Okibi wrote:Great update, glad to see you get much deserved attention and respect.

Thanks Dave. The response has blown me away!

monty11ez wrote:Where did the throttle pedal come from? I looks like it was meant to be there.

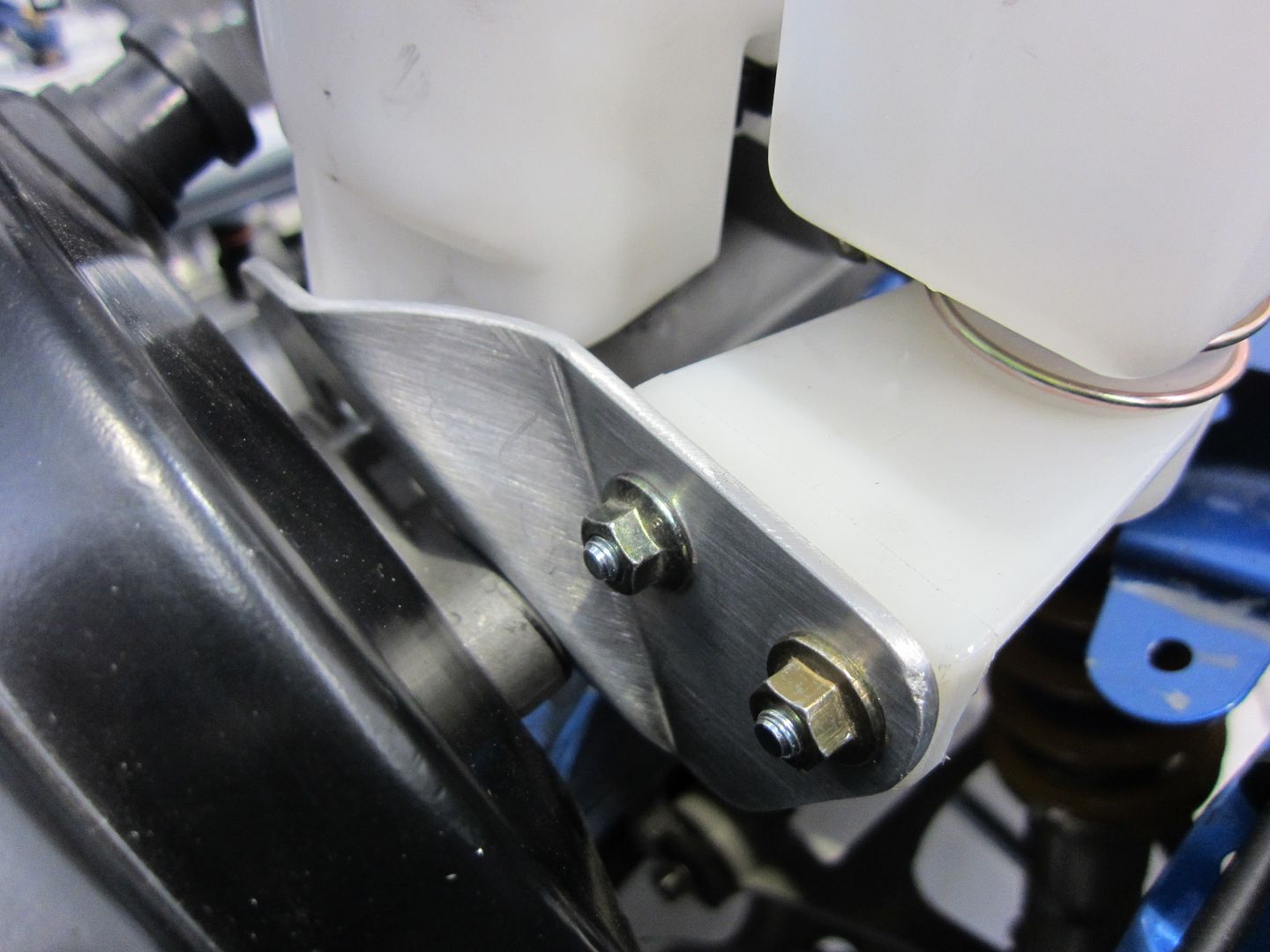

Monty, it's a bitsa! Part JC Cosmo and part NA MX-5 with an obvious tweak to get the cable in the right position.

monty11ez wrote:Also did you say that was a copy of a mazdaspeed front bumper?

The front bar is made by Odula in Japan. It isn't a copy of the Mazdaspeed bar.

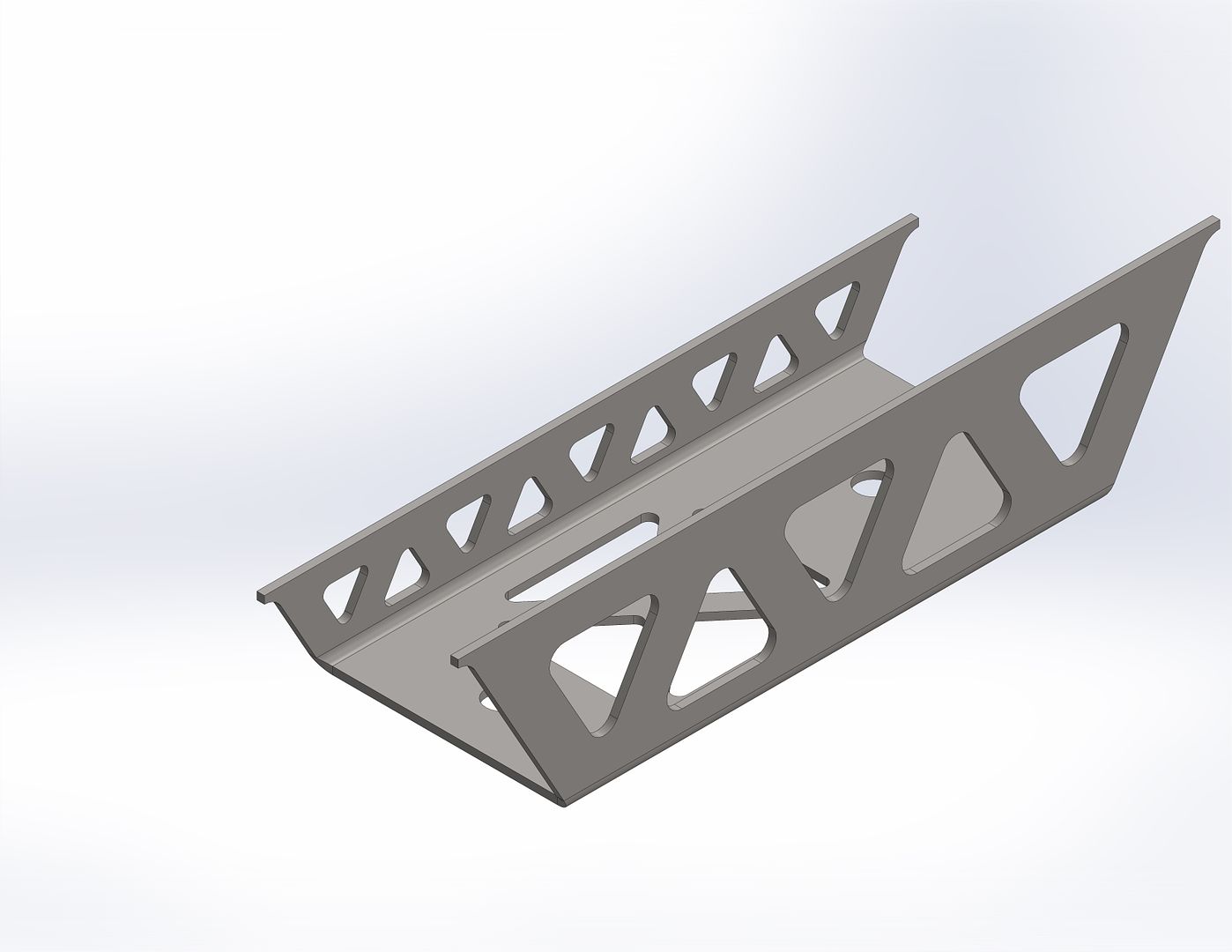

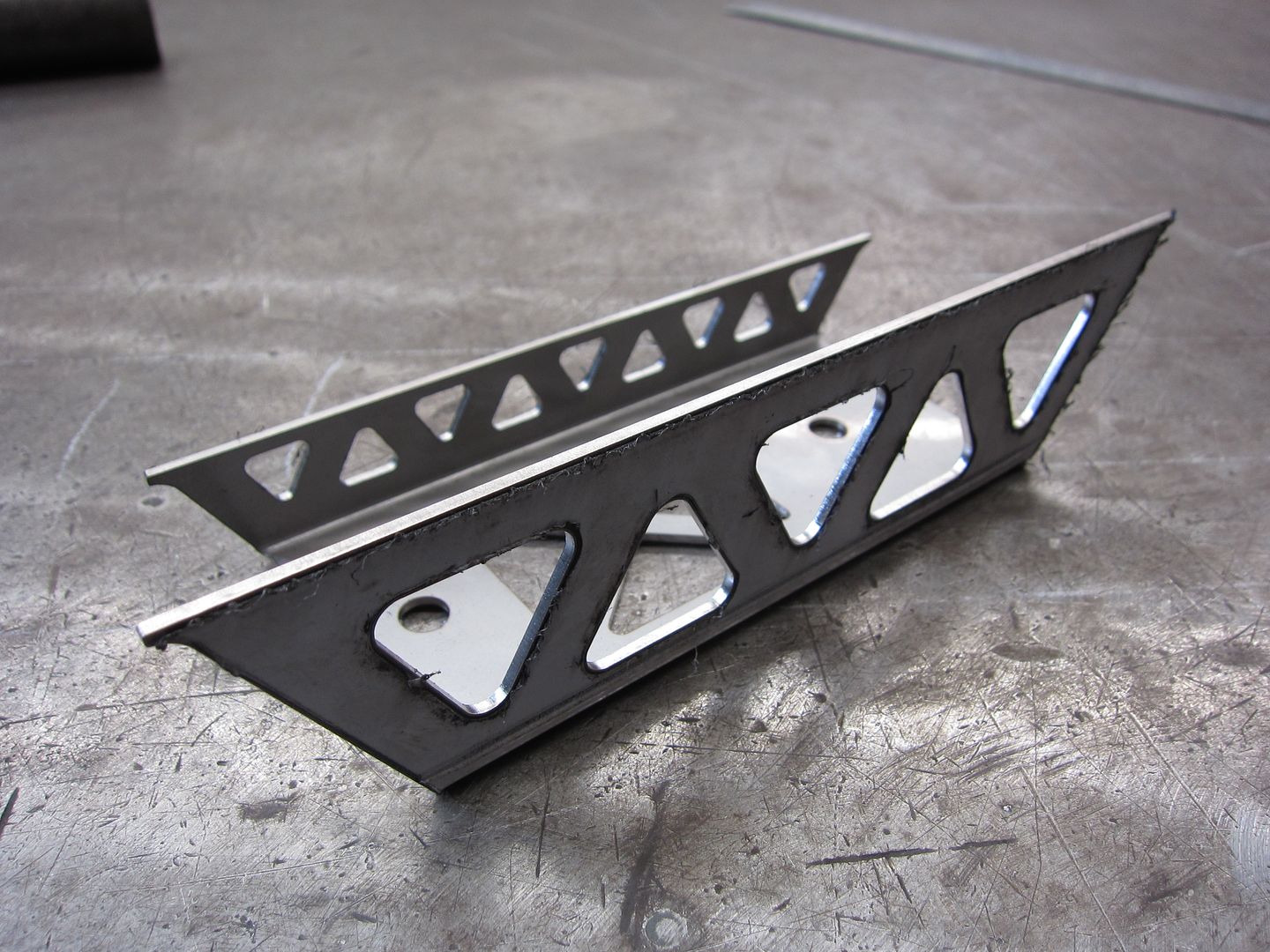

monty11ez wrote:I really like the front splitter design. The car is coming along great.

Thanks!

plohl wrote:Were there any major reasons to get rid of the Fly-by-wire, or just a simplification? You would have been able to set up some cool stuff with the m800.

Hi Shane, it was purely a cost vs benefit exercise (cost being time and money). I really didn't need another project within a project to design a fly-by-wire system for the throttle bodies. It was fine with the previous engine as it already had a fly-by-wire throttle body but no real benefit now.

Cheers,

Danny