mrpham's summer build

Moderators: timk, Stu, -alex, miata, StanTheMan, greenMachine, ManiacLachy, Daffy, zombie, Andrew, The American, Lokiel

- NitroDann

- Forum sponsor

- Posts: 10280

- Joined: Thu Nov 05, 2009 12:10 pm

- Vehicle: NA6

- Location: Newcastle NSW

- Contact:

Re: mrpham's summer build

Torsen brakes etc?

Dann

Dann

http://www.NitroDann.com

speed wrote:If I was to do it again, I wouldn't even consider the supercharger.

-

sailaholic

- Speed Racer

- Posts: 3511

- Joined: Thu May 19, 2011 3:38 pm

- Vehicle: NA8

- Location: Brisbane

Re: mrpham's summer build

Forgot brakes, didn't know standard nbb had torsen diff?

Sent from my GT-I9100 using Tapatalk 2

Sent from my GT-I9100 using Tapatalk 2

- hks_kansei

- Speed Racer

- Posts: 6154

- Joined: Tue Feb 03, 2009 10:43 am

- Vehicle: NB8A

- Location: Victoria

Re: mrpham's summer build

8B doesn't have a stock LSD, only the SE

1999 Mazda MX5 - 1989 Honda CT110 (for sale) - 1994 Mazda 626 wagon (GF's)

-

chooshoe

- Learner Driver

- Posts: 17

- Joined: Tue Oct 16, 2012 9:35 pm

Re: mrpham's summer build

mrpham wrote:So I picked up a NB8A for a daily

Pretty much stock, paint is in good condition, has later model headlights, taillights, front bar, interior and seats.

Bought it in brissy?

There's not many listed online - where did you find it?

- mrpham

- Forum sponsor

- Posts: 856

- Joined: Tue Sep 20, 2011 8:42 pm

- Vehicle: NA6

- Location: Brisbane

- Contact:

Re: mrpham's summer build

Current Forum Specials!

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

- bootz

- Racing Driver

- Posts: 892

- Joined: Thu Aug 19, 2010 1:13 pm

- Vehicle: NB8B

- Location: The Wild Wild West

Re: mrpham's summer build

Looks good, do mind telling us how much?

Bootz and Boof - On the road to somewhere.

- mrpham

- Forum sponsor

- Posts: 856

- Joined: Tue Sep 20, 2011 8:42 pm

- Vehicle: NA6

- Location: Brisbane

- Contact:

Re: mrpham's summer build

Not a big update, haven't been able to do much since the cylinder head is still away.

Bluetooth x Megasquirt - http://omgpham.com/bluetooth-x-megasquirt

This is something I've been wanting to do for a long time, implementing Bluetooth connectivity for my Megasquirt ECU.

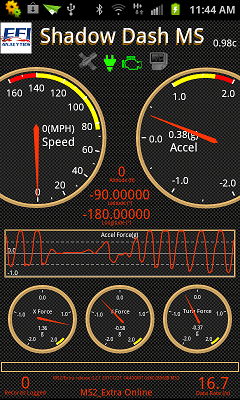

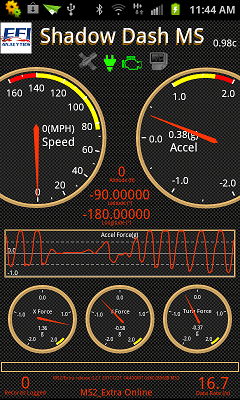

No more cables for tuning and data logging, I can even use my Android smartphone/tablet for data logging and digital gauge/dashes. The Android App is called Shadow Dash MS, free of charge from the EFI Analytics.

http://tunerstudio.com/index.php/shadowdashmsmenu

You can buy off the self devices that are plug and play, around $50-$100, but I've decided to take the DIY route which cost me $12!

These can be found on eBay for about $12-$14 shipped to Australia.

There is a bit of work to do like adjust settings as well as some soldering.

1. The module needs to be jumpered temporarily so settings can be applied.

Used some copper wire and soldered it from 3.3V to PIO (11), these are pin 12 and pin 34 respectively on the main circuit board.

2. Use some paper to insulate pins 6, 7, 8 and 9 on the DB9 Male connector. And than solder a wire from pin 9 to V+ pad, this is next to the break-out pins.

This wire takes +5V from pin 9 of the serial connector (Megasquirt side) and supplies it for the Bluetooth module.

3. An external +5V supply has to applied to the break-out pins.

This temporarily powers the device so settings can be applied.

So that completes most of the modifications needed, now on to software. I used Microsoft Hyper Terminal, which is available on Windows XP machines. You can download it below:

http://omgpham.com/wp-content/uploads/2012/11/HyperTerminal.zip

1. Connect the module to your serial port, or your USB-Serial adapter.

2. Open up Hyper Terminal and create a new connection. Select your serial connection's COM port., mine was COM4. The settings below should be applied.

3. To confirm that the connection is correct, quickly type in AT. It won't display what you've typed but it should display the response OK.

4. Open up Notepad and type the following AT+NAME(insert the name you want here), in my case I typed AT+NAMEomgpham.com . CUT all the text, go back to your Hyper Terminal window and click on Paste to Host. You should than get a response saying OKsetname.

5. Next up we'll set the PIN Code. So back to Notepad and type in AT+PIN(insert your 4 digit pin here), eg. AT+PIN1234. CUT all the text, go back to your Hyper Terminal window and click on Paste to Host. You should than get a response saying OKsetPIN.

6. Finally, we'll set the baud rate. By default it's 9600 but this needs to be set to 115200. So in Notepad you'll type AT+BAUD8, CUT all the text than go back to your Hyper Terminal window and click on Paste to Host. You should than get a response saying OK115200.

The reason we have to cut and paste commands from Notepad is because Hyper Terminal needs commands to be typed completely in under a second. Stupid? Yes, but ah well.

So everything software wise is now done, this next part is optional and it involves removing the female DB9 connector which is used for applying settings. It's the connector that plugs into your computer's serial port.

Connector removed and heat shrink applied to protect the circuit board.

Bluetooth x Megasquirt - http://omgpham.com/bluetooth-x-megasquirt

This is something I've been wanting to do for a long time, implementing Bluetooth connectivity for my Megasquirt ECU.

No more cables for tuning and data logging, I can even use my Android smartphone/tablet for data logging and digital gauge/dashes. The Android App is called Shadow Dash MS, free of charge from the EFI Analytics.

http://tunerstudio.com/index.php/shadowdashmsmenu

You can buy off the self devices that are plug and play, around $50-$100, but I've decided to take the DIY route which cost me $12!

These can be found on eBay for about $12-$14 shipped to Australia.

There is a bit of work to do like adjust settings as well as some soldering.

1. The module needs to be jumpered temporarily so settings can be applied.

Used some copper wire and soldered it from 3.3V to PIO (11), these are pin 12 and pin 34 respectively on the main circuit board.

2. Use some paper to insulate pins 6, 7, 8 and 9 on the DB9 Male connector. And than solder a wire from pin 9 to V+ pad, this is next to the break-out pins.

This wire takes +5V from pin 9 of the serial connector (Megasquirt side) and supplies it for the Bluetooth module.

3. An external +5V supply has to applied to the break-out pins.

This temporarily powers the device so settings can be applied.

So that completes most of the modifications needed, now on to software. I used Microsoft Hyper Terminal, which is available on Windows XP machines. You can download it below:

http://omgpham.com/wp-content/uploads/2012/11/HyperTerminal.zip

1. Connect the module to your serial port, or your USB-Serial adapter.

2. Open up Hyper Terminal and create a new connection. Select your serial connection's COM port., mine was COM4. The settings below should be applied.

3. To confirm that the connection is correct, quickly type in AT. It won't display what you've typed but it should display the response OK.

4. Open up Notepad and type the following AT+NAME(insert the name you want here), in my case I typed AT+NAMEomgpham.com . CUT all the text, go back to your Hyper Terminal window and click on Paste to Host. You should than get a response saying OKsetname.

5. Next up we'll set the PIN Code. So back to Notepad and type in AT+PIN(insert your 4 digit pin here), eg. AT+PIN1234. CUT all the text, go back to your Hyper Terminal window and click on Paste to Host. You should than get a response saying OKsetPIN.

6. Finally, we'll set the baud rate. By default it's 9600 but this needs to be set to 115200. So in Notepad you'll type AT+BAUD8, CUT all the text than go back to your Hyper Terminal window and click on Paste to Host. You should than get a response saying OK115200.

The reason we have to cut and paste commands from Notepad is because Hyper Terminal needs commands to be typed completely in under a second. Stupid? Yes, but ah well.

So everything software wise is now done, this next part is optional and it involves removing the female DB9 connector which is used for applying settings. It's the connector that plugs into your computer's serial port.

Connector removed and heat shrink applied to protect the circuit board.

Current Forum Specials!

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

- gslender

- Speed Racer

- Posts: 2330

- Joined: Sat Feb 19, 2011 10:49 pm

- Vehicle: NA6

- Location: Brisbane, QLD

Re: mrpham's summer build

...or just buy this for $60 plus shipping and its done - already configured and it just works (and the developer who built the apps gets a little $$ for his troubles)

http://www.tunerstudio.com/index.php/cablesandbluetooth

G

http://www.tunerstudio.com/index.php/cablesandbluetooth

G

MX5 91 NA6 LE completely stock and loving it!

MX5 92 NA8/ITBs Silver "aka Track Beeotch"

MX5 92 NA8/ITBs Silver "aka Track Beeotch"

-

sailaholic

- Speed Racer

- Posts: 3511

- Joined: Thu May 19, 2011 3:38 pm

- Vehicle: NA8

- Location: Brisbane

Re: mrpham's summer build

Come on g he said you could buy them ready done.

Besides isn't the point of a megasquirt that you can buy for a low cost and self assemble?

Sent from my GT-I9100 using Tapatalk 2

Besides isn't the point of a megasquirt that you can buy for a low cost and self assemble?

Sent from my GT-I9100 using Tapatalk 2

- Lokiel

- Forum legend

- Posts: 4126

- Joined: Thu May 28, 2009 2:39 pm

- Vehicle: NB SE

- Location: Brisbania

Re: mrpham's summer build

gslender, you're not embracing "Jinba-DIY" - the next level up from "Jinba-Ittai"

Don't worry about dying, worry about not living!

Garage Thread: http://www.mx5cartalk.com/forum/viewtopic.php?f=57&t=76716

Garage Thread: http://www.mx5cartalk.com/forum/viewtopic.php?f=57&t=76716

- mrpham

- Forum sponsor

- Posts: 856

- Joined: Tue Sep 20, 2011 8:42 pm

- Vehicle: NA6

- Location: Brisbane

- Contact:

Re: mrpham's summer build

Nearly There! - http://omgpham.com/nearly-there

Last post before I'm in Japan, leaving in a few days =)

Just some quick photos on the progress of my cylinder head, all nearly done just getting a few extra things machined.

More progress on the inlet side, bit more work needed around the valve guides.

The combustion chamber and areas around the valve seats cleaned up.

New oversized valves fitted!

The port mismatch between head and manifold, painted area shows what needs to be removed.

Last post before I'm in Japan, leaving in a few days =)

Just some quick photos on the progress of my cylinder head, all nearly done just getting a few extra things machined.

More progress on the inlet side, bit more work needed around the valve guides.

The combustion chamber and areas around the valve seats cleaned up.

New oversized valves fitted!

The port mismatch between head and manifold, painted area shows what needs to be removed.

Current Forum Specials!

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

- mrpham

- Forum sponsor

- Posts: 856

- Joined: Tue Sep 20, 2011 8:42 pm

- Vehicle: NA6

- Location: Brisbane

- Contact:

Re: mrpham's summer build

What up everyone, no build updates as I just got back from Japan. Hopefully my ported head is ready soon and I can start whacking sh*t back together

I picked up a few things from Japan, visited a few workshops, checked out a few UpGarages. Very cool trip.

All photos car related photos from the trip can be found here:

Facebook - omgpham.com

Picked up an extra Sparco Sprint V from UpGarage.

Bought 480 cans of Boss Coffee.

Found some awesome Pole Position keys to bring back for people.

Boss Coffee Gum....

Visited the Mazda Factory and Museum.

Quad rotor, variable length runner ITBs...

Oh before leaving for Japan, I packed and shipped out roughly 30 frame rail brace kits...

Not fun at all!

I picked up a few things from Japan, visited a few workshops, checked out a few UpGarages. Very cool trip.

All photos car related photos from the trip can be found here:

Facebook - omgpham.com

Picked up an extra Sparco Sprint V from UpGarage.

Bought 480 cans of Boss Coffee.

Found some awesome Pole Position keys to bring back for people.

Boss Coffee Gum....

Visited the Mazda Factory and Museum.

Quad rotor, variable length runner ITBs...

Oh before leaving for Japan, I packed and shipped out roughly 30 frame rail brace kits...

Not fun at all!

Current Forum Specials!

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

- bruce

- Speed Racer

- Posts: 7783

- Joined: Fri Apr 25, 2003 11:00 am

- Vehicle: NA8 - Turbo

- Location: Victoria

- Contact:

Re: mrpham's summer build

I thought that was a baby seat Sparco!

Methinks you like Coffee Boss?

Methinks you like Coffee Boss?

- mrpham

- Forum sponsor

- Posts: 856

- Joined: Tue Sep 20, 2011 8:42 pm

- Vehicle: NA6

- Location: Brisbane

- Contact:

Re: mrpham's summer build

Low-Profile Headlight Kit Install - http://omgpham.com/low-profile-headlight-install

This is a install walk-through of the Low-Profile Headlight Kit. It's quite straight forward to get everything bolted into the car, but it does take a bit of time to make minor adjustments so that both headlights are level with each other.

The supplied instructions can be found below, please use it together with this guide:

http://omgpham.com/wp-content/uploads/2012/11/low-pro.pdf

Before you start, have your headlights popped up than remove the retractor fuse/relay.

1. Remove the factory headlight and it's frame. This consists of 3 small screws, 2 large screws and a spring.

2. Using a pen, outline the brackets holding the headlight lid to the assemble. This will be used as a guide when you re-assemble.

3. Using a 14mm spanner, remove the nut and spring washer that holds the control arm to the retractor motor.

4. Remove the bolts/nuts on both sides of the assembly, this is the pivot point of the headlight assembly.

5. Remove entire headlight assembly from the car.

6. Remove the control arm from the assembly, carefully pry it evenly at the ball joint.

7. Drill two 6mm holes for the new control arm bracket.

8. Use one of the original factory screws, slip the supplied washer and spring onto the screw. Attach to the adapter frame and screw into bottom plastic clip.

9. Top holes of the frame are attached to the assembly using the supplied counter-sunk screws, washer, spring and nut.

10. Attach the Hella lense to the frame using the self tapping screws.

11. Loosen the locking nut and remove the factory stopper, install the supplied curved stopper.

12. Re-install the assembly into the car, plug headlight cable back in.

13. Loosen the bottom stopper, set the top stopper temporarily down.

14. With the retractor motor in the UP position, attach the control arm to the retractor motor shaft. Make sure the control arm is as straight as possible and the assembly is in the UP position too. Tighten the nut just enough so that you can do some tests by popping the headlights up and down a few times and make sure that the headlight is lifted to the highest point. Tighten the nut when done.

15. With the headlight up, set the top stopper so it just pushes against the assembly. With the headlights in the down position, set the bottom stopper so it just pushes back against the assembly. In both up/down positions, there should be very little movement, this ensures that the assembly will not bounce around whether the lights are up or down.

16. Repeat the instructions for the other side, and make minor adjustments to ensure both headlight heights are equal.

17. Adjustments are made using the control arm, remove it from the retractor motor shaft to do so. Lengthening the control arm will raise the headlight, shortening the control arm will lower the height.

18. You can now install the headlight lid and the side panels, the outer panel uses 1 short screw towards the back and the front uses a long screw with the supplied plastic spacer. Inner panels uses 2 short screws, the front screw uses a washer as a spacer.

19. Aligning the beam is done using the 2 top screws on the lense housing, black plastic surround. These screws allow adjustments for vertical and horizontal alignment. For any reason you need more vertical alignment, the bottom screw that holds the adapter bracket to the assembly can be adjust to raise/lower the lense.

20. Enjoy your new low-profile headlights!

This is a install walk-through of the Low-Profile Headlight Kit. It's quite straight forward to get everything bolted into the car, but it does take a bit of time to make minor adjustments so that both headlights are level with each other.

The supplied instructions can be found below, please use it together with this guide:

http://omgpham.com/wp-content/uploads/2012/11/low-pro.pdf

Before you start, have your headlights popped up than remove the retractor fuse/relay.

1. Remove the factory headlight and it's frame. This consists of 3 small screws, 2 large screws and a spring.

2. Using a pen, outline the brackets holding the headlight lid to the assemble. This will be used as a guide when you re-assemble.

3. Using a 14mm spanner, remove the nut and spring washer that holds the control arm to the retractor motor.

4. Remove the bolts/nuts on both sides of the assembly, this is the pivot point of the headlight assembly.

5. Remove entire headlight assembly from the car.

6. Remove the control arm from the assembly, carefully pry it evenly at the ball joint.

7. Drill two 6mm holes for the new control arm bracket.

8. Use one of the original factory screws, slip the supplied washer and spring onto the screw. Attach to the adapter frame and screw into bottom plastic clip.

9. Top holes of the frame are attached to the assembly using the supplied counter-sunk screws, washer, spring and nut.

10. Attach the Hella lense to the frame using the self tapping screws.

11. Loosen the locking nut and remove the factory stopper, install the supplied curved stopper.

12. Re-install the assembly into the car, plug headlight cable back in.

13. Loosen the bottom stopper, set the top stopper temporarily down.

14. With the retractor motor in the UP position, attach the control arm to the retractor motor shaft. Make sure the control arm is as straight as possible and the assembly is in the UP position too. Tighten the nut just enough so that you can do some tests by popping the headlights up and down a few times and make sure that the headlight is lifted to the highest point. Tighten the nut when done.

15. With the headlight up, set the top stopper so it just pushes against the assembly. With the headlights in the down position, set the bottom stopper so it just pushes back against the assembly. In both up/down positions, there should be very little movement, this ensures that the assembly will not bounce around whether the lights are up or down.

16. Repeat the instructions for the other side, and make minor adjustments to ensure both headlight heights are equal.

17. Adjustments are made using the control arm, remove it from the retractor motor shaft to do so. Lengthening the control arm will raise the headlight, shortening the control arm will lower the height.

18. You can now install the headlight lid and the side panels, the outer panel uses 1 short screw towards the back and the front uses a long screw with the supplied plastic spacer. Inner panels uses 2 short screws, the front screw uses a washer as a spacer.

19. Aligning the beam is done using the 2 top screws on the lense housing, black plastic surround. These screws allow adjustments for vertical and horizontal alignment. For any reason you need more vertical alignment, the bottom screw that holds the adapter bracket to the assembly can be adjust to raise/lower the lense.

20. Enjoy your new low-profile headlights!

Current Forum Specials!

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

- mrpham

- Forum sponsor

- Posts: 856

- Joined: Tue Sep 20, 2011 8:42 pm

- Vehicle: NA6

- Location: Brisbane

- Contact:

Re: mrpham's summer build

COPs Bracket - http://omgpham.com/cops-bracket

Just some quick photos of the COPs Bracket installed on my engine, I gave it a quick coat of satin black enamel paint too. Came out great and really suits my painted valve cover.

Now with the COPs bolted onto the bracket.

Just some quick photos of the COPs Bracket installed on my engine, I gave it a quick coat of satin black enamel paint too. Came out great and really suits my painted valve cover.

Now with the COPs bolted onto the bracket.

Current Forum Specials!

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

Frame Rail Braces - http://goo.gl/xJtRTs

COPs Bracket - http://goo.gl/sxJWhF

Build Thread - http://goo.gl/L3ZuKU

Who is online

Users browsing this forum: No registered users and 3 guests