I really appreciate your support and positive feedback guys!

It's certainly a substantial project (in terms of time and R & D), that will hopefully result in the car I dreamt it would be.

In late January I got some spare time to look at fitting an RX-8 differential into the NC rear suspension subframe. After putting a tape measure over both the NC and RX-8 diff 'ear' brackets I found that the RX-8 diff ear bracket mounting centres were indentical to the NC. NC diff ear bracket on right in below photo.

I also found that the studs in the diff housings also had the same spacing. However, the RX-8 diff housing has an extra bump that prevents the NC diff ear bracket from fitting. Note the narrowed section with ribbing on the RX-8 bracket. Net result.....I purchased an RX-8 diff ear bracket and bolted her in!

The next step was to look at a suitable solution for reinstating the structural connection between the gearbox extension housing and the nose of differential (better known as the PPF - Power Plant Frame). The NC like its predecessors uses a pressed aluminium section for the PPF (FWIW - NA & NB is a C-section whereas the NC is a Z-section). The RX-8 uses a fabricated steel member not unlike the item used in the FD RX-7. Besides being made of steel, the RX-8 PPF also has some torsional capacity as it is predominantly a closed section. I only needed a quick look at the NC PPF to realise that major rework was necessary to make it fit to both the RX-8 gearbox and diff attachment points. Once again the solution was to use the RX-8 item as this would give me the correct end connections....but it is also a nominal 370mm too long because of the shorter wheelbase of the NC. The next question that needed to be answered was where to remove this extra length. The RX-8 PPF section changes its shape all along its length so the goal was to find two positions along its length that were as close as possible in cross-section. The below photos show the end result. I used a diaphragm plate to assist with reconnecting the two slightly different cross-sections.

Once I fully weld it out, the excess diaphragm material will be removed back to the silhouette of the PPF cross-section.

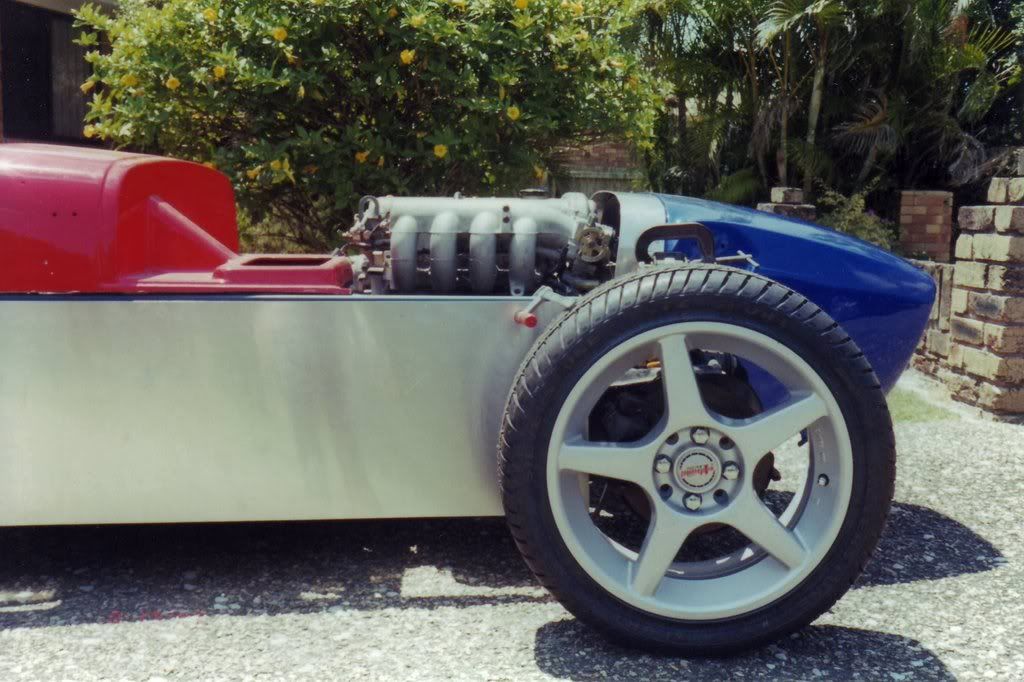

In January I also began laying out the supercharger, air to water IC core and inlet manifold header plate to get a feel for the required manifolding and the necessary space.

Cheers,

Danny

.