Cheers,

Danny

Moderators: timk, Stu, -alex, miata, StanTheMan, greenMachine, ManiacLachy, Daffy, zombie, Andrew, The American, Lokiel

sliq wrote:do they light up amber? (not like you'd probably need to drive it at night)

MXHEVN wrote:That sh*t is hot!

just curious, are you going to run a fuel gauge somewhere? dont want to run out on the track somewhere

Hammer wrote:Looking good.

Old Dude wrote:Looks great danny, you have a real nack for this sort of stuff..! By the way hows the bub going?

Regards

Old Dude

Mokesta wrote:Is that a shift light or 2 I see in the tacho? If not, do you plan to have one?

M

philz wrote:Love all this work Danny.

Only with the best gauges! truely awesome.

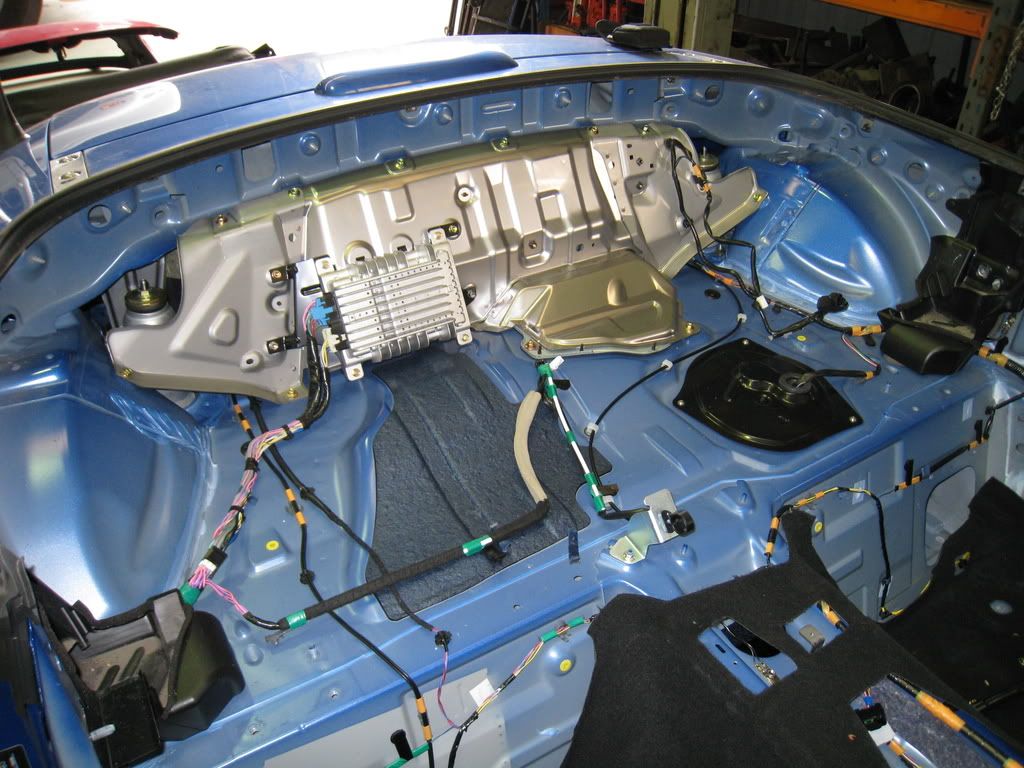

AJ wrote:so................they mask off the deadener & paint around it??.......I assume this is because adhesion is better without paint??

Users browsing this forum: No registered users and 8 guests