NC 20BPP Time Attack / Track Car - Build Thread

Moderators: timk, Stu, -alex, miata, StanTheMan, greenMachine, ManiacLachy, Daffy, zombie, Andrew, The American, Lokiel

-

toppertee

- Racing Driver

- Posts: 699

- Joined: Mon Jul 11, 2011 4:16 pm

- Vehicle: NA6

- Location: Brisbane

Re: NC Track Car - In the Build

Devcon is better than WD40!

- timk

- Racing Driver

- Posts: 1928

- Joined: Fri Dec 31, 2004 3:16 pm

- Vehicle: NC

Re: NC Track Car - In the Build

Danny just out of interest, what would those ports be for in the OE configuration? Better fuel economy or emissions stuff?

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - In the Build

timk wrote:Danny just out of interest, what would those ports be for in the OE configuration? Better fuel economy or emissions stuff?

The exact opposite of what I'm building!

So you are correct Tim.

Cheers,

Danny

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - In the Build

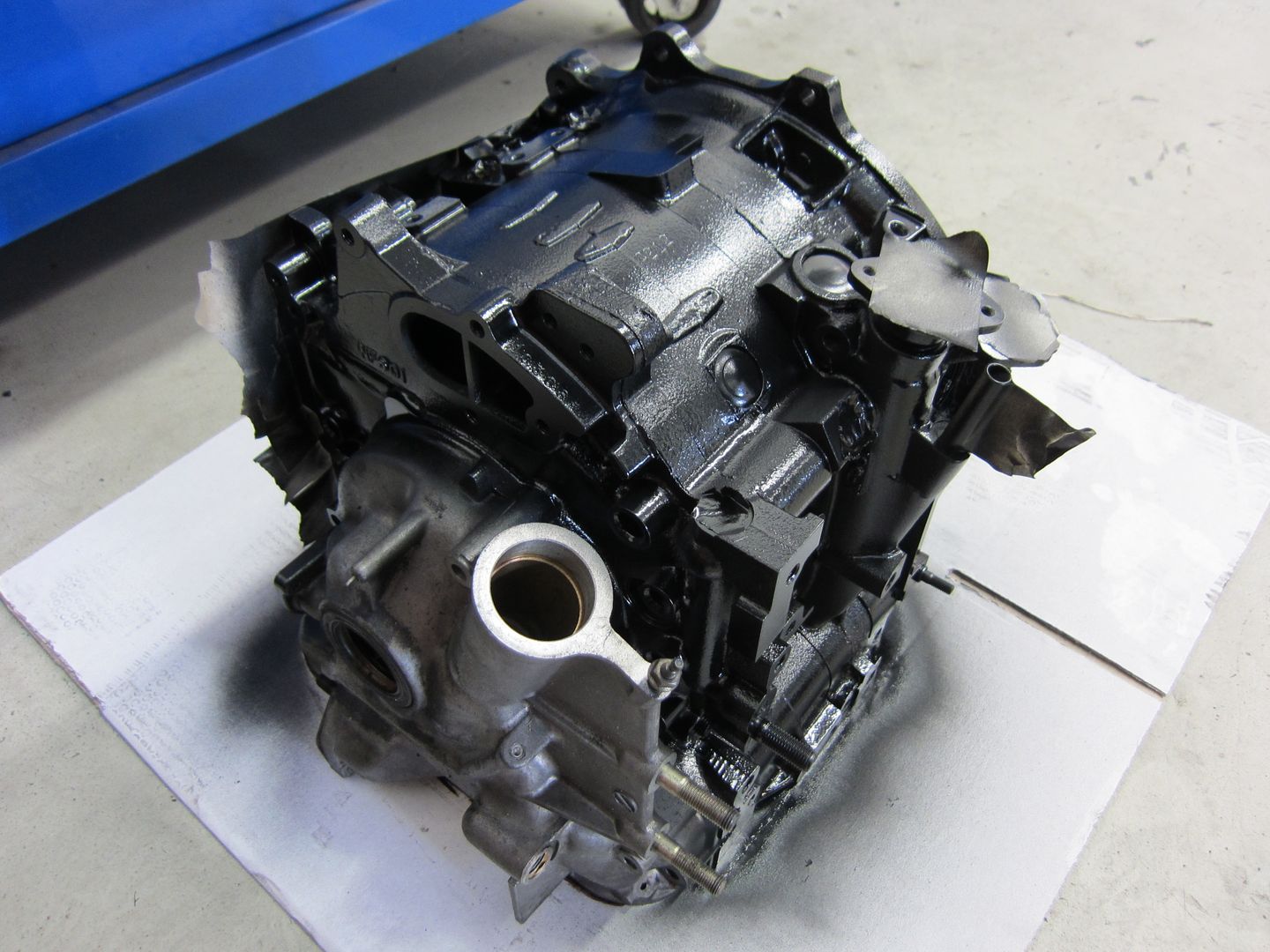

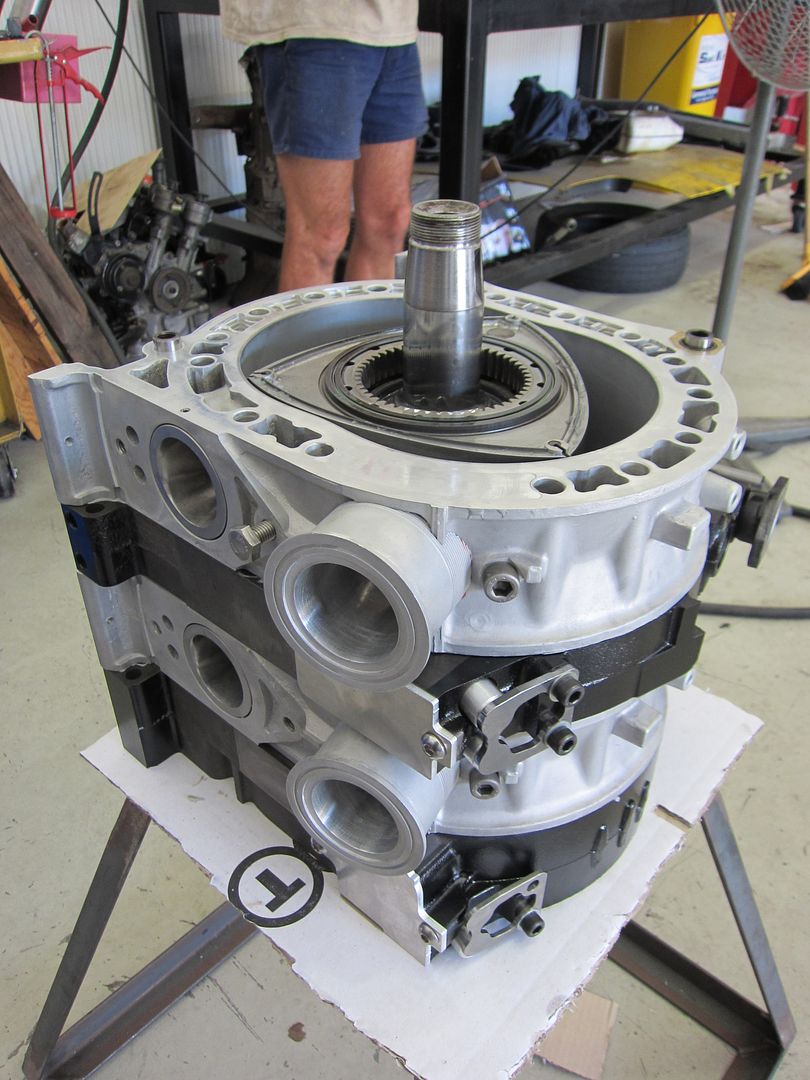

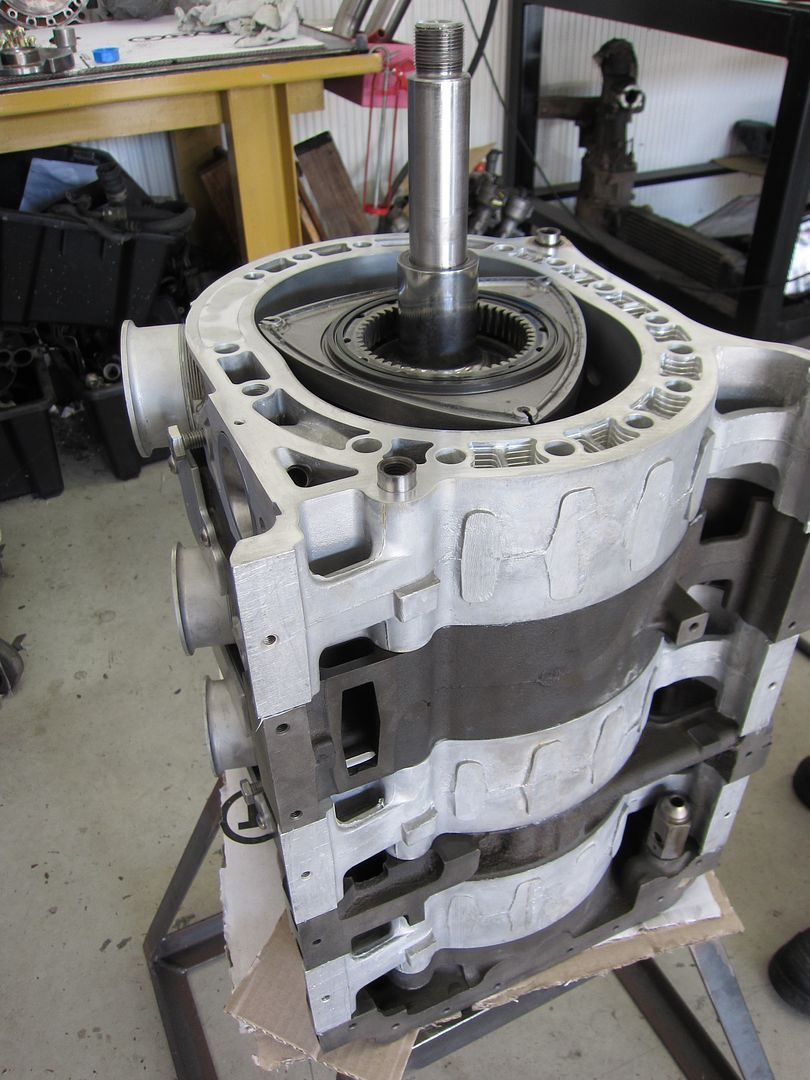

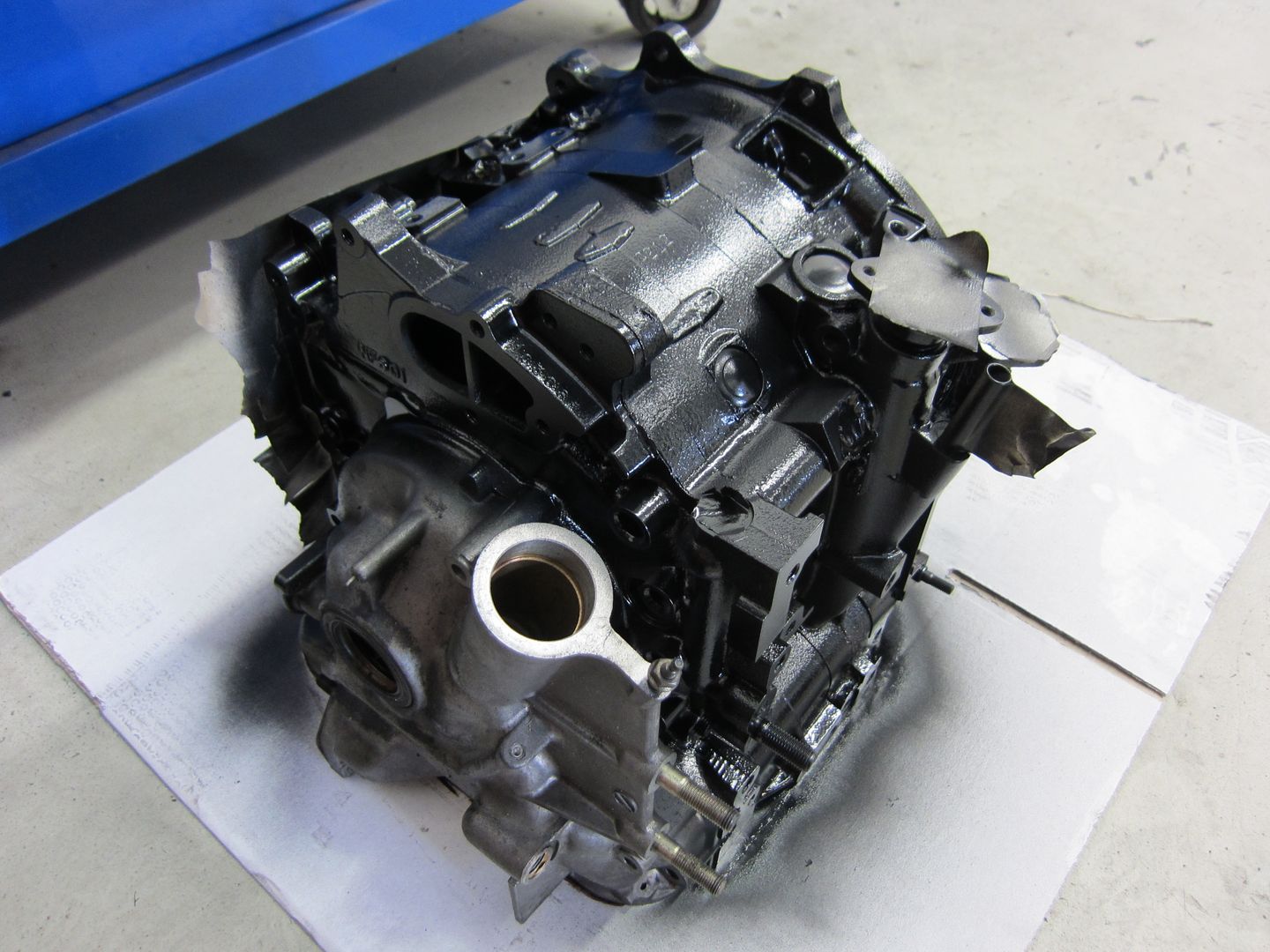

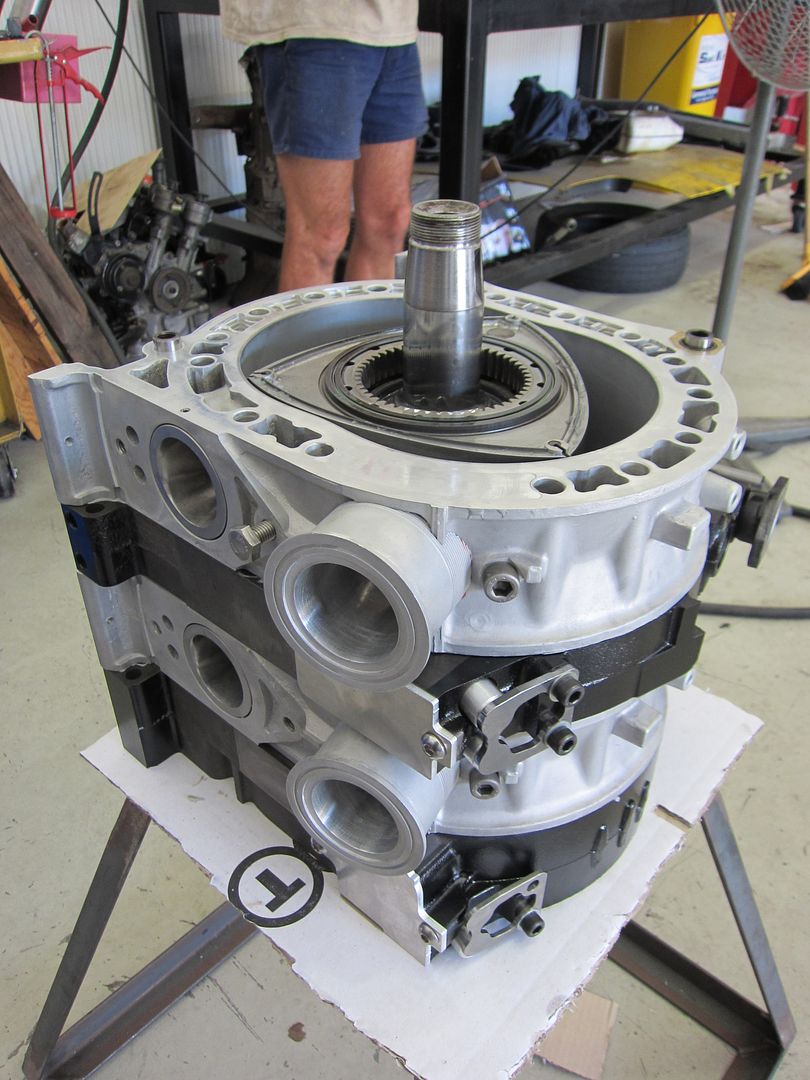

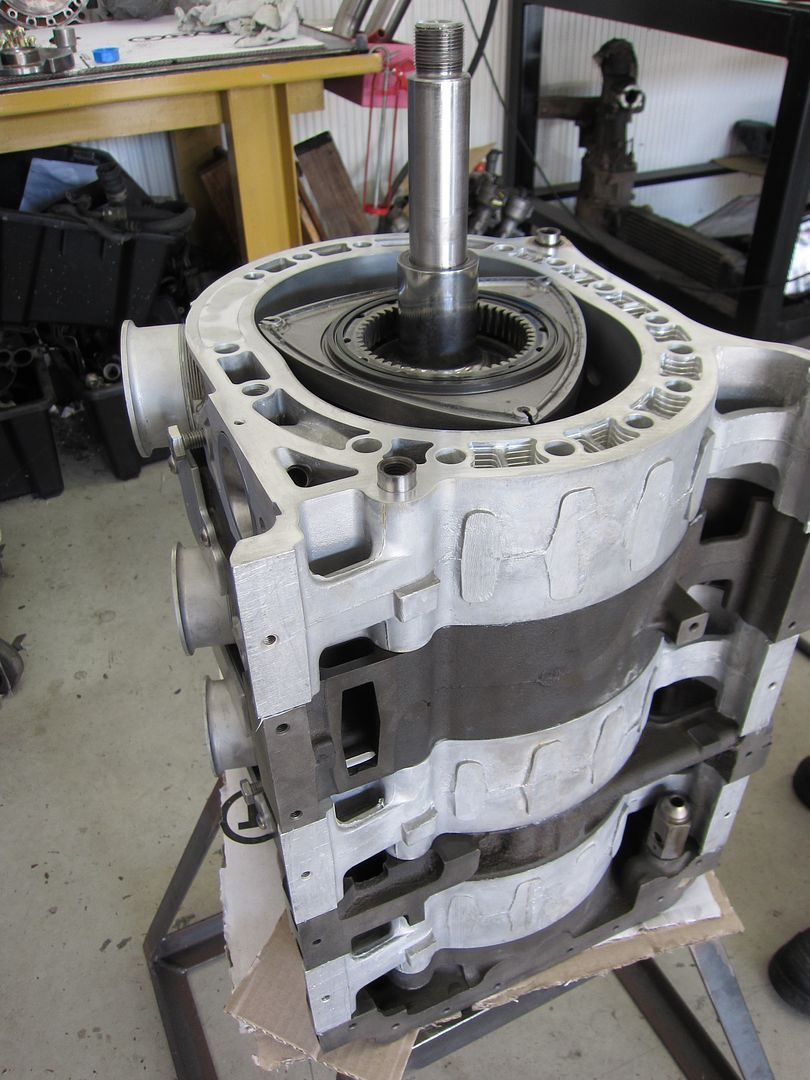

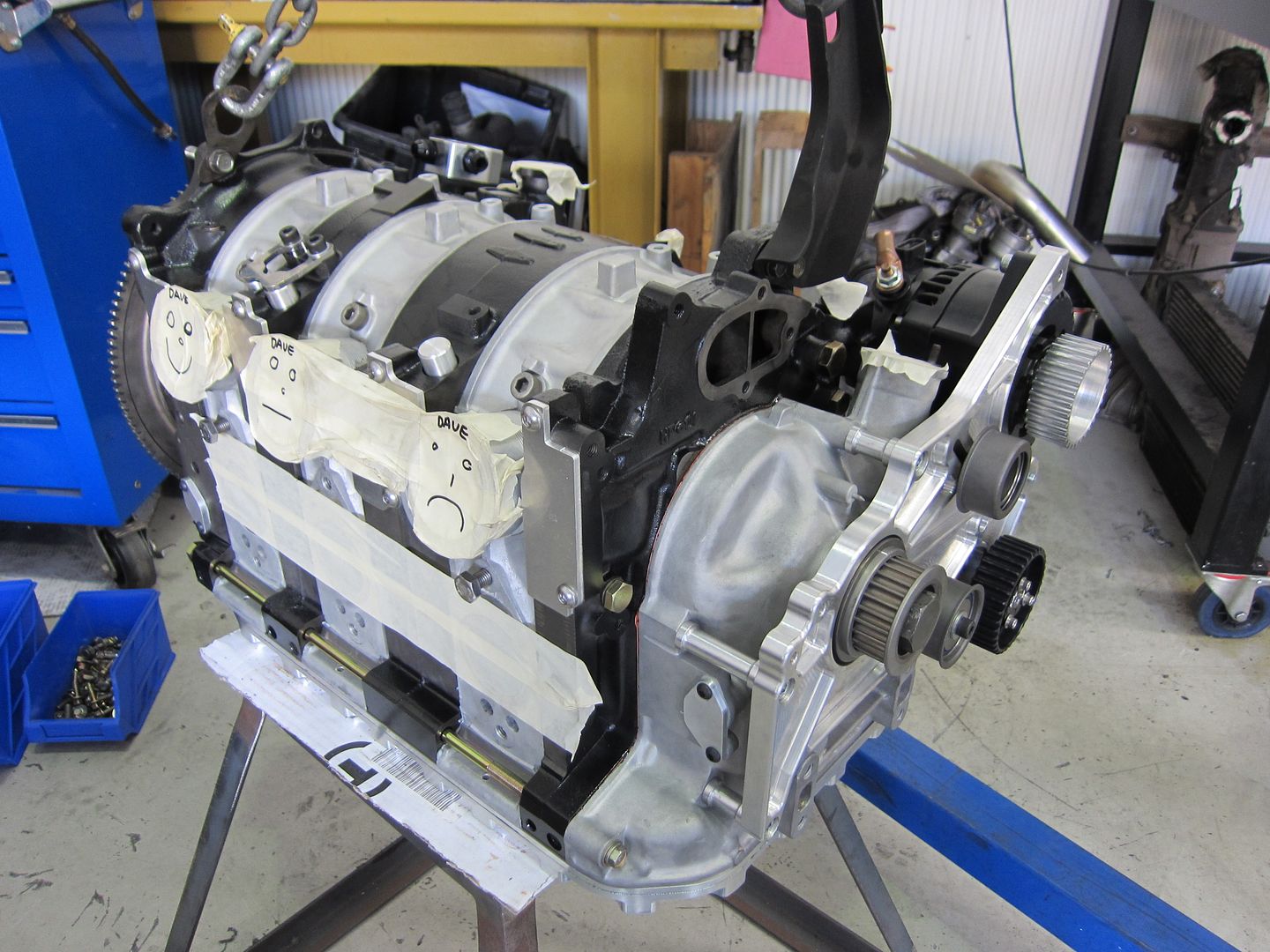

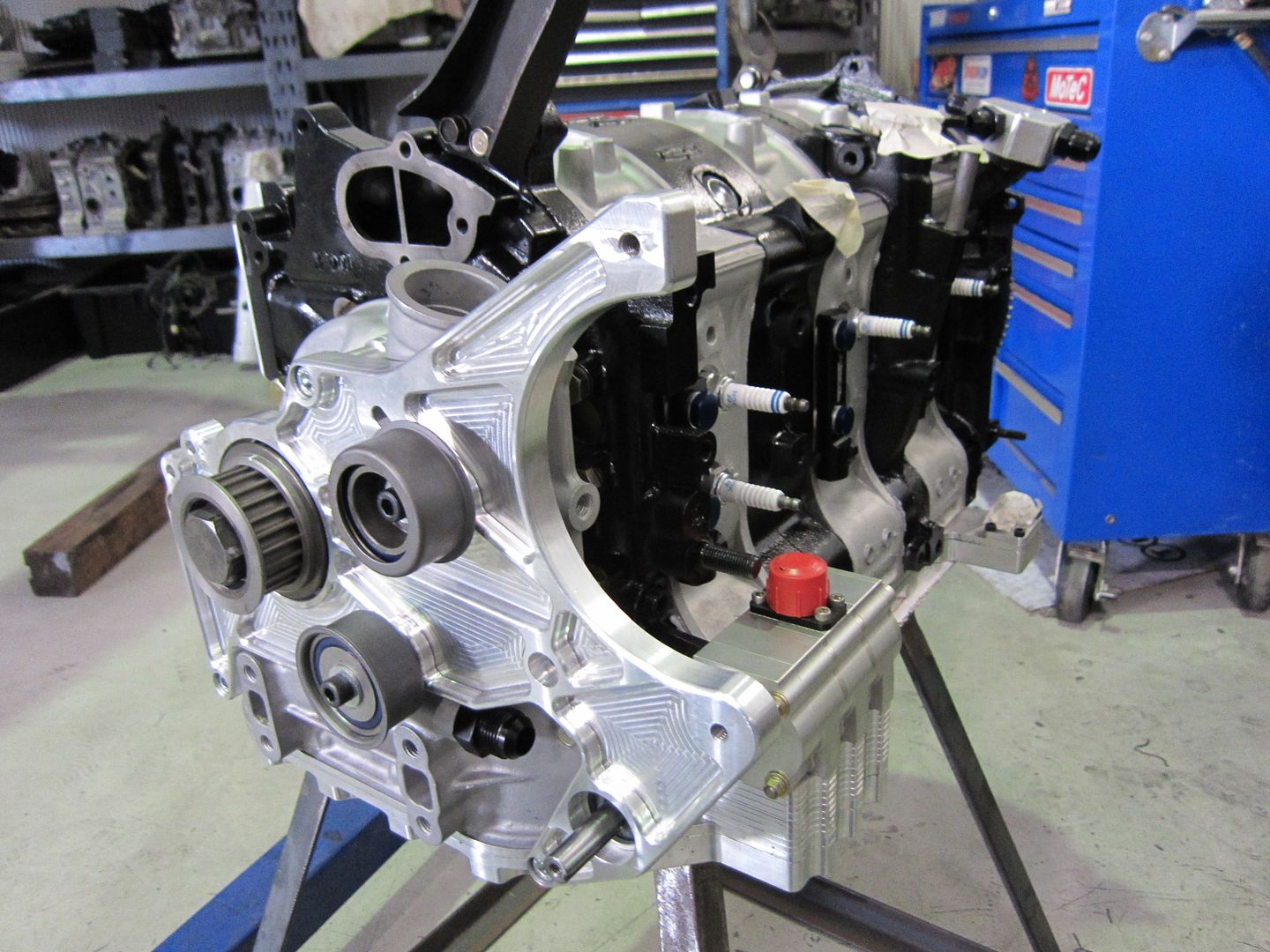

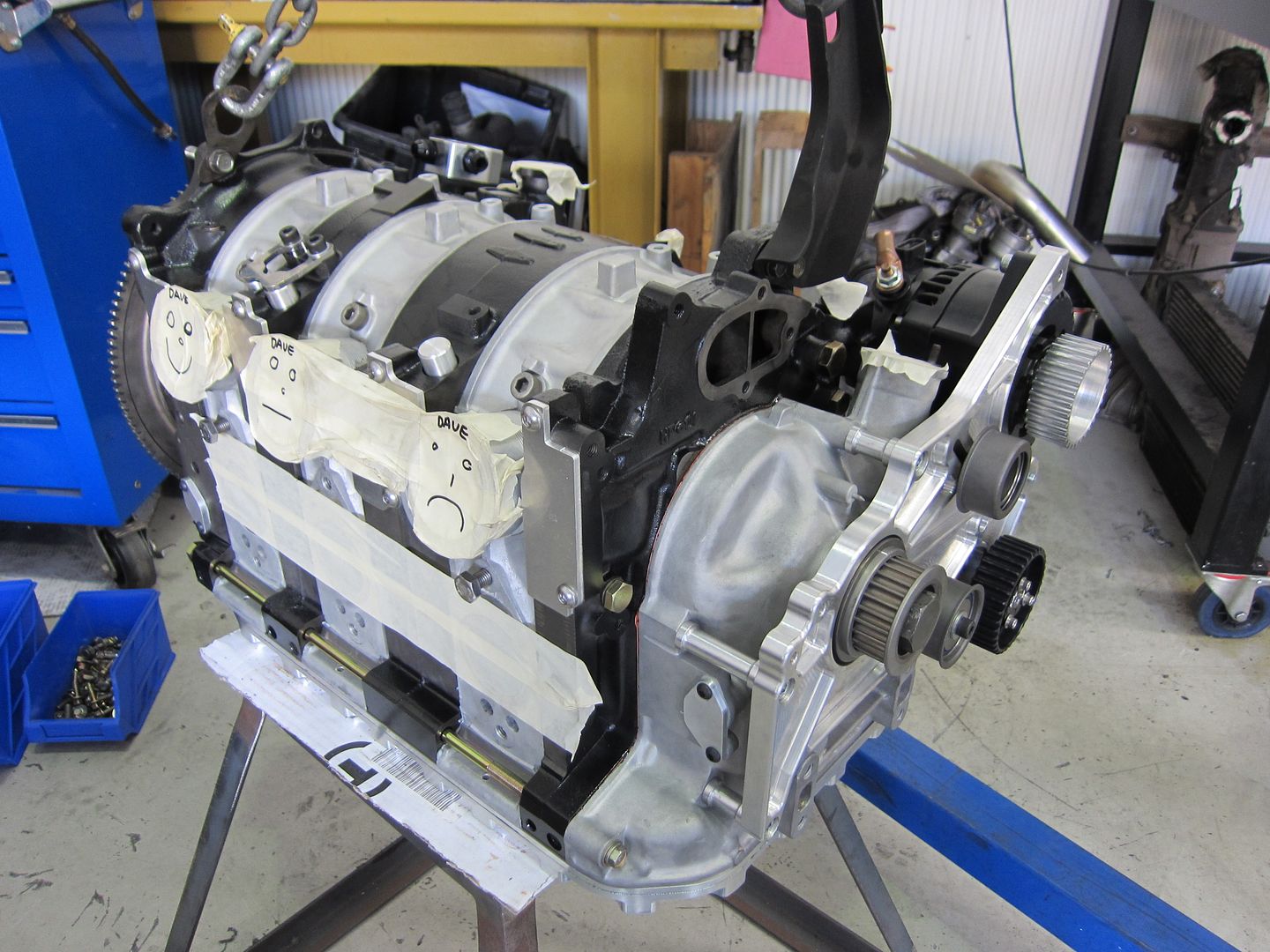

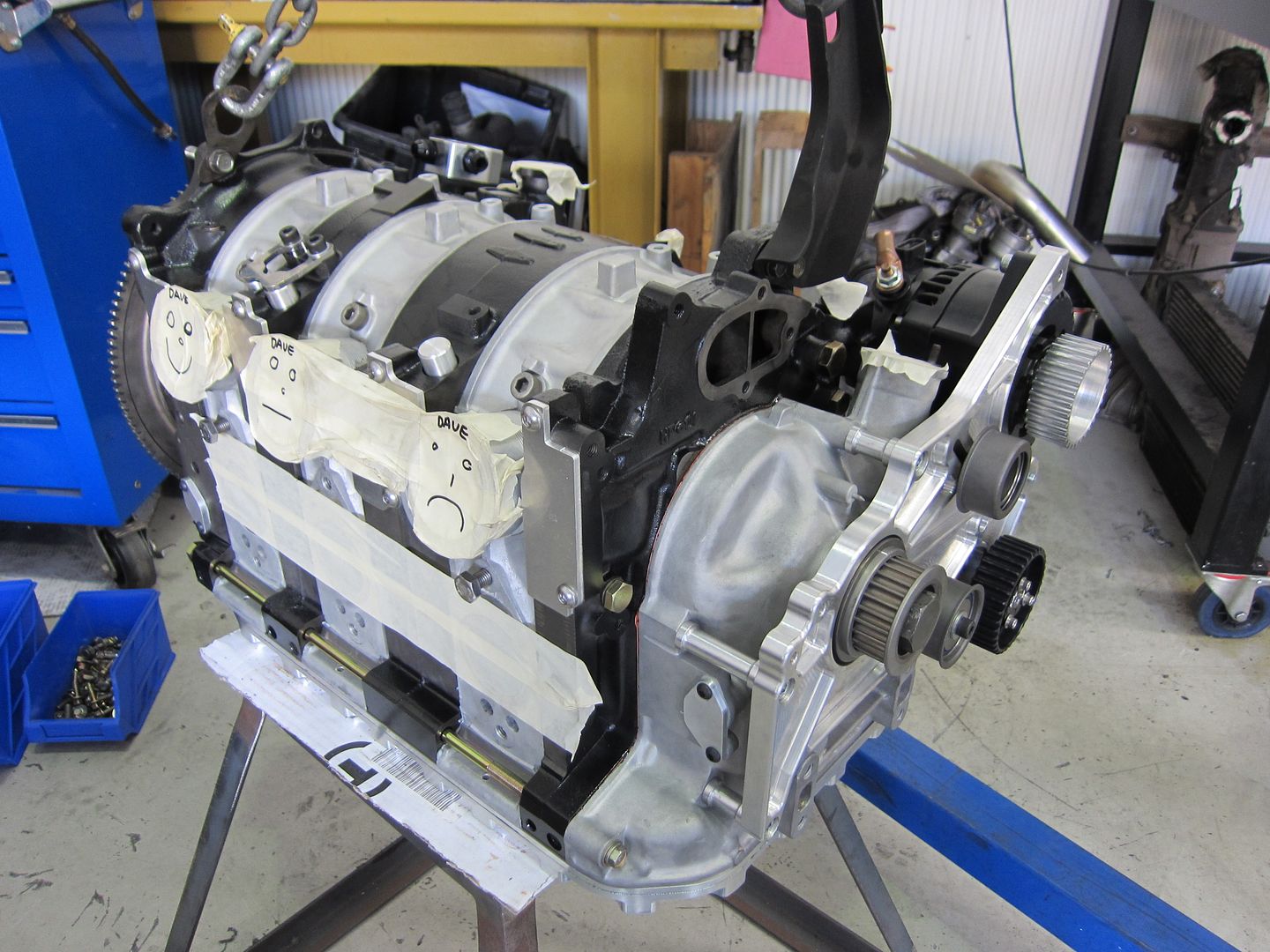

It's finally time to assemble the engine.....well at least the core.

The rotors were lightened, side clearanced and balanced to ensure the engine is vibration free all the way up to 10,000rpm.

Each of the 18 side seals were then clearanced to suit their respective grooves.

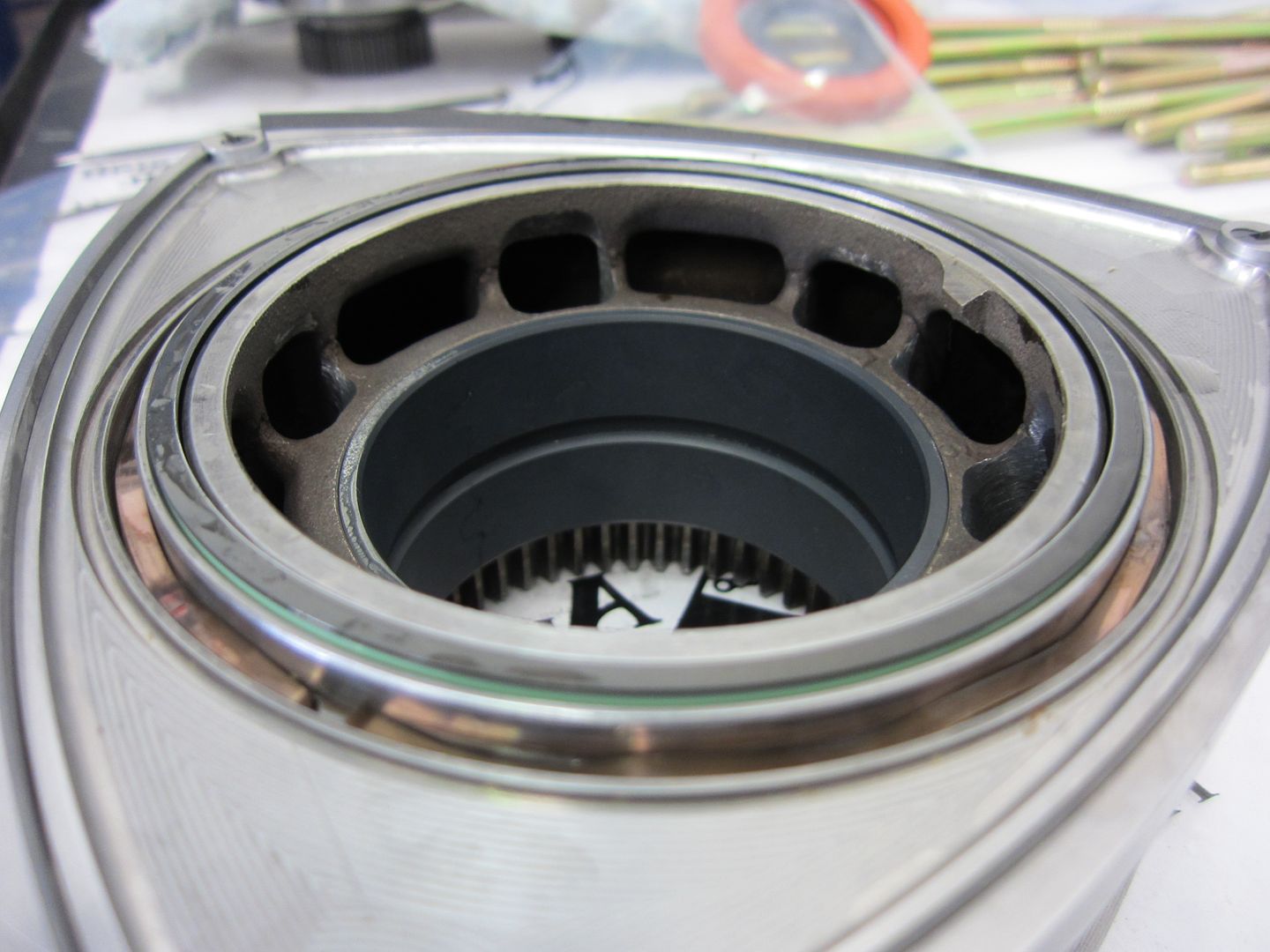

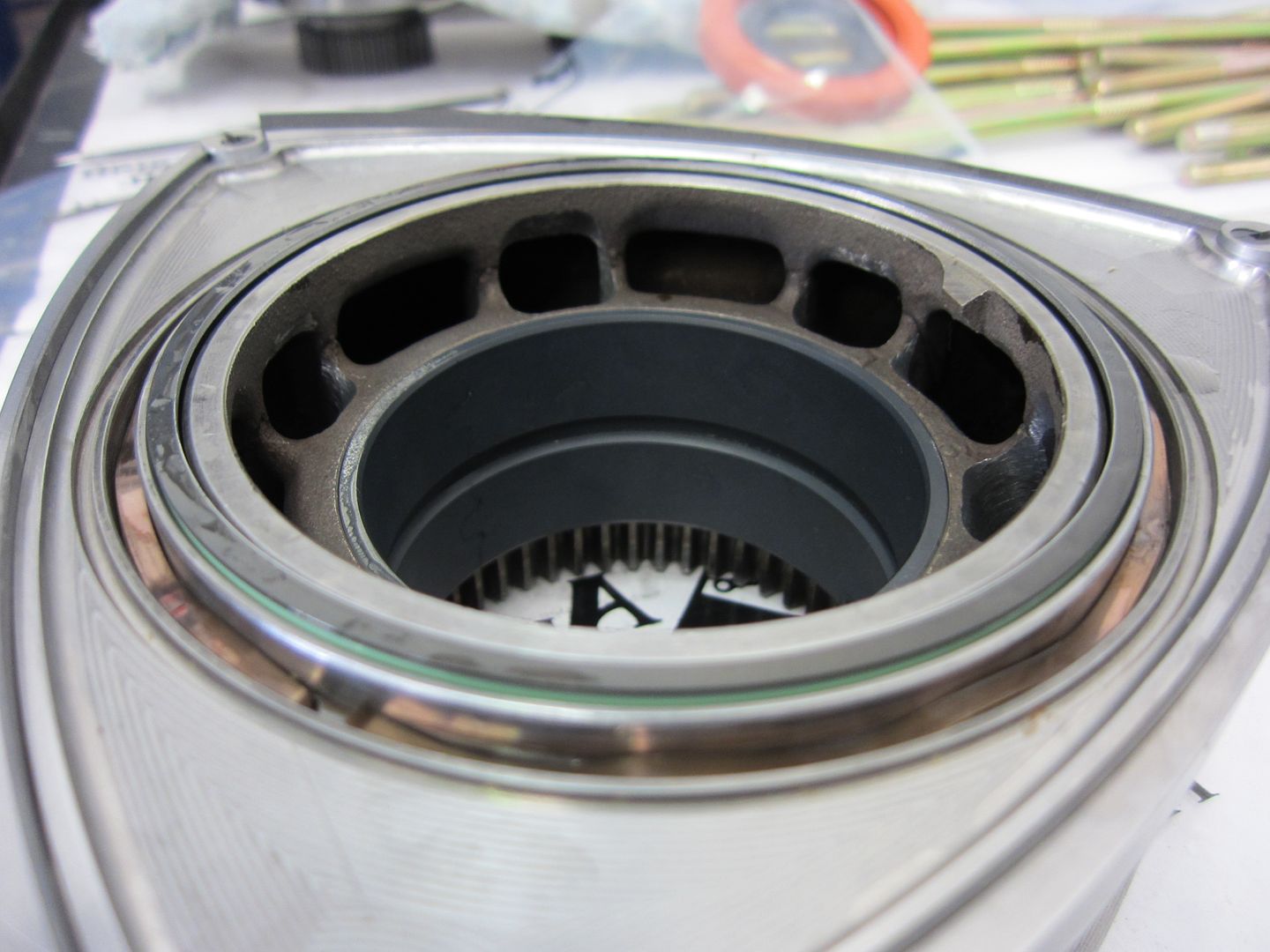

This is a rather rare item (well NLA new)...the centre stationary gear from the "Thick" plate. It has had a new bearing (also NLA) installed.

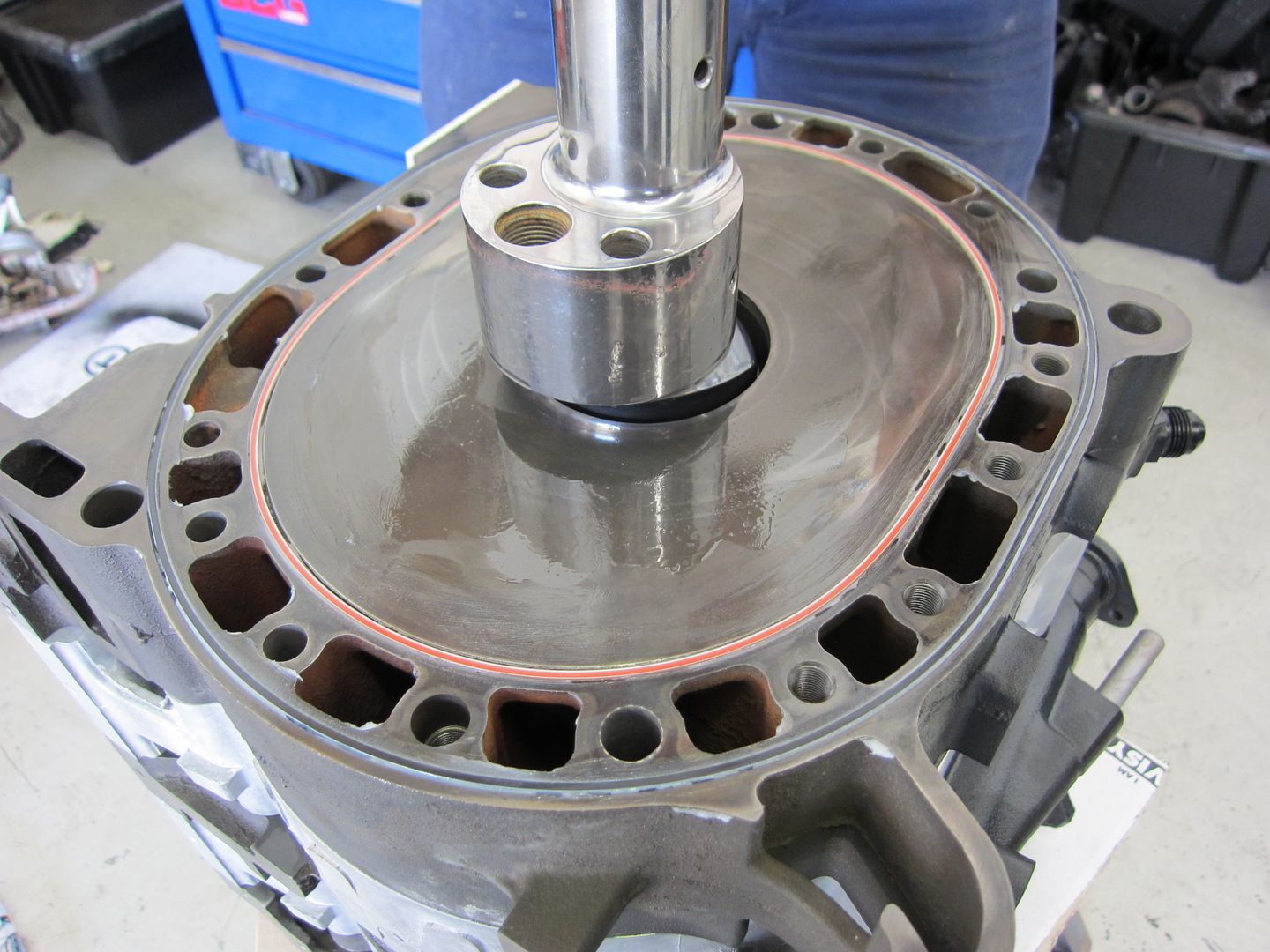

The front and rear stationary gears also scored a new bearing each and a rear main seal.

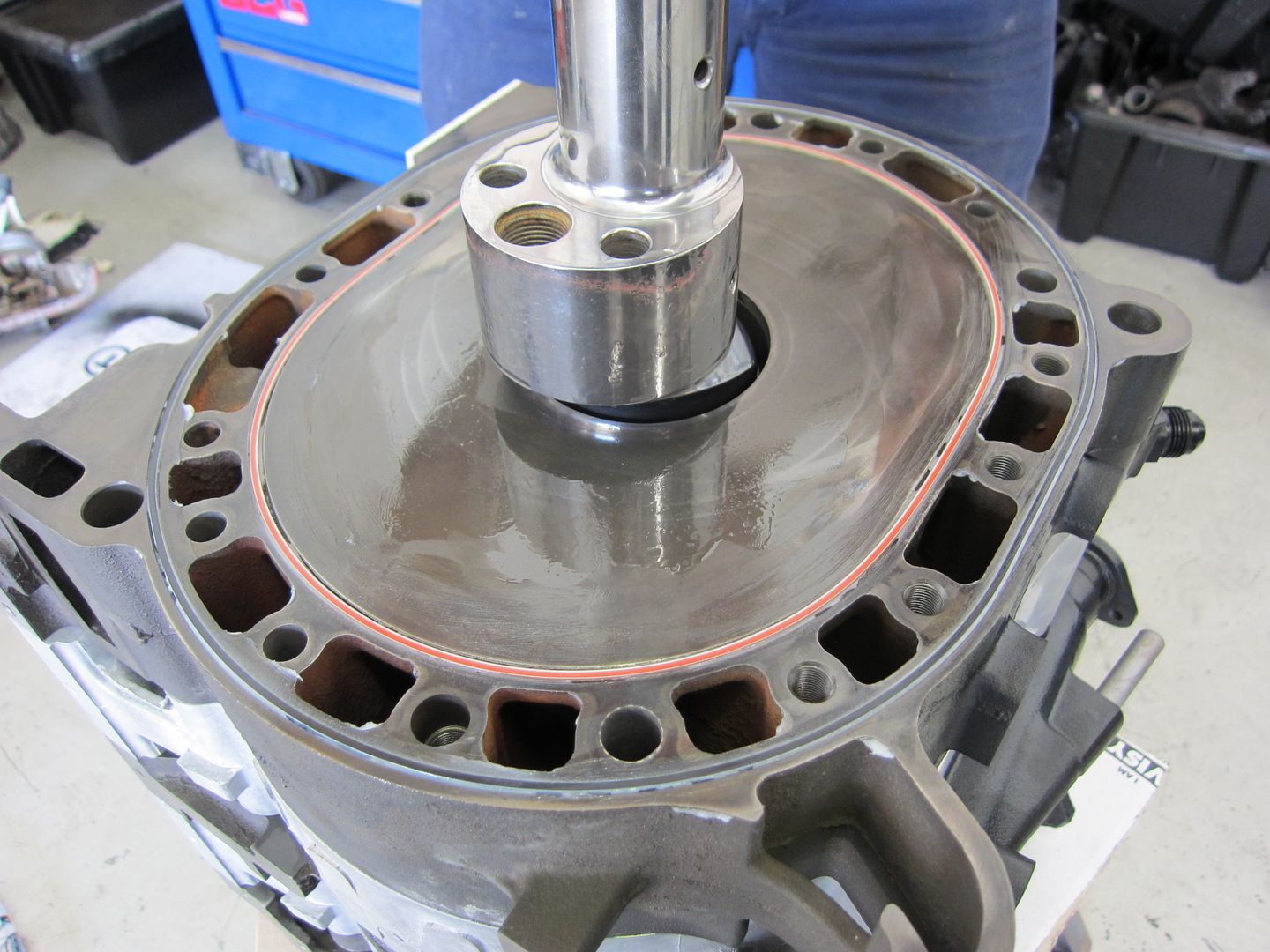

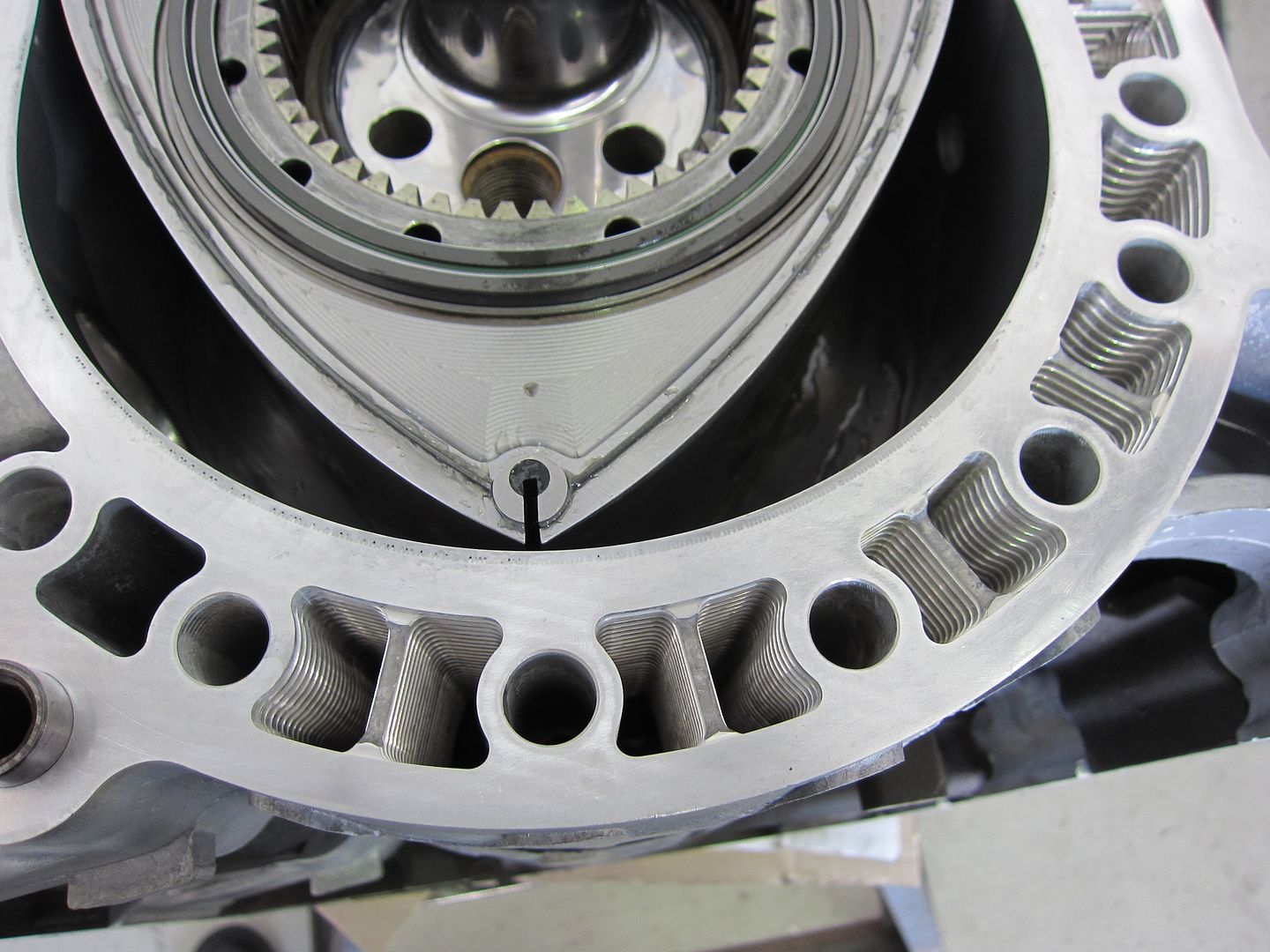

The through bolts were zinc plating.

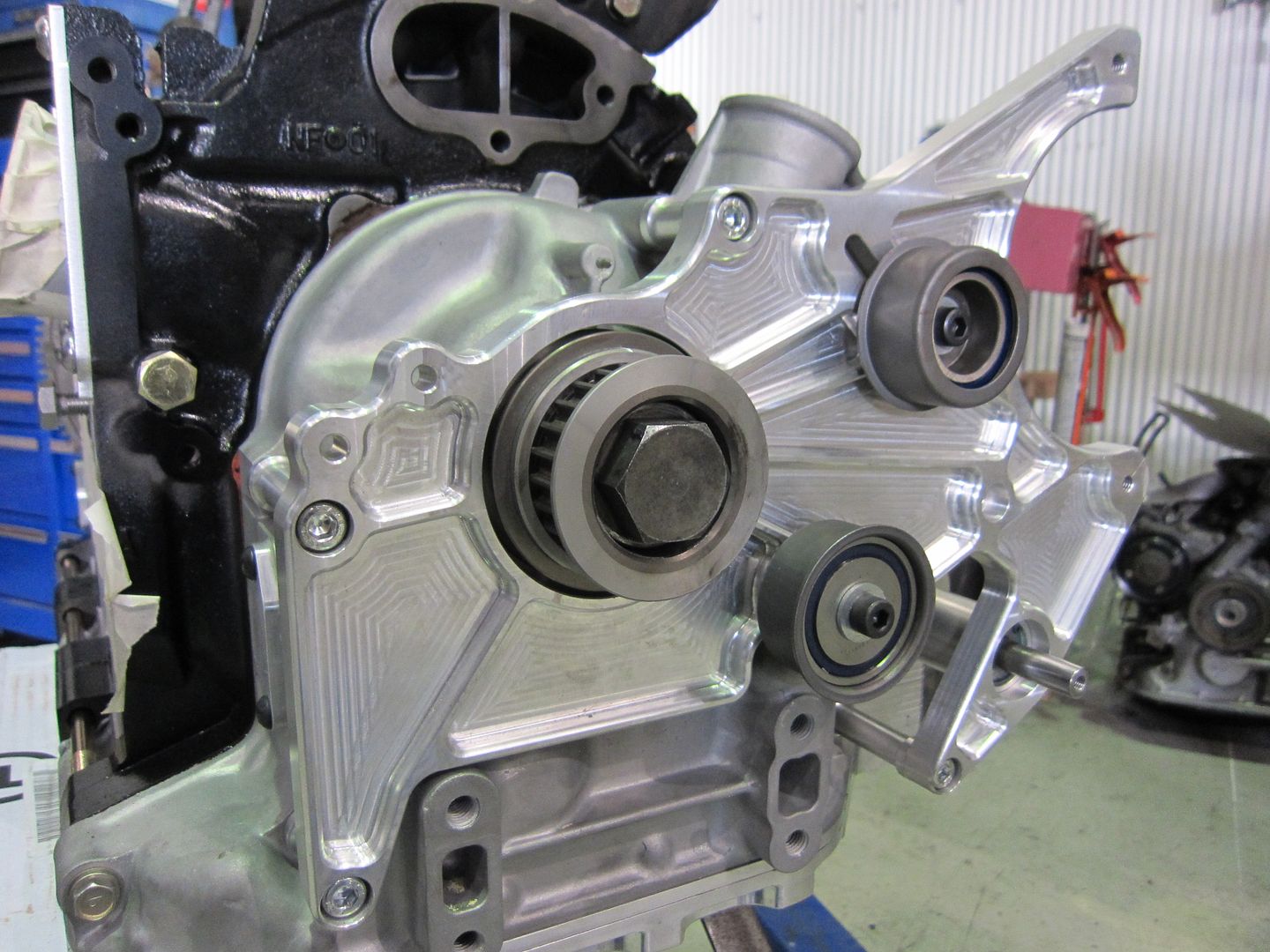

Now this is a really neat modification....the addition of an 'O'-ring groove in the front plate where the oil pump mounts. Normally the oil pump is bolted here just as a metal to metal seal. However, as you increase the oil relief pressure the sealing surface has been known to be breached resulting in a loss of all pressure to the rest of the engine. The addition of an 'O'-ring to this mating face ensures that no oil pressure is lost at elevated oil pressure. You can that the oil pump galleries have also been ported and polished to improve oil flow.

The plates also got a lick of paint.

The oil control rings in each rotor were then installed.

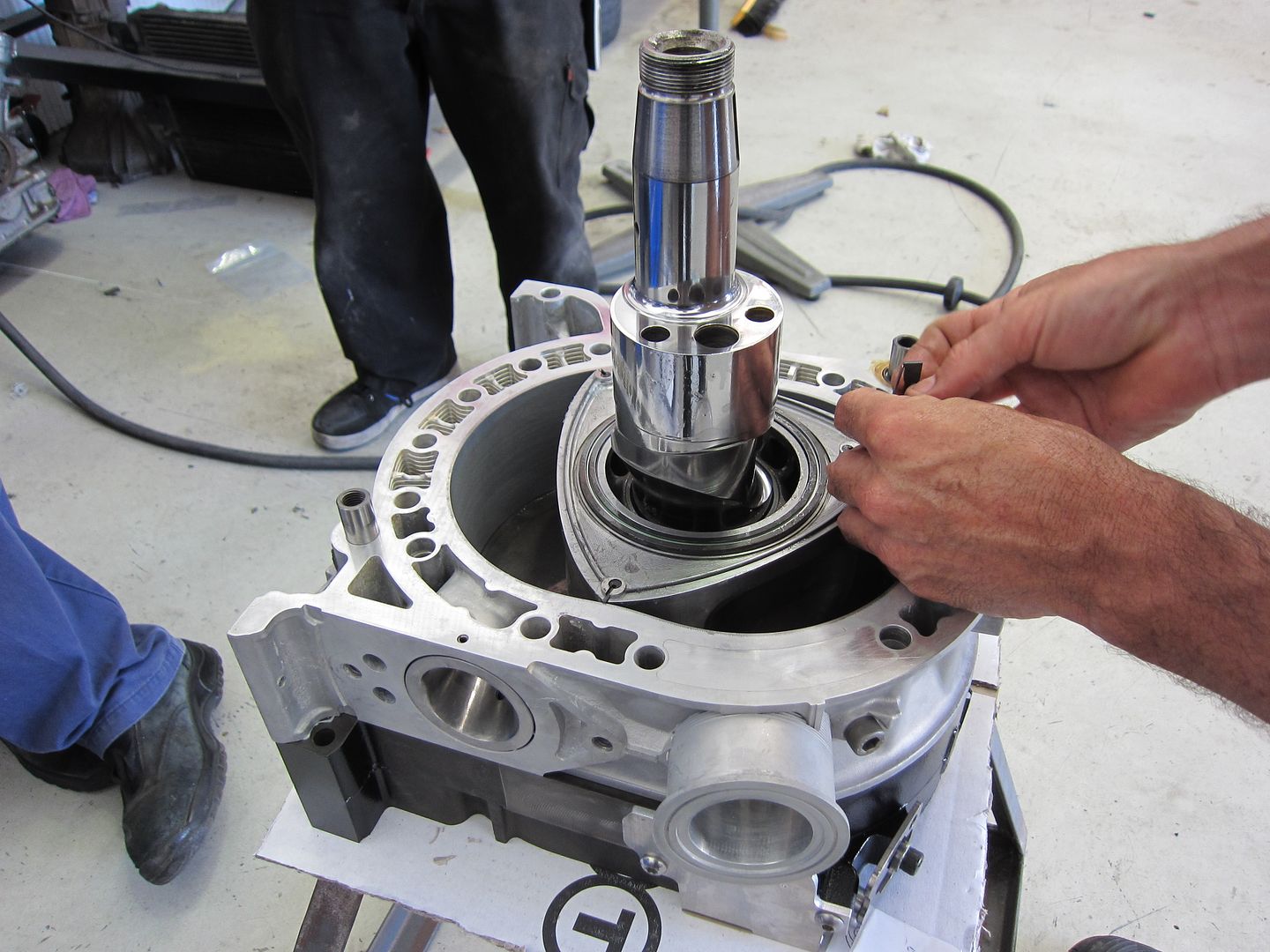

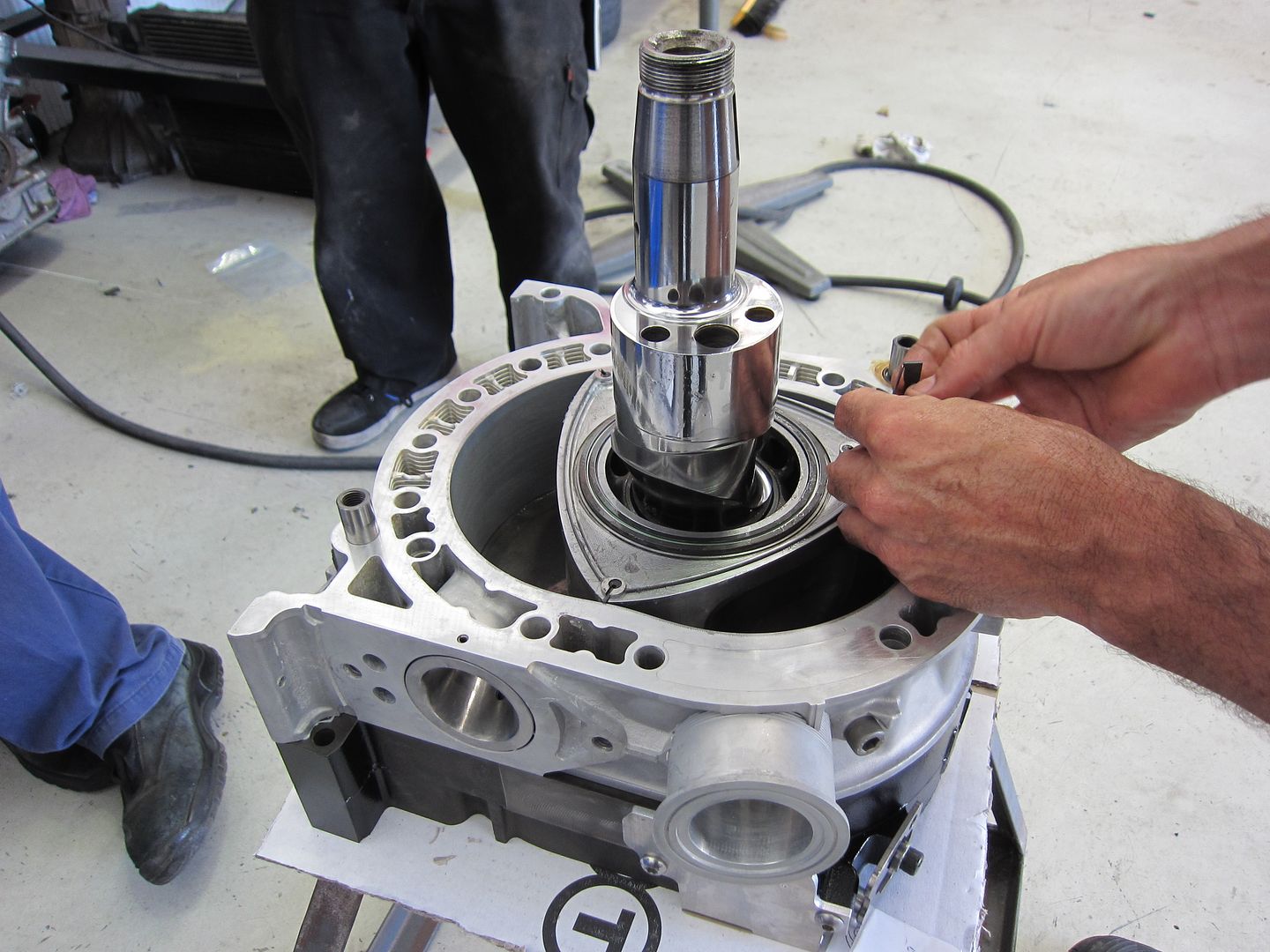

Beside the rotors the only other moving part is the eccentric shaft. In 20B engines they are two piece so that the engine can be assembled. It has also been isotropically finished. More info here http://xtremerotaries.com/services/isotropic-superfinishing/isotropic-superfinishing

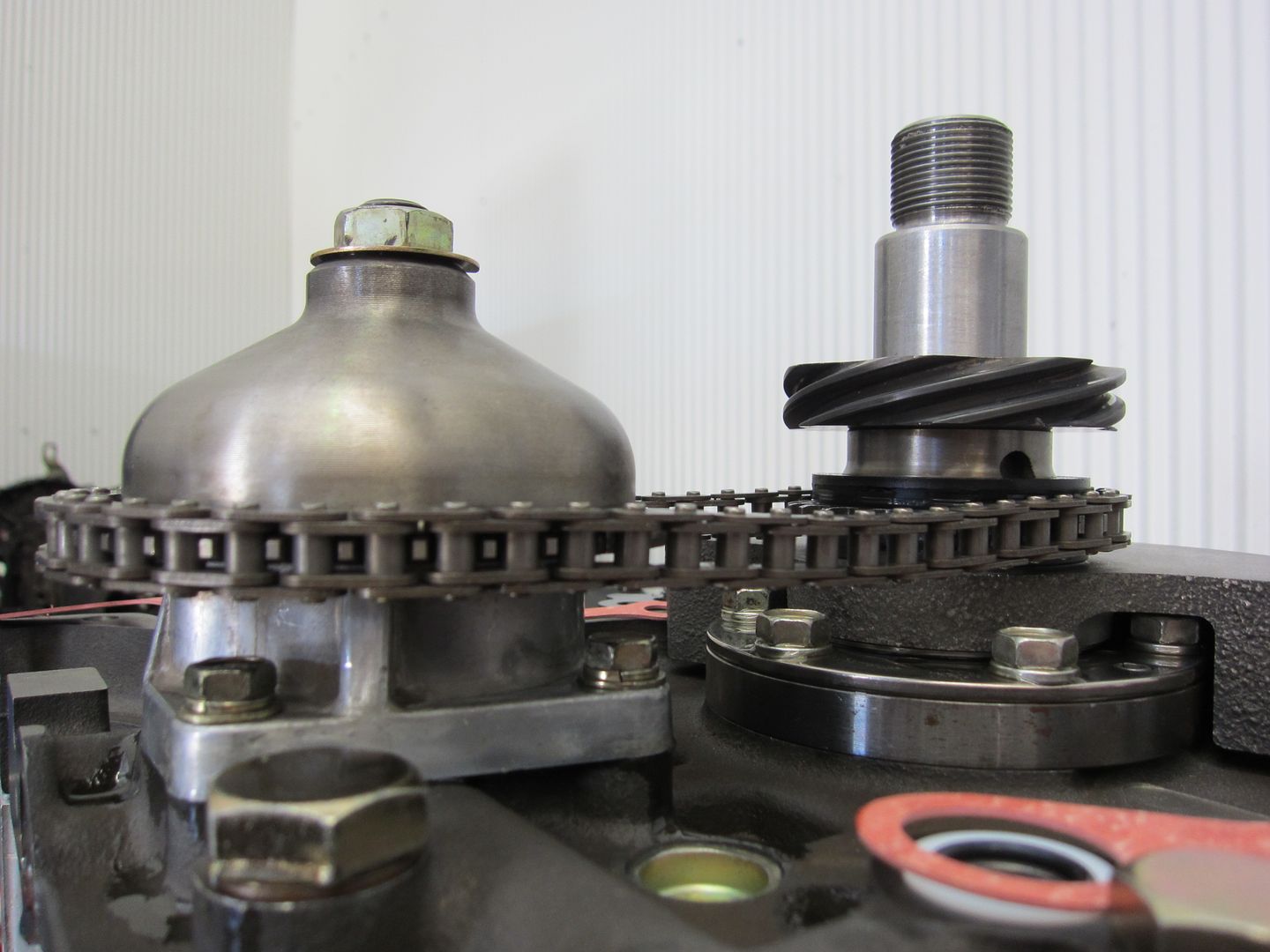

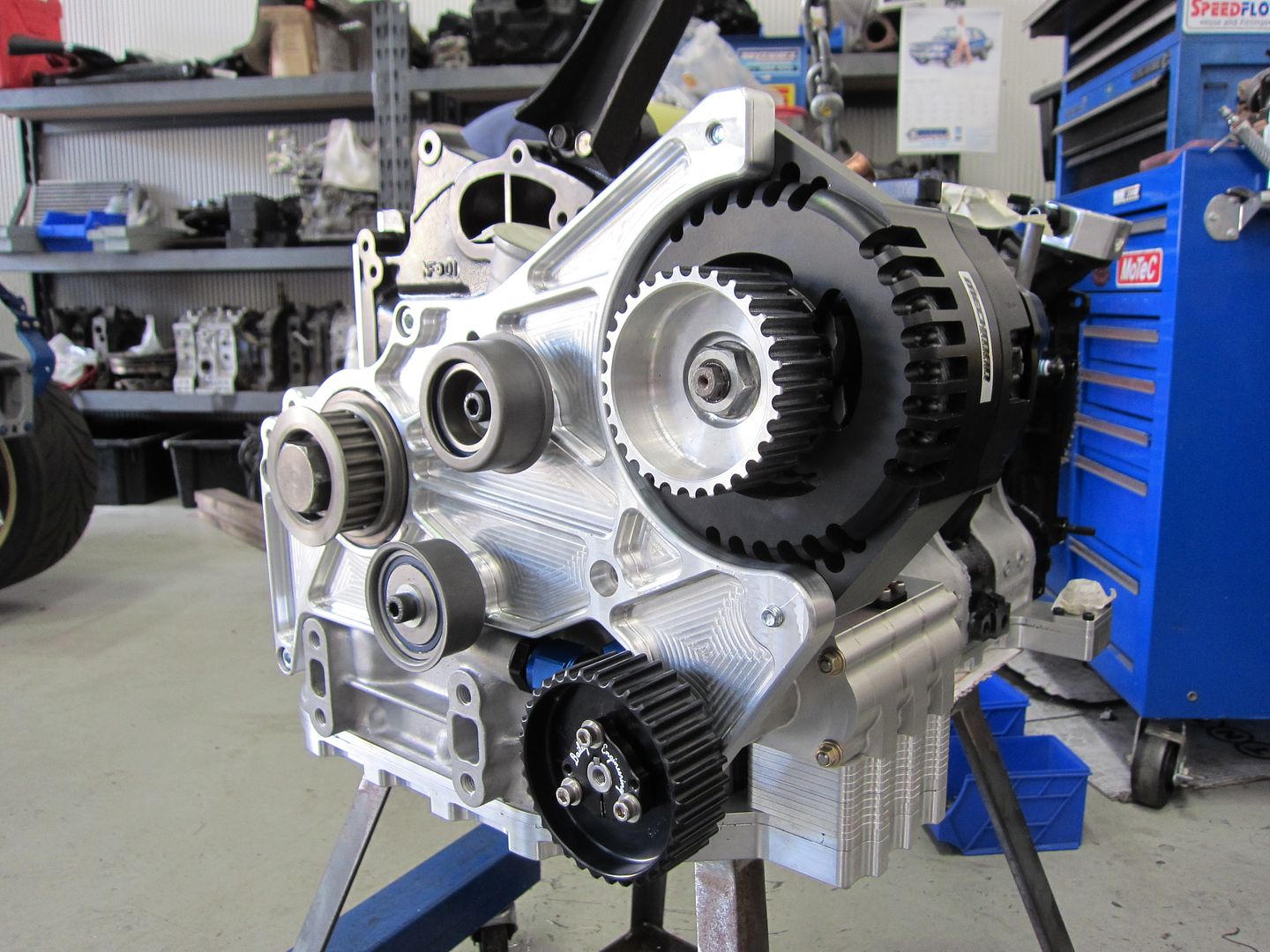

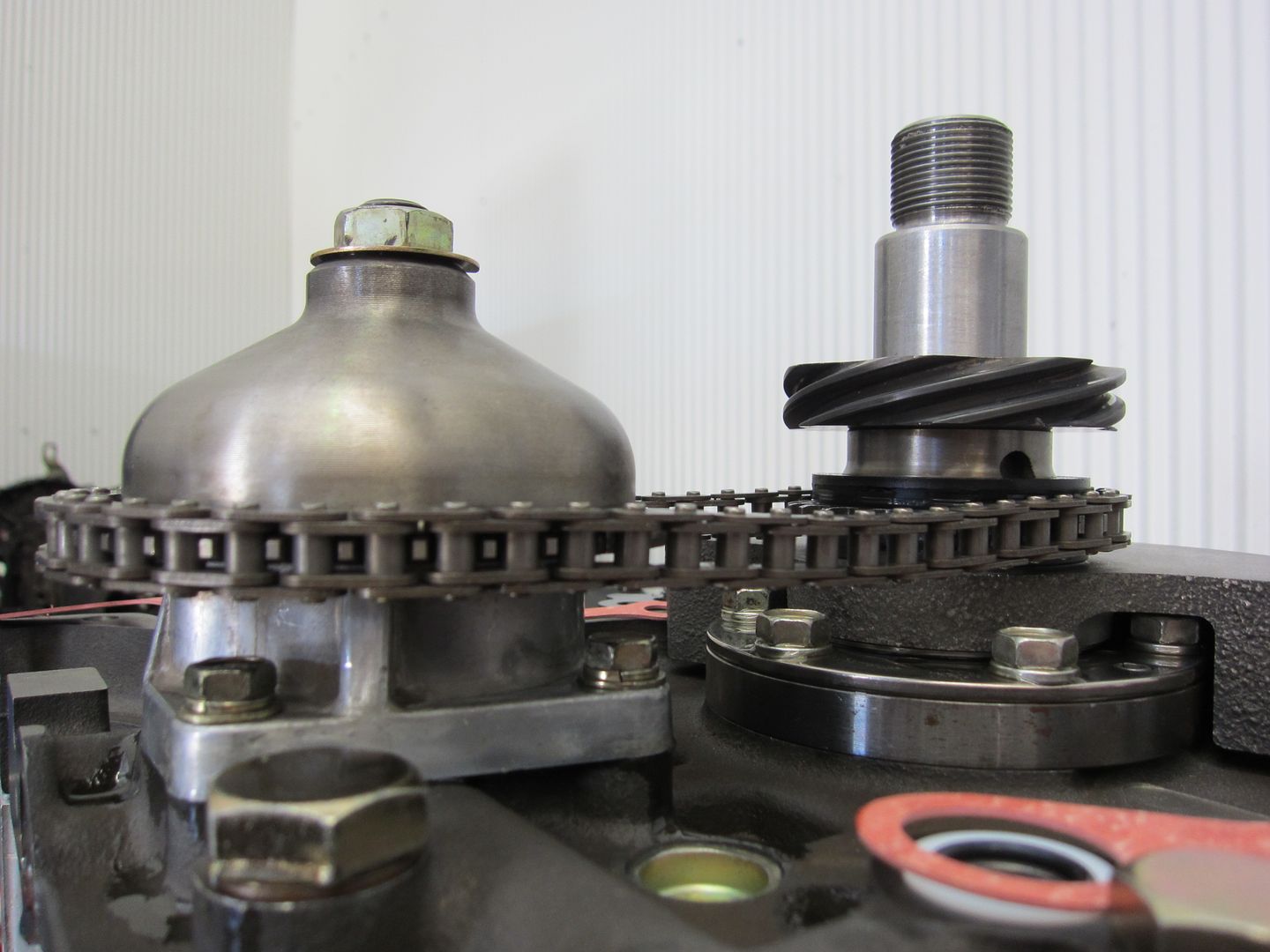

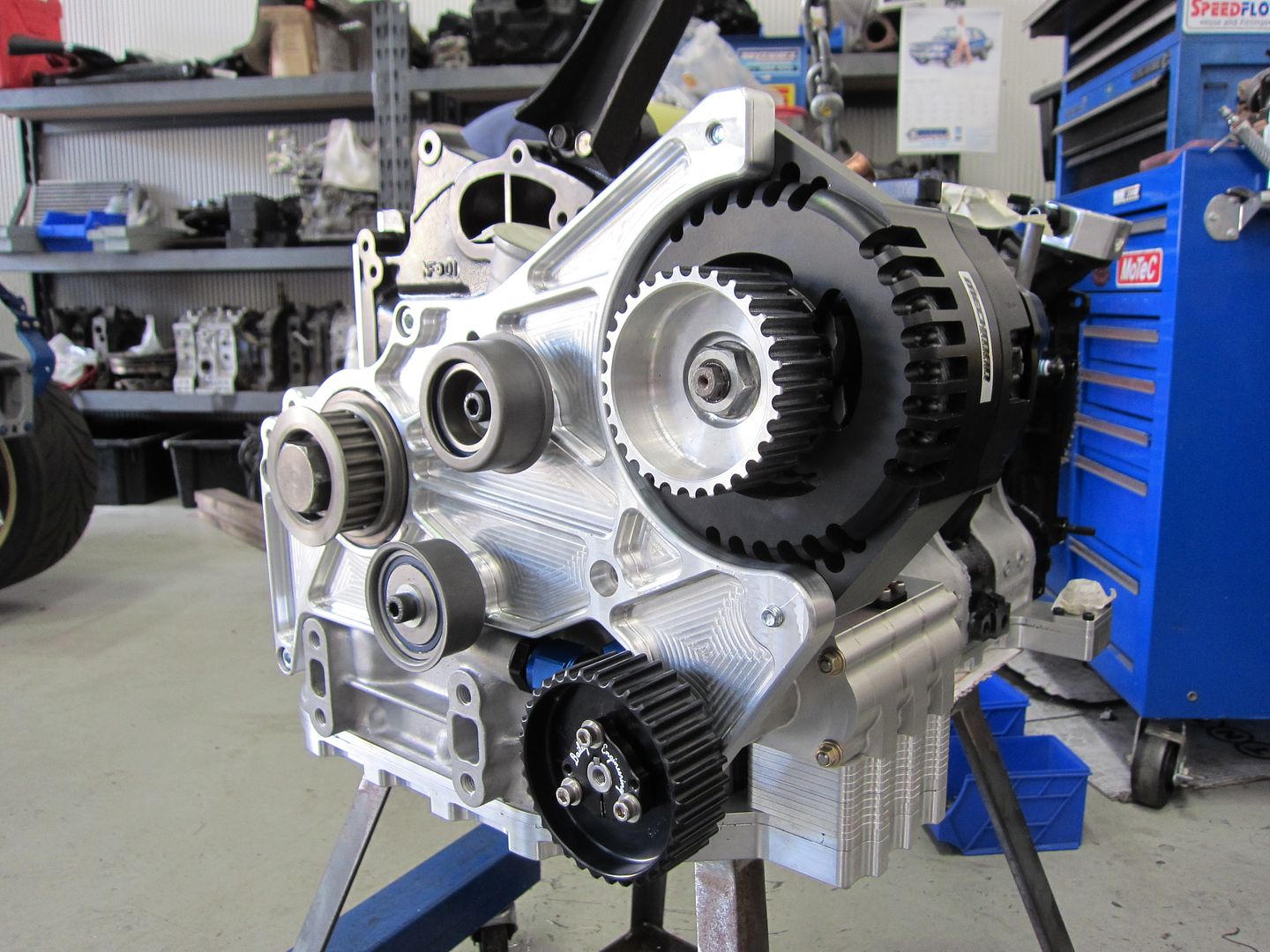

This is the custom front pulley that will drive the dry sump scavange pump and alternator.

The Iannetti 'Gold' apex seals and spring assemblies.

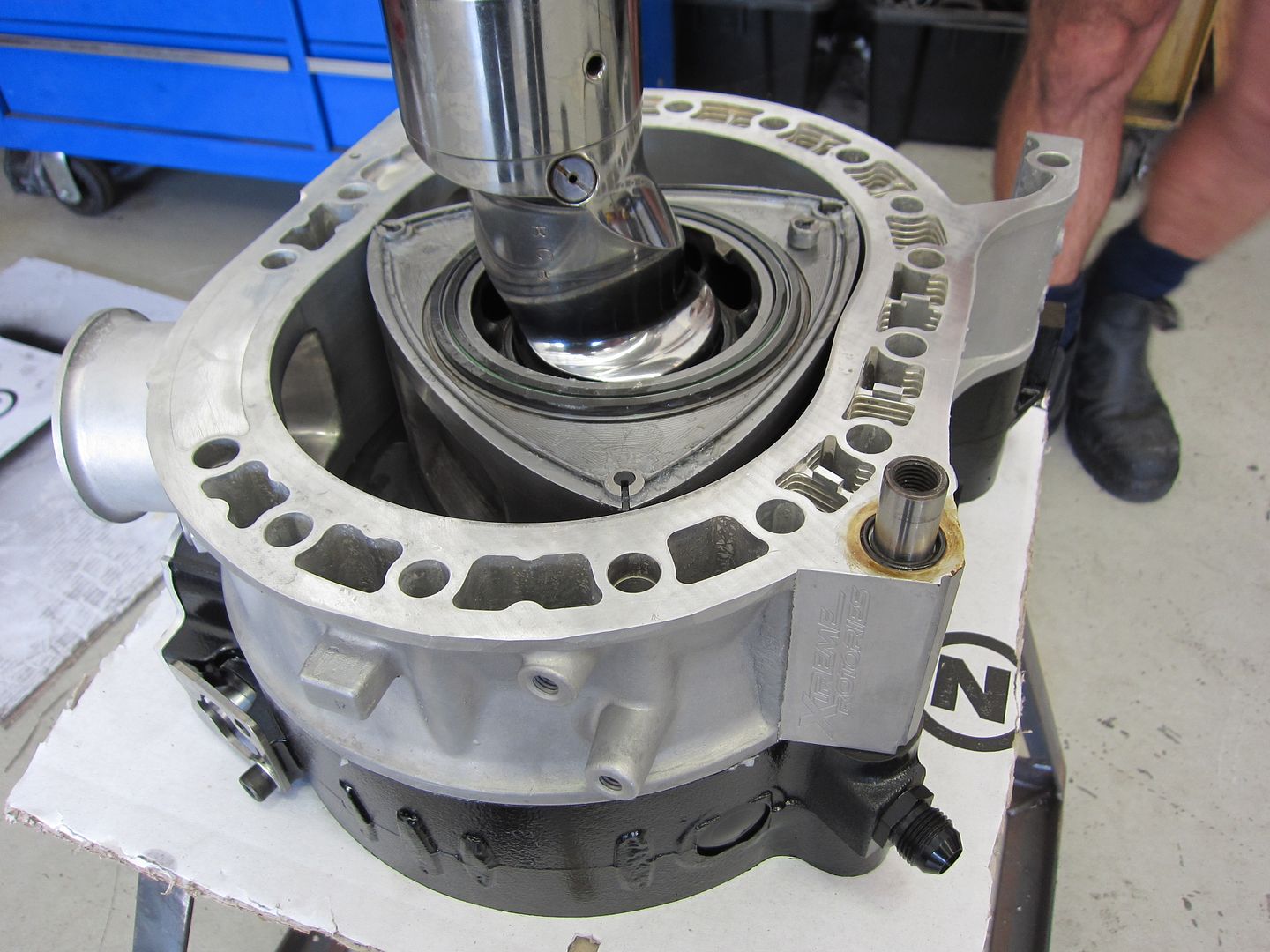

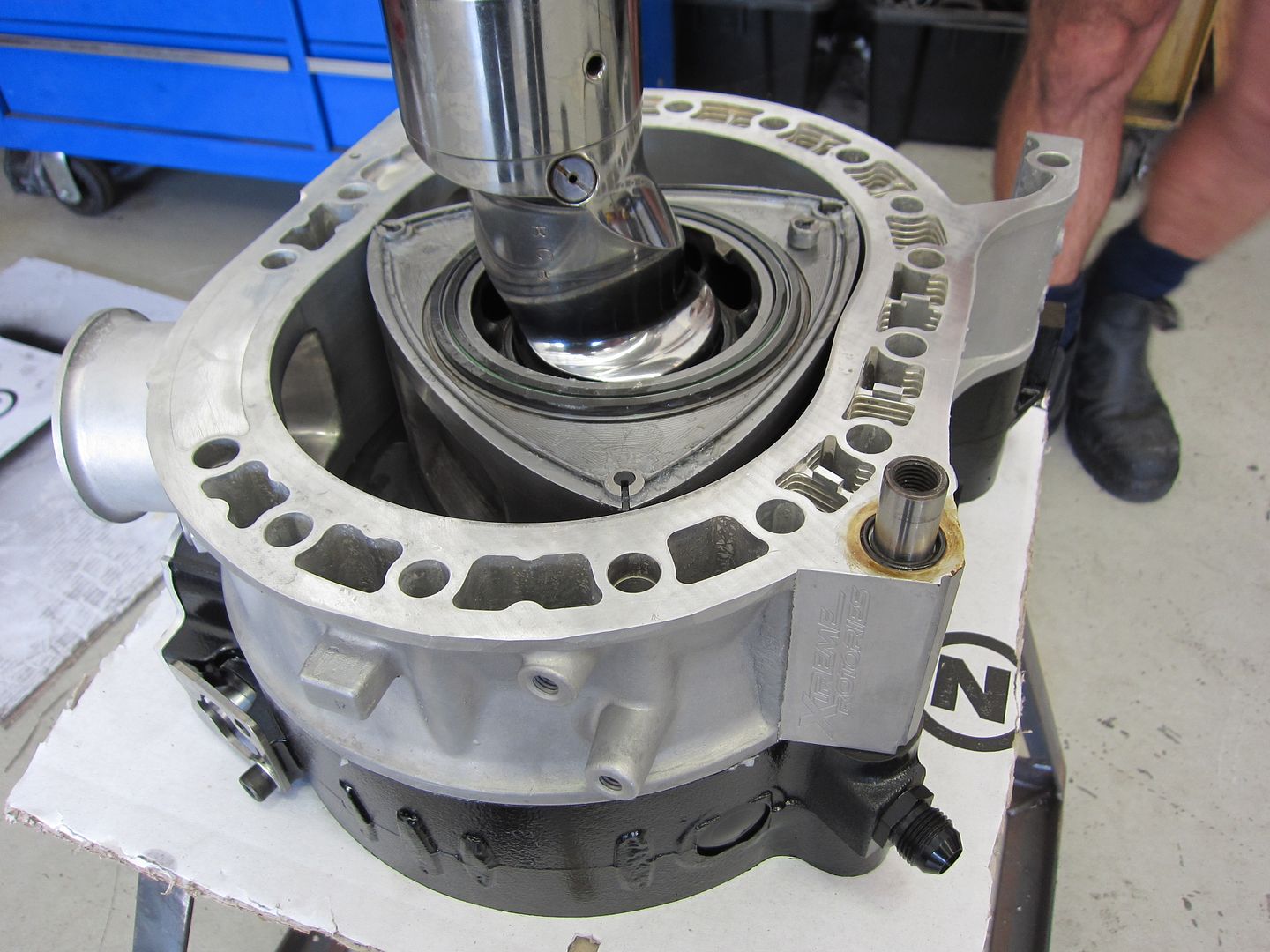

Starting at the "Thick" plate the first rotor was positioned.

Eccentric shaft in place.

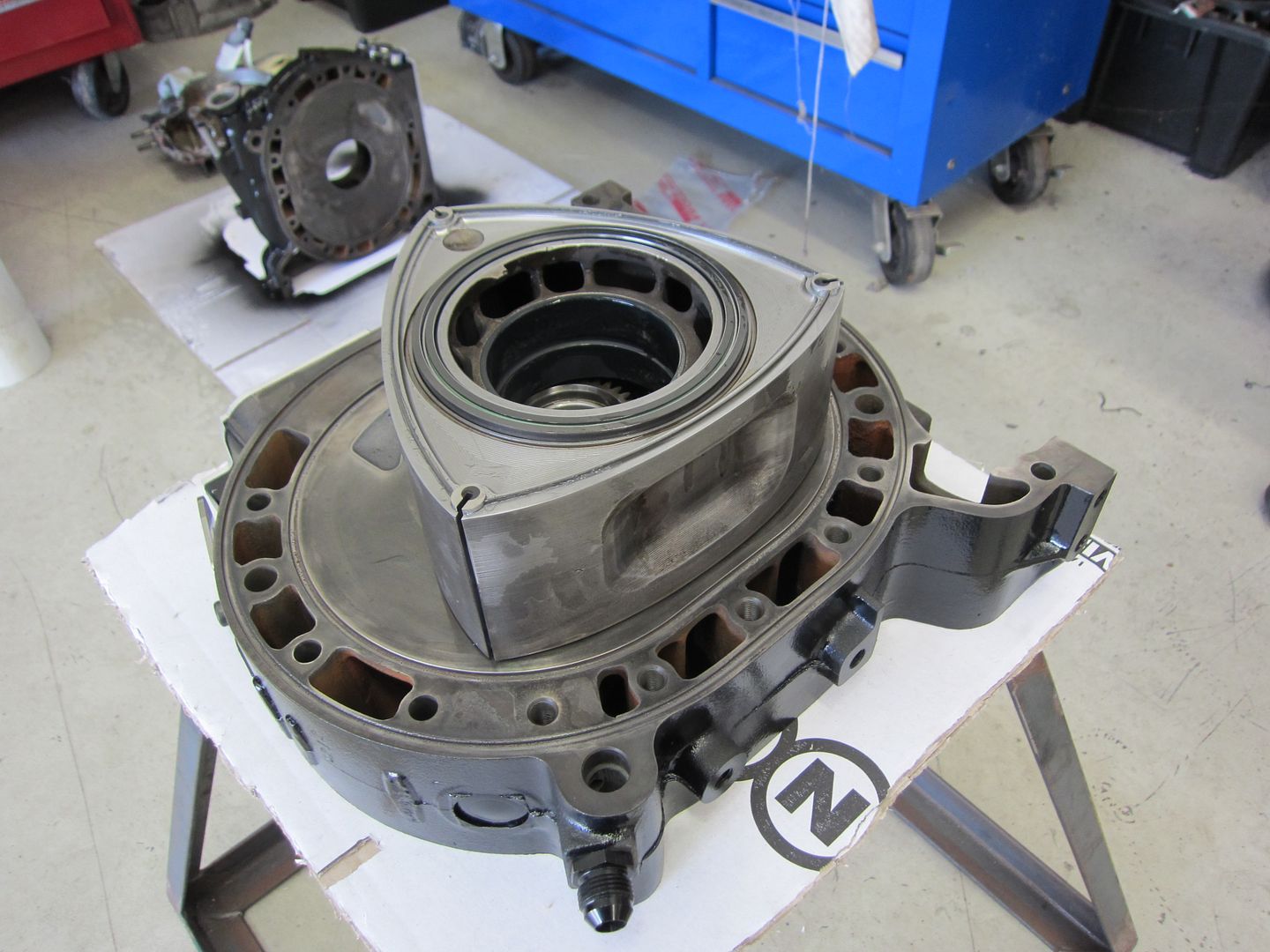

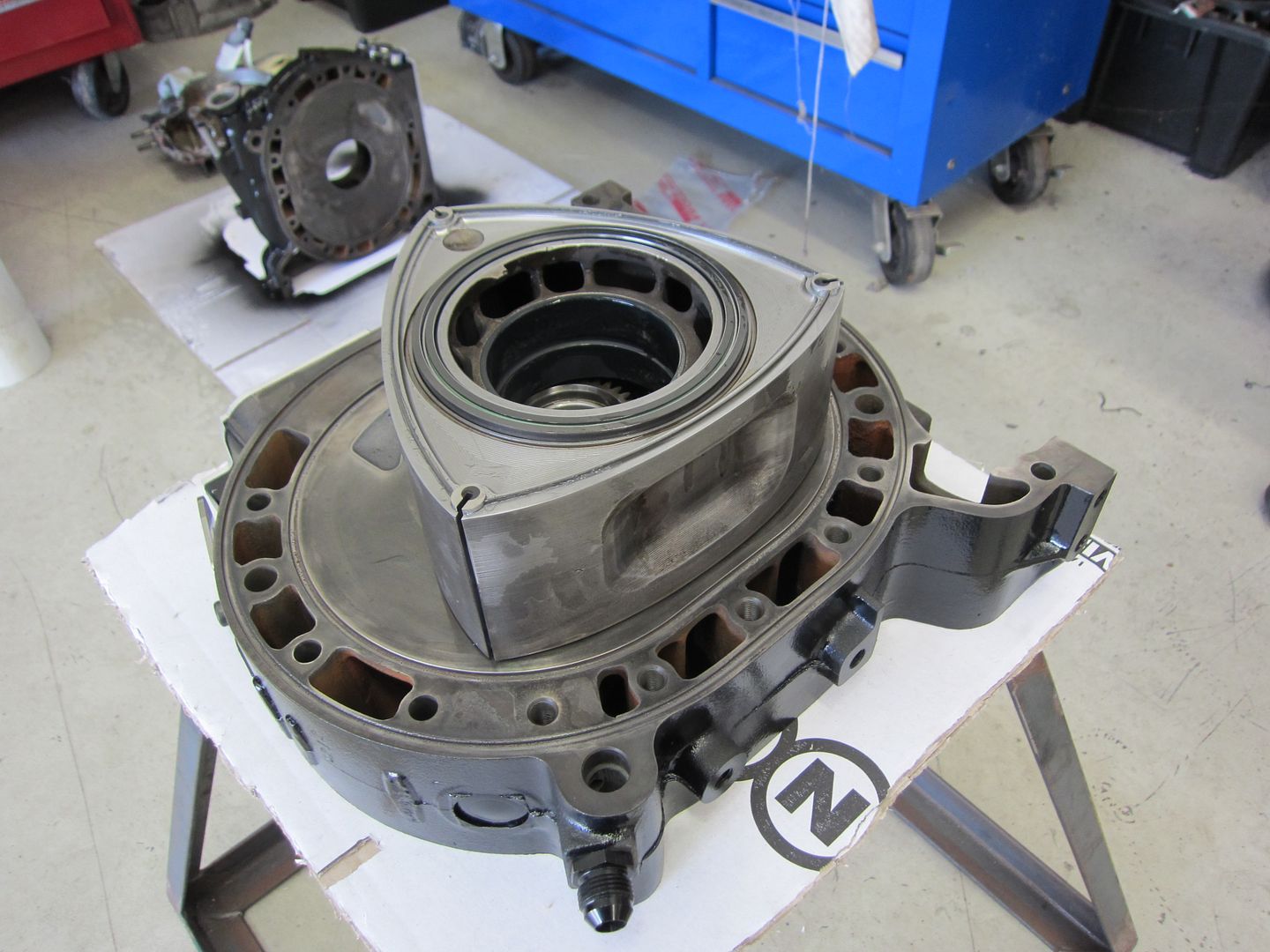

Rotor housings ready to go.

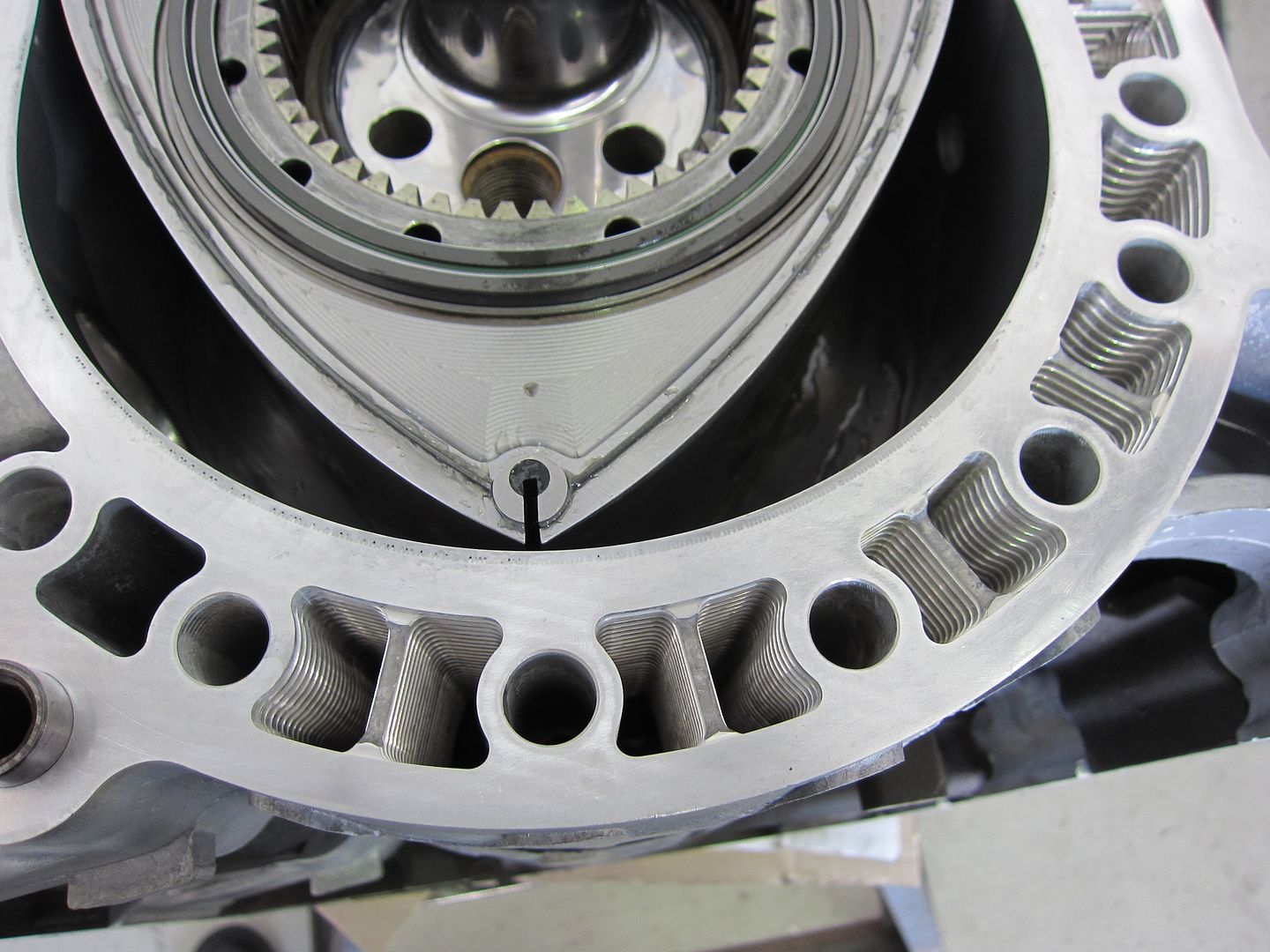

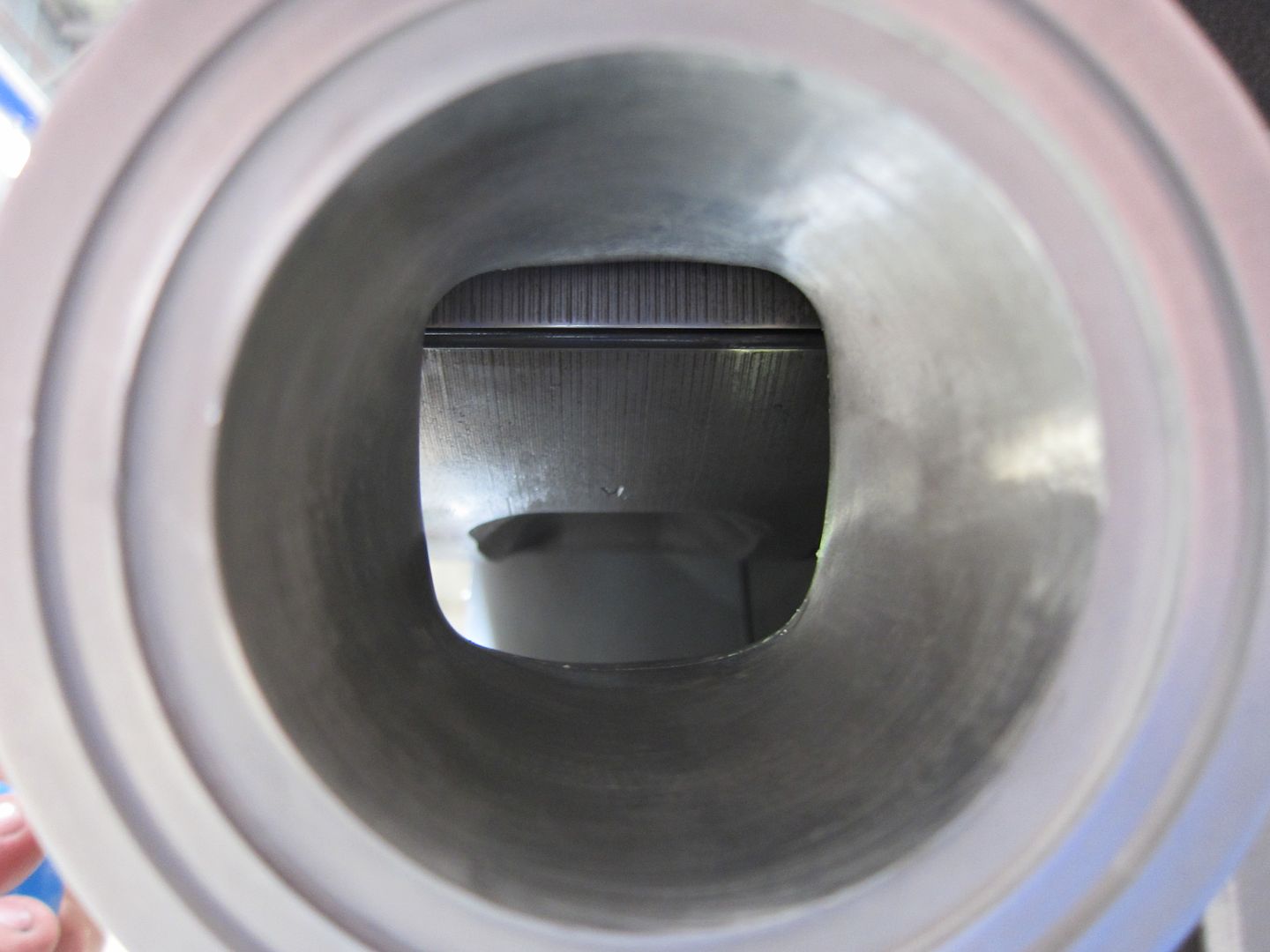

First rotor housing positioned and apex seals going in.

First chamber sealed.

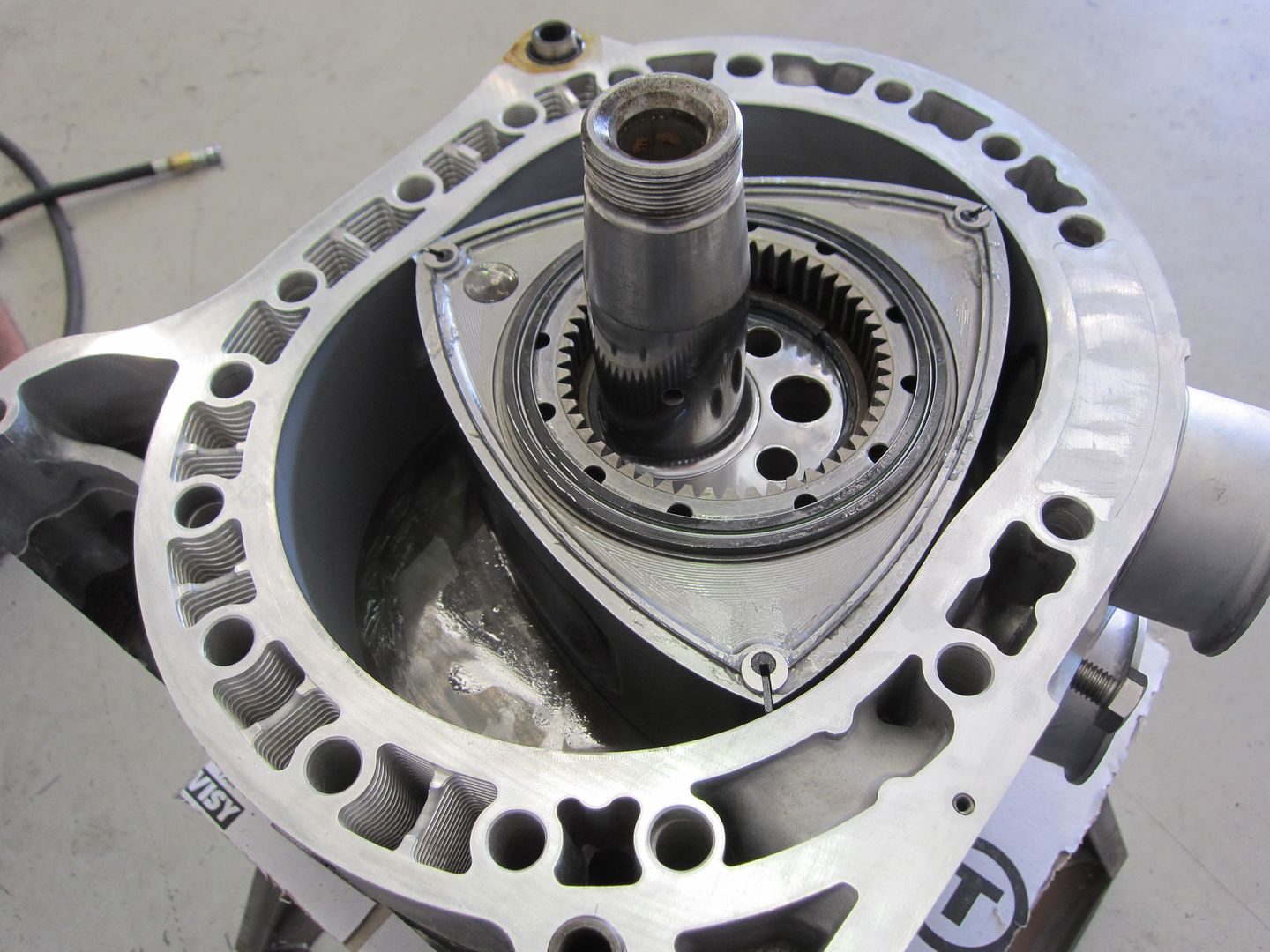

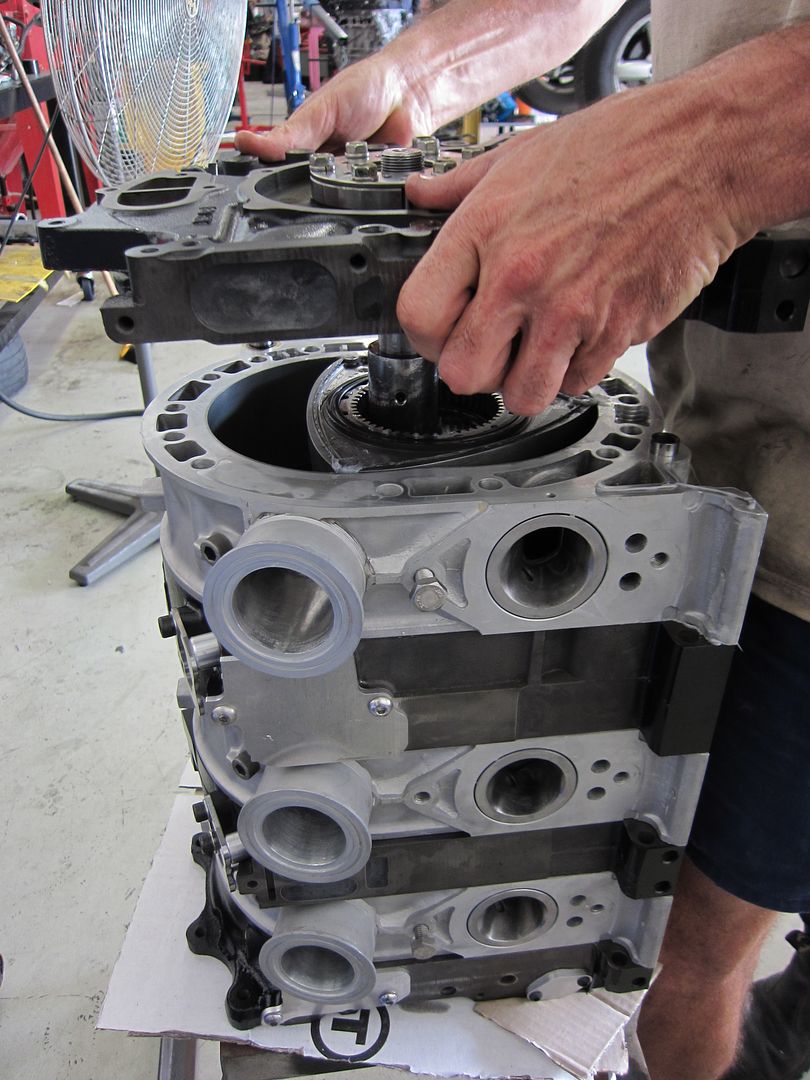

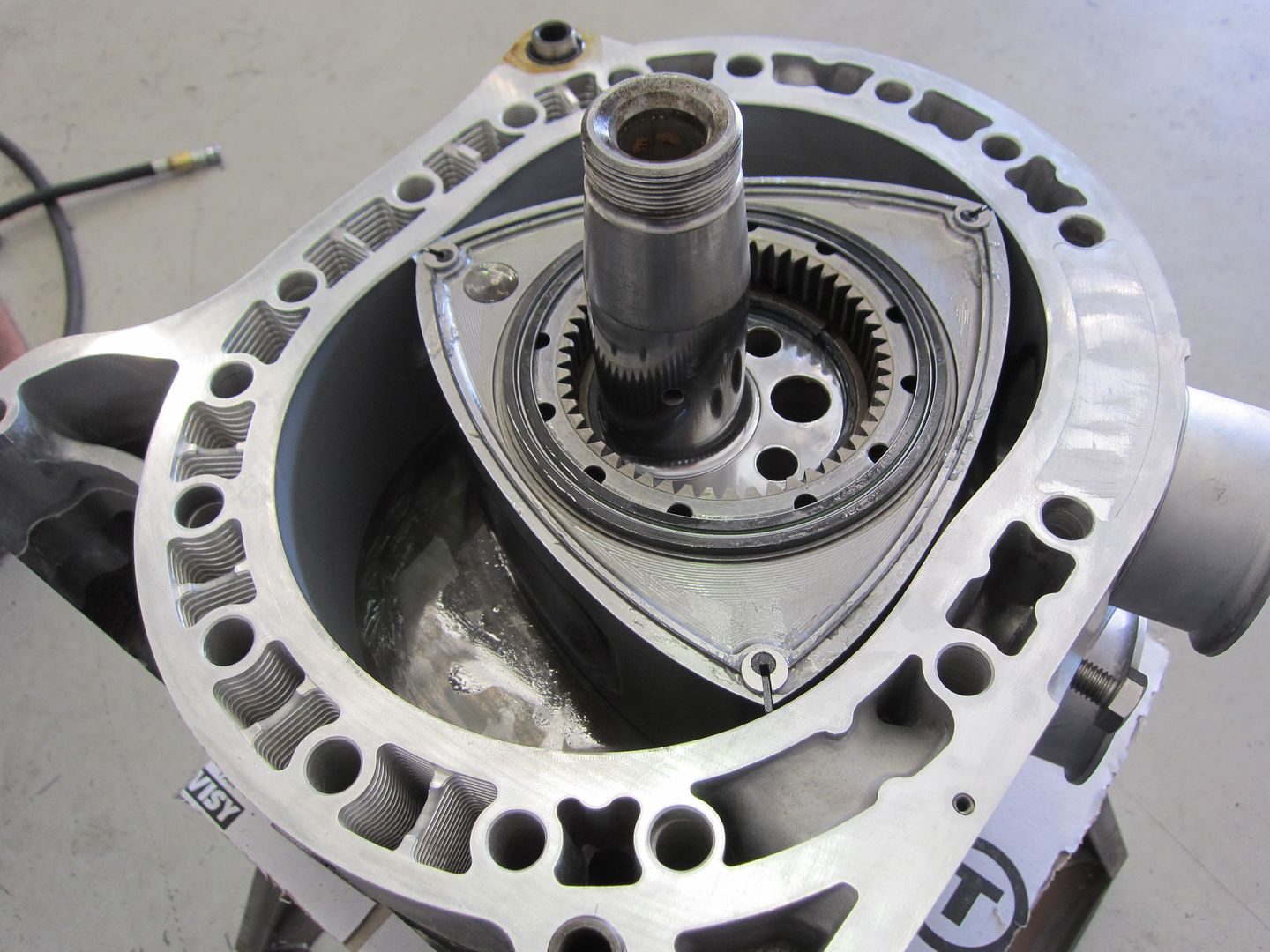

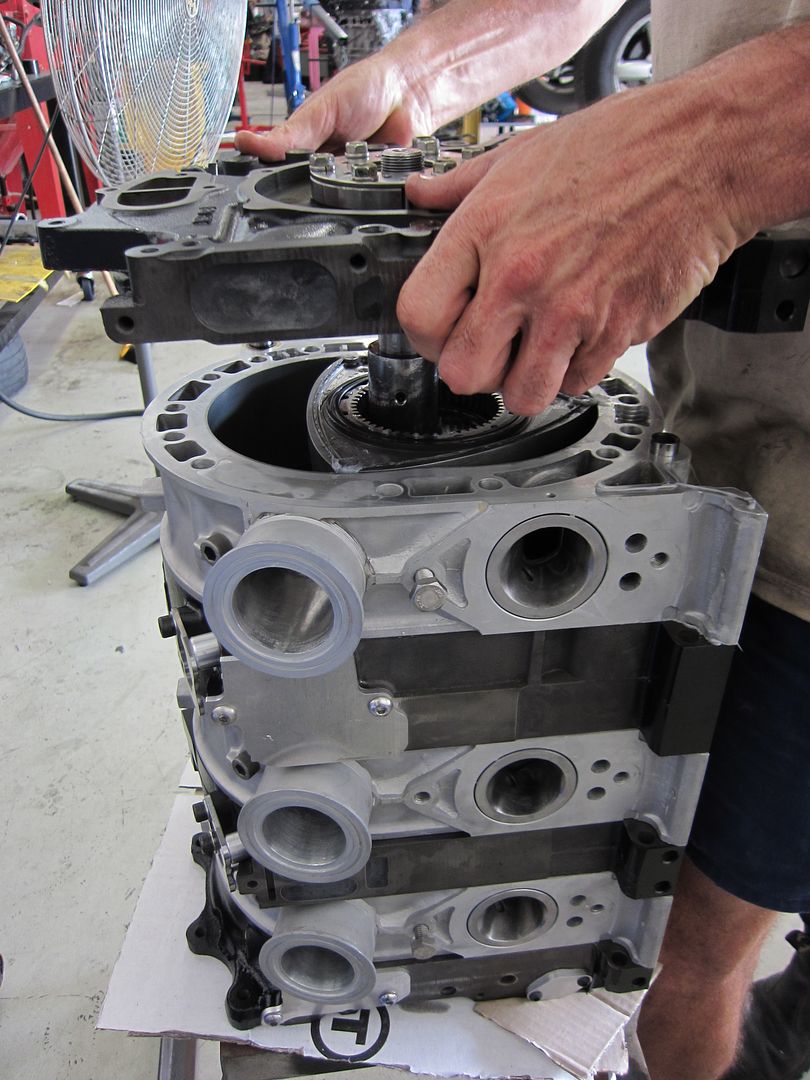

Second rotor in position.

Rotor housing in place.

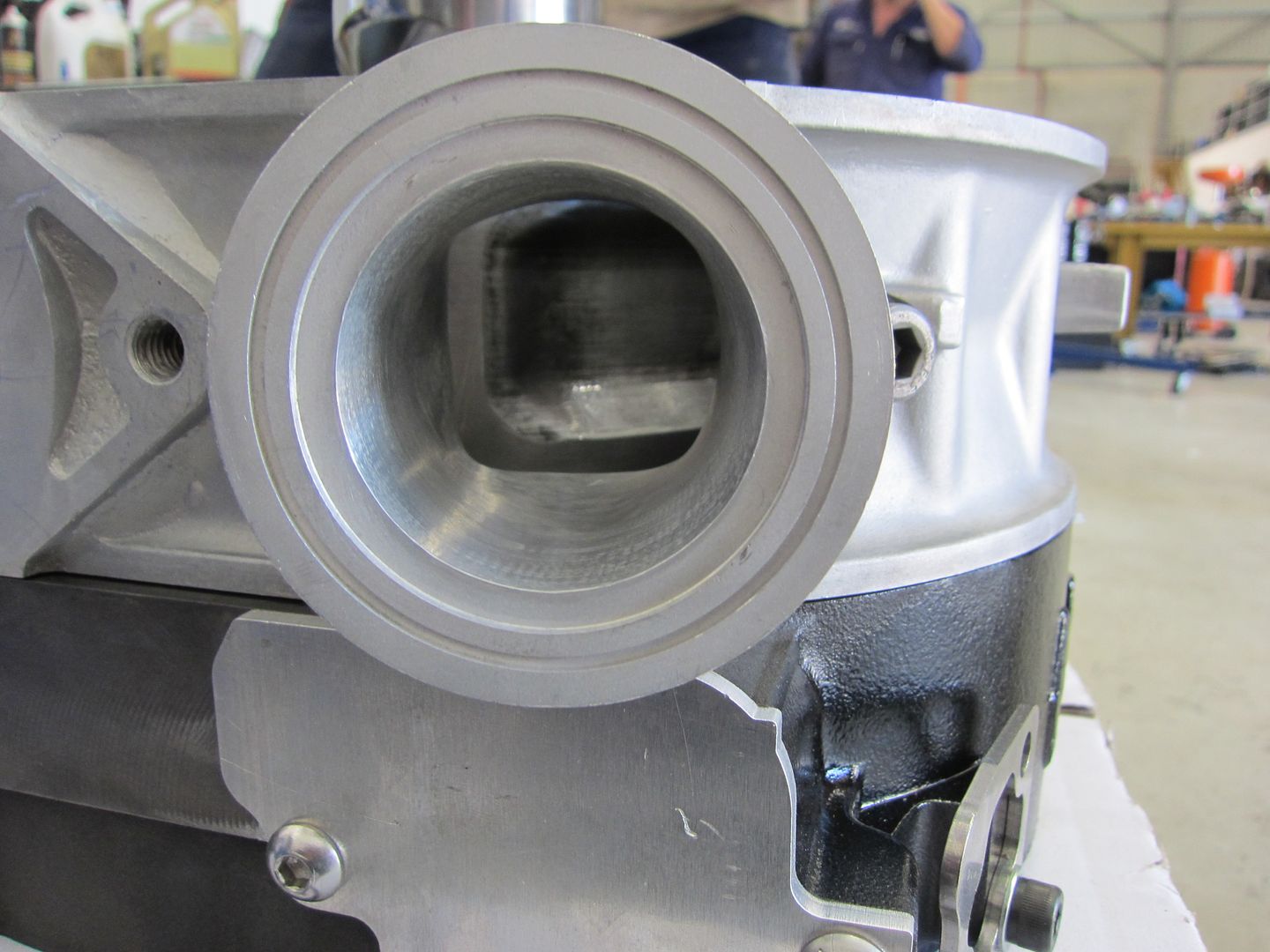

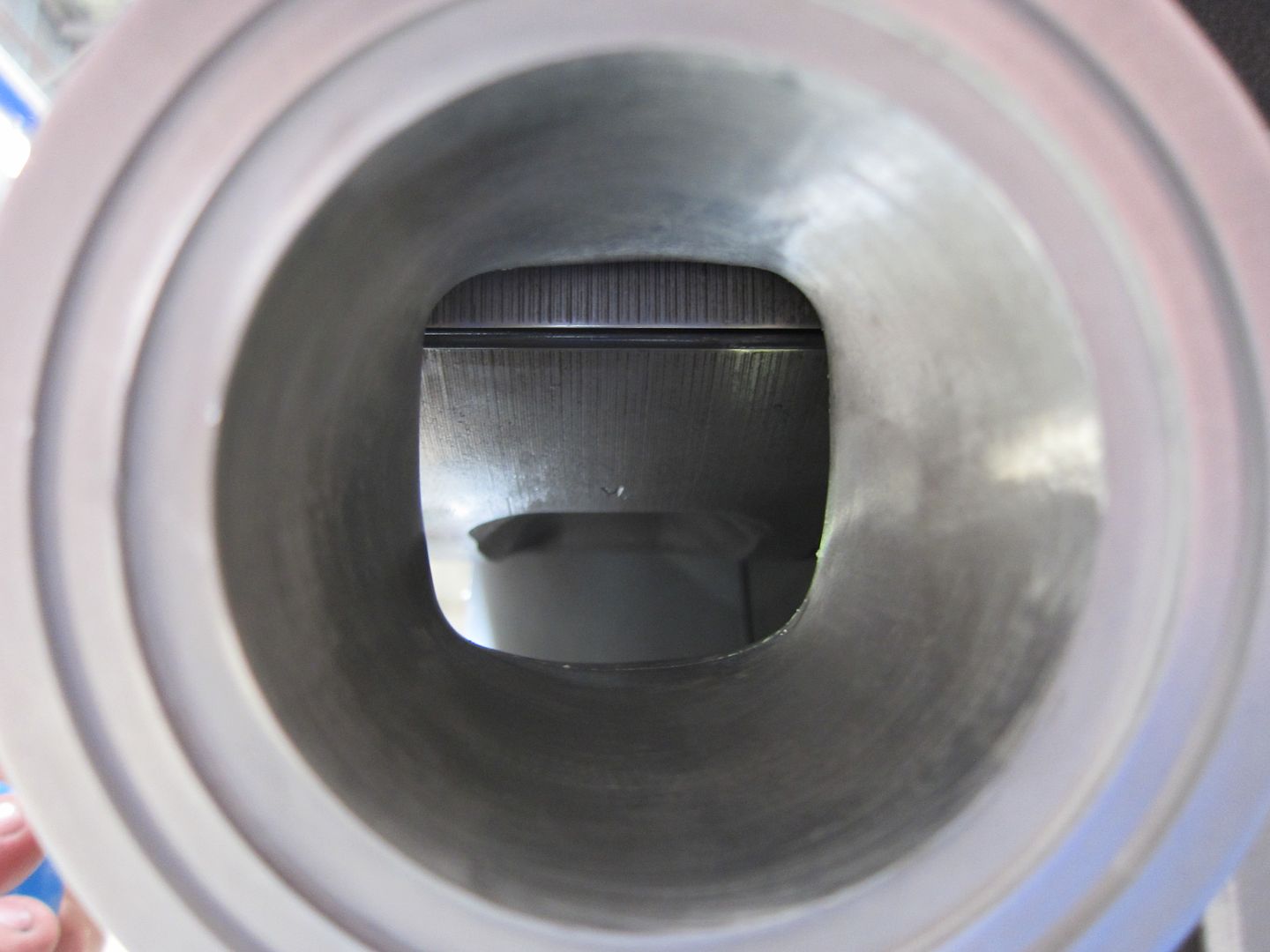

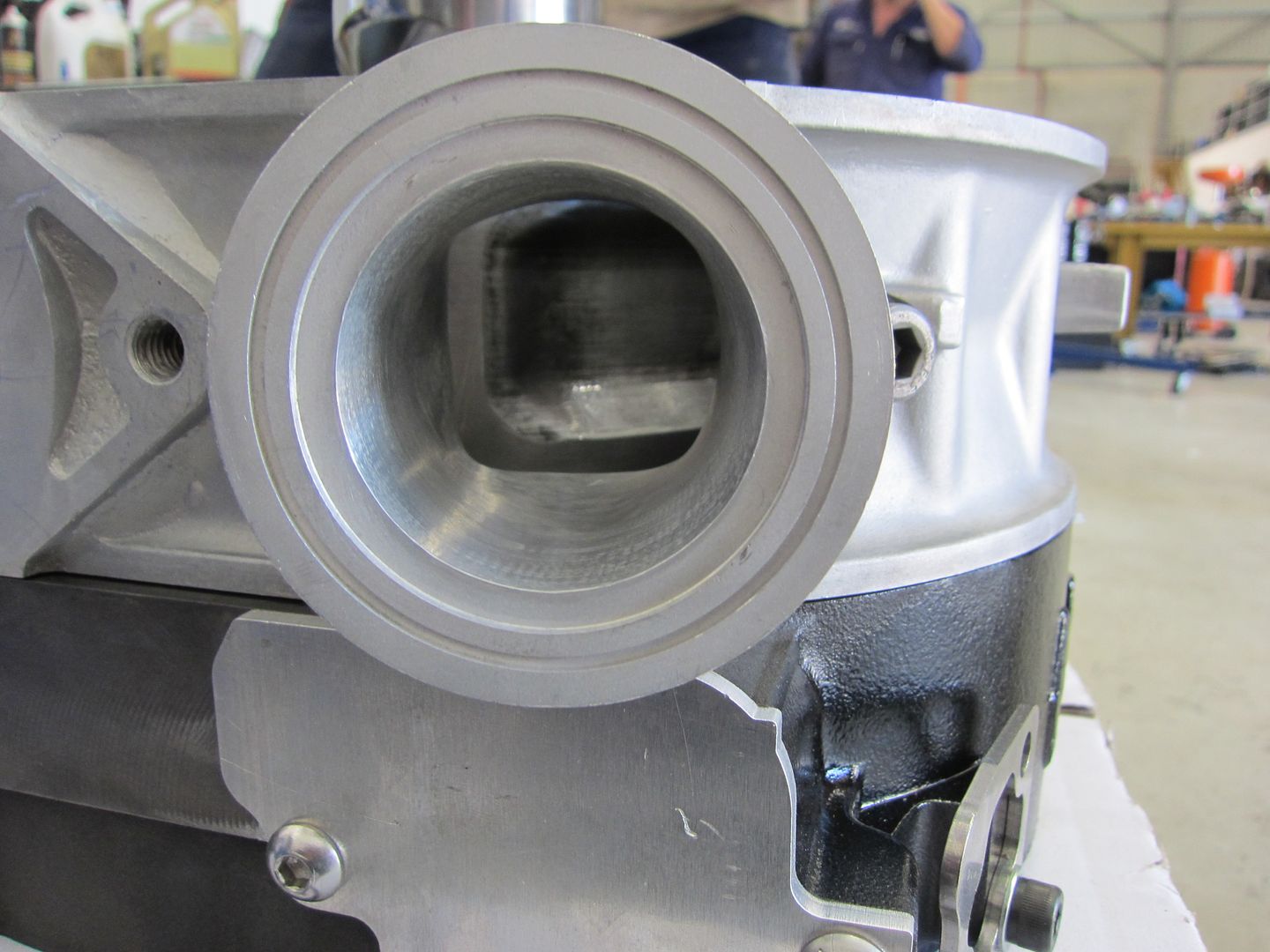

A couple of sneaky port shots...

Apex seals fitted.

...and sealed.

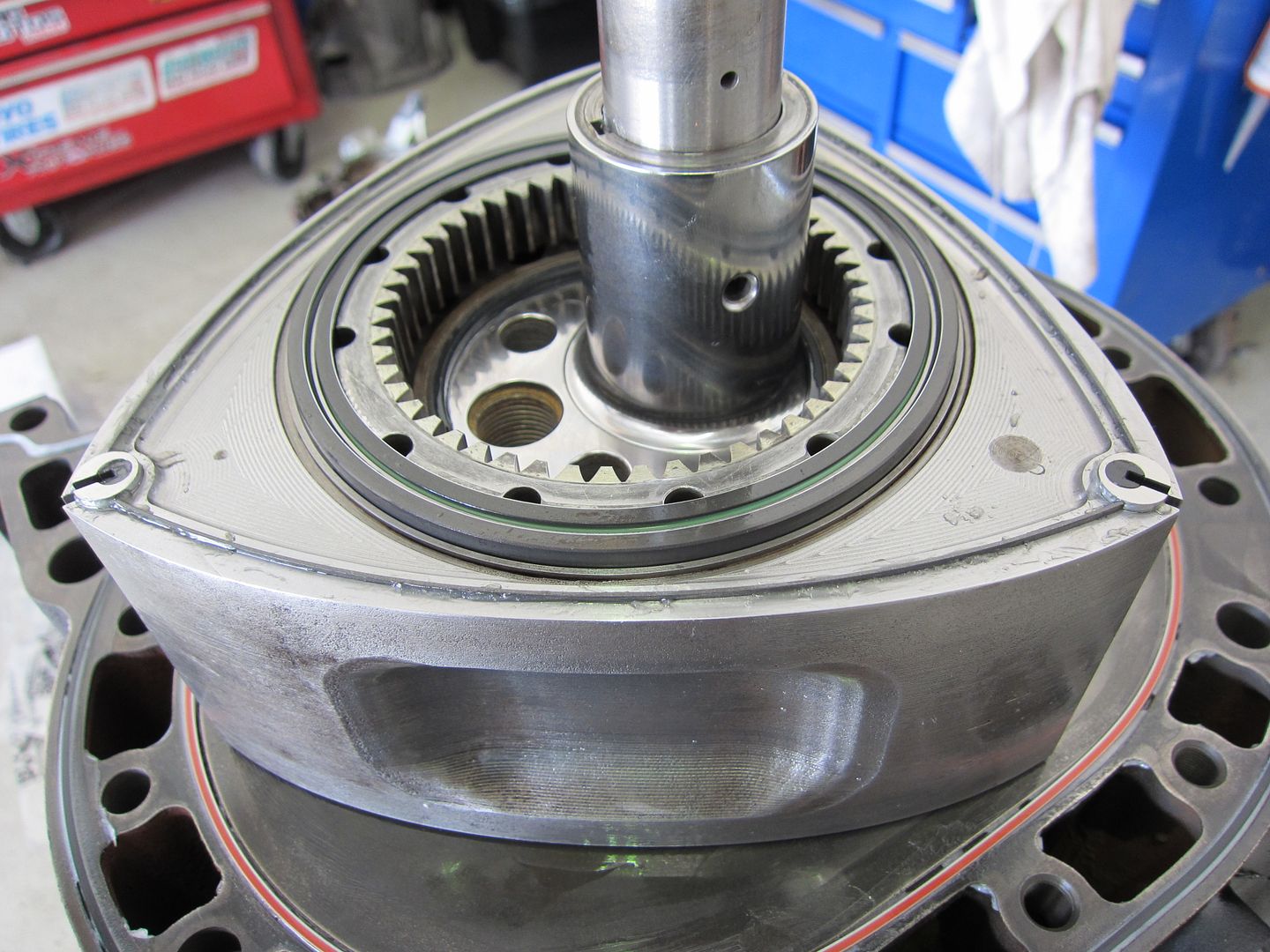

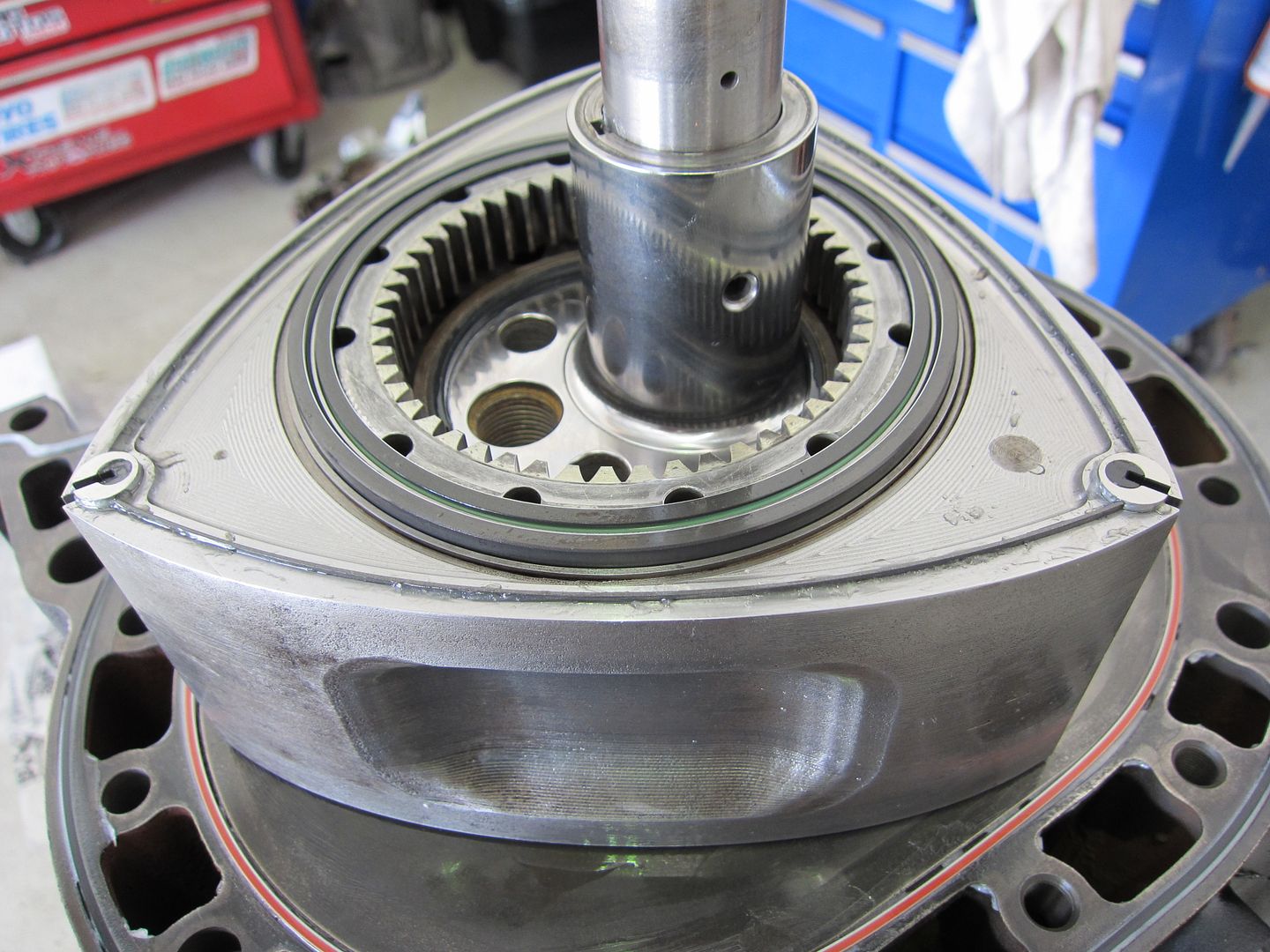

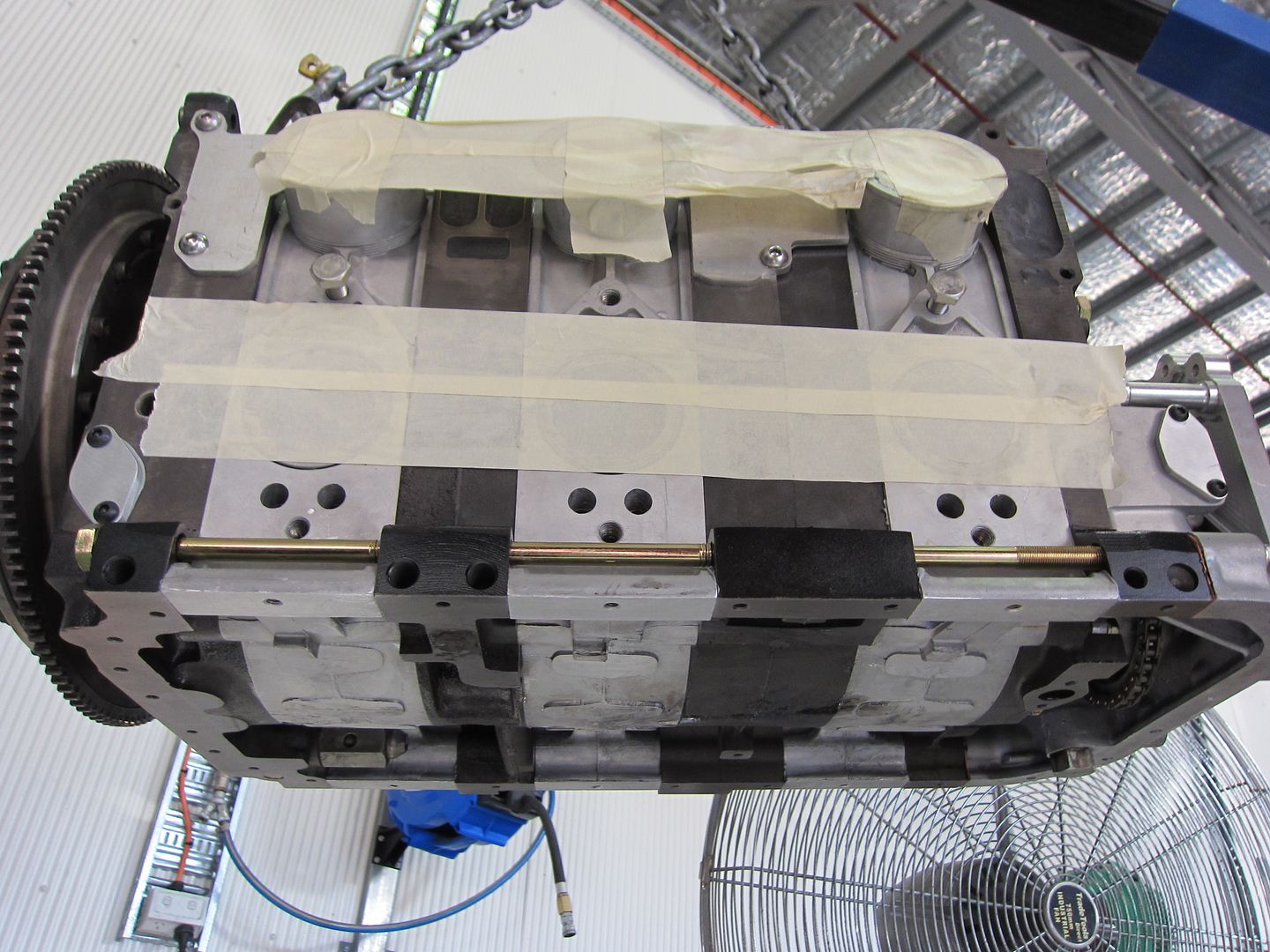

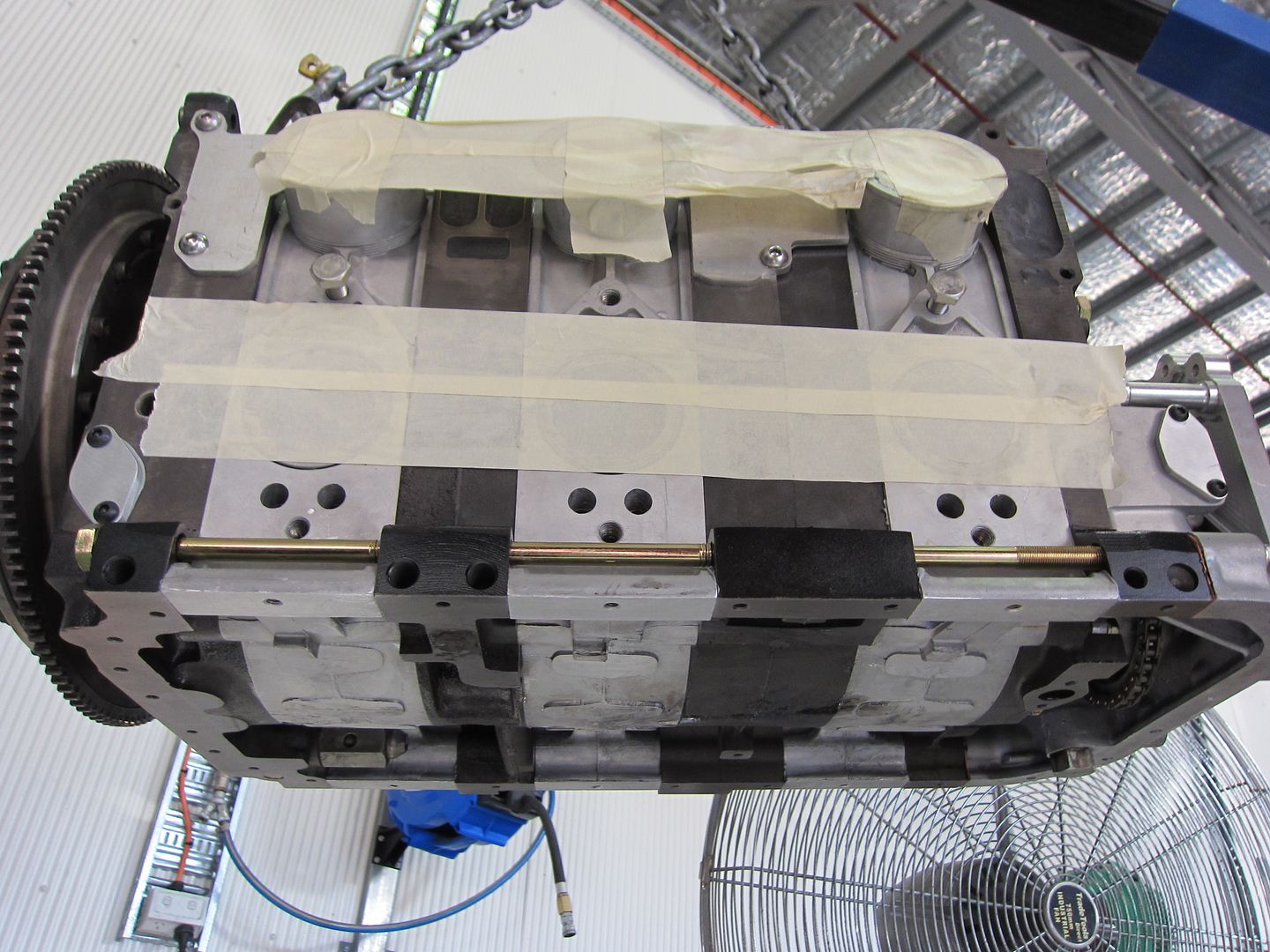

Time to flip the engine over and add the last rotor housing.

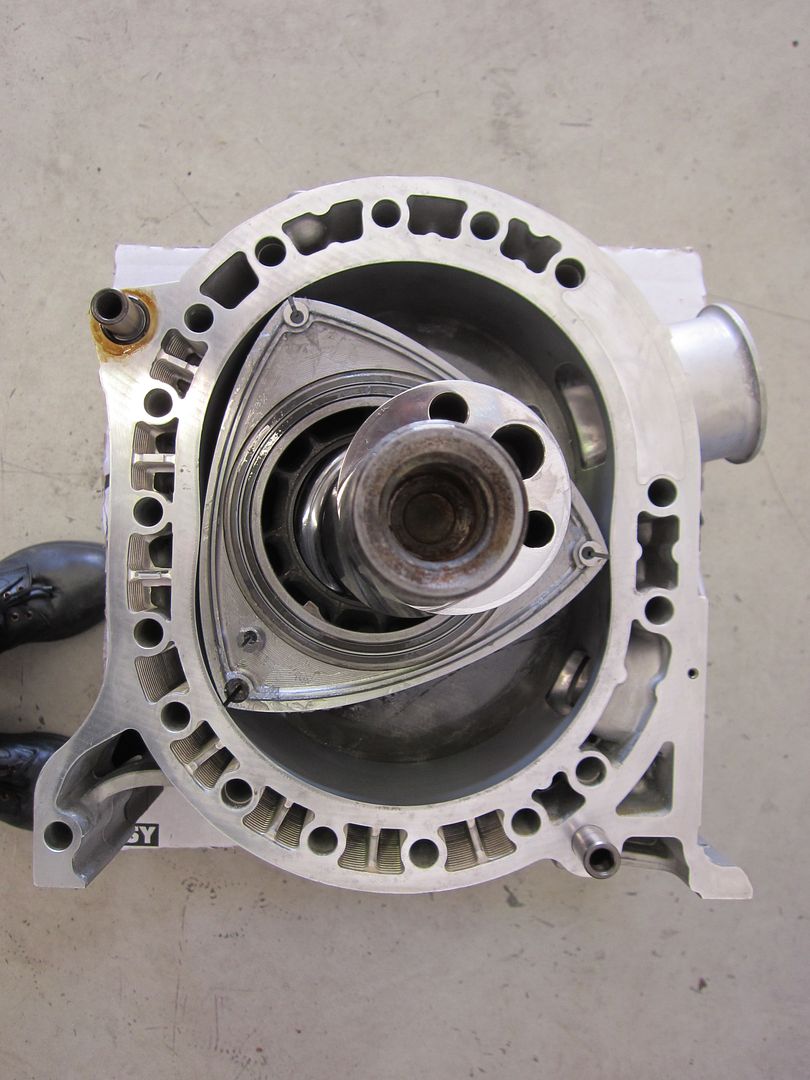

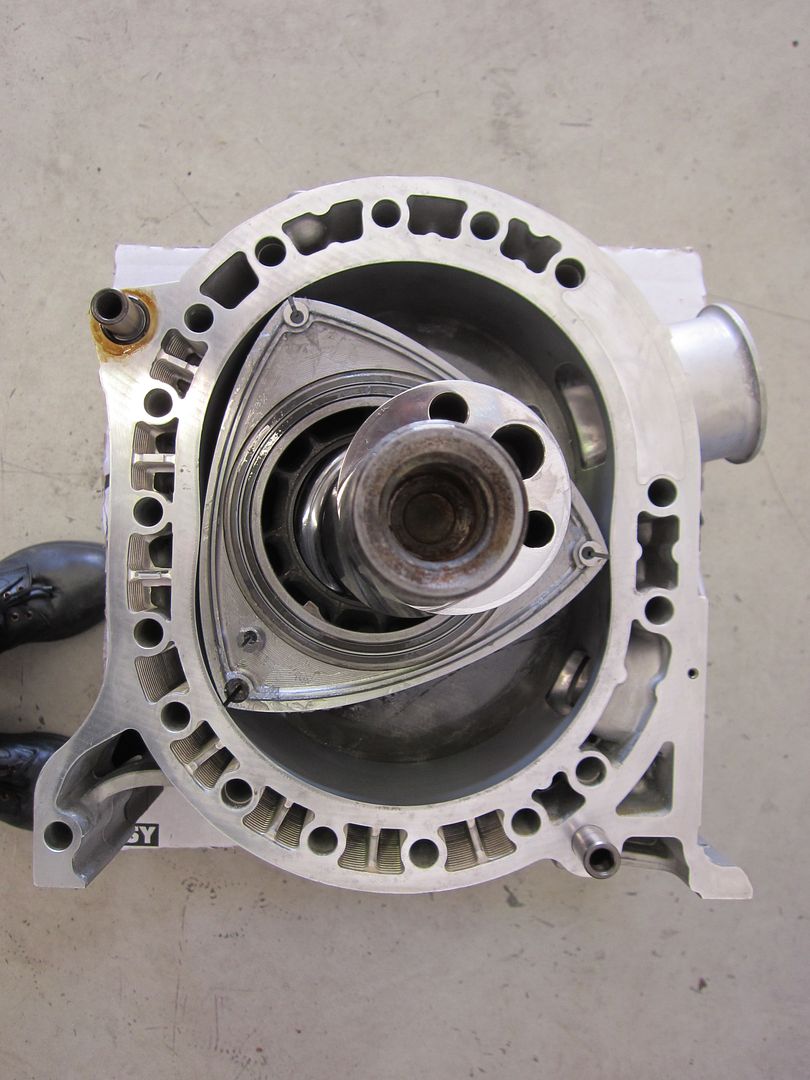

Last rotor in position.

Last rotor housing in place.

Apex seals in....

....and sealed.

So that's the engine core assembled. There's still a whole lot of ancillaries that are yet to be attached.

Cheers,

Danny

The rotors were lightened, side clearanced and balanced to ensure the engine is vibration free all the way up to 10,000rpm.

Each of the 18 side seals were then clearanced to suit their respective grooves.

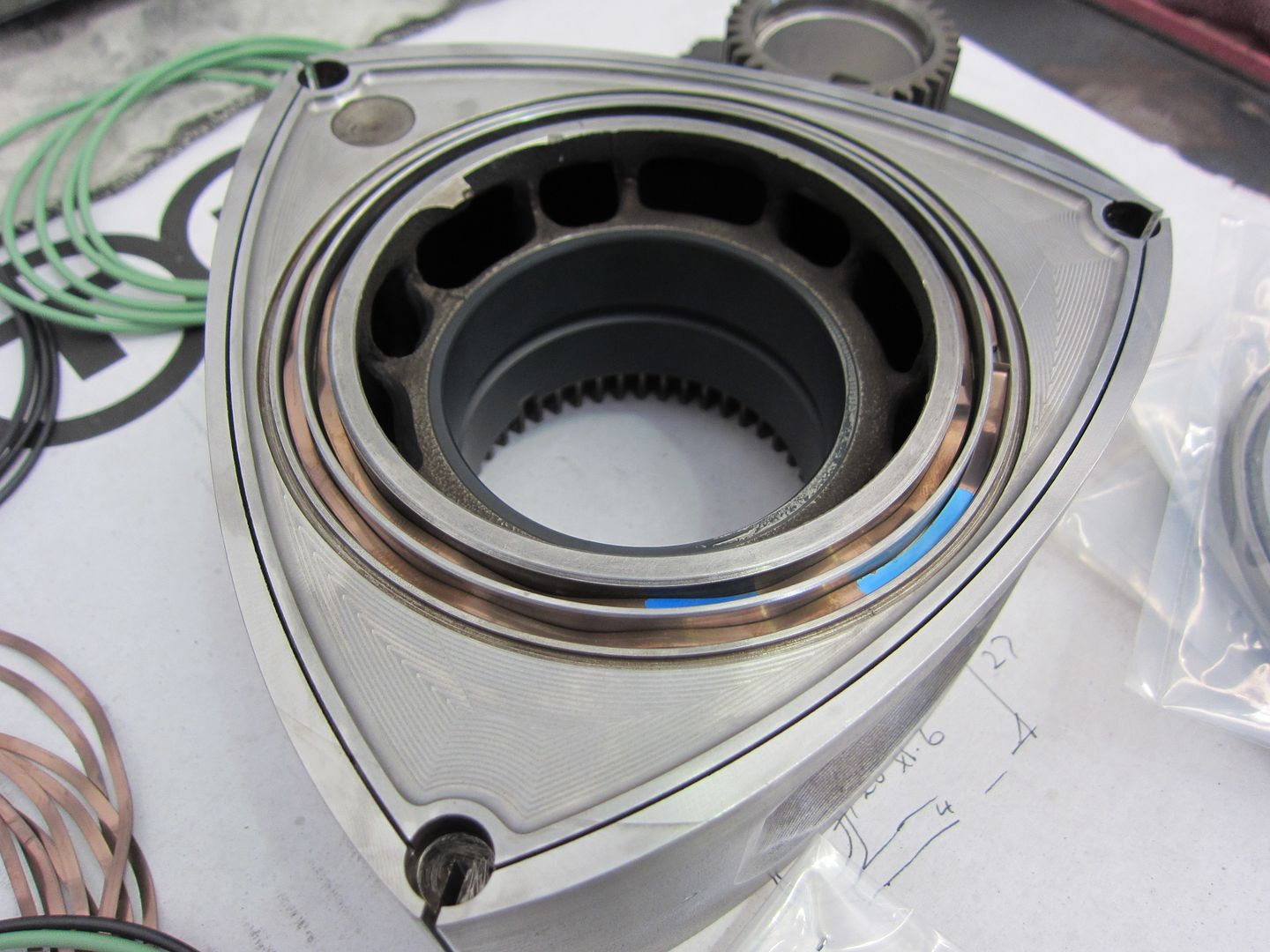

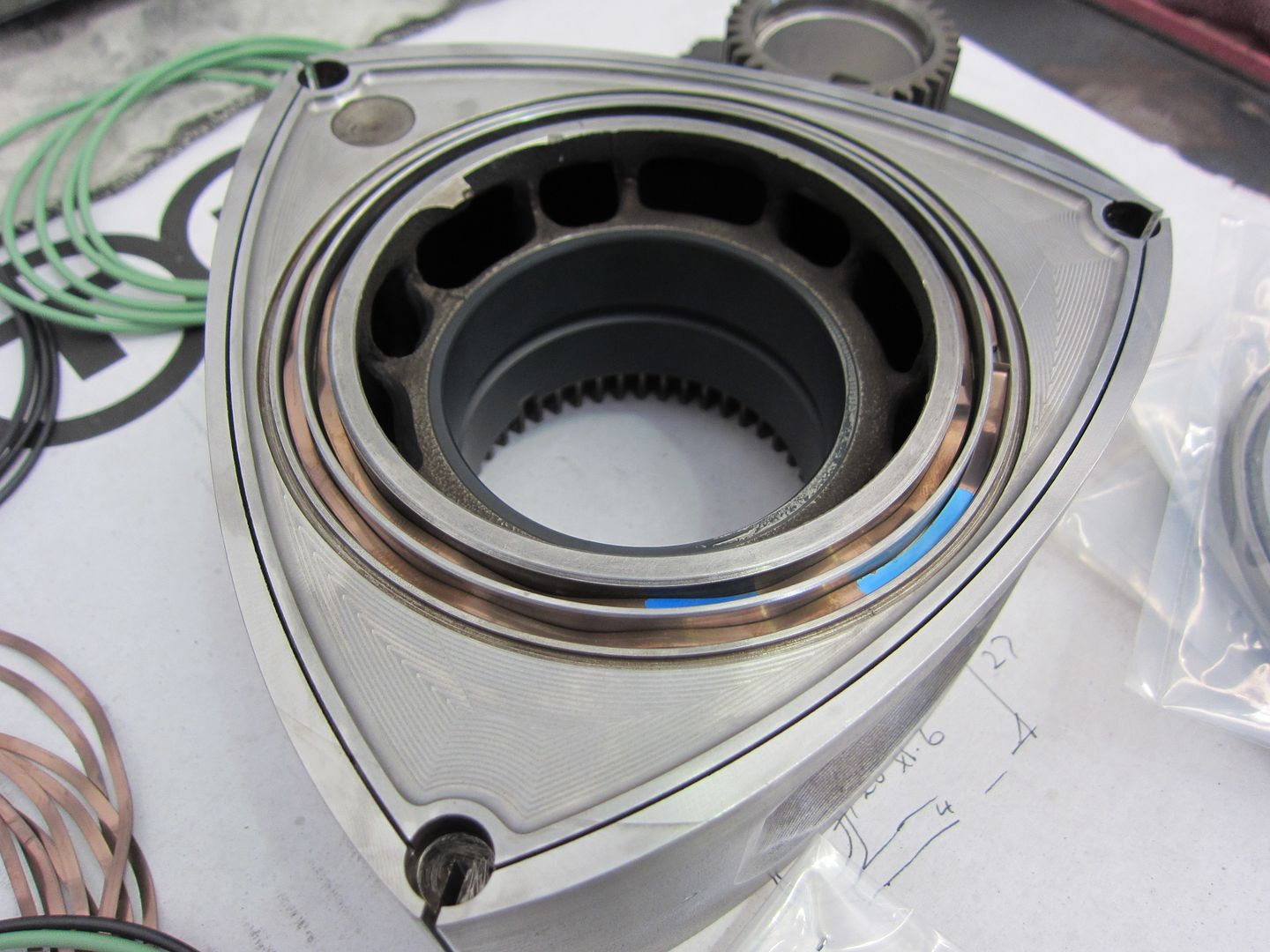

This is a rather rare item (well NLA new)...the centre stationary gear from the "Thick" plate. It has had a new bearing (also NLA) installed.

The front and rear stationary gears also scored a new bearing each and a rear main seal.

The through bolts were zinc plating.

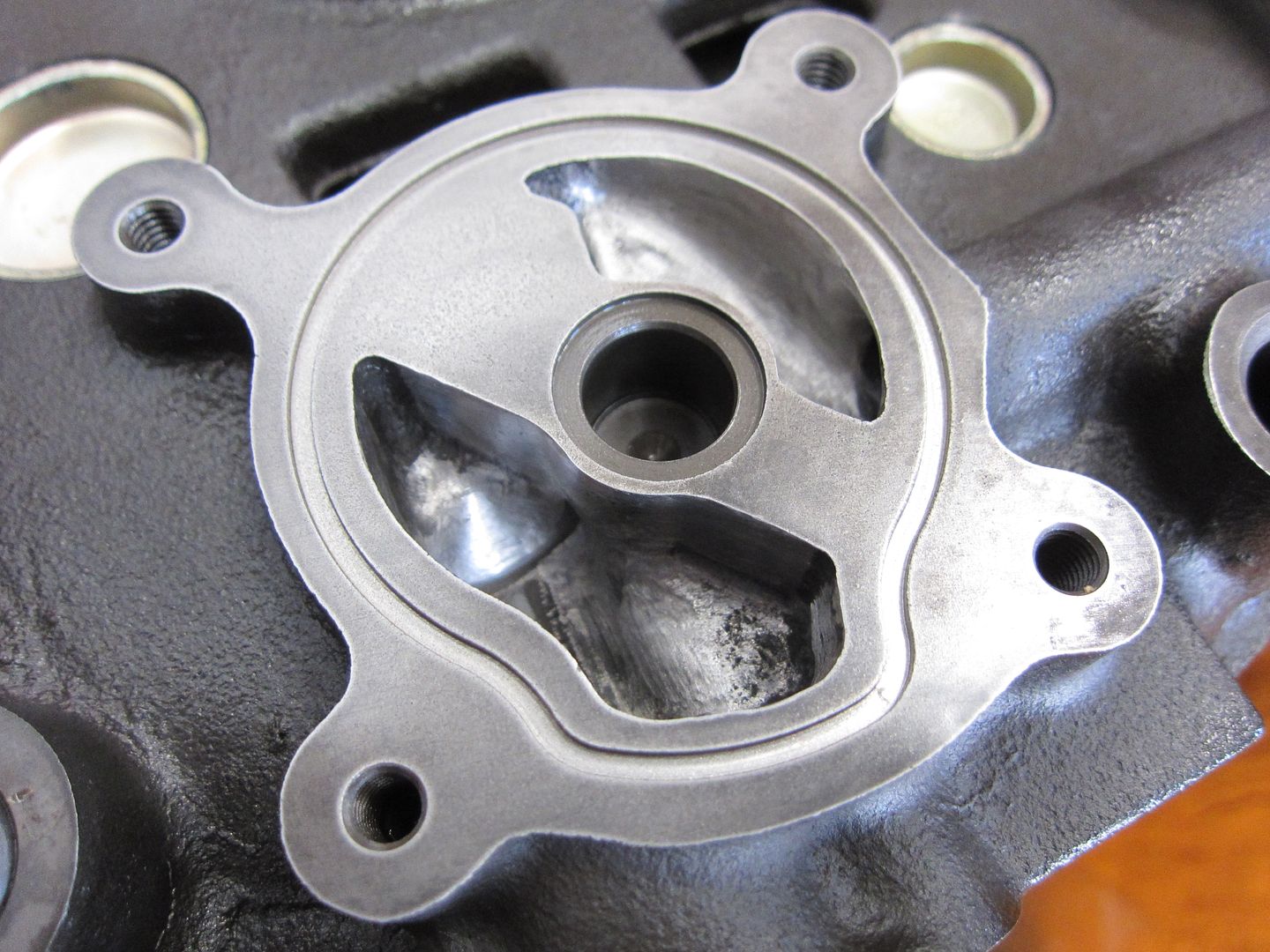

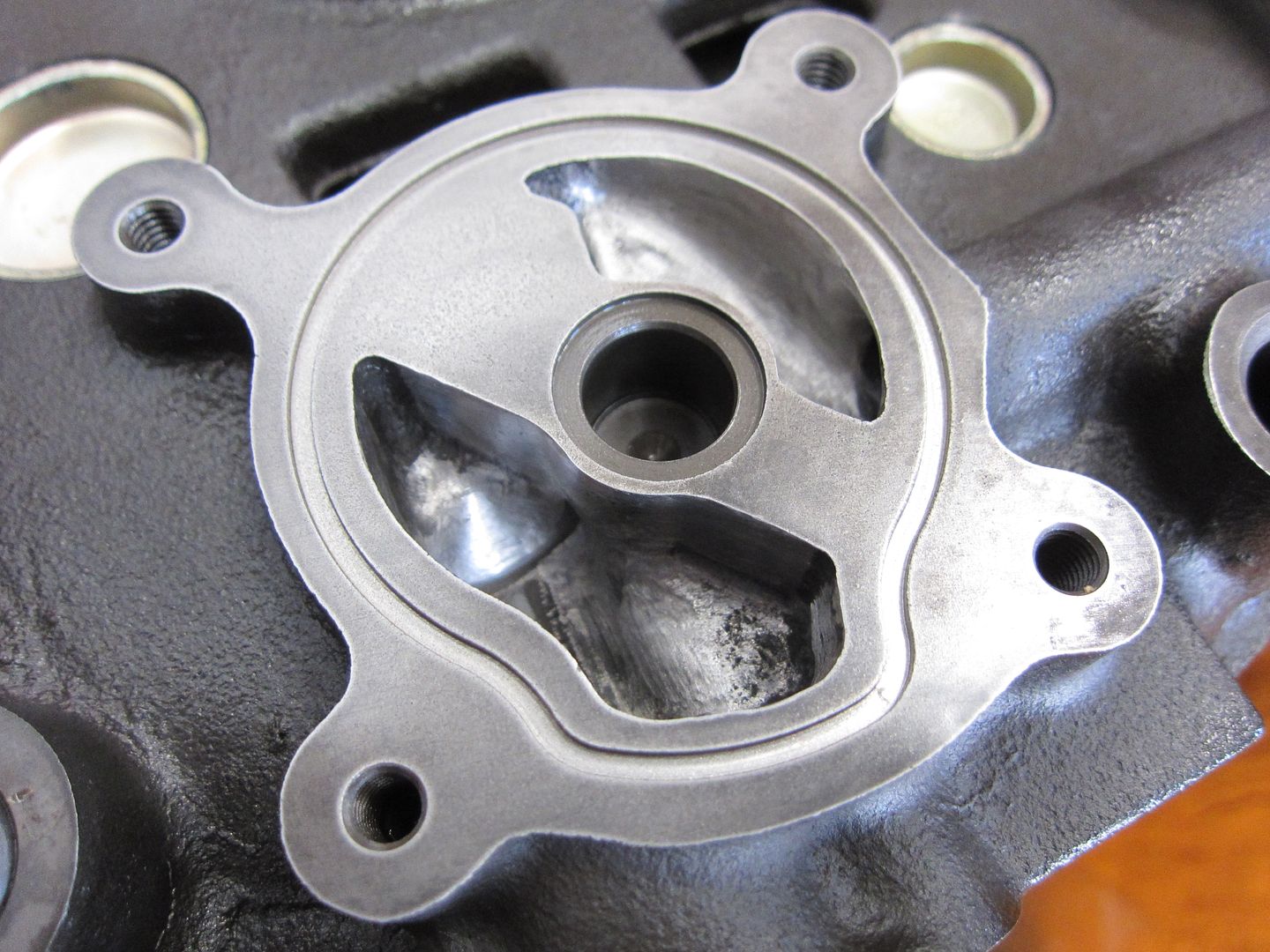

Now this is a really neat modification....the addition of an 'O'-ring groove in the front plate where the oil pump mounts. Normally the oil pump is bolted here just as a metal to metal seal. However, as you increase the oil relief pressure the sealing surface has been known to be breached resulting in a loss of all pressure to the rest of the engine. The addition of an 'O'-ring to this mating face ensures that no oil pressure is lost at elevated oil pressure. You can that the oil pump galleries have also been ported and polished to improve oil flow.

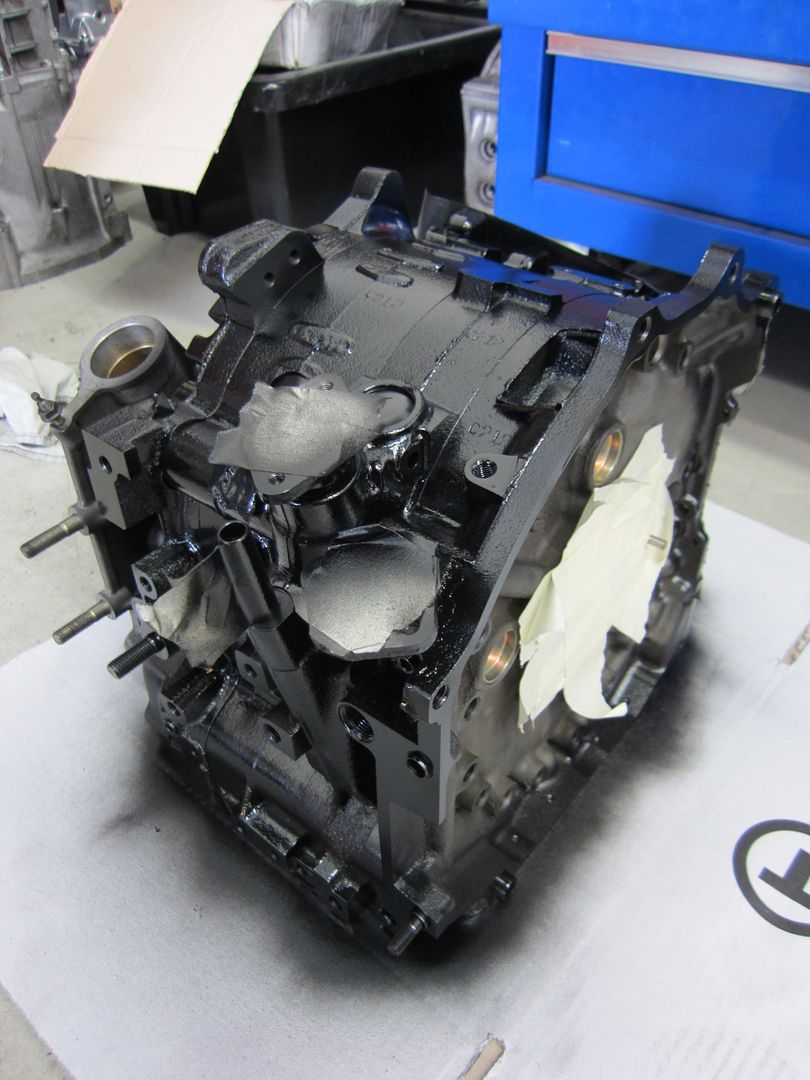

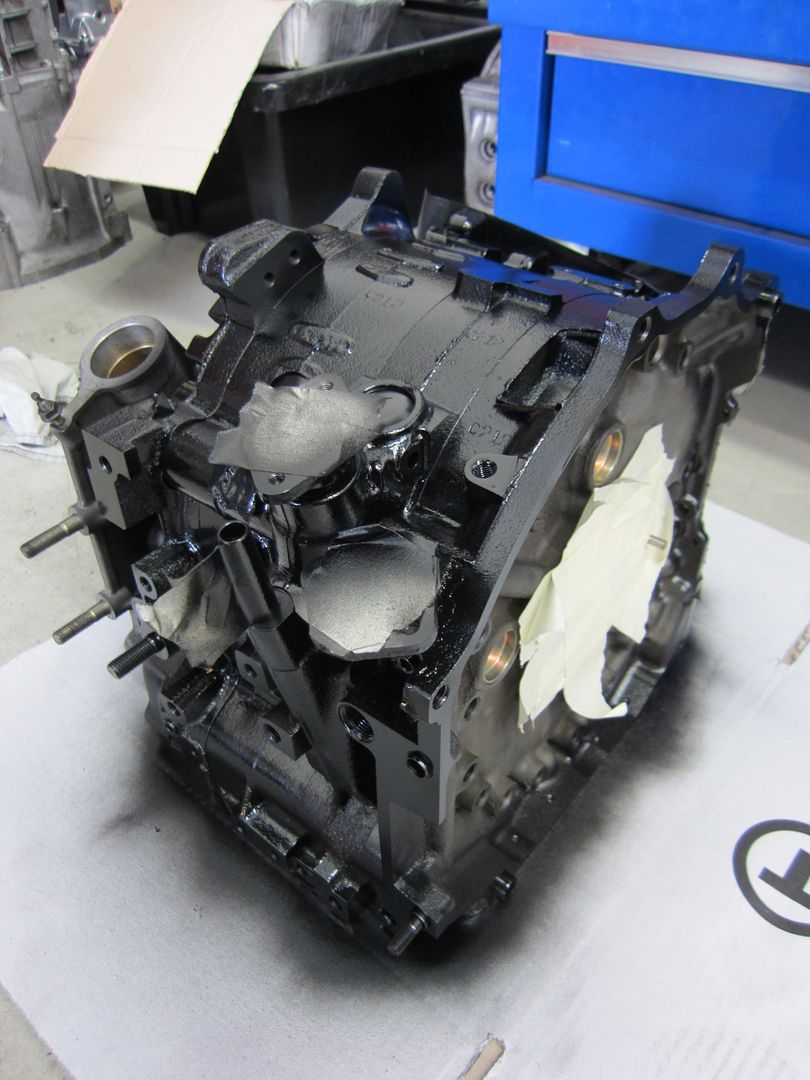

The plates also got a lick of paint.

The oil control rings in each rotor were then installed.

Beside the rotors the only other moving part is the eccentric shaft. In 20B engines they are two piece so that the engine can be assembled. It has also been isotropically finished. More info here http://xtremerotaries.com/services/isotropic-superfinishing/isotropic-superfinishing

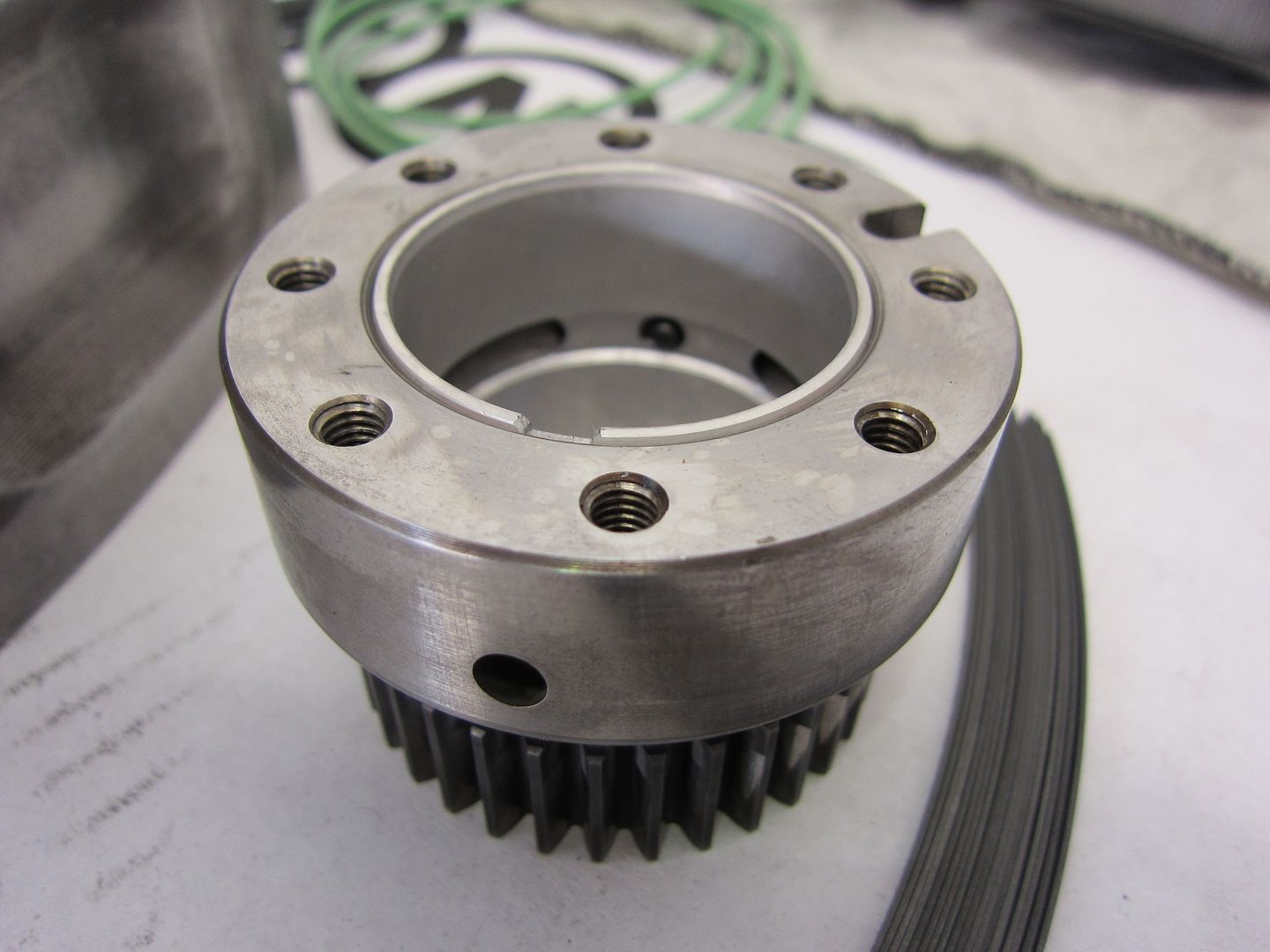

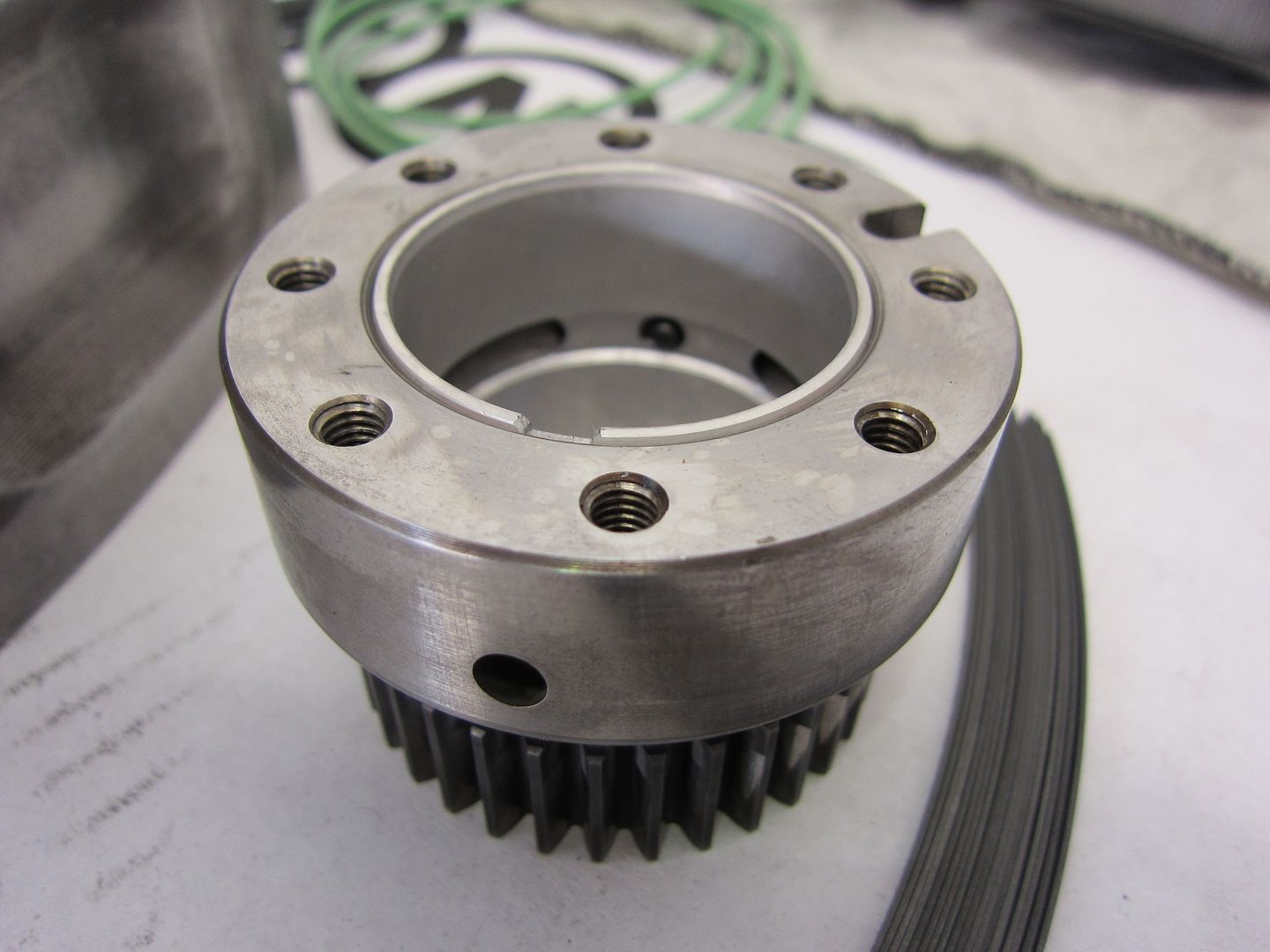

This is the custom front pulley that will drive the dry sump scavange pump and alternator.

The Iannetti 'Gold' apex seals and spring assemblies.

Starting at the "Thick" plate the first rotor was positioned.

Eccentric shaft in place.

Rotor housings ready to go.

First rotor housing positioned and apex seals going in.

First chamber sealed.

Second rotor in position.

Rotor housing in place.

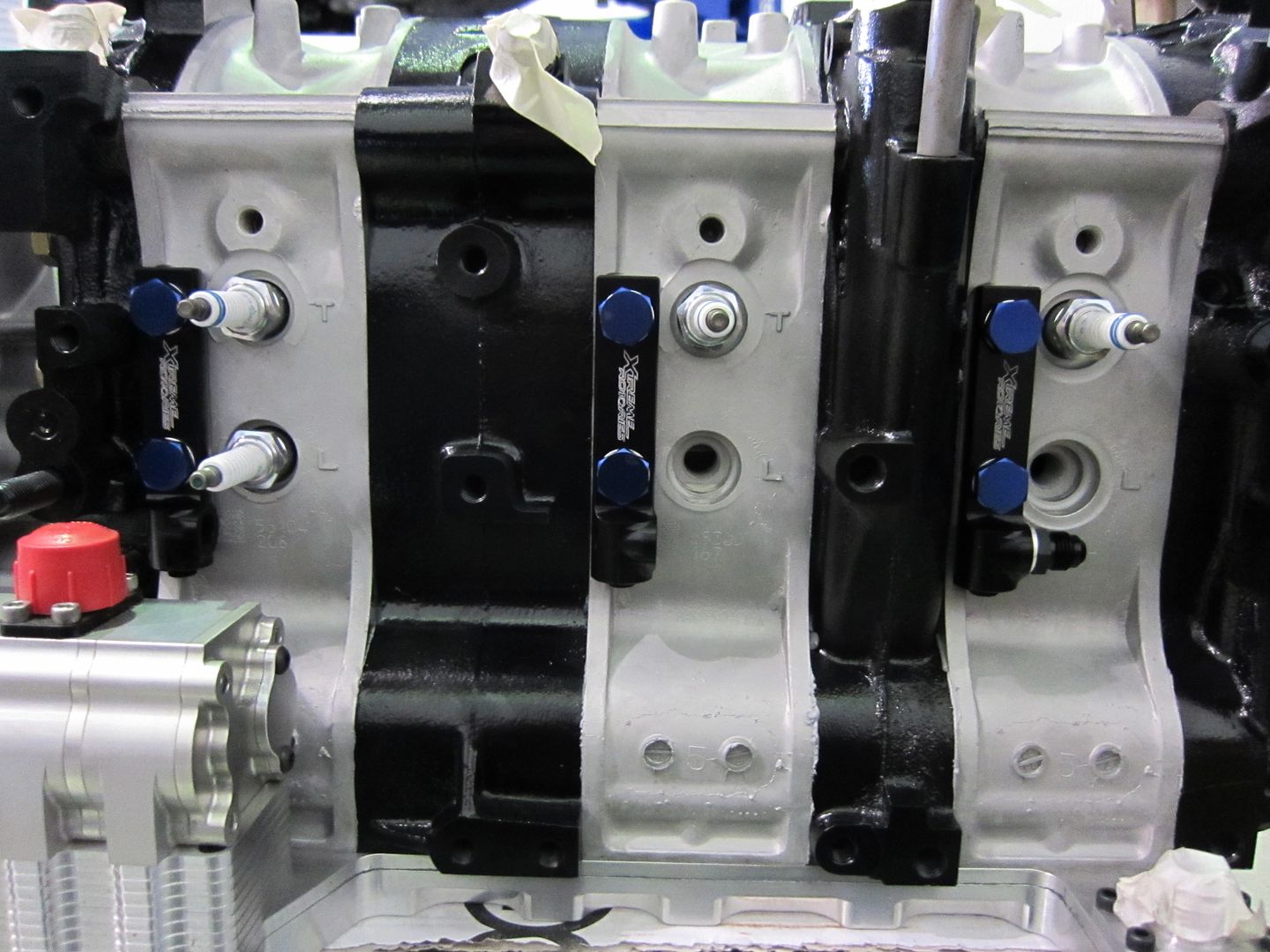

A couple of sneaky port shots...

Apex seals fitted.

...and sealed.

Time to flip the engine over and add the last rotor housing.

Last rotor in position.

Last rotor housing in place.

Apex seals in....

....and sealed.

So that's the engine core assembled. There's still a whole lot of ancillaries that are yet to be attached.

Cheers,

Danny

- Caffeine

- Racing Driver

- Posts: 1806

- Joined: Wed Apr 23, 2003 11:00 am

- Vehicle: NB8B

- Location: Sydney

Re: NC Track Car - In the Build

Wow!

Awful! (as in full of awe, in a good way!)

Awful! (as in full of awe, in a good way!)

Supreme Blue NB8B, 1:16.98 at Wakefield when stock, but it's not stock any more...

- plohl

- Racing Driver

- Posts: 1922

- Joined: Wed Oct 14, 2009 12:13 am

- Vehicle: NA8

- Location: Brisbane

Re: NC Track Car - In the Build

seeing it assemble almost makes me want a rotary in my car...

Cheers,

plohl

plohl

- 16bit

- Speed Racer

- Posts: 2346

- Joined: Wed Nov 29, 2006 1:51 pm

- Vehicle: NB8A - Supercharged

- Location: Brisbane Southside

Re: NC Track Car - In the Build

looking forward to the noise.

98 evo gold - rotrexed and loving it.

This post has been printed using recycled pixels

This post has been printed using recycled pixels

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - In the Build

HAPPY NEW YEAR!!!

With everything currently falling into place, 2014 will be the year to finally see the NC on a race track and hear the scream of the 20B PP at full noise!!!

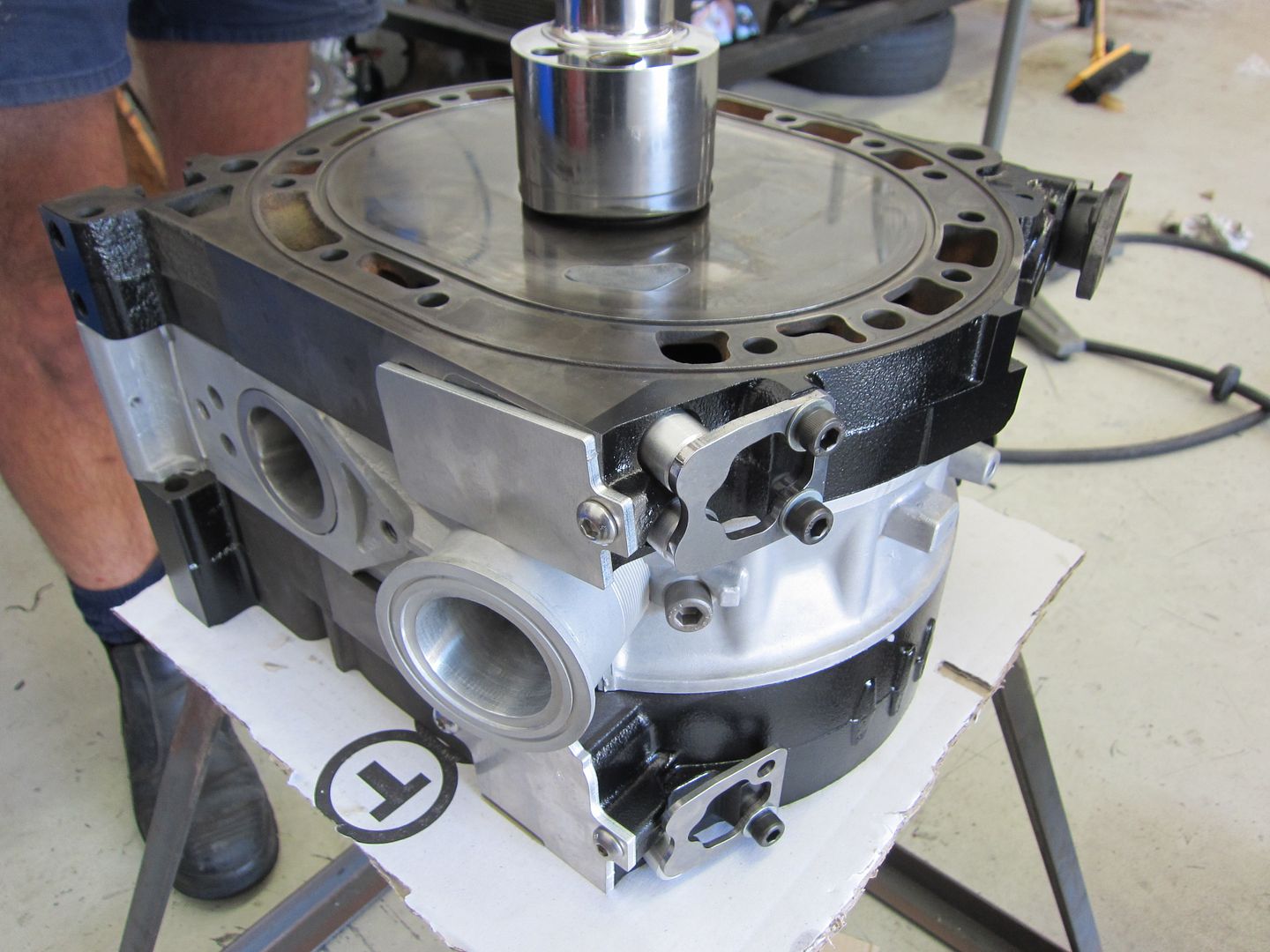

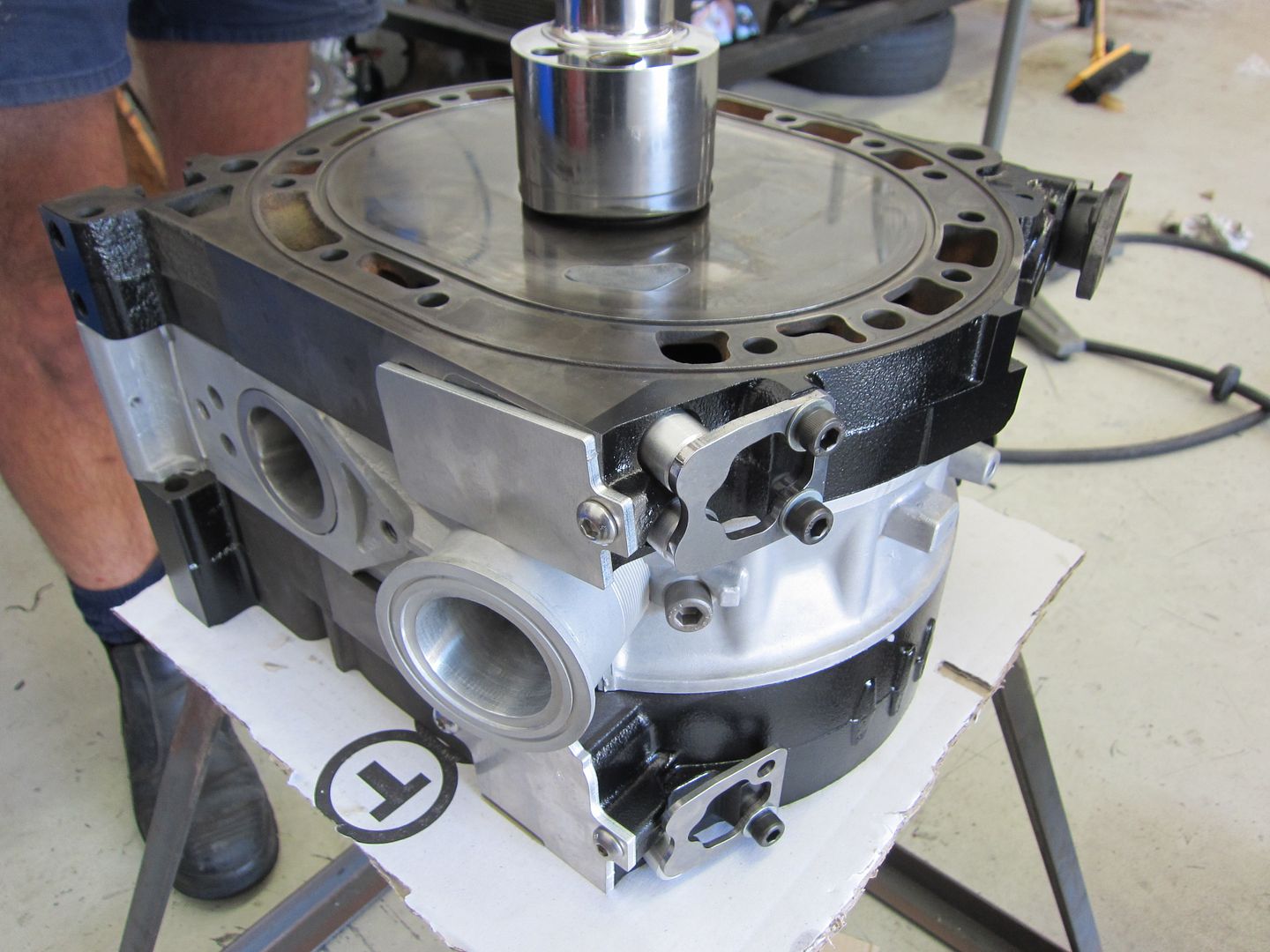

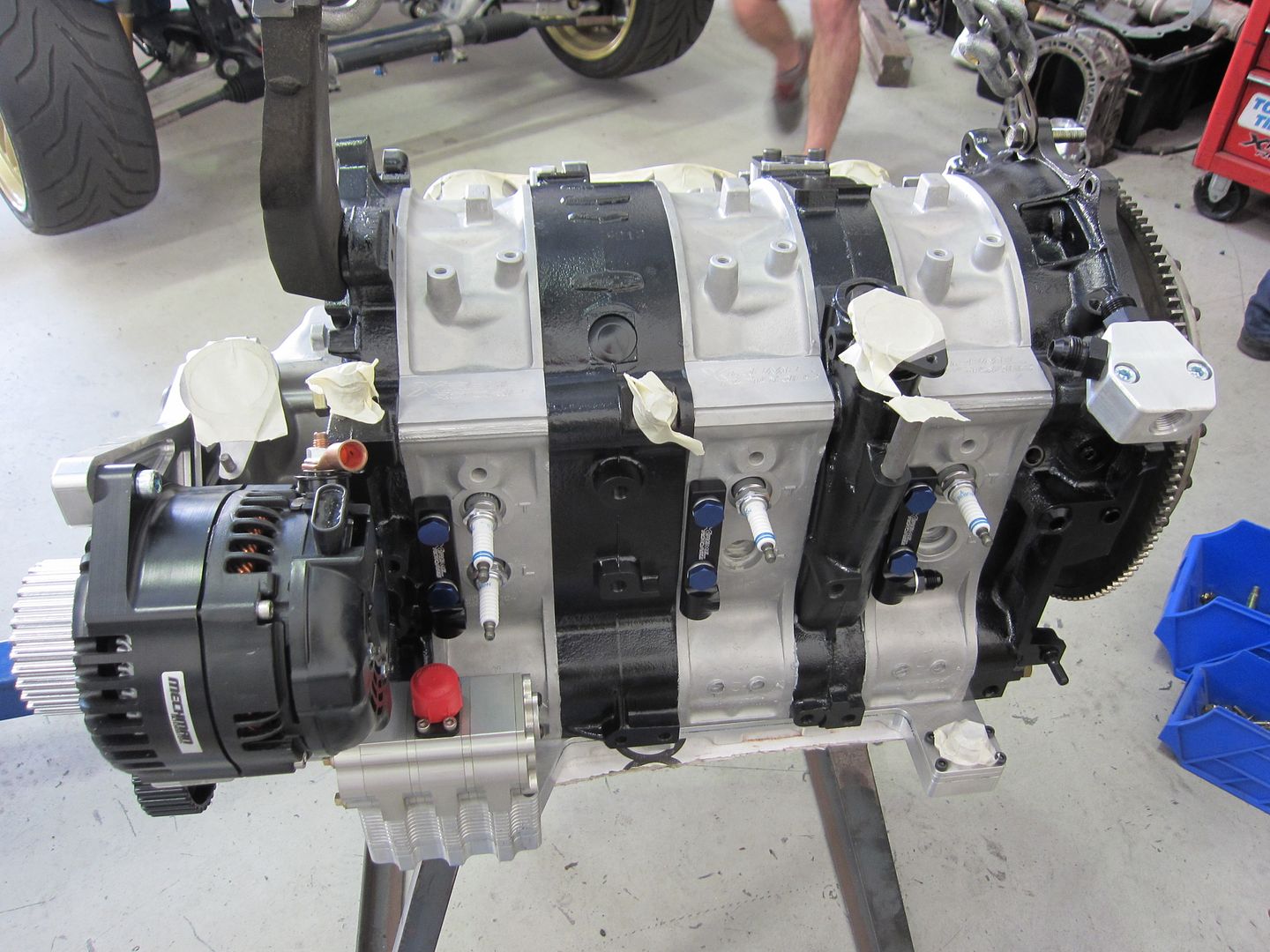

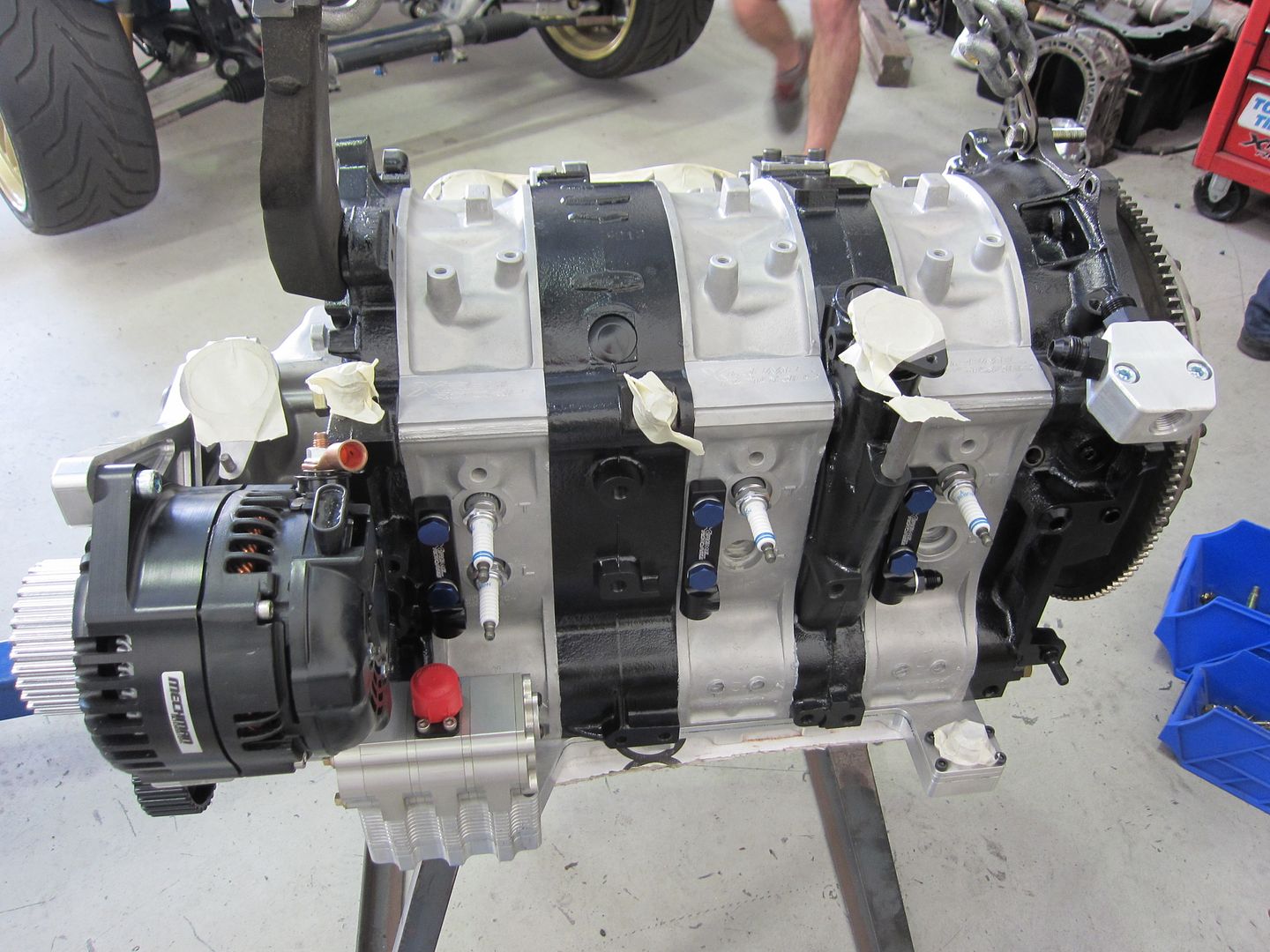

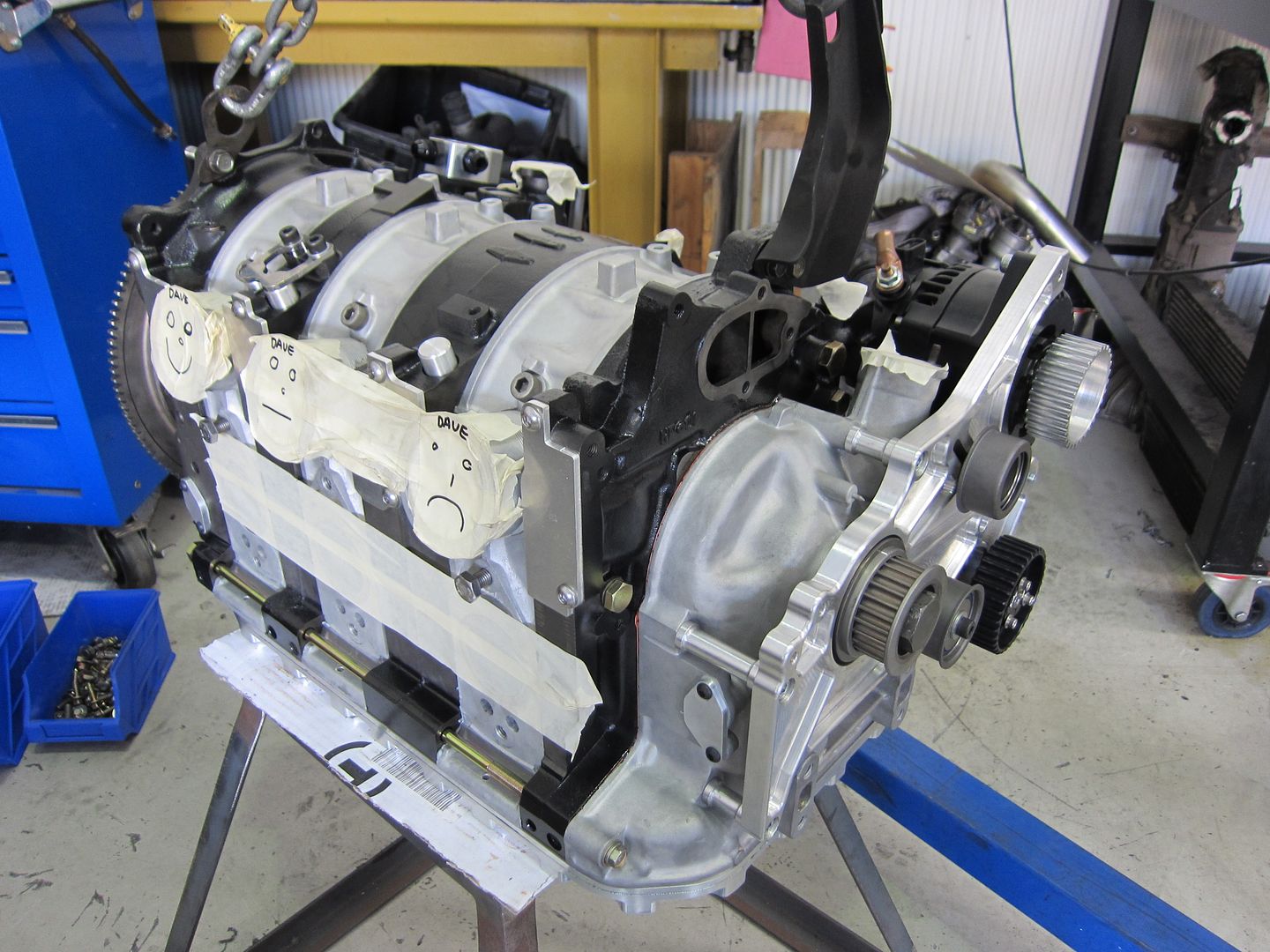

So continuing on with the engine assembly....the oil pump and front counterweight assemblies were installed.

Main oil gallery 'O'-ring...things get rather expensive if you don't install in properly or there is an act of god and it fails!

Inlet and exhaust ports temporarily sealed.

Rear stationary gear and counterweight fitted.

In preparation for the dry sump to be installed.

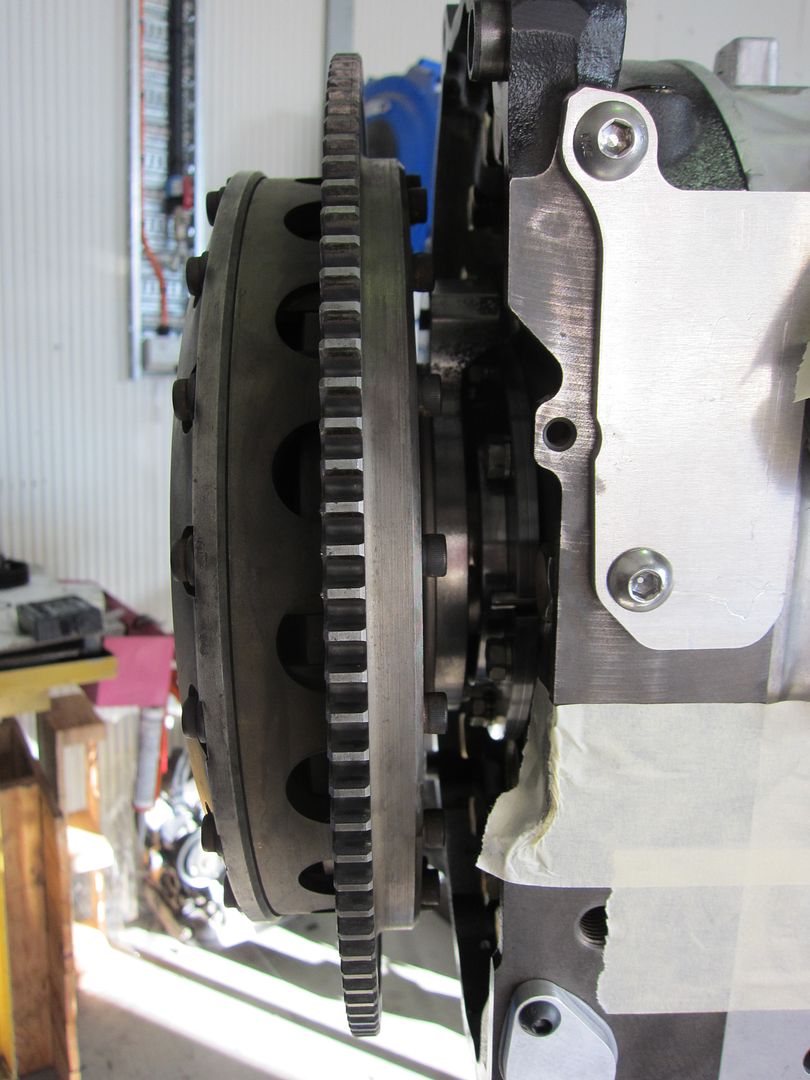

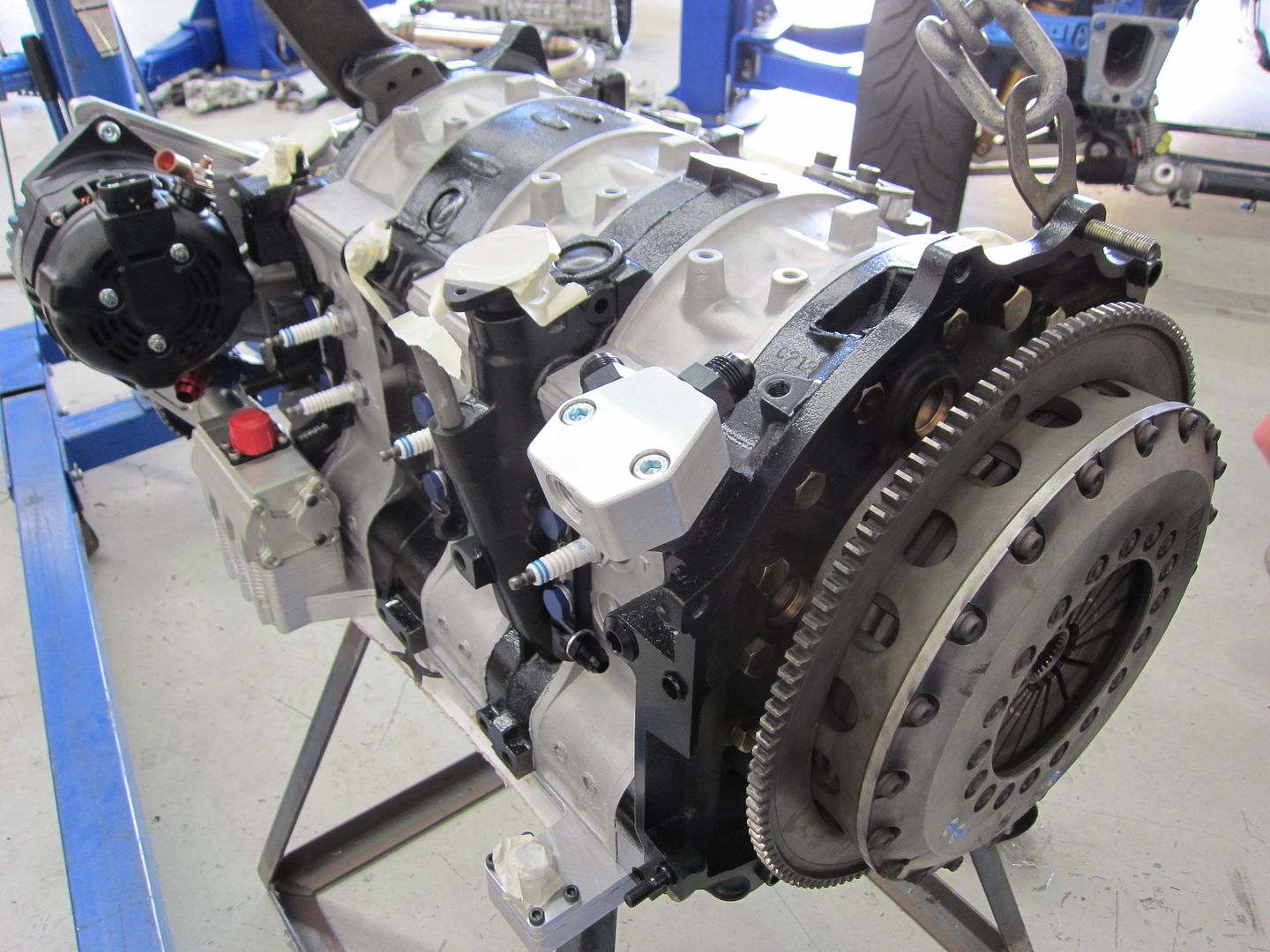

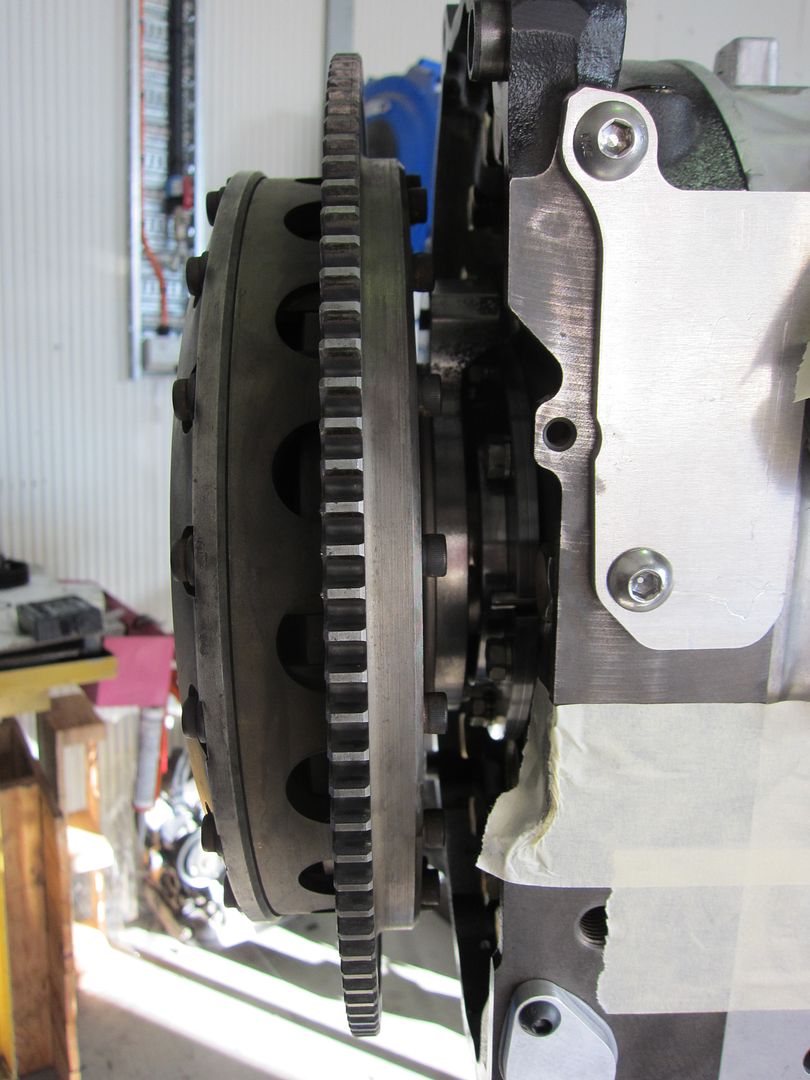

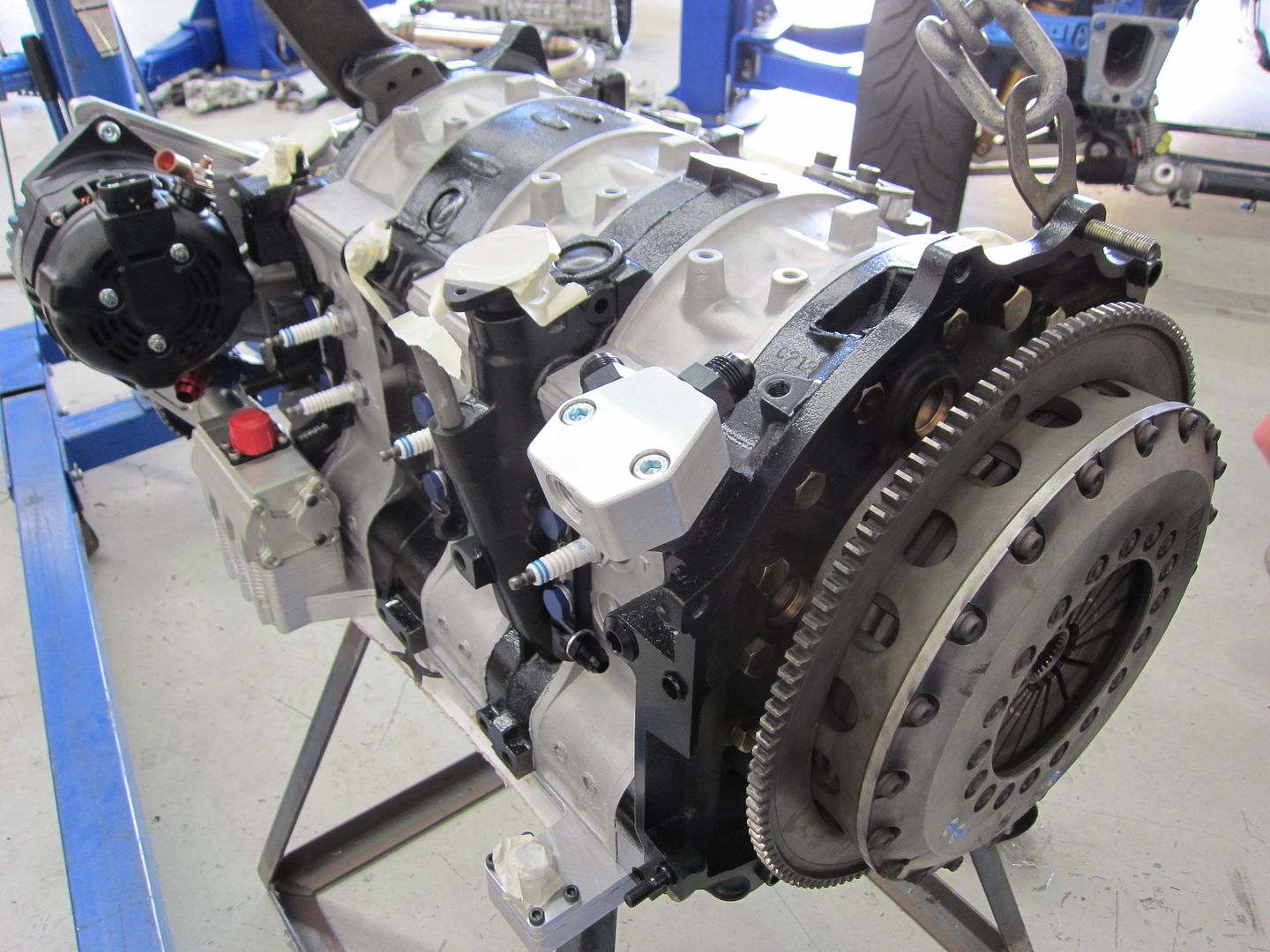

Clutch and flywheel assembly fitted.

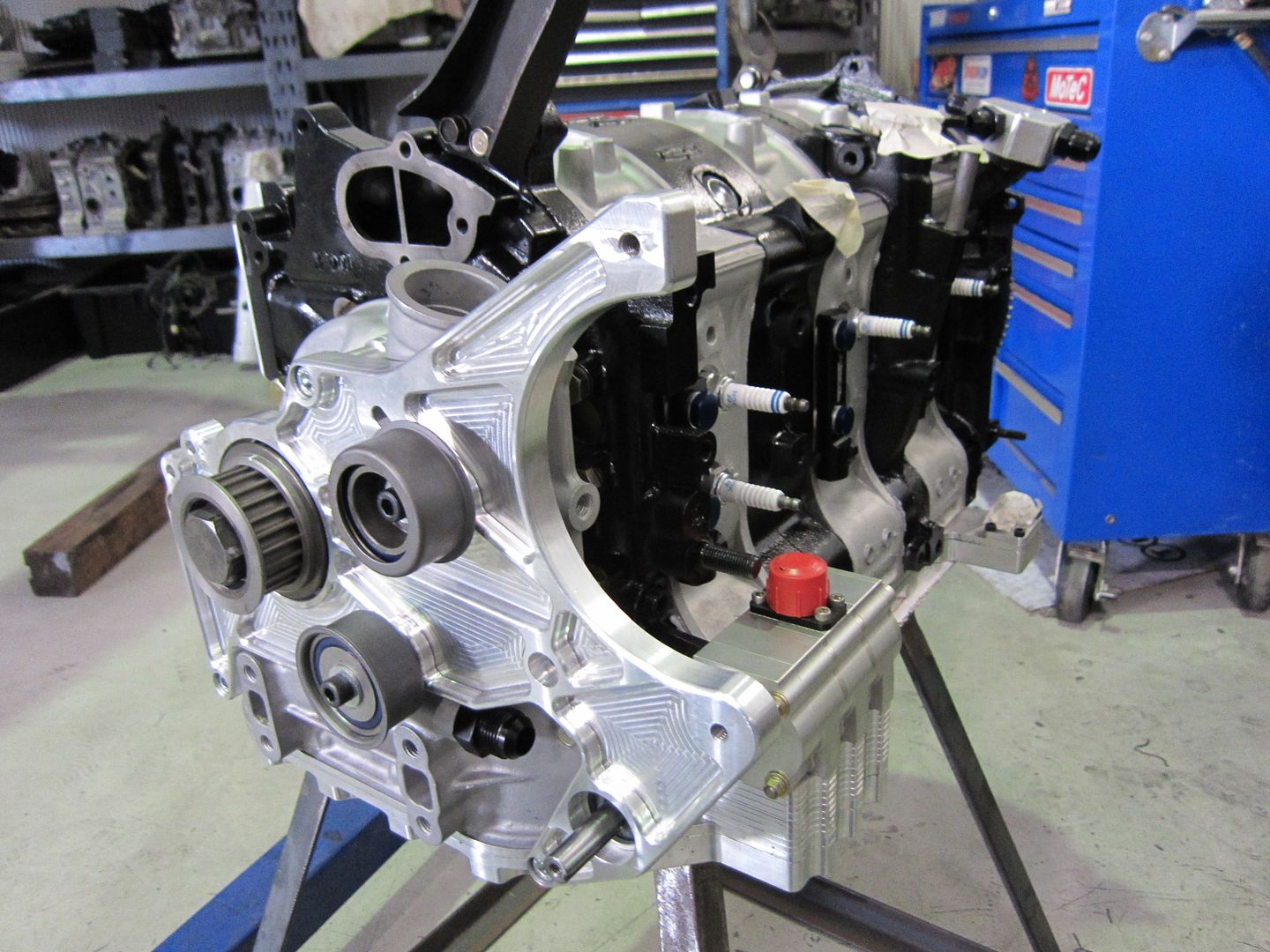

Dry sump and front cover bracket fitted.

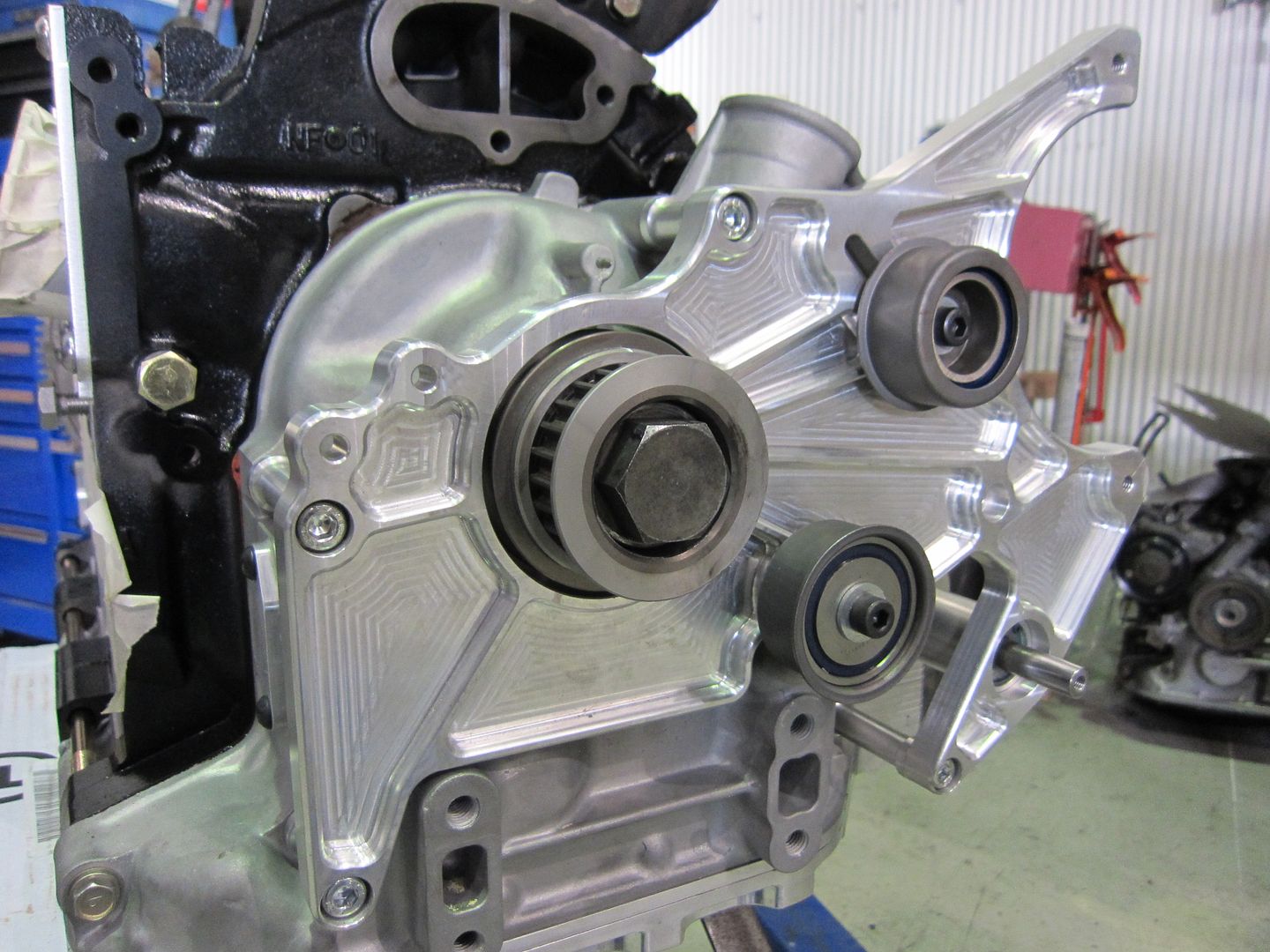

Front pulley installed and bolt torqued.

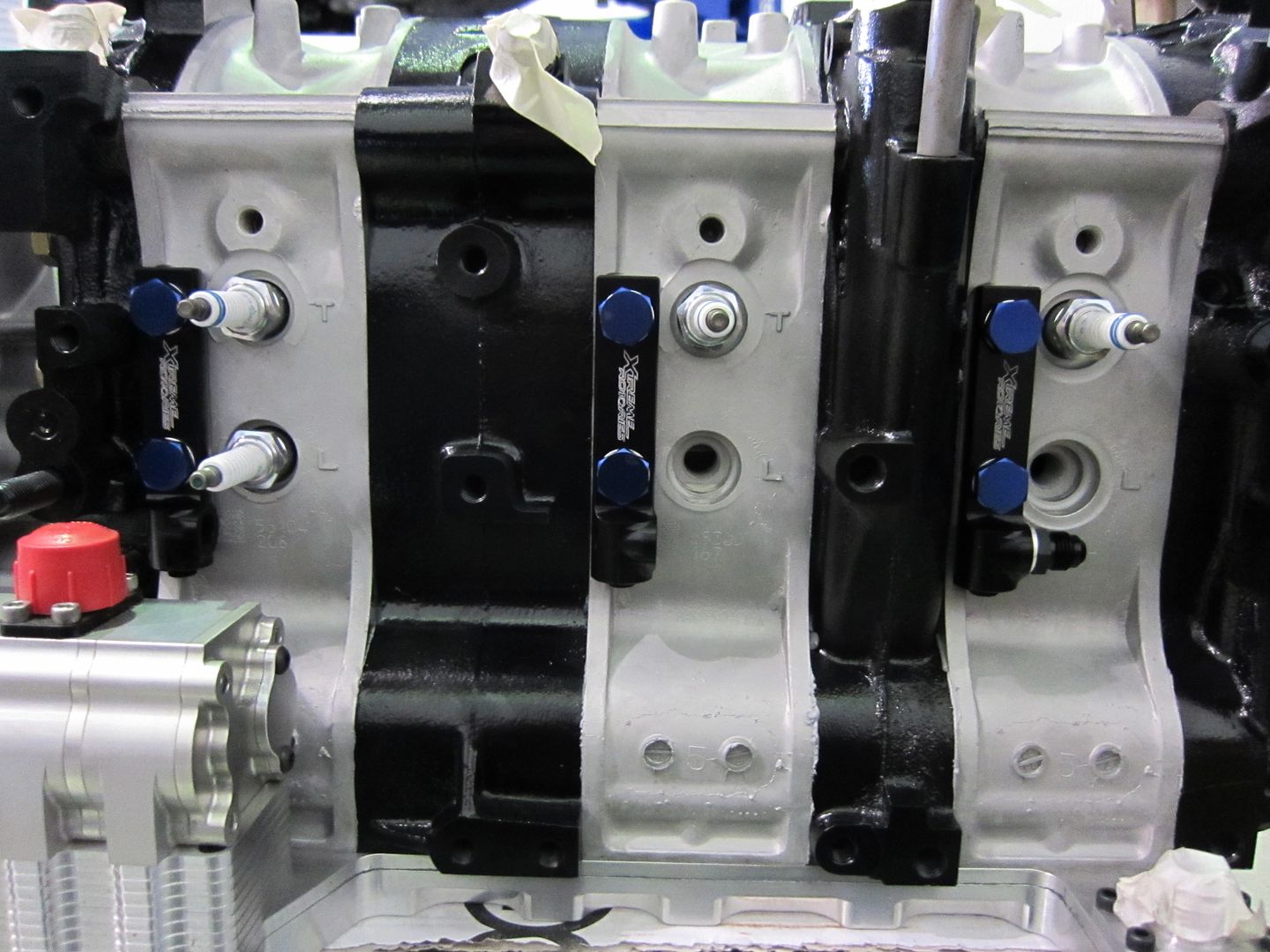

All three rotor housing supplementary coolant delivery blocks installed.

Alternator on.

The engine ready to be dropped back into the chassis for the second last time....but the last time before it will finally run.

The chassis with dummy engine removed awaiting the new engine.

Cheers,

Danny

With everything currently falling into place, 2014 will be the year to finally see the NC on a race track and hear the scream of the 20B PP at full noise!!!

So continuing on with the engine assembly....the oil pump and front counterweight assemblies were installed.

Main oil gallery 'O'-ring...things get rather expensive if you don't install in properly or there is an act of god and it fails!

Inlet and exhaust ports temporarily sealed.

Rear stationary gear and counterweight fitted.

In preparation for the dry sump to be installed.

Clutch and flywheel assembly fitted.

Dry sump and front cover bracket fitted.

Front pulley installed and bolt torqued.

All three rotor housing supplementary coolant delivery blocks installed.

Alternator on.

The engine ready to be dropped back into the chassis for the second last time....but the last time before it will finally run.

The chassis with dummy engine removed awaiting the new engine.

Cheers,

Danny

-

Magpie

- Speed Racer

- Posts: 7468

- Joined: Fri Feb 11, 2011 12:49 pm

- Vehicle: NA6

- Location: Purga, QLD

Re: NC Track Car - In the Build

It must be quite there with no customers  No Charlie 91 or Magpie's car to take up your time or garage floor space

No Charlie 91 or Magpie's car to take up your time or garage floor space

Will you do a open day to showcase this car (once you confirm it starts)?

Will you do a open day to showcase this car (once you confirm it starts)?

-

sailaholic

- Speed Racer

- Posts: 3511

- Joined: Thu May 19, 2011 3:38 pm

- Vehicle: NA8

- Location: Brisbane

Re: NC Track Car - In the Build

Magpie wrote:It must be quite there with no customersNo Charlie 91 or Magpie's car to take up your time or garage floor space

Lokiel's se is there getting its engine built though.

Sent from my iPhone using Tapatalk

-

NMX516

- Speed Racer

- Posts: 2057

- Joined: Mon Jun 19, 2006 12:05 pm

- Vehicle: NB SP

- Location: Brisbane

- MattR

- Racing Driver

- Posts: 1305

- Joined: Wed Feb 25, 2009 11:26 pm

- Vehicle: NA6

- Location: Brisbane

Re: NC Track Car - In the Build

It amazes me how a 9 gallon keg can go so quickly

Will the oil reservoir for the dry sump be in the passenger compartment or boot? As a timeattack car you have a lot more freedom than a car built for racing.

Danny, good to see it's coming along between helping Dave as TA with the S14 cage (well that's what he told me would be happening ).

).

I assume we won't be able to see the finished car running at Lakeside, but it will be fine at QR????

So next project, this drivetrain in a spaceframe draped in a RX8 body for sports sedans?????

Will the oil reservoir for the dry sump be in the passenger compartment or boot? As a timeattack car you have a lot more freedom than a car built for racing.

Danny, good to see it's coming along between helping Dave as TA with the S14 cage (well that's what he told me would be happening

I assume we won't be able to see the finished car running at Lakeside, but it will be fine at QR????

So next project, this drivetrain in a spaceframe draped in a RX8 body for sports sedans?????

- Lokiel

- Forum legend

- Posts: 4126

- Joined: Thu May 28, 2009 2:39 pm

- Vehicle: NB SE

- Location: Brisbania

Re: NC Track Car - In the Build

What are these "DAVE" ports?

- a custom Automotive-Plus innovation set to revolutionise the world in Rotary engineering?

What does "DAVE" stand for?

Direct Air Volumetric Efficiency?

- a custom Automotive-Plus innovation set to revolutionise the world in Rotary engineering?

What does "DAVE" stand for?

Direct Air Volumetric Efficiency?

Don't worry about dying, worry about not living!

Garage Thread: http://www.mx5cartalk.com/forum/viewtopic.php?f=57&t=76716

Garage Thread: http://www.mx5cartalk.com/forum/viewtopic.php?f=57&t=76716

- timk

- Racing Driver

- Posts: 1928

- Joined: Fri Dec 31, 2004 3:16 pm

- Vehicle: NC

Re: NC Track Car - In the Build

Pretty sure you need to have the name Dave to get a job at Automotive Plus these days. Could be Dave the eBay guy, Dave the fabricator (one of two) or Dave the engine tuner.

-

Magpie

- Speed Racer

- Posts: 7468

- Joined: Fri Feb 11, 2011 12:49 pm

- Vehicle: NA6

- Location: Purga, QLD

Re: NC Track Car - In the Build

DAVE - Dangerous And Very Expensive

Who is online

Users browsing this forum: No registered users and 5 guests