Wazman's NB8a

Moderators: timk, Stu, zombie, Andrew, The American, Lokiel, -alex, miata, StanTheMan, greenMachine, ManiacLachy, Daffy

- Okibi

- Speed Racer

- Posts: 10899

- Joined: Thu Aug 21, 2003 11:00 am

- Vehicle: NB SE

- Location: Perth, Western Australia

- Contact:

Wazman's NB8a

Nice work with the turbo manifold and IC, wish I had those skils.

If you had access to a car like this, would you take it back right away? Neither would I.

- wazman

- Fast Driver

- Posts: 394

- Joined: Sun Feb 15, 2009 11:39 pm

Wazman's NB8a

Well i have had a super busy week on the car..... Well i should say i have been a slave driver all week on my house mates back!

Last Monday i booked the car in for a tune for the following week on Tuesday !!!! so i just needed to wire in the injectors (that i have no idea what they are), make custom cooler piping, plumb up/make the water/oil lines for the turbo...including tap into the sump for the oil return, make intake for turbo, make custom 3 inch exhaust (which i want to be as quiet as possible)........dosn't seem like much but when you go to do these things there is always some little thing that is missing and holds you up

So off came the top of the plenum and in go the new injectors (as far as i can work out they are 295cc) ( i could be wrong )

)

as usual nothing is a straight fit for me so i had to swap O rings and reduce the fuel rail spacers to get em in without leaking.

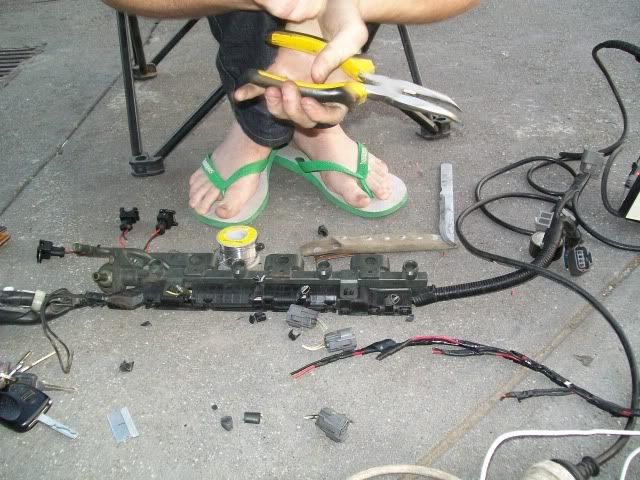

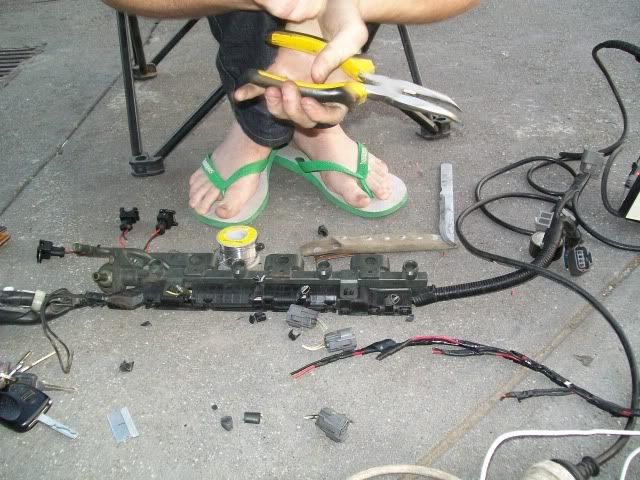

New plugs needed to be wired on to suit the new injectors. (thanks pinky)

After the plenum top was refitted i primed the rail to check for leaks...... yeah it leaked

so i just put smaller spacers (washers) in between the rail and its mounting points to get enough preasure on the injector seals to stop them from leaking.

It worked

Last Monday i booked the car in for a tune for the following week on Tuesday !!!! so i just needed to wire in the injectors (that i have no idea what they are), make custom cooler piping, plumb up/make the water/oil lines for the turbo...including tap into the sump for the oil return, make intake for turbo, make custom 3 inch exhaust (which i want to be as quiet as possible)........dosn't seem like much but when you go to do these things there is always some little thing that is missing and holds you up

So off came the top of the plenum and in go the new injectors (as far as i can work out they are 295cc) ( i could be wrong

as usual nothing is a straight fit for me so i had to swap O rings and reduce the fuel rail spacers to get em in without leaking.

New plugs needed to be wired on to suit the new injectors. (thanks pinky)

After the plenum top was refitted i primed the rail to check for leaks...... yeah it leaked

so i just put smaller spacers (washers) in between the rail and its mounting points to get enough preasure on the injector seals to stop them from leaking.

It worked

Last edited by wazman on Sun Dec 20, 2009 9:42 pm, edited 1 time in total.

ilovedrift.com

- wazman

- Fast Driver

- Posts: 394

- Joined: Sun Feb 15, 2009 11:39 pm

Wazman's NB8a

Next came the cooler piping. Luckily for me my house mate has done many different custom piping setups on all kinds of cars, so this "was a walk in the park" for him.

First the standard s13 silvia outlet was cut back and an cast alloy bend was sourced from AVO to be welded on. This simply reduces the chance of a silicon bend popping off (if thats what you were going to use straight off the turbo snout) all the time when a combination of high boost and engine lurching when the clutch is kicked mid corner etc.......

The piping 2" from the turbo down to below the chassis rail where it changes to 2.5"

Due to my tiny budget i had to re use a mates old cooler piping which was already painted black.

I want a subtle engine bay so i'll be sticking with the black piping theme.

Most of these pics are of the piping just tacked in position. It will all be tig welded after we are satisfied with the fit.

The cold side is 2.5" from cooler to throttle.

First the standard s13 silvia outlet was cut back and an cast alloy bend was sourced from AVO to be welded on. This simply reduces the chance of a silicon bend popping off (if thats what you were going to use straight off the turbo snout) all the time when a combination of high boost and engine lurching when the clutch is kicked mid corner etc.......

The piping 2" from the turbo down to below the chassis rail where it changes to 2.5"

Due to my tiny budget i had to re use a mates old cooler piping which was already painted black.

I want a subtle engine bay so i'll be sticking with the black piping theme.

Most of these pics are of the piping just tacked in position. It will all be tig welded after we are satisfied with the fit.

The cold side is 2.5" from cooler to throttle.

ilovedrift.com

- wazman

- Fast Driver

- Posts: 394

- Joined: Sun Feb 15, 2009 11:39 pm

Wazman's NB8a

You can also see the modified intake pipe in those pic's....

Its the standard s13 silvia sr20det snout cut back with a 45 deg alloy bend welded on to get the pob filter away from the turbo a little more.

Next is the oil drain for the turbo.... Using the "AVO" technique i used an air compressor to pressurize the engine so the alloy shavings didn't go into the motor as i drilled in...... I was in a rush to do this so i didn't get that many action shots sorry

Check the AVO website, turbo kits for mx5, for the link to their how to fit their kit instructions......very helpful

Water lines are just a matter of re-routing the front line to the turbo then back in where it used to go.

I used standard s13 water lines.....just chopped em back and re bent them with a couple of ring spanners. Leaving enough length to keep the rubber line away from the hot turbo center and rear housing.

This is the oil line fitting on the motor end.

as it comes around the back of the motor

The actuator is "T" ed in to the hot pipe nice and close to the turbo.

Oil return line

This is how i made room for the cooler piping.... i turned the power steering reservoir slightly.

I drilled some new holes in the air con line bracket to move it away from to hot dump pipe.

I also shortened a heater hose to move it away from the rear of the turbo and bent the metal line that runs behind the manifold to it so its not so close.

Its the standard s13 silvia sr20det snout cut back with a 45 deg alloy bend welded on to get the pob filter away from the turbo a little more.

Next is the oil drain for the turbo.... Using the "AVO" technique i used an air compressor to pressurize the engine so the alloy shavings didn't go into the motor as i drilled in...... I was in a rush to do this so i didn't get that many action shots sorry

Check the AVO website, turbo kits for mx5, for the link to their how to fit their kit instructions......very helpful

Water lines are just a matter of re-routing the front line to the turbo then back in where it used to go.

I used standard s13 water lines.....just chopped em back and re bent them with a couple of ring spanners. Leaving enough length to keep the rubber line away from the hot turbo center and rear housing.

This is the oil line fitting on the motor end.

as it comes around the back of the motor

The actuator is "T" ed in to the hot pipe nice and close to the turbo.

Oil return line

This is how i made room for the cooler piping.... i turned the power steering reservoir slightly.

I drilled some new holes in the air con line bracket to move it away from to hot dump pipe.

I also shortened a heater hose to move it away from the rear of the turbo and bent the metal line that runs behind the manifold to it so its not so close.

Last edited by wazman on Sun Dec 20, 2009 9:56 pm, edited 1 time in total.

ilovedrift.com

- wazman

- Fast Driver

- Posts: 394

- Joined: Sun Feb 15, 2009 11:39 pm

Wazman's NB8a

The oil feed line i got from merridian motor sport. It has a 90 deg fitting on the turbo end and a straight fitting on the engine side. Its simply "T" ed into the oil preasure sender with a fitting i got when i installed the oil temp gauge.

Next comes the exhaust. I didn't want to restrict flow later if i decide to go a bigger turbo so 3" is the way to go i decided..... That and my house mate said he is only making it ONCE ! I used some mufflers off an exhaust that belonged to a friend that was in my back yard.....two offset straight through type mufflers.

Its a tight fit ! With just 8mm of clearence in some spots.....so A LOT of time and patience was required while making it......

I was thinking of using this..... lol Chinese junk.

A slight bend was required to get enough clearance....this is the kind of thing your local exhaust guy CBF doing and gives you a 2.5" exhaust instead

Next comes the exhaust. I didn't want to restrict flow later if i decide to go a bigger turbo so 3" is the way to go i decided..... That and my house mate said he is only making it ONCE ! I used some mufflers off an exhaust that belonged to a friend that was in my back yard.....two offset straight through type mufflers.

Its a tight fit ! With just 8mm of clearence in some spots.....so A LOT of time and patience was required while making it......

I was thinking of using this..... lol Chinese junk.

A slight bend was required to get enough clearance....this is the kind of thing your local exhaust guy CBF doing and gives you a 2.5" exhaust instead

ilovedrift.com

- wazman

- Fast Driver

- Posts: 394

- Joined: Sun Feb 15, 2009 11:39 pm

Wazman's NB8a

Once it was all plumbed up and painted black it was time to see if it would start and run..... and it did

Super happy ! all ready for my tune on tuesday. 10psi should be enough for now.....

After the manifold heated up it turned a sweet colour

Cant wait to get back on the track and take it to those EVO's on the straights now !!

Super happy ! all ready for my tune on tuesday. 10psi should be enough for now.....

After the manifold heated up it turned a sweet colour

Cant wait to get back on the track and take it to those EVO's on the straights now !!

ilovedrift.com

- wazman

- Fast Driver

- Posts: 394

- Joined: Sun Feb 15, 2009 11:39 pm

Wazman's NB8a

I'll try get some photo's up of the various lines i had to relocate etc soon.

still on the list....

Brakes....(now it goes it needs to stop )

)

Bushes.... (the mx5 squirm is really starting to annoy me )

Oil cooler....... (low budget means i need to preserve the motor as long as i can, new motors every 6 months aint in the budget)

Clutch......which i have....just need a NA6 flywheel

"I'll be back"

still on the list....

Brakes....(now it goes it needs to stop

Bushes.... (the mx5 squirm is really starting to annoy me )

Oil cooler....... (low budget means i need to preserve the motor as long as i can, new motors every 6 months aint in the budget)

Clutch......which i have....just need a NA6 flywheel

"I'll be back"

ilovedrift.com

-

dorifta

- Fast Driver

- Posts: 152

- Joined: Tue Dec 02, 2008 3:03 am

- Vehicle: ND - 2 GT

- Location: Melbourne

- Lokiel

- Forum legend

- Posts: 4126

- Joined: Thu May 28, 2009 2:39 pm

- Vehicle: NB SE

- Location: Brisbania

Wazman's NB8a

WOW - and he did it all wearing thongs too.

Love your work!

Love your work!

Don't worry about dying, worry about not living!

Garage Thread: http://www.mx5cartalk.com/forum/viewtopic.php?f=57&t=76716

Garage Thread: http://www.mx5cartalk.com/forum/viewtopic.php?f=57&t=76716

- Jeo

- Speed Racer

- Posts: 3648

- Joined: Thu Jun 26, 2008 9:33 am

- Vehicle: NB8B

- Location: Canberra

Wazman's NB8a

Looks awesome mate. So cool to be able to DIY this stuff.

- wazman

- Fast Driver

- Posts: 394

- Joined: Sun Feb 15, 2009 11:39 pm

Wazman's NB8a

It gets tuned tomorrow at what was formerly "Status Tuning"

Hoping for 160 at the treads on 10 psi ..... fingers crossed

I'll post up the result and dyno graph after.

Hoping for 160 at the treads on 10 psi ..... fingers crossed

I'll post up the result and dyno graph after.

ilovedrift.com

-

Sasso

Wazman's NB8a

wazman wrote:It gets tuned tomorrow at what was formerly "Status Tuning"

Hoping for 160 at the treads on 10 psi ..... fingers crossed

I'll post up the result and dyno graph after.

KW or HP?

-

rxmx

- Fast Driver

- Posts: 338

- Joined: Tue Dec 16, 2003 11:43 pm

- Vehicle: NA6 - Turbo

- Location: Sydney

Wazman's NB8a

I think he'll be aiming for kw, he will easily make that in rwhp with 10psi...

http://www.facebook.com/purefabcustom

EFR6758 run-in tune 259hp atw on 10psi pump 98 dyno dynamics

E85 tune - 445hp @ wheels 17psi

EFR6758 run-in tune 259hp atw on 10psi pump 98 dyno dynamics

E85 tune - 445hp @ wheels 17psi

-

Sasso

Wazman's NB8a

rxmx wrote:I think he'll be aiming for kw, he will easily make that in rwhp with 10psi...

Isn't that a little ambitious? Might get that at 14 pounds but 10?? Will be interesting.

- lightyear

- Infinity & Beyond

- Posts: 2331

- Joined: Mon Jun 02, 2008 7:54 pm

- Vehicle: NA6 - Turbo

- Location: s.e. melbourne

Wazman's NB8a

My little 1.6 with tiny turbo makes 143rwkw at 9 psi, so he should get 160 at 10 psi easily with the bigger motor and turbo.

NA8B - P.I 1:50.1 Wntn1:38.0 Sand1:27.6 Wntn S1:08 Bfrd1:06.9 Cldr1:08.5 Wak1:10.4

"SE" - P.I 1:43.8 Wntn1:32.9 Sand1:22.0 Bfrd1:05.3

"SE" - P.I 1:43.8 Wntn1:32.9 Sand1:22.0 Bfrd1:05.3

Who is online

Users browsing this forum: No registered users and 44 guests