Crapweasel wrote:

100 posts Roadrunner!!

Here's a theoretical top speed in each gear using 3.636 rear end like we have:

Awesome! And my prize is correct information on the internet! Thanks

Moderators: timk, Stu, -alex, miata, StanTheMan, greenMachine, ManiacLachy, Daffy, zombie, Andrew, The American, Lokiel

Crapweasel wrote:

100 posts Roadrunner!!

Here's a theoretical top speed in each gear using 3.636 rear end like we have:

Kev05 wrote:Is the car back on track? i.e problem fixed?

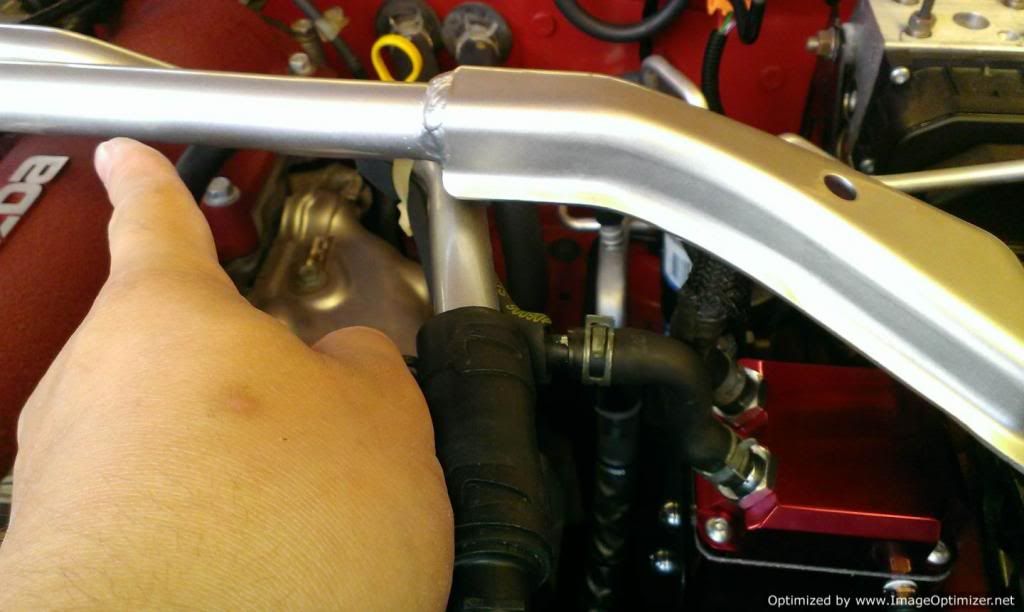

speed freak wrote:Looking good

How good are the braided brake lines hey? I couldnt believe the difference it made when I got mine put on.

With the innovate oil temp/press gauge does it come with the 'normal' screw in type sesnors that would go into say a oil filter relocation kit port?

Also where abouts have you routed your wires for the gauges? I cant work out how to get them through the firewall and into the engine bay. Meaning I cant find a rubber grommet that leads to behind the dash somewhere.

tomli123001 wrote:Finally I fixed up the annoying kept coming off loose hardtop bolts with some threadlock. First time used it, I think I put a bit too much on the bolt here.

tomli123001 wrote:Finally, I did my suspension height to raising it, after Lockiel protesting this in my thread a number of times and reading the benefits of higher rear end. After all, I can now driver through Macca's speed bump now no problem at all.

:

raised rear height now. Looks very 4wd to some of you here, probably due to the angle of photo

tomli123001 wrote:The thread which the spring covers should never be changed, as this will reduce your travel.

Users browsing this forum: No registered users and 8 guests