched and not making good contact with the ECU pins. It happened to be worse when everything was hot, but being hot was not the issue only the symptom.

Oh and maybe it's time to ask haltec why the ECU couldn't handle that 36tooth trigger wheel ;). Might let you delete the cas all together as others are saying.

I agree with Plus, you've tried 6? new oem sensors, you re wired the signal cables to be shielded. Time to start looking at the other end of the system (ECU). I would have said aftermarket is just as or more likely to have an issue as OEM. You could also look at swapping in some non haltec ECUs. There would be alittle fiddling copying the fuel and ignition tables and various bits and pieces across between sets of software but it really wouldn't be that hard compared to everything else your looking at as well.

Coming good for a while with a new sensor could just be the ECU cooling down while you swap everything over...

That said...low hanging fruit first. Try Johns Ziptie

My experience is if you become fixated at a time like this on what you "know" the problem is, you'll miss the real problem. I thought my ECU was getting too hot and that was causing ignition breakdowns. I had some circumstantial evidence to suggest that. Turned out that the sockets in the stock loom were stretched and not making good contact with the ECU pins. It happened to be worse when everything was hot, but being hot was not the issue only the symptom.

Oh and maybe it's time to ask haltec why the ECU couldn't handle that 36tooth trigger wheel ;). Might let you delete the cas all together as others are saying.

-

Magpie

- Speed Racer

- Posts: 7468

- Joined: Fri Feb 11, 2011 12:49 pm

- Vehicle: NA6

- Location: Purga, QLD

Re: The Roadster NA Journey Begins

Ice88 - much appreciated. I'm running an OEM crank wheel and sequential ignition. NitroDann has also made the same suggestion so I have already started the conversations about this.

For my build would batch fire be better than sequential considering I have no regard for fuel economy or being able to drive it below 5,000 RPM? I owned 2 stroke road bikes in my youth Plus I have no knowledge or understanding the tuning process of a car. I will however google sequential/batch tuning whilst at work. For the record my car is tuned via TPS not AFR's.

Plus I have no knowledge or understanding the tuning process of a car. I will however google sequential/batch tuning whilst at work. For the record my car is tuned via TPS not AFR's.

sailaholic - again comments appreciated. It was Danny/Jeff's suggestion regarding the ECU. Agreed I'm having tunnel vision on the Cam Angle Sensor and it could be the red herring... I have never considered the ECU temperature or other parts cooling down as a possible cause. Yes John's zip tie is first cab off the rank. Nobody at WTAC I spoke to had small enough zip ties, I was worried about wire damage so went around the plug and not as per the way John did. Yes the 36 tooth trigger wheel is also being discussed!

Problem with swapping ECU's now is it would need to be able to link into the IQ3 dash. I may have burnt my bridges too early

Morgan Park will be a test ground for another Haltech ECU with the same sensors as used previously. I will change some of the logging parameters to include ECU temperature and triggers since last home. From memory the Cam sensor installed has started to 'miss' at high RPM, only got 1 lap in on the last session due to a crash so it should show very early. If it works I will swap in a failed sensor and try and duplicate the issue.

Appreciate all the advice given and pointing out my tunnel vision/focus on cam angle sensor.

For my build would batch fire be better than sequential considering I have no regard for fuel economy or being able to drive it below 5,000 RPM? I owned 2 stroke road bikes in my youth

sailaholic - again comments appreciated. It was Danny/Jeff's suggestion regarding the ECU. Agreed I'm having tunnel vision on the Cam Angle Sensor and it could be the red herring... I have never considered the ECU temperature or other parts cooling down as a possible cause. Yes John's zip tie is first cab off the rank. Nobody at WTAC I spoke to had small enough zip ties, I was worried about wire damage so went around the plug and not as per the way John did. Yes the 36 tooth trigger wheel is also being discussed!

Problem with swapping ECU's now is it would need to be able to link into the IQ3 dash. I may have burnt my bridges too early

Morgan Park will be a test ground for another Haltech ECU with the same sensors as used previously. I will change some of the logging parameters to include ECU temperature and triggers since last home. From memory the Cam sensor installed has started to 'miss' at high RPM, only got 1 lap in on the last session due to a crash so it should show very early. If it works I will swap in a failed sensor and try and duplicate the issue.

Appreciate all the advice given and pointing out my tunnel vision/focus on cam angle sensor.

-

sailaholic

- Speed Racer

- Posts: 3511

- Joined: Thu May 19, 2011 3:38 pm

- Vehicle: NA8

- Location: Brisbane

Re: The Roadster NA Journey Begins

Good luck.

Your dash doesn't have to work if all you need to do is replicate a fault / show a fault didn't exist with another brand unit.

Sent from my iPhone using Tapatalk

Your dash doesn't have to work if all you need to do is replicate a fault / show a fault didn't exist with another brand unit.

Sent from my iPhone using Tapatalk

-

Ice88

- Fast Driver

- Posts: 149

- Joined: Mon Jan 05, 2015 10:31 am

- Vehicle: ND - 2 GT

Re: The Roadster NA Journey Begins

Magpie wrote:Ice88 - much appreciated. I'm running an OEM crank wheel and sequential ignition. NitroDann has also made the same suggestion so I have already started the conversations about this.

For my build would batch fire be better than sequential considering I have no regard for fuel economy or being able to drive it below 5,000 RPM? I owned 2 stroke road bikes in my youthPlus I have no knowledge or understanding the tuning process of a car. I will however google sequential/batch tuning whilst at work. For the record my car is tuned via TPS not AFR's.

sailaholic - again comments appreciated. It was Danny/Jeff's suggestion regarding the ECU. Agreed I'm having tunnel vision on the Cam Angle Sensor and it could be the red herring... I have never considered the ECU temperature or other parts cooling down as a possible cause. Yes John's zip tie is first cab off the rank. Nobody at WTAC I spoke to had small enough zip ties, I was worried about wire damage so went around the plug and not as per the way John did. Yes the 36 tooth trigger wheel is also being discussed!

Problem with swapping ECU's now is it would need to be able to link into the IQ3 dash. I may have burnt my bridges too early

Morgan Park will be a test ground for another Haltech ECU with the same sensors as used previously. I will change some of the logging parameters to include ECU temperature and triggers since last home. From memory the Cam sensor installed has started to 'miss' at high RPM, only got 1 lap in on the last session due to a crash so it should show very early. If it works I will swap in a failed sensor and try and duplicate the issue.

Appreciate all the advice given and pointing out my tunnel vision/focus on cam angle sensor.

I misspoke in my sleepiness this morning, sequential and batch are two terms associated with injection. In terms of ignition, there are waste spark which alot of OEM engines run and direct fire. Wasted spark is where two opposing cylinders firing at the same time. i.e. 1 and 4 fire on cylinder 1 coming up to TDC. The other is individual triggering of each coil based on which cylinder is at TDC.

There are limitations or downsides associated with wasted spark but there not as big as some boards or people will make out. Wasted spark for instance (all else being equal) doesn't result in reduced spark or coil performance. The first is coil life, essentially the coil is igniting twice as often, so the coil will die sooner. Personally I don't consider this an issue given the life span of OEM denso or such coils, my last set on my car had lasted 9 years or around 170k before replacing them (and they still worked).

From memory at high dwell times, you'd run into issues with the engine spinning so fast that the associated piston will fire at an inappropriate time. But this doesn't become a factor to about 12k rpm which is hardly an issue for most people. It is however an issue on rotaries as they have a firing period of 360 degrees vs a four stroke engine of 720. (hope that makes sense).

The biggest issue however is wiring, if the wiring in your car has significant resistance, you will suffer a decrease in coil performance. But I've never heard or read of anyone having this problem in modern cars which came with coils stock

Some people also postulate that the coil firing in an empty cylinder may increase cylinder temperatures, but I can only see that happening in a cylinder which has residual fuel in the chamber that gets ignited? Otherwise your igniting air?

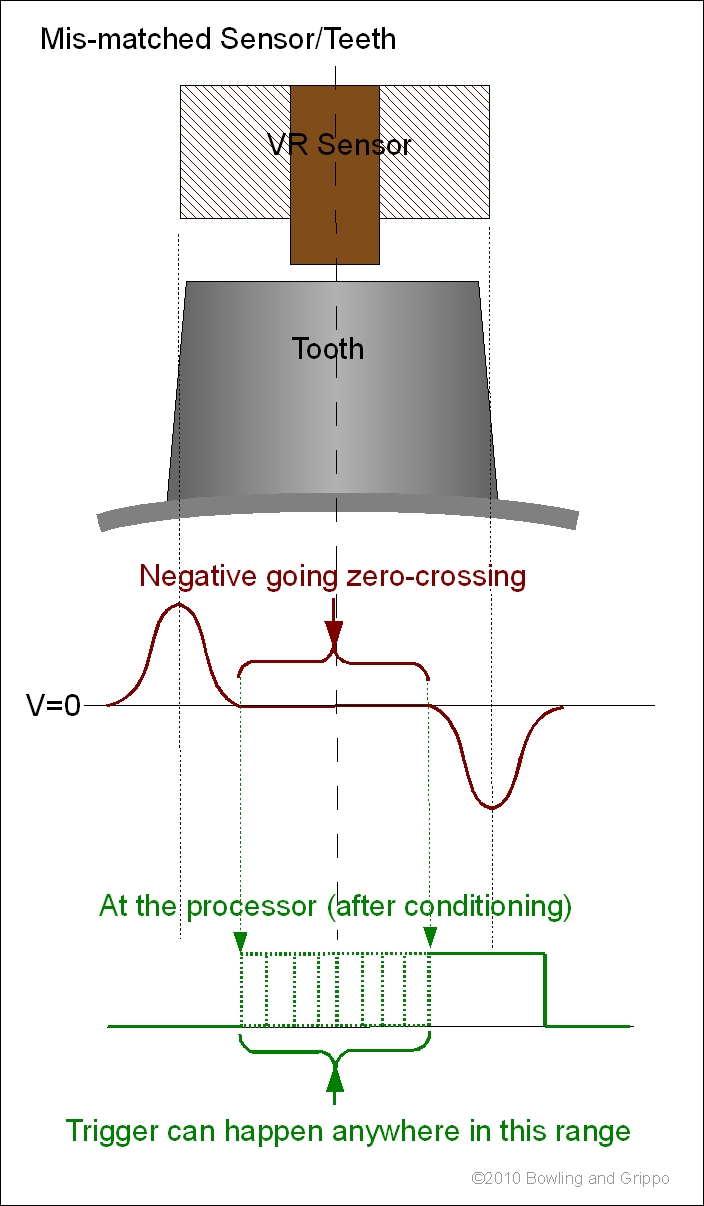

Regarding the post width vs cam wheel, if the widths are to different you can get various issues one of which is:

This shows the sensor being too narrow for the tooth, but the opposite is possible. Do i think its likely? No.

Things I can think of to try in order of cost/hardness:

- Ziptie

- OEM Reluctor Sensor

- Stock Cam wheel - check to see if its an issue with post width on the sensor vs the cam wheel. I don't see it being an issue, but the time and cost to swap a wheel beats pursuing a new ECU.

EDIT: picture doesn't work, scroll down to about halfway here:

http://www.megamanual.com/ms2/pickups.htm

Further. You may be using the cam for ignition you may not. Depends on how the haltechs are configured, it might just be being used for vvti like dann suggests. I haven't had to deal with it.

Who is online

Users browsing this forum: No registered users and 3 guests