NC 20BPP Time Attack / Track Car - Build Thread

Moderators: timk, Stu, -alex, miata, StanTheMan, greenMachine, ManiacLachy, Daffy, zombie, Andrew, The American, Lokiel

-

Magpie

- Speed Racer

- Posts: 7468

- Joined: Fri Feb 11, 2011 12:49 pm

- Vehicle: NA6

- Location: Purga, QLD

Re: NC Track Car - In the Build

I am to on the PDM, at one point I was looking at the Smartwire but dropped It from my budget as a nice thing that I don't really need

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - In the Build

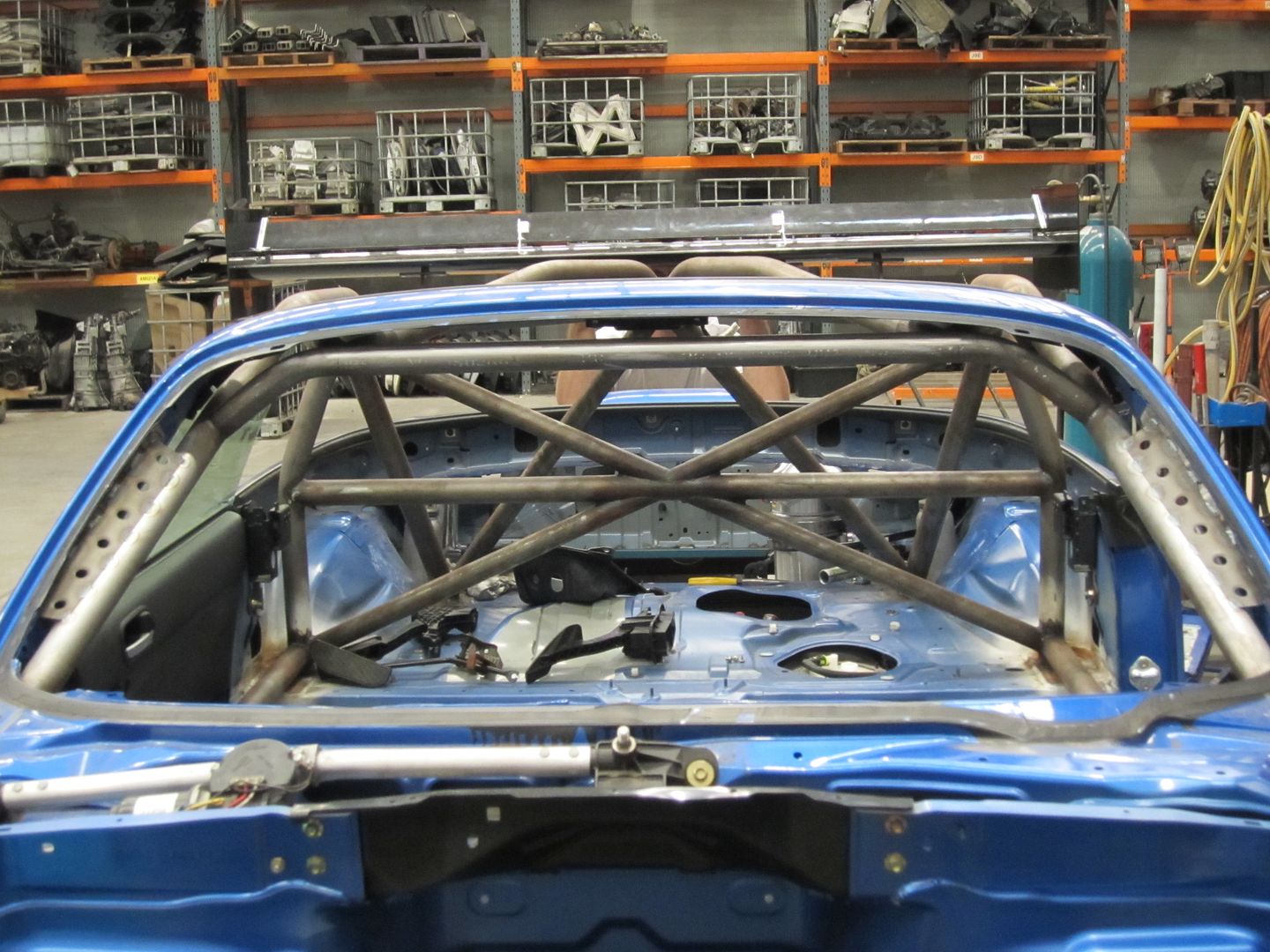

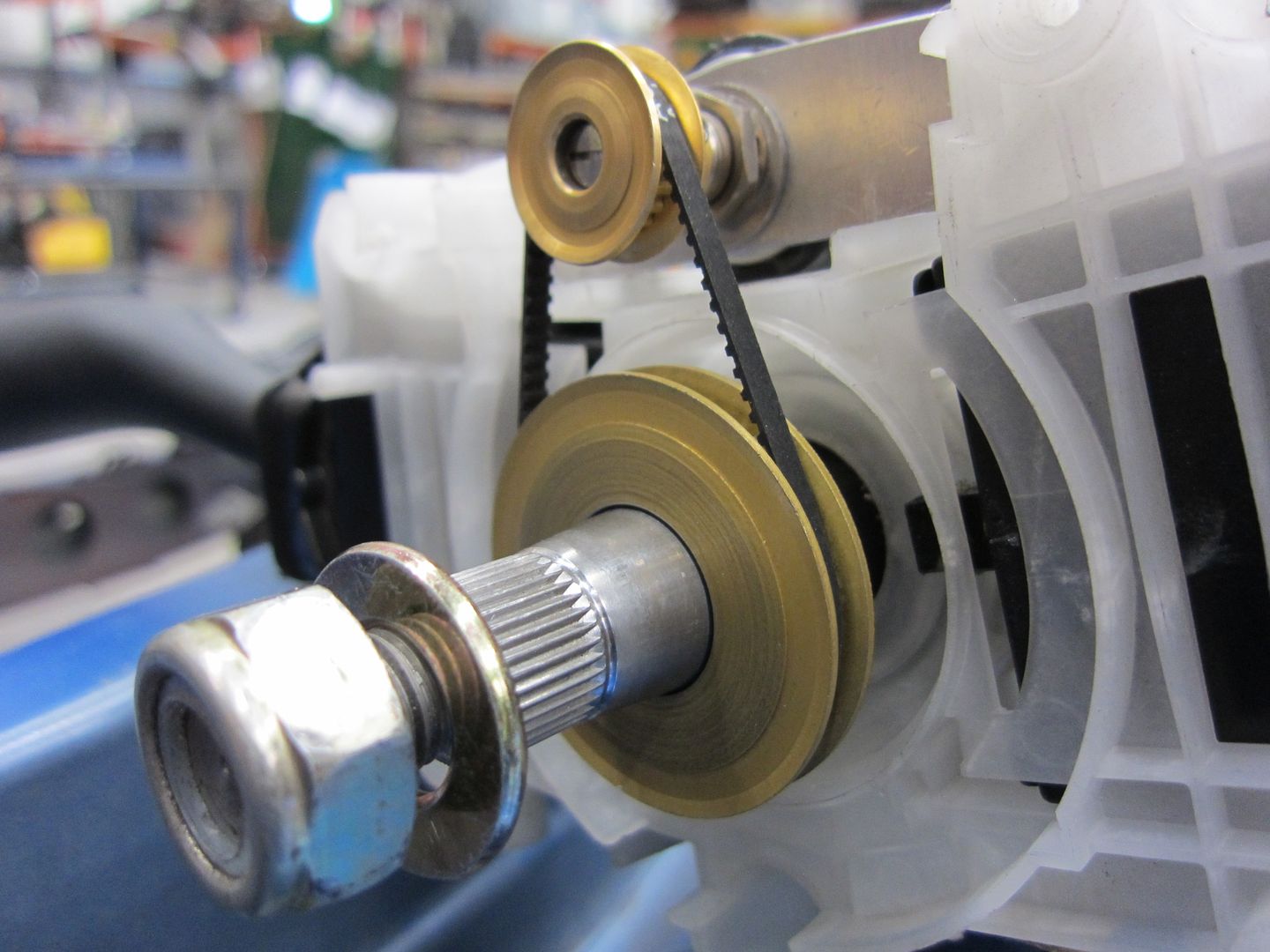

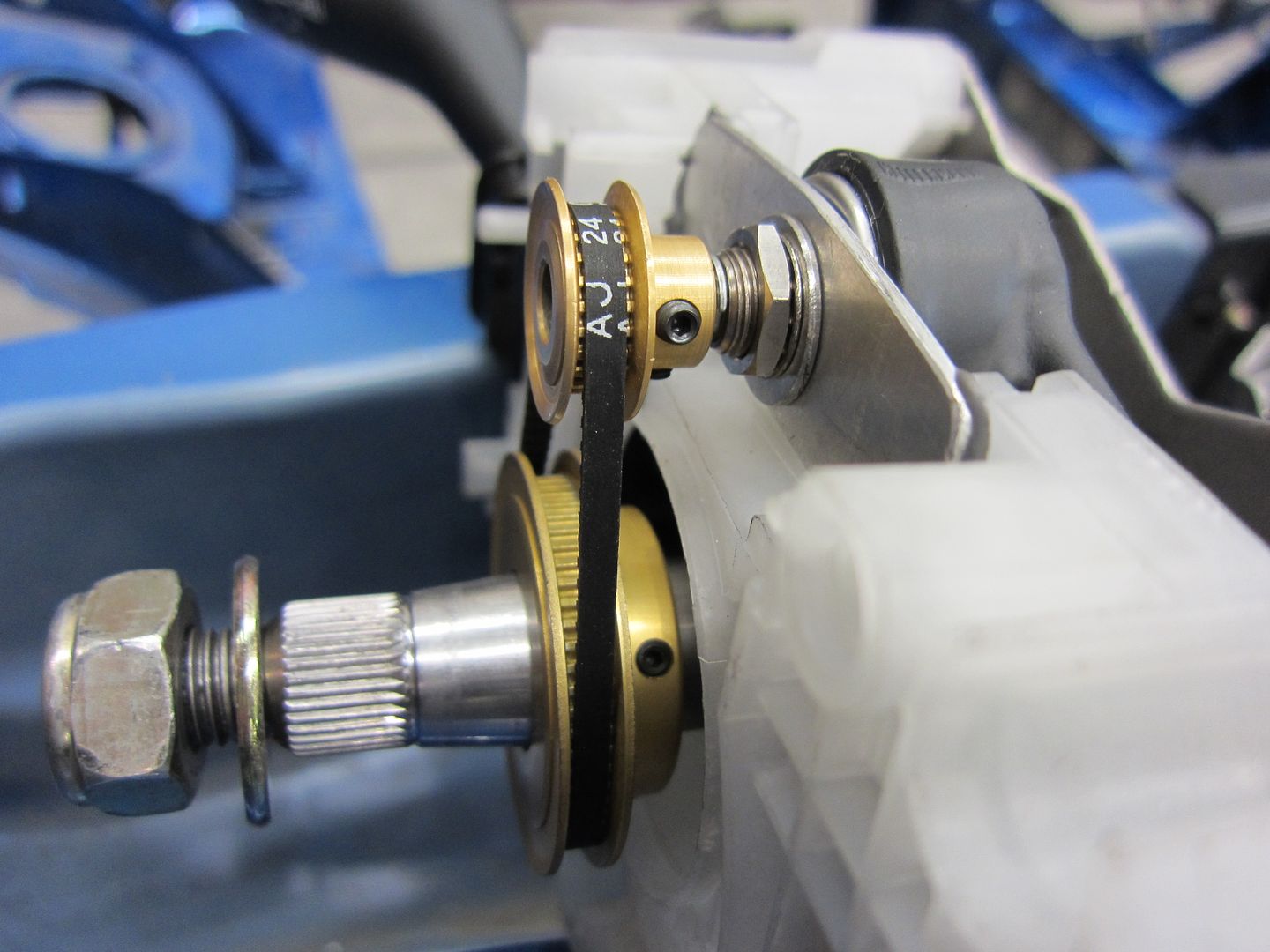

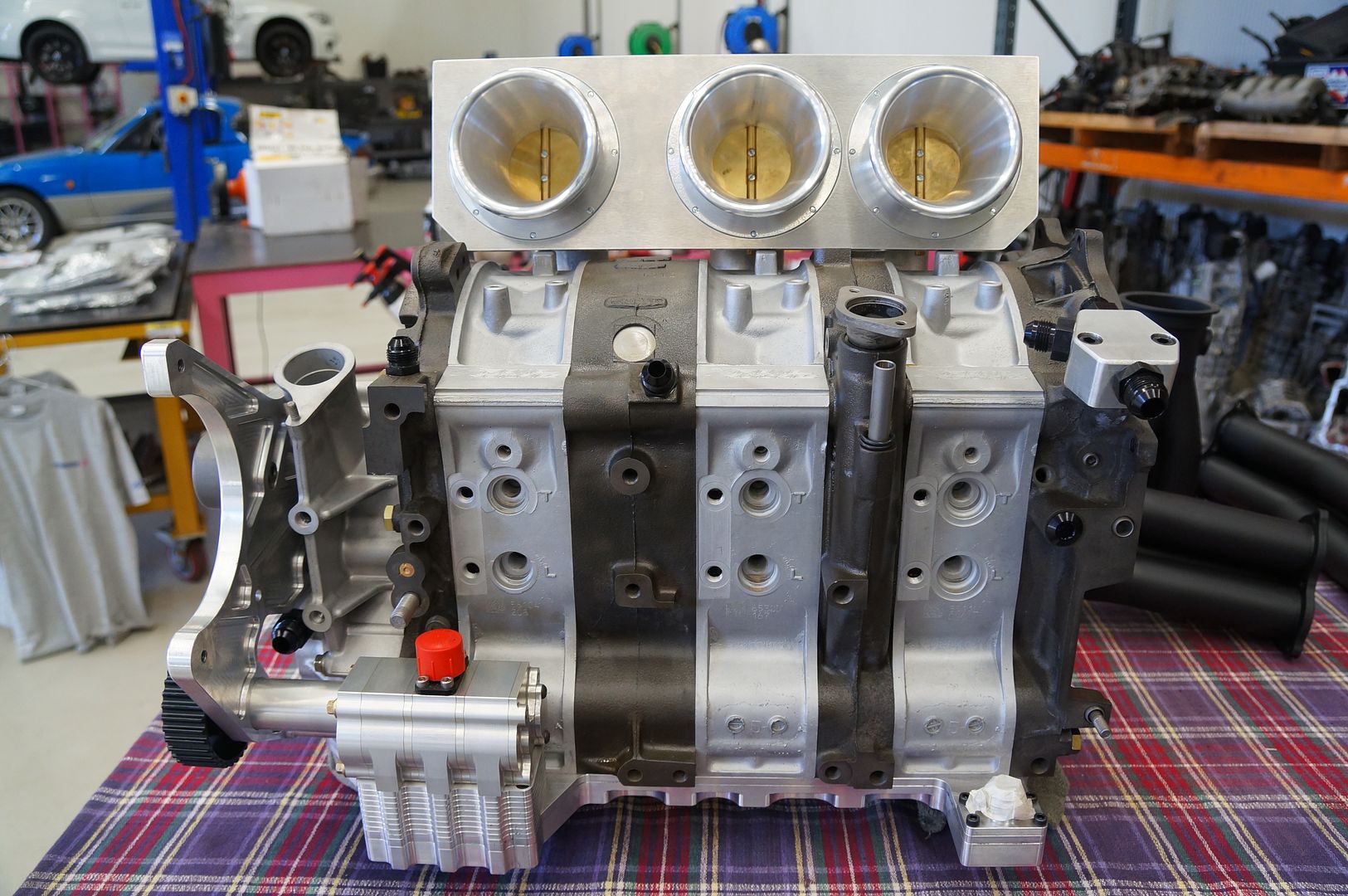

Whilst engine component machining and finishing was underway another dummy block was installed to assist with other aspects of the build.

The dash's steel back bone was removed and tidied up around the roll cage structure and any unnecessary brackets removed.

Some effort was also put into reinstating the bulkhead between the boot and the cab. The standard panel was trimmed to fit around the roll cage and then zinc plated to stop it rusting. Additional panels will be necessary to make it essentially air tight.

The roll cage received some more attention with attachments to the windscreen (A-pillars) frame being added.

I thought I'd have a quick go at how the Andrew Brilliant designed APR rear wing looked on the NC...this is the wing being used on his Time Attack Eclipse. Probably a bit hard to see in these photos.

Cheers,

Danny

The dash's steel back bone was removed and tidied up around the roll cage structure and any unnecessary brackets removed.

Some effort was also put into reinstating the bulkhead between the boot and the cab. The standard panel was trimmed to fit around the roll cage and then zinc plated to stop it rusting. Additional panels will be necessary to make it essentially air tight.

The roll cage received some more attention with attachments to the windscreen (A-pillars) frame being added.

I thought I'd have a quick go at how the Andrew Brilliant designed APR rear wing looked on the NC...this is the wing being used on his Time Attack Eclipse. Probably a bit hard to see in these photos.

Cheers,

Danny

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - In the Build

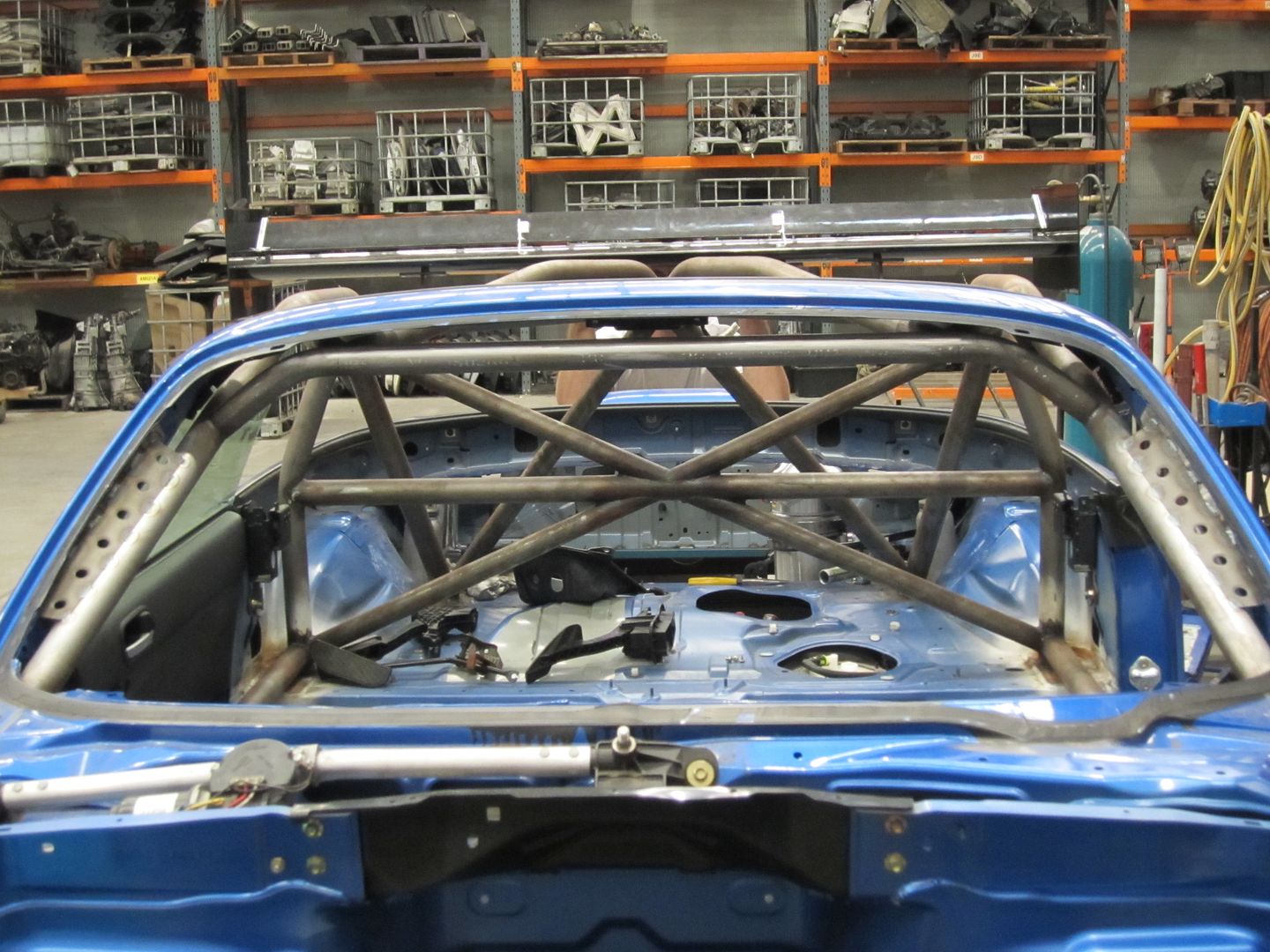

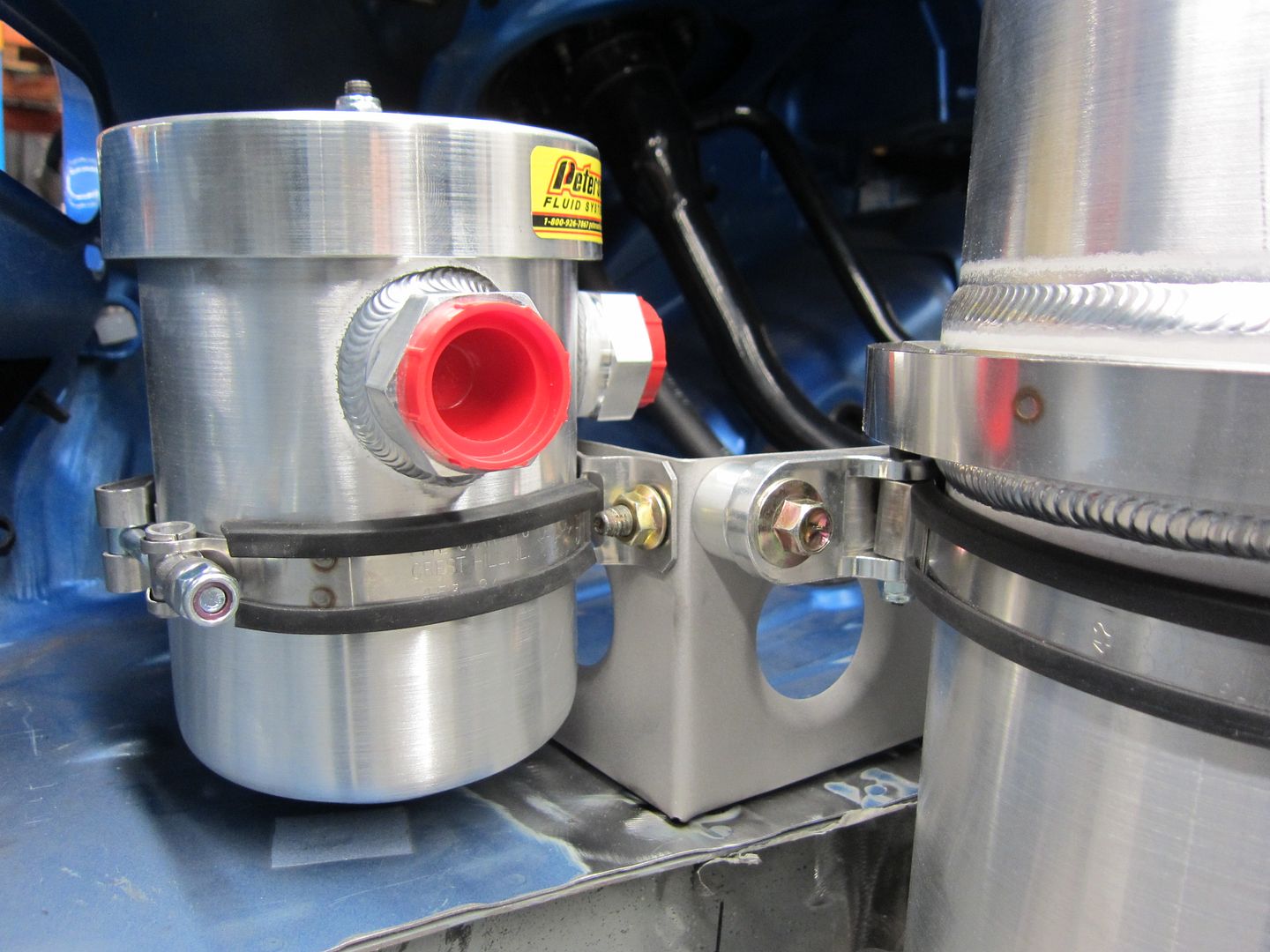

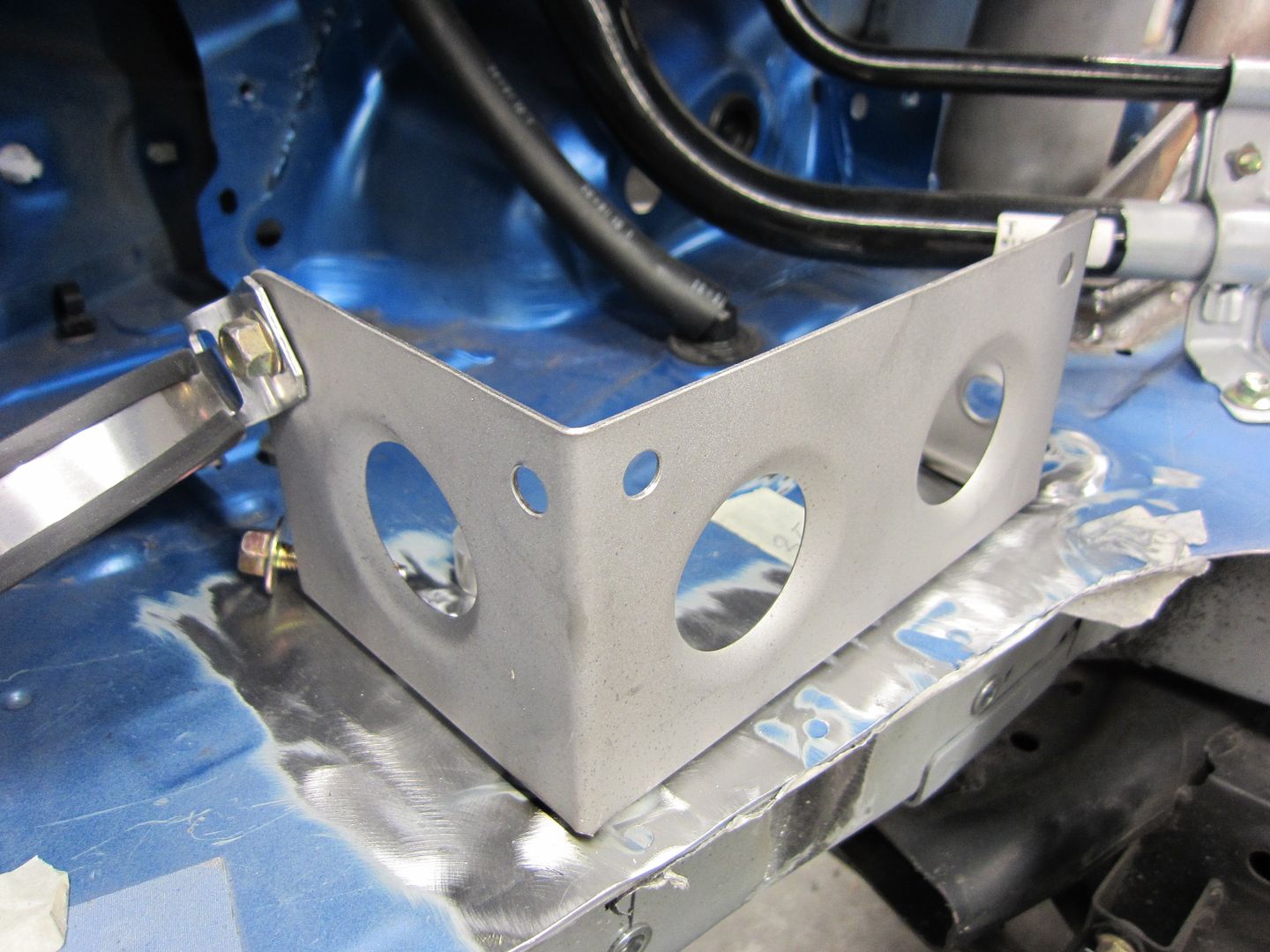

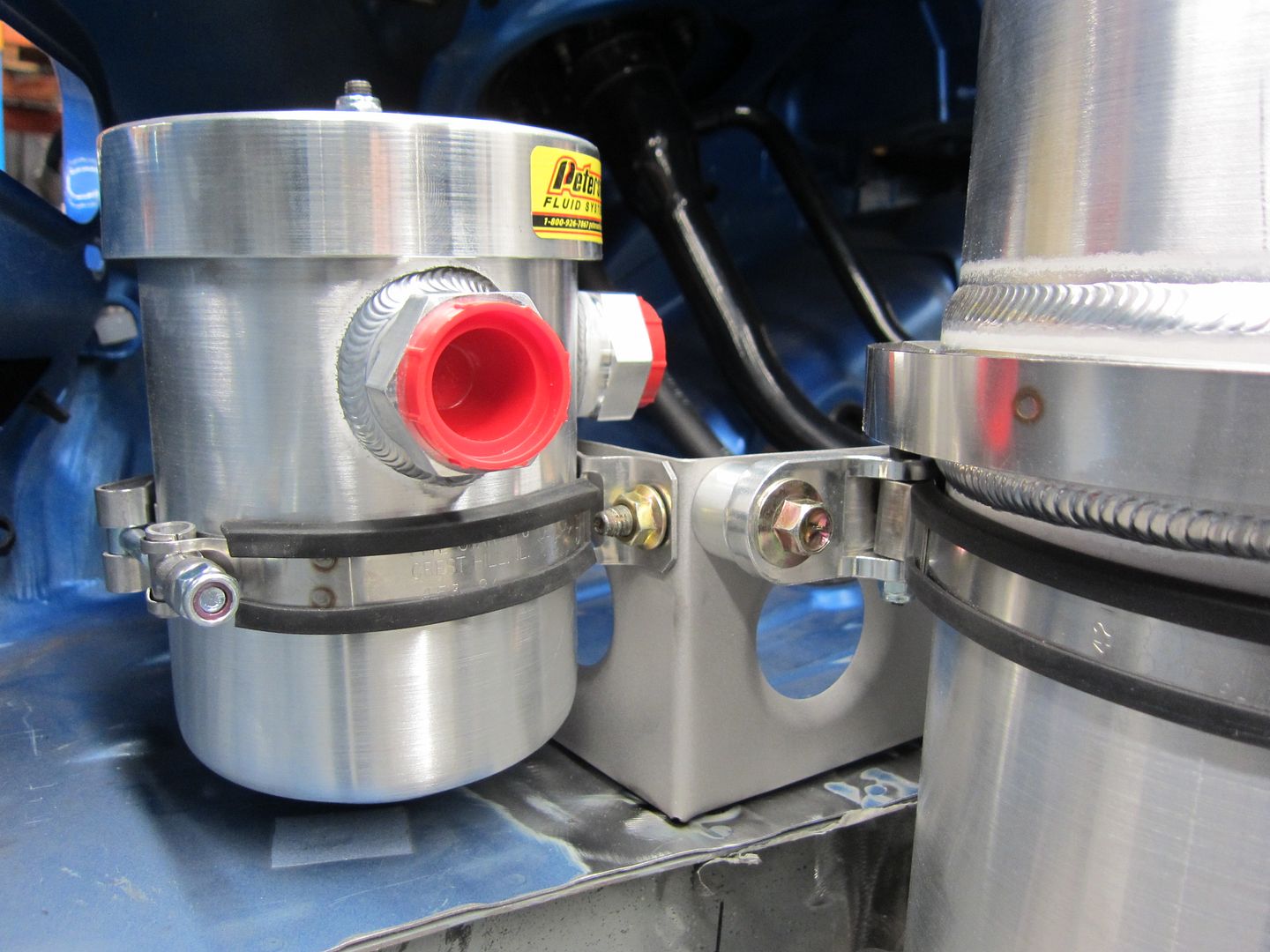

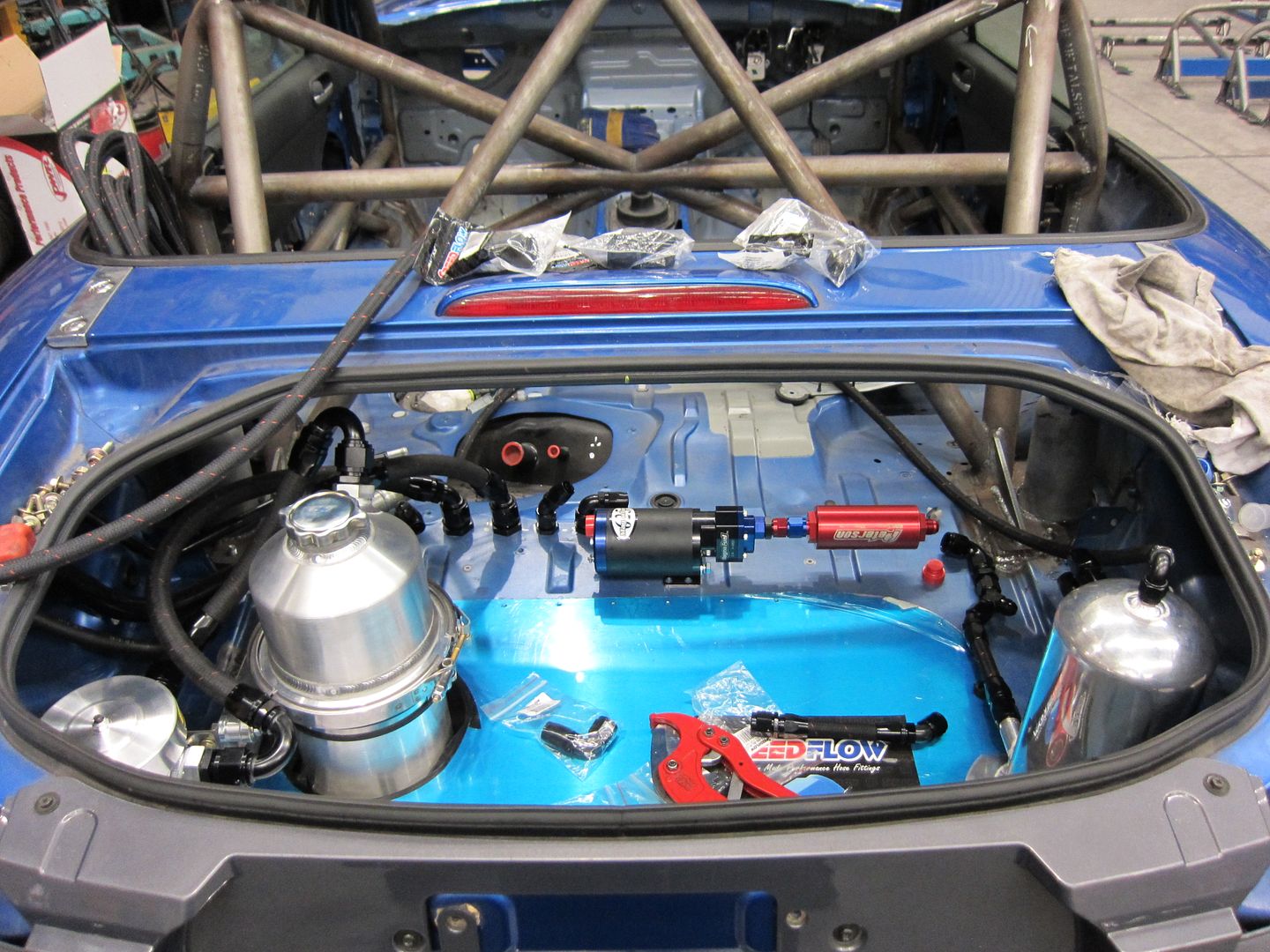

Whilst things are under control at the front end, the focus is now at the rear.

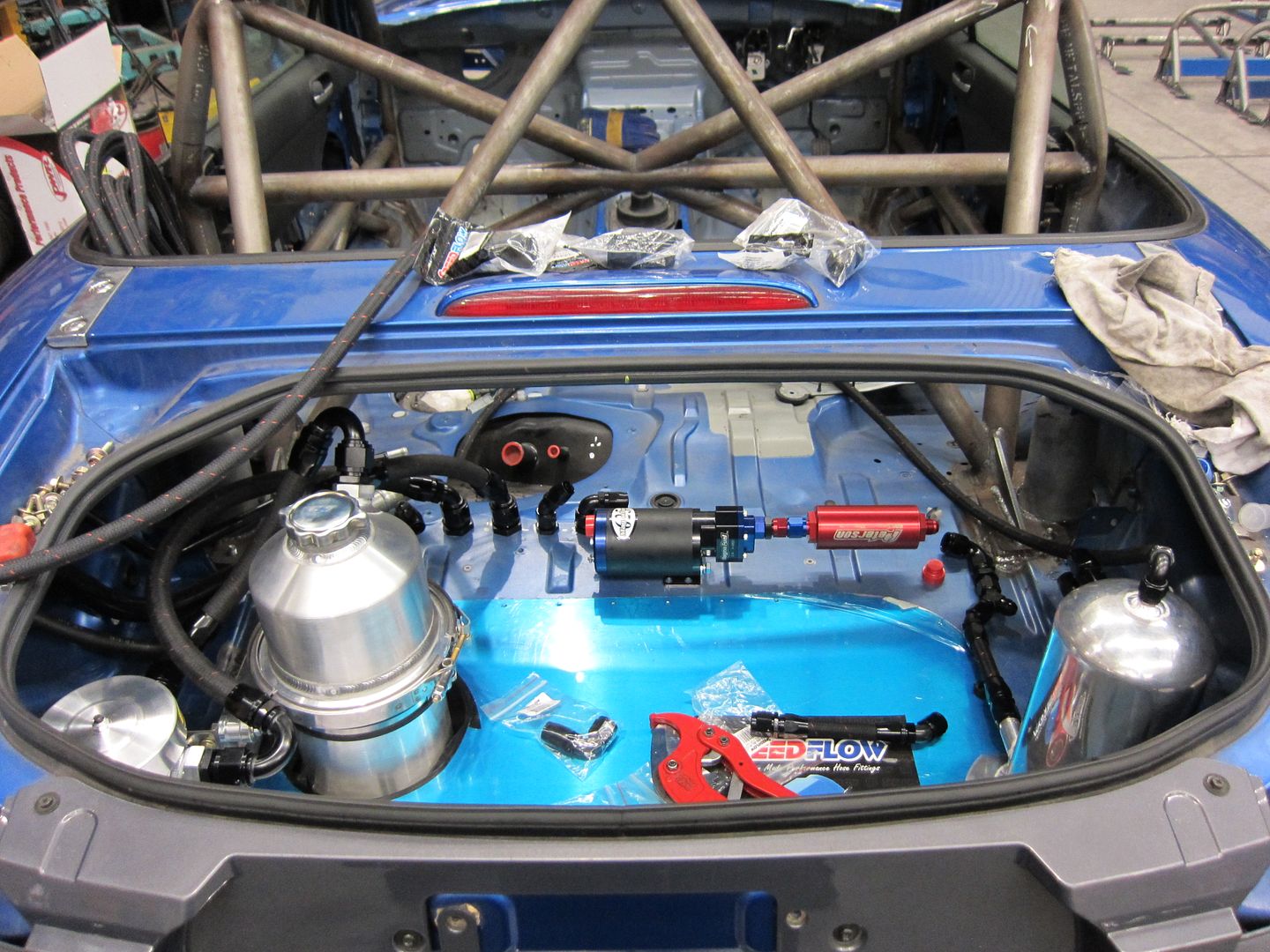

More specifically, the dry sump tank & breather, and the fuel delivery system.

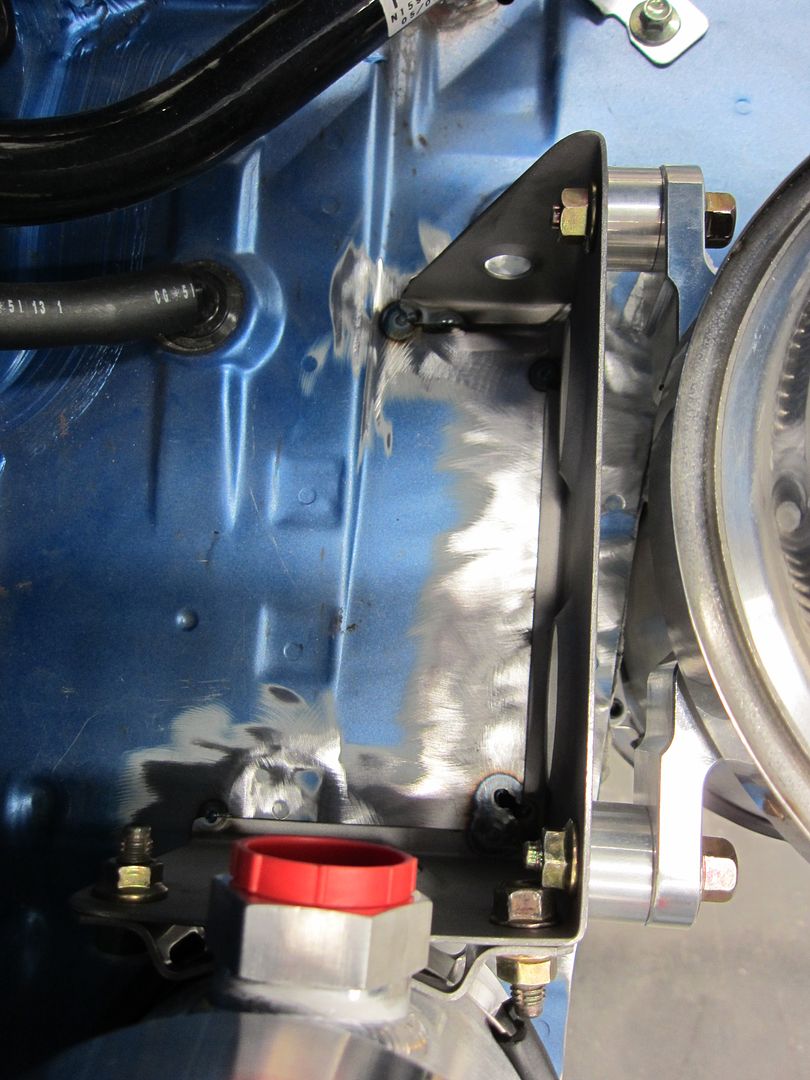

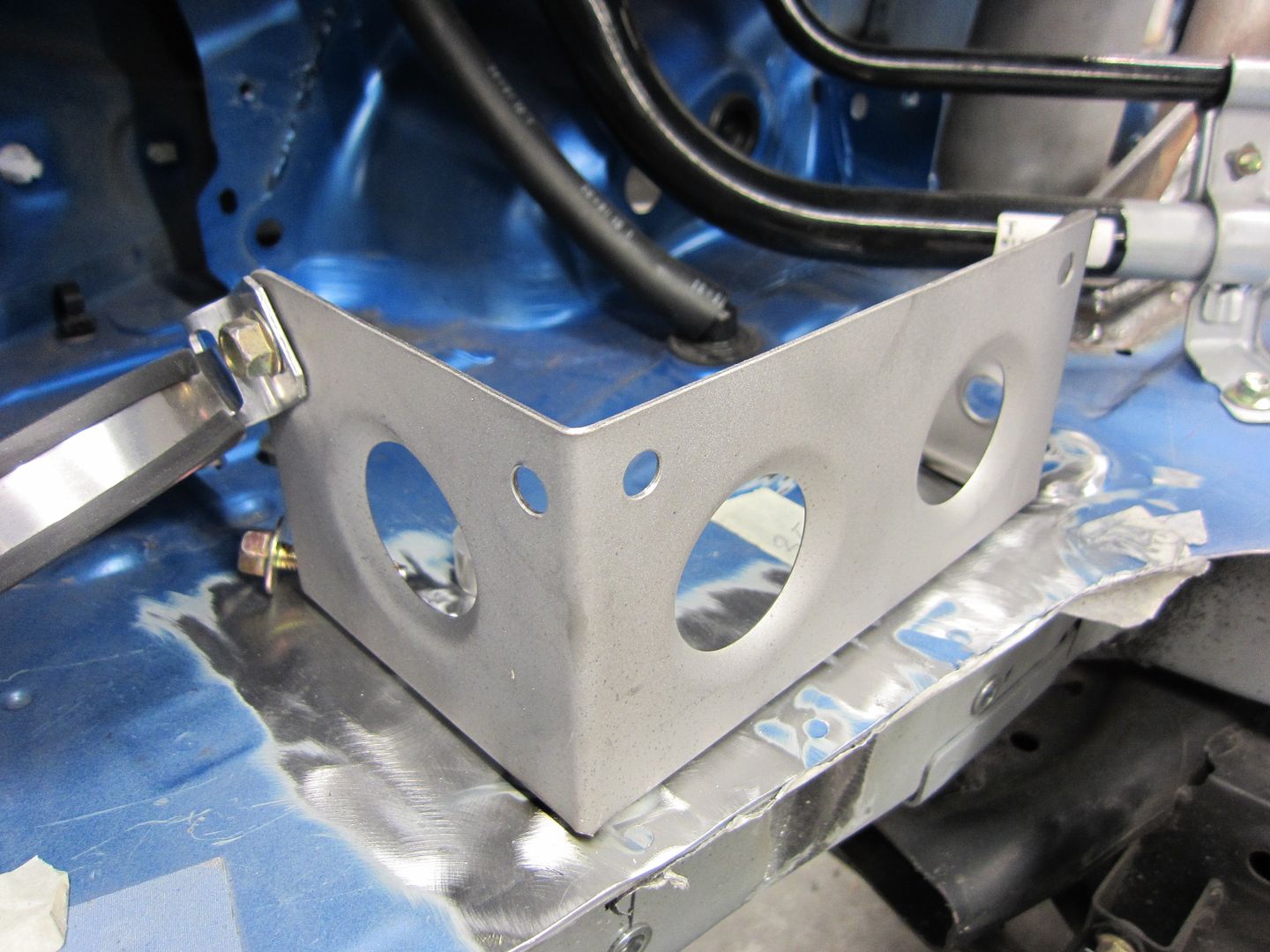

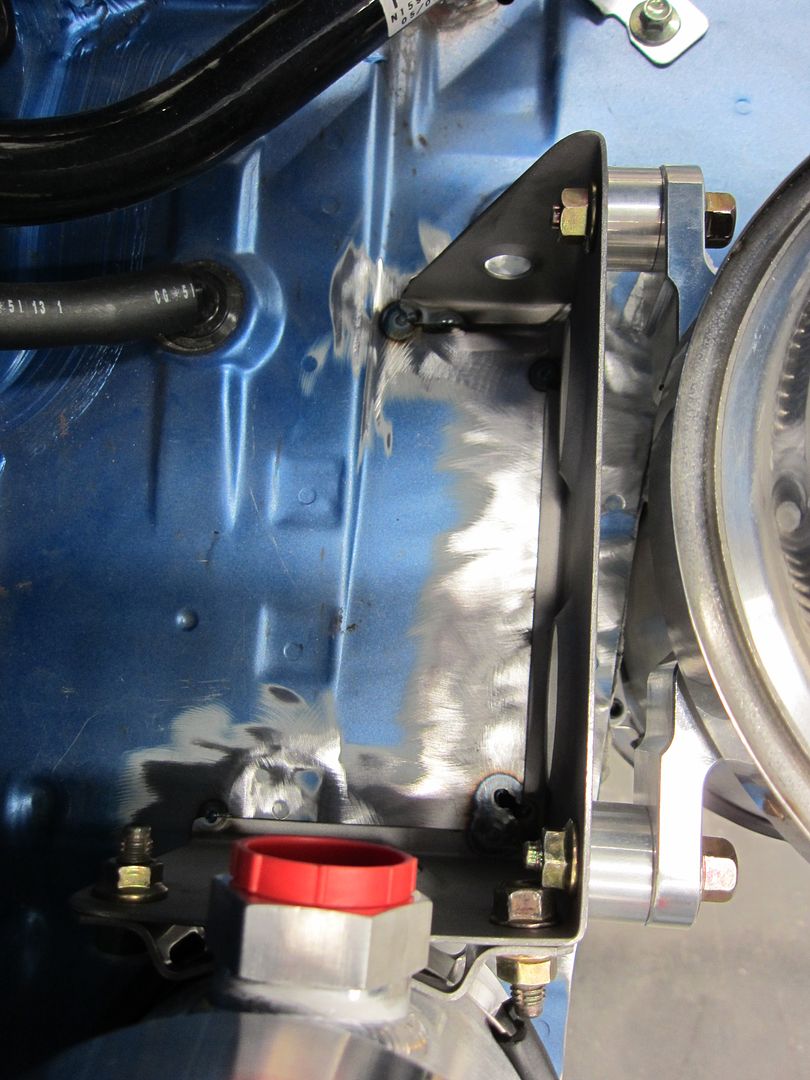

The mounting bracket....

The boot bulkhead panel in position....

A suitably sized pinchweld will seal between the dry sump tank and the bulkhead panel.

All the oil and fuel lines are utilising bulkhead fittings to get from the boot to the underbody before heading forward to the engine bay.

The following photos show the progression of the boot fit-out....

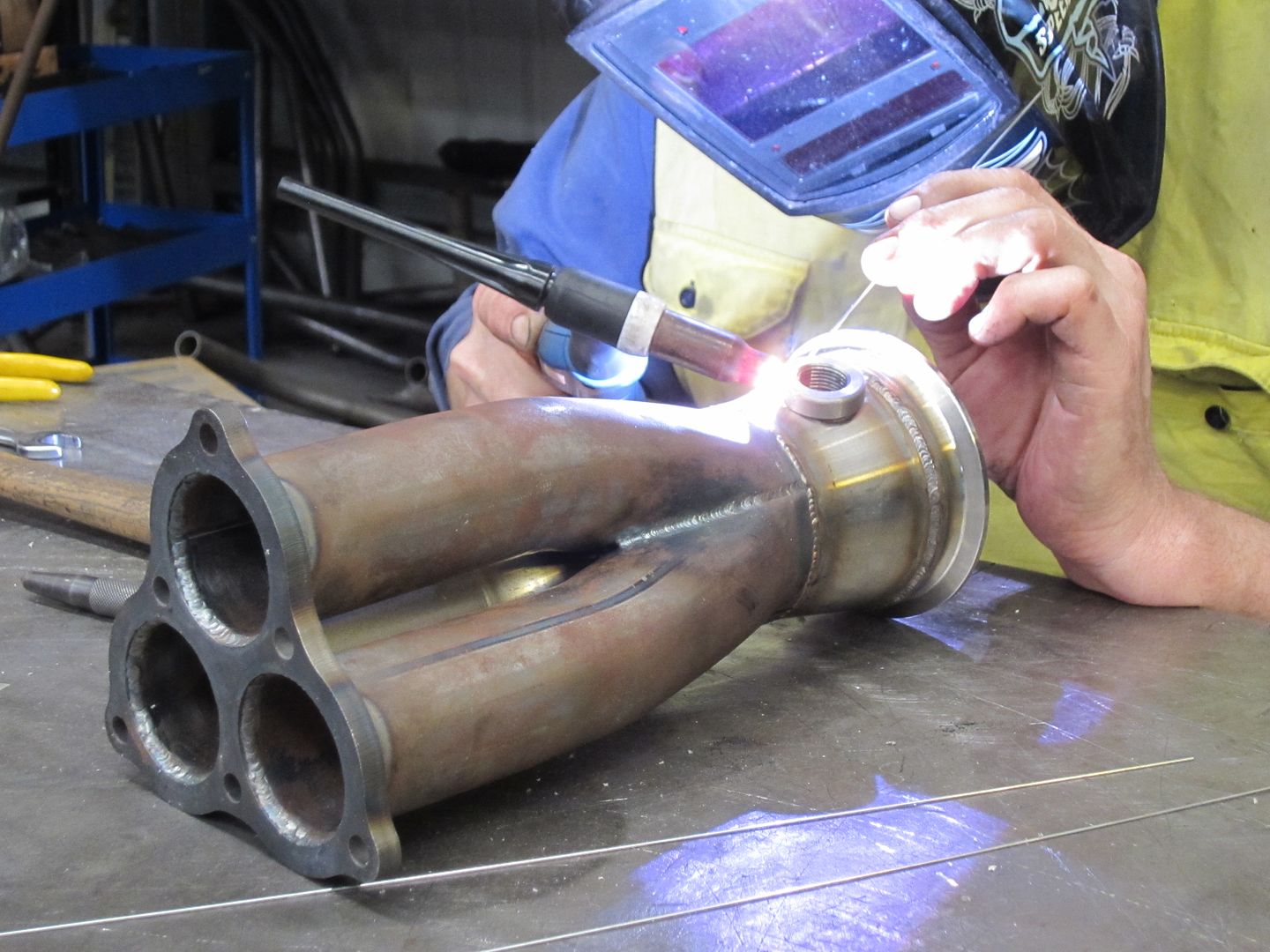

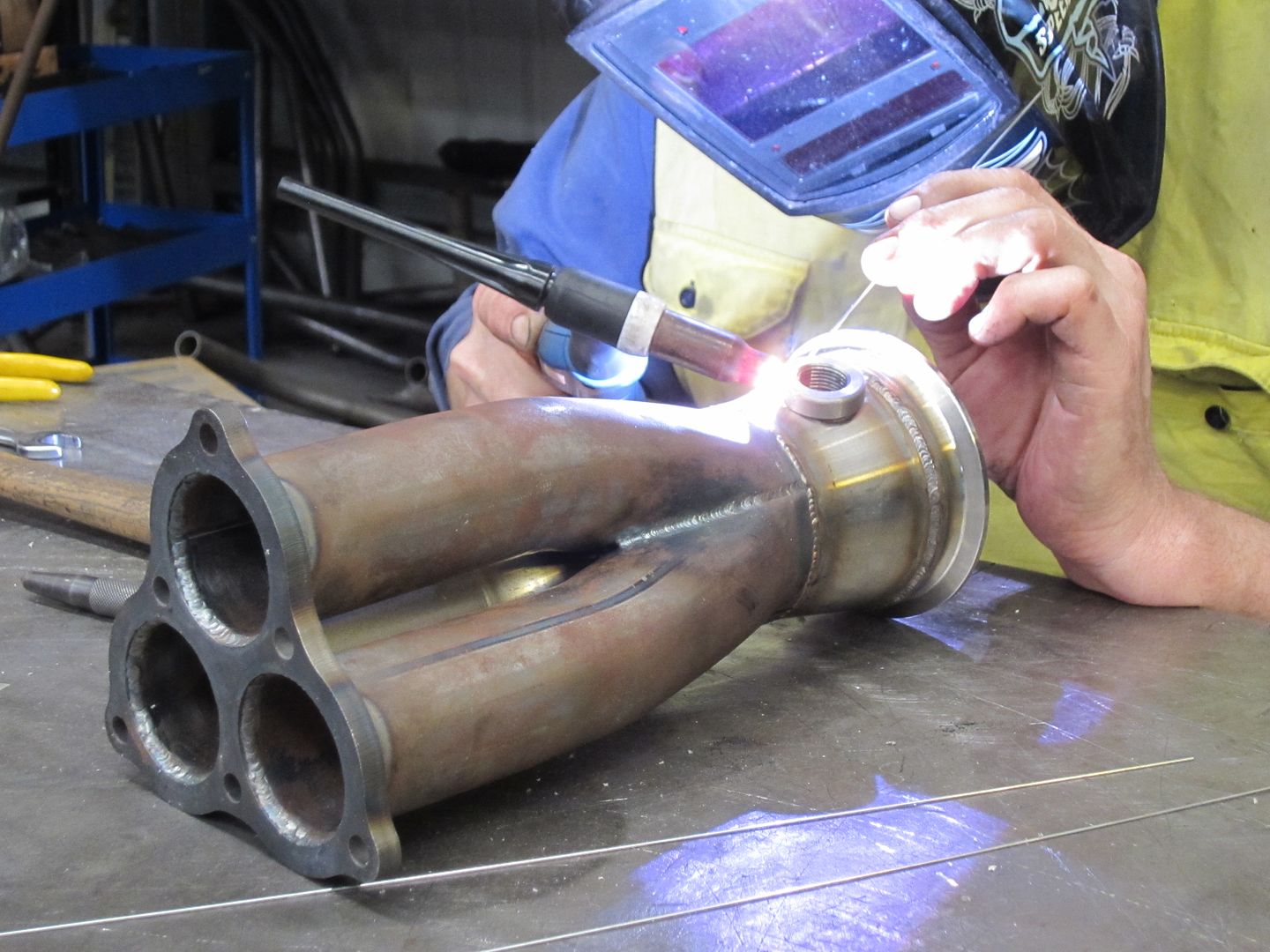

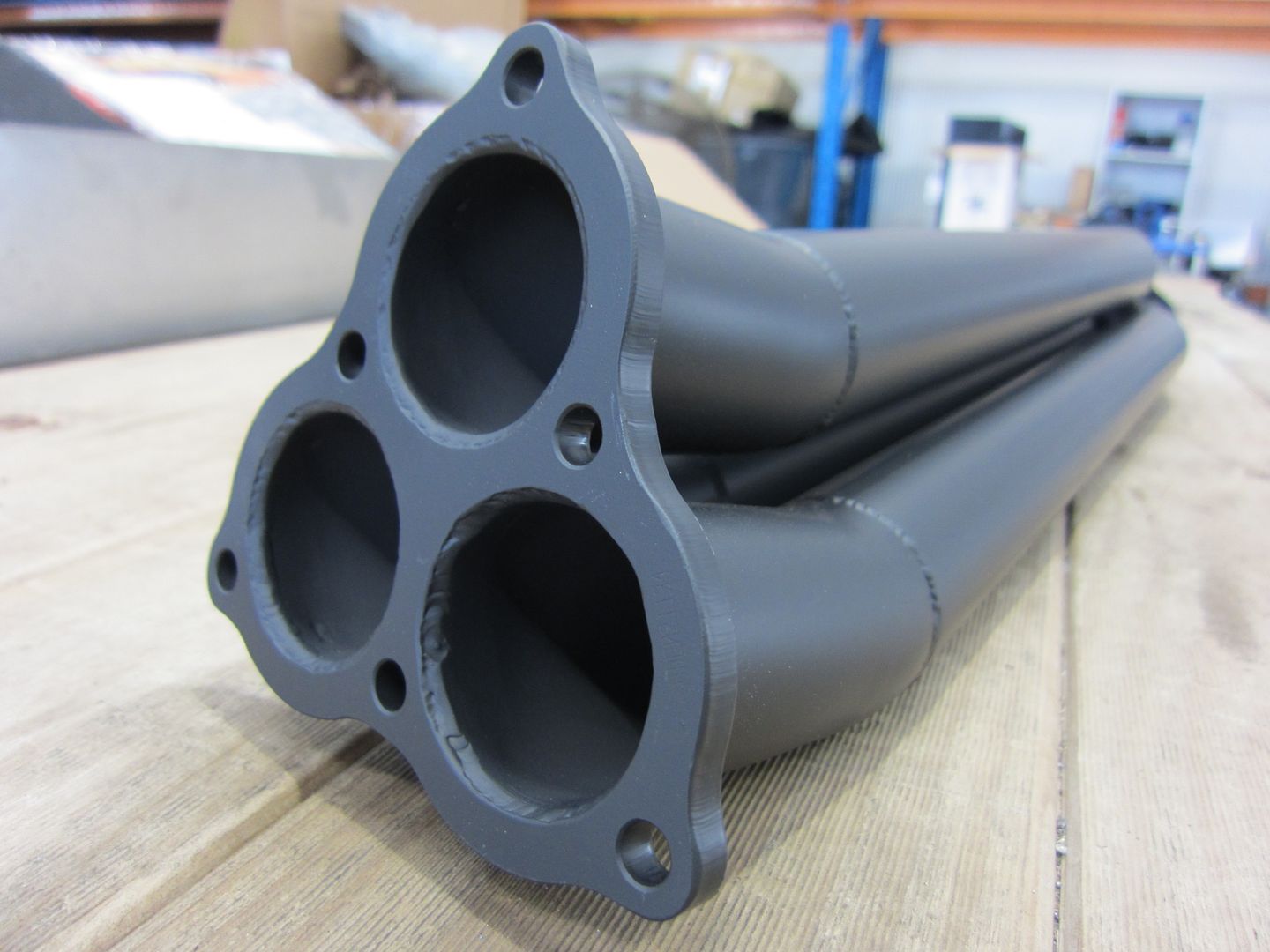

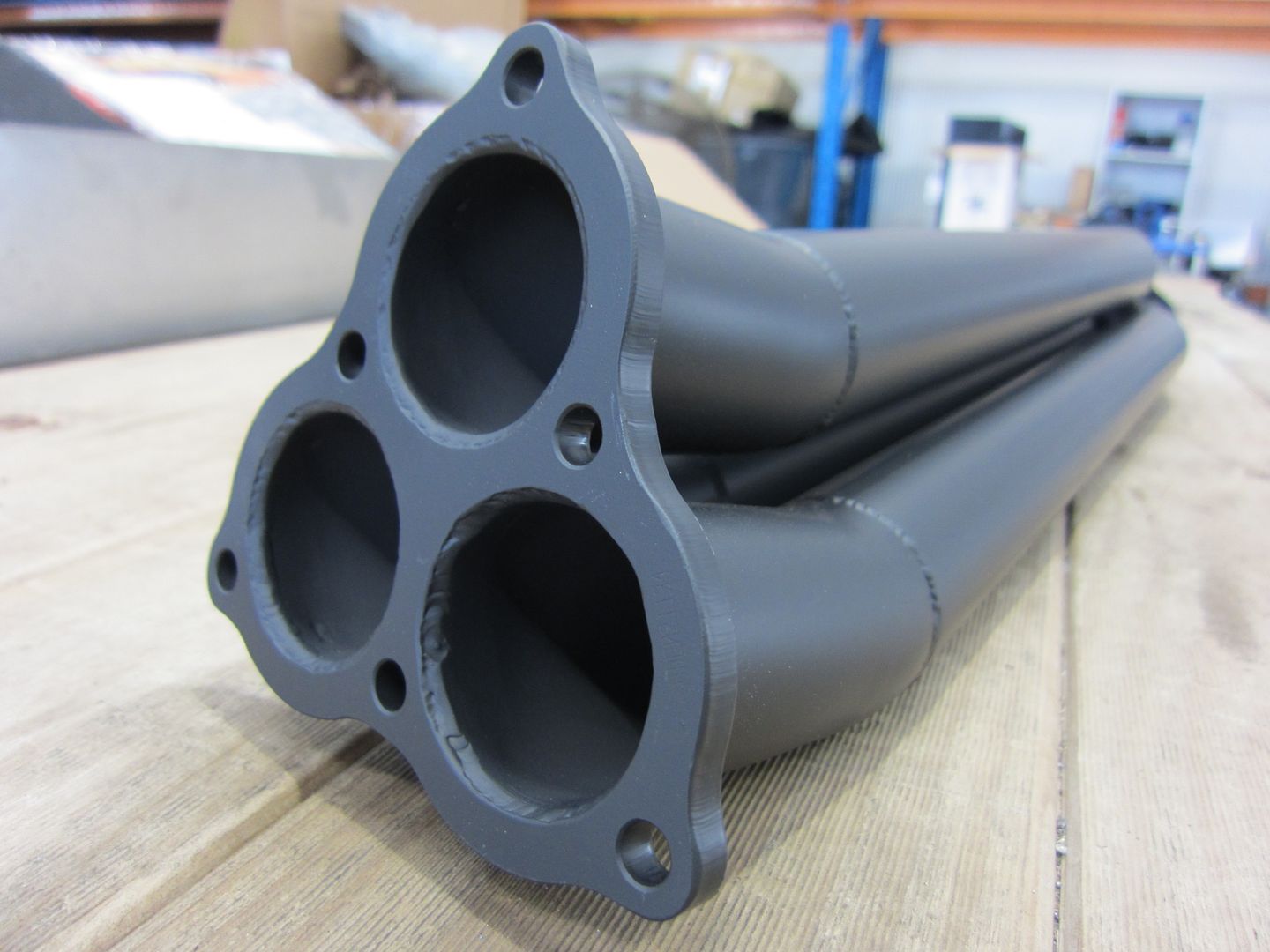

The exhaust system components that need to be ceramic coated have also been completed with the tapped bosses for the EGT's and Lamba sensors added.

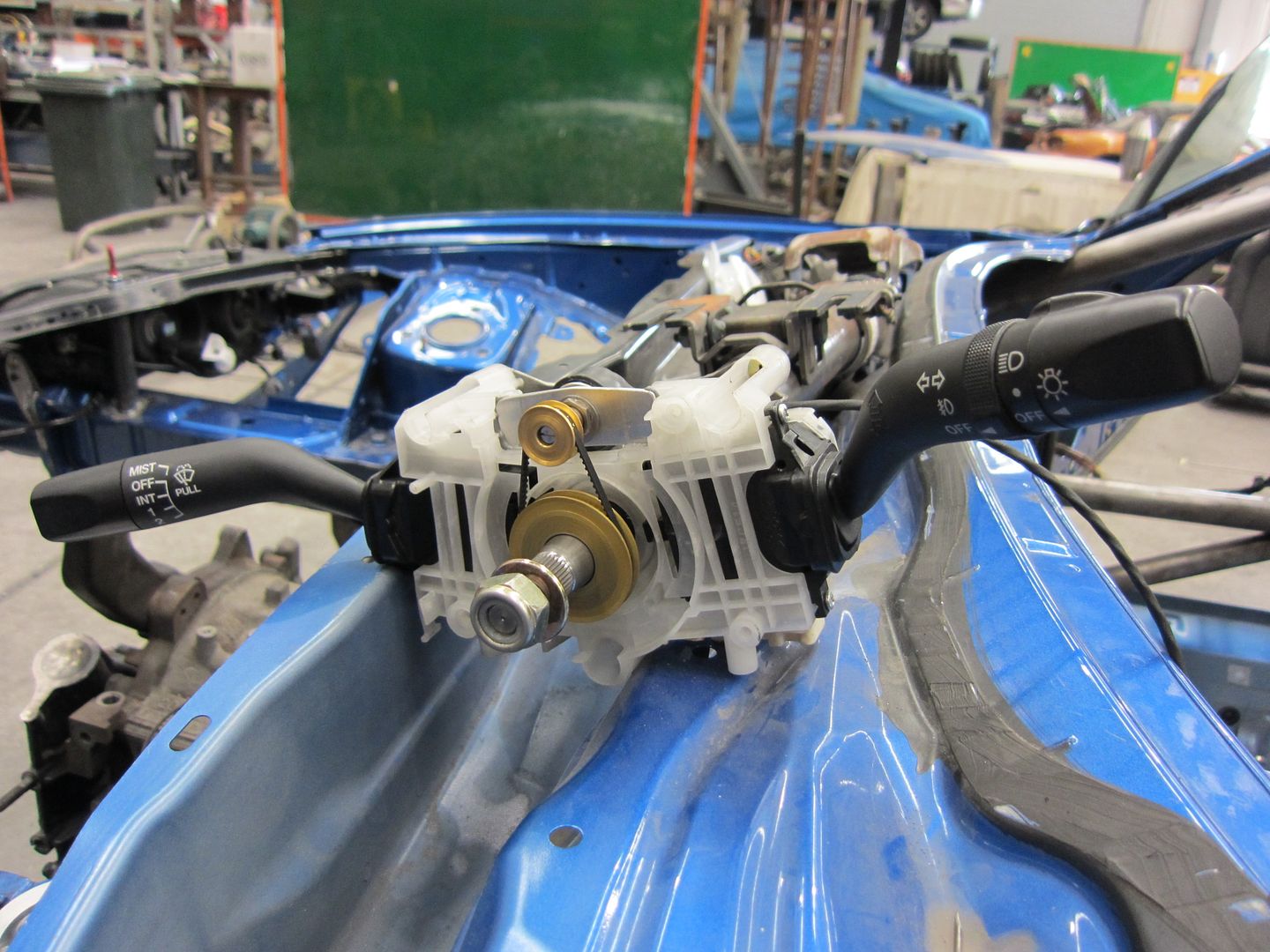

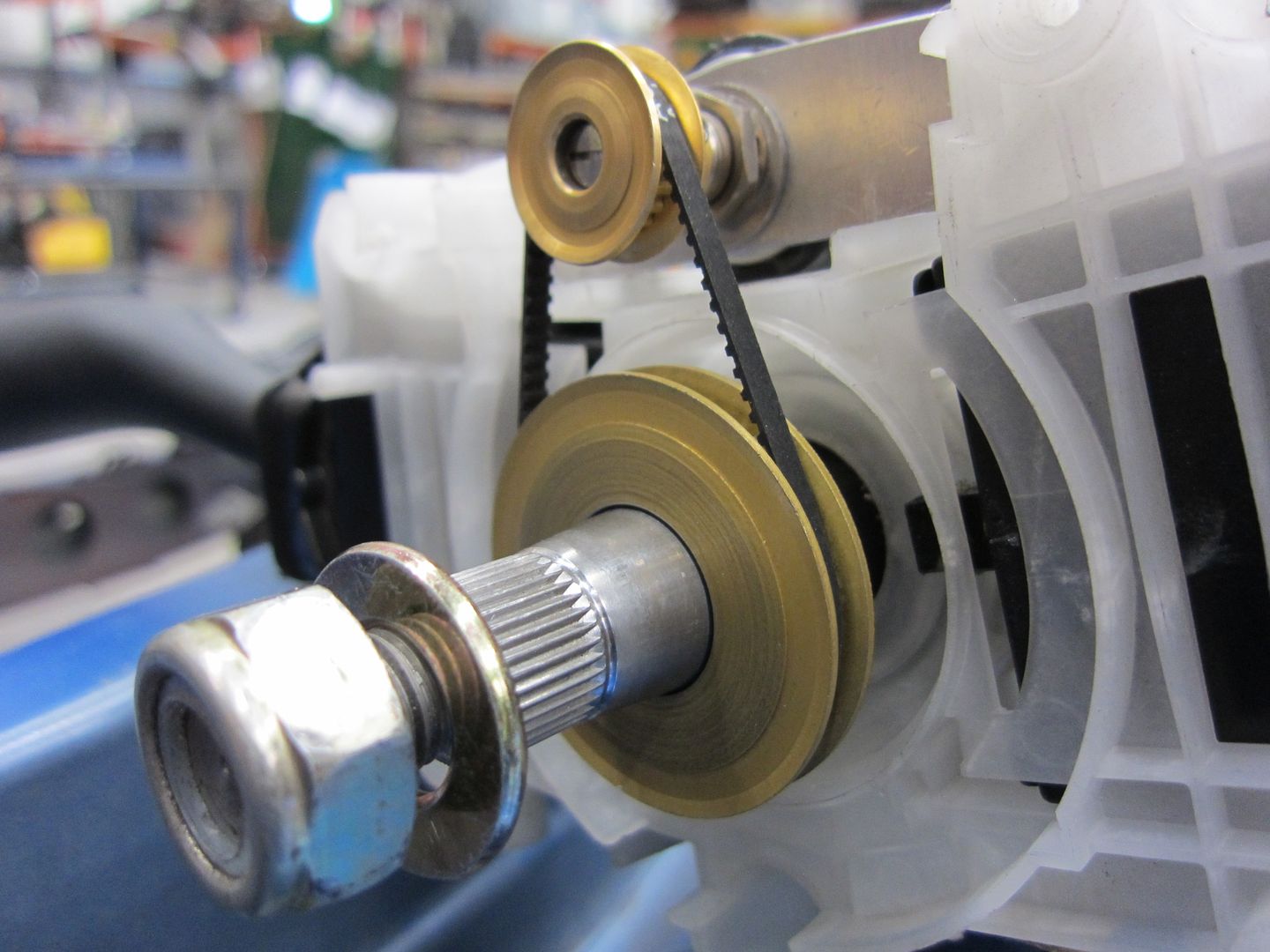

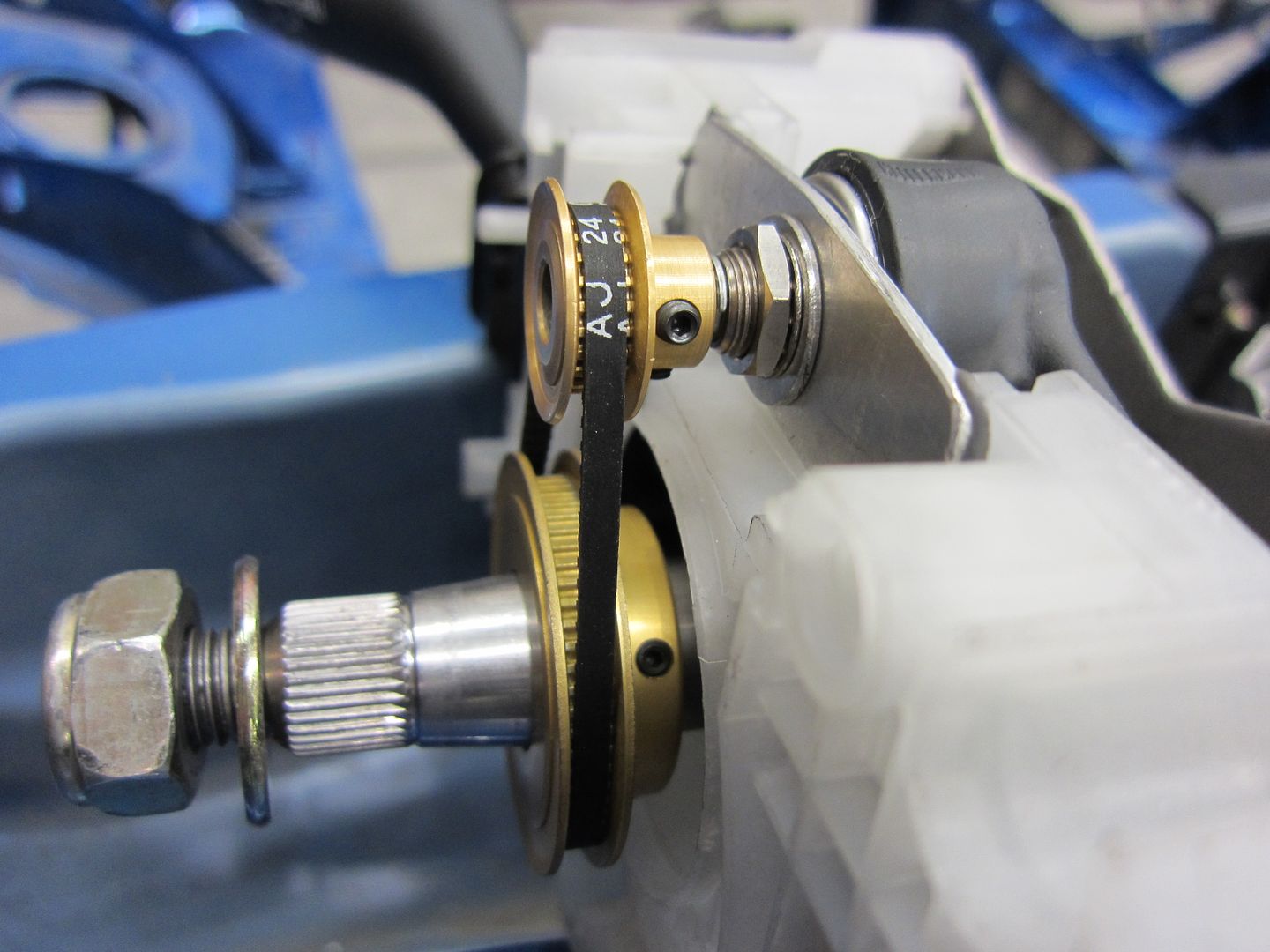

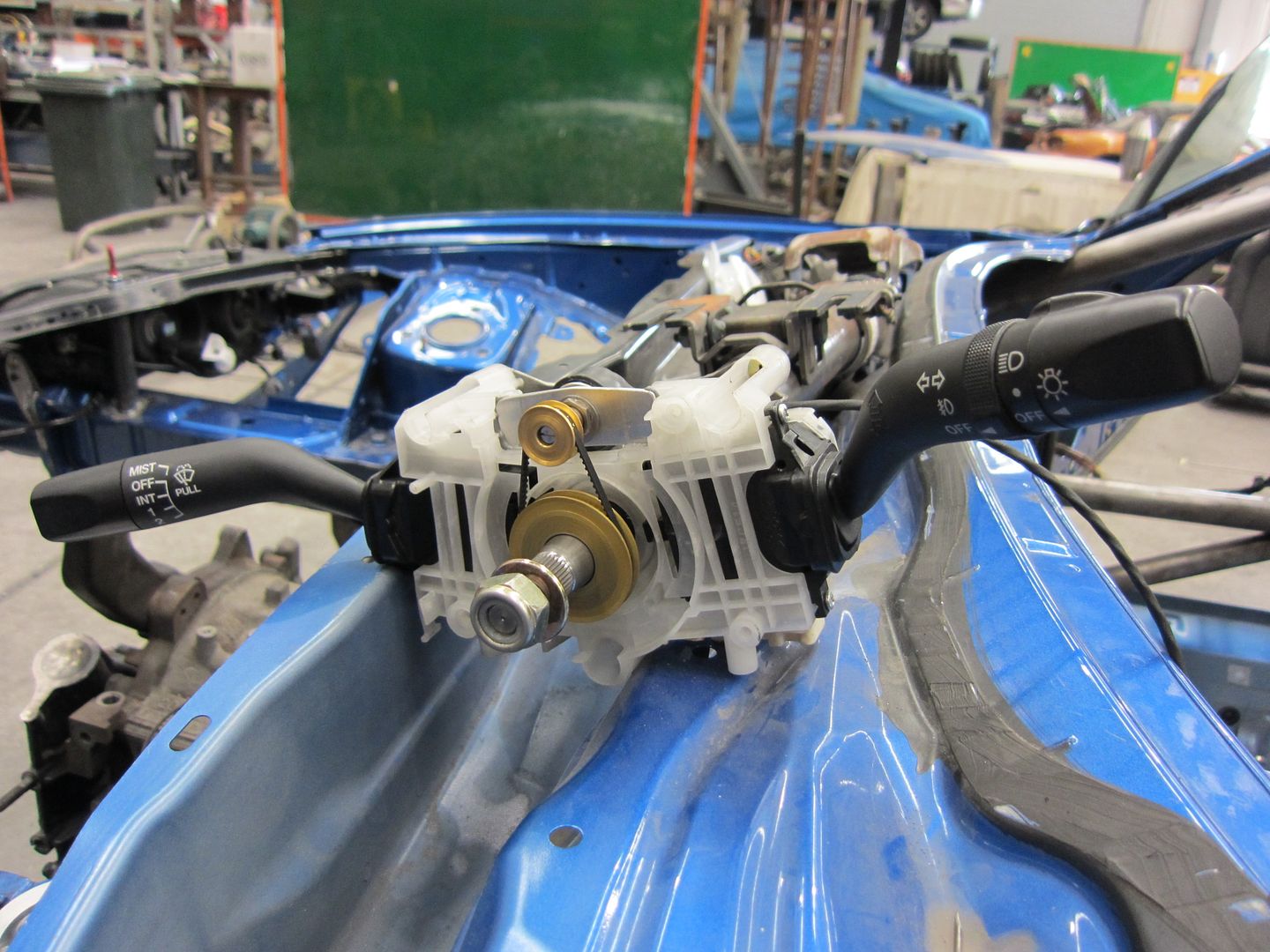

The steering angle position sensor has also been fitted.

Cheers,

Danny

More specifically, the dry sump tank & breather, and the fuel delivery system.

The mounting bracket....

The boot bulkhead panel in position....

A suitably sized pinchweld will seal between the dry sump tank and the bulkhead panel.

All the oil and fuel lines are utilising bulkhead fittings to get from the boot to the underbody before heading forward to the engine bay.

The following photos show the progression of the boot fit-out....

The exhaust system components that need to be ceramic coated have also been completed with the tapped bosses for the EGT's and Lamba sensors added.

The steering angle position sensor has also been fitted.

Cheers,

Danny

-

Magpie

- Speed Racer

- Posts: 7468

- Joined: Fri Feb 11, 2011 12:49 pm

- Vehicle: NA6

- Location: Purga, QLD

Re: NC Track Car - In the Build

Danny can you please duplicate that steering angle senor install on a certain MX5 in your workshop? Also that same MX5 could use a similar size surge tank and plate in its boot

- Okibi

- Speed Racer

- Posts: 10912

- Joined: Thu Aug 21, 2003 11:00 am

- Vehicle: NB SE

- Location: Perth, Western Australia

- Contact:

Re: NC Track Car - In the Build

Would there be any benefit to try and mount the squirl pot as close to the centre of the car as possible or is the difference so negligible it's not worth the hassle?

If you had access to a car like this, would you take it back right away? Neither would I.

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - In the Build

Okibi wrote:Would there be any benefit to try and mount the squirl pot as close to the centre of the car as possible or is the difference so negligible it's not worth the hassle?

Hi Dave, what is the benefit you're considering?

Cheers,

Danny

- NitroDann

- Forum sponsor

- Posts: 10280

- Joined: Thu Nov 05, 2009 12:10 pm

- Vehicle: NA6

- Location: Newcastle NSW

- Contact:

Re: NC Track Car - In the Build

Reduced moment of inertia.

Dann

Dann

http://www.NitroDann.com

speed wrote:If I was to do it again, I wouldn't even consider the supercharger.

- Okibi

- Speed Racer

- Posts: 10912

- Joined: Thu Aug 21, 2003 11:00 am

- Vehicle: NB SE

- Location: Perth, Western Australia

- Contact:

Re: NC Track Car - In the Build

Yeah i'm not full bottle in the physics of it all, and I know the entire car is experiencing G forces but I was thinking if the bottle is closer to the centre of rotation when the car gets loose then the amount of force might be reduced slightly. You're the engineer so humour/educate me.

If you had access to a car like this, would you take it back right away? Neither would I.

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - In the Build

NitroDann wrote:Reduced moment of inertia.

Dann

Moving it to the the middle of the boot from where it is now won't reduce the moment of inertia as the change in distance from the vehicle's centre of inertia is quite small and more so, the surge tank full of fuel would only weigh around 2kg (less than 0.2% of the vehicle mass)....plus I don't want to have it right above the rear muffler (even though there will be a heat shield) and I don't want it in the cab with me!

Cheers,

Danny

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - In the Build

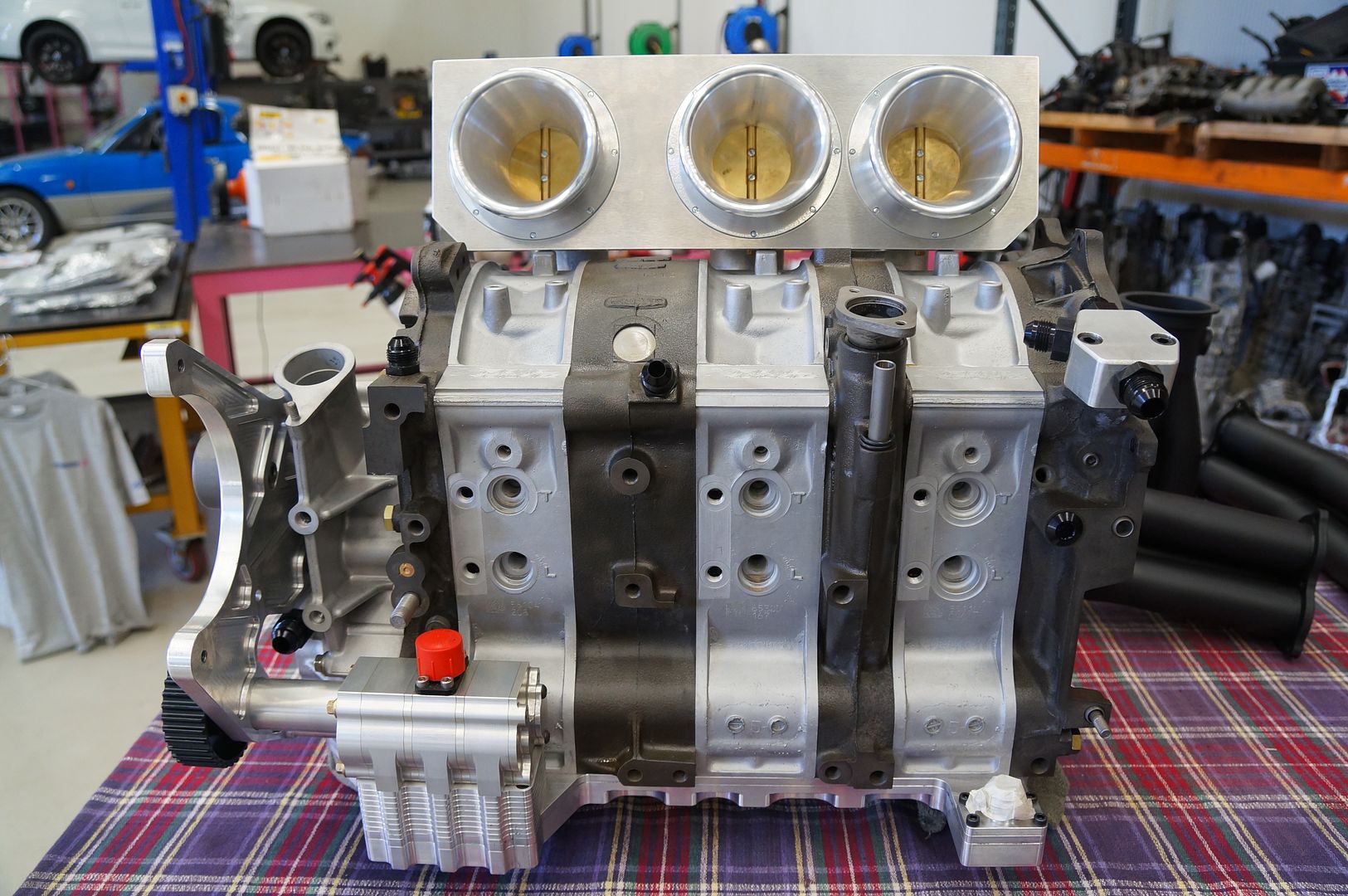

As some of you were aware Automotive Plus had their annual open day a couple of weeks ago. On the Thursday before the rotor housings and side plates returned from Xtreme Rotaries after having all machining and surface treatment work finished. For display purposes I through the inlet manifold and freshly ceramic coated exhaust back on.  Once the rotating assembly is finished I'll dismantle the "display engine" and take detailed photos of the finished machining and surface treatments.

Once the rotating assembly is finished I'll dismantle the "display engine" and take detailed photos of the finished machining and surface treatments.

The chassis got a bit of TLC as well.

I'm very happy with the ceramic coating of the exhaust system. This was undertaken by Hi-Octane Coatings in Sydney.

The next major item on the project list is the electricals....all of it!

Cheers,

Danny

The chassis got a bit of TLC as well.

I'm very happy with the ceramic coating of the exhaust system. This was undertaken by Hi-Octane Coatings in Sydney.

The next major item on the project list is the electricals....all of it!

Cheers,

Danny

- Okibi

- Speed Racer

- Posts: 10912

- Joined: Thu Aug 21, 2003 11:00 am

- Vehicle: NB SE

- Location: Perth, Western Australia

- Contact:

Re: NC Track Car - In the Build

Still in awe

If you had access to a car like this, would you take it back right away? Neither would I.

- zero00

- Speed Racer

- Posts: 3248

- Joined: Mon Apr 12, 2010 6:54 pm

- Vehicle: NB8A

- Location: Sunshine Coast Queensland

Re: NC Track Car - In the Build

Me too Okibi, I don't understand most of it but I love looking at it every time I'm in there - see you Tuesday Danny as the NB is in for pre-track day 'attention'

Roger D-SUNSHINE COAST

2000 NB8A-LP 69.1248|QR Clubman 71.9235|QR Sprint 68.1412

1989 NA6 B-SPEC #77|Toyota GTS86 MT

2000 NB8A-LP 69.1248|QR Clubman 71.9235|QR Sprint 68.1412

1989 NA6 B-SPEC #77|Toyota GTS86 MT

- Old Dude

- Racing Driver

- Posts: 1166

- Joined: Tue Apr 07, 2009 8:06 pm

- Vehicle: NB8B

- Location: Gold Coast

Re: NC Track Car - In the Build

Cant wait to see this up and running and all painted. Love your work Danny

Cheers

Dale

Cheers

Dale

"Everybody dies......, but not everybody lives" ;-)

MX 5 2001 Grace Green

NB8B

MX 5 2001 Grace Green

NB8B

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - In the Build

zero00 wrote:Me too Okibi, I don't understand most of it but I love looking at it every time I'm in there - see you Tuesday Danny as the NB is in for pre-track day 'attention'

Hi Roger, I won't catch you in the morning as I got an appointment off site first up. Might see you in the afternoon.

Old Dude wrote:Cant wait to see this up and running and all painted. Love your work Danny

Cheers

Dale

Me too!

Cheers,

Danny

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - In the Build

Actual work on the car has slowed down in the last few weeks...that's not saying that nothing is happening at all. As previously mentioned, the engines rotating assembly is away being balanced. I hope to have it back this week so that assembly can begin either late next week or early the week after.

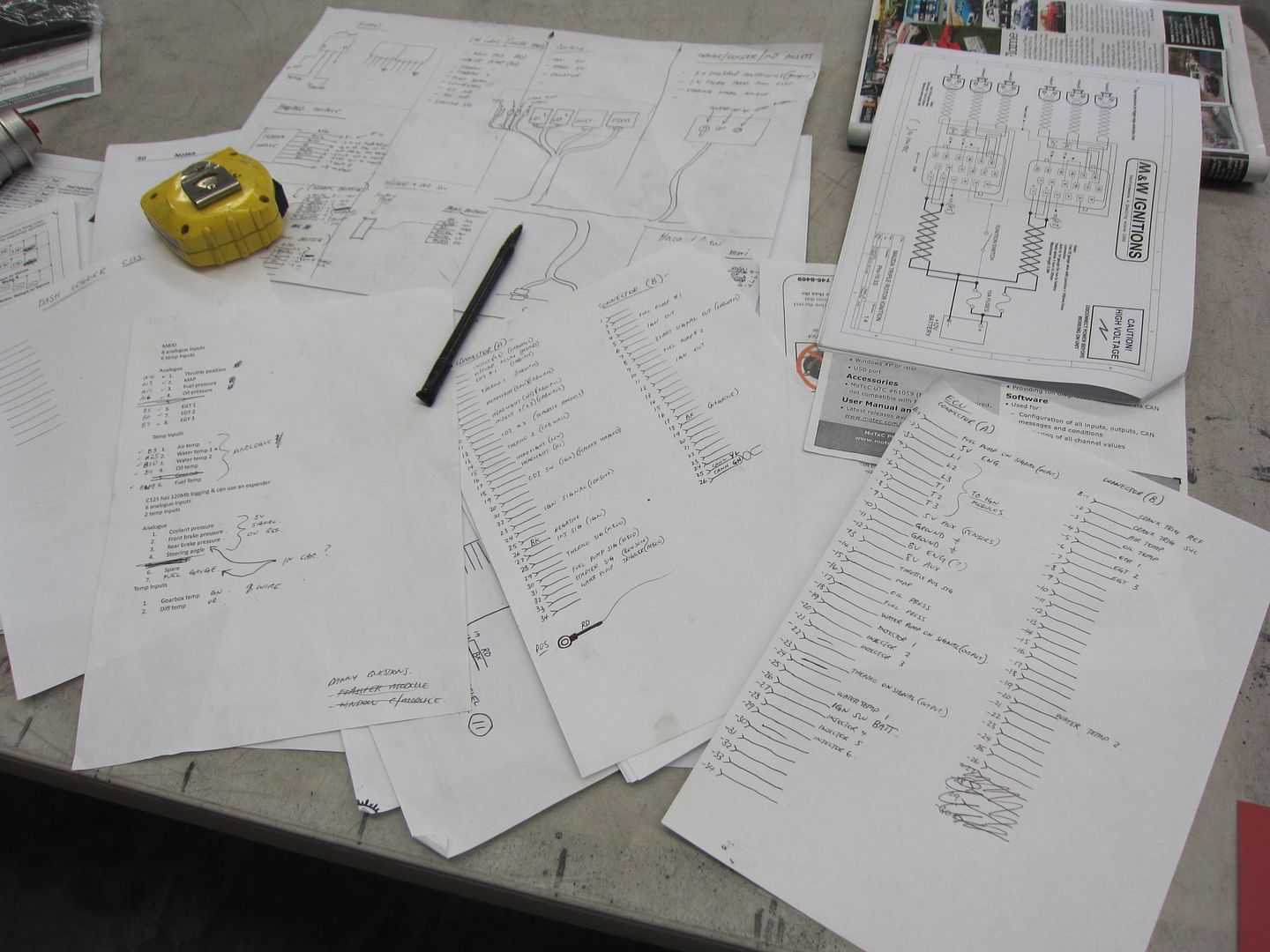

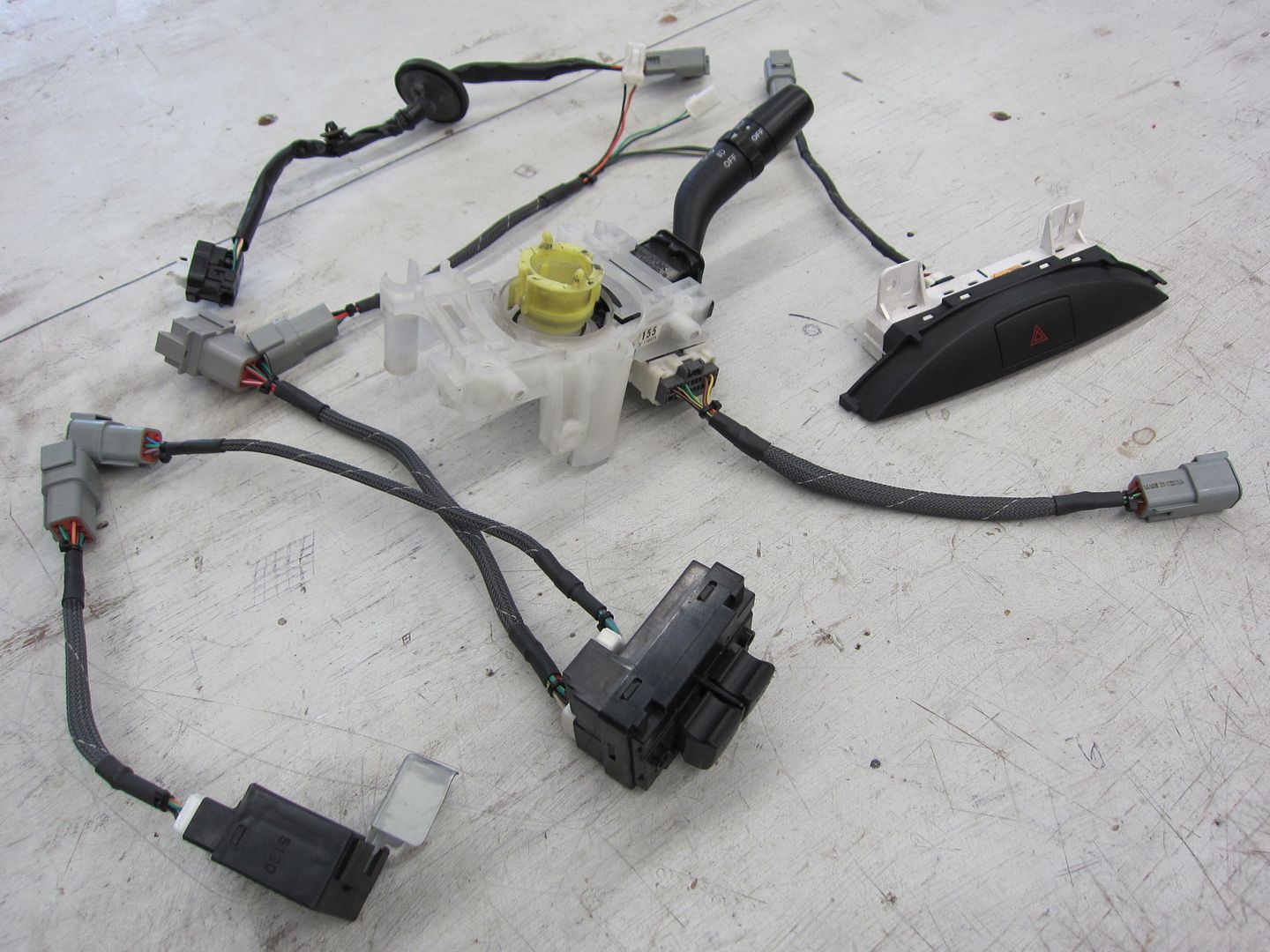

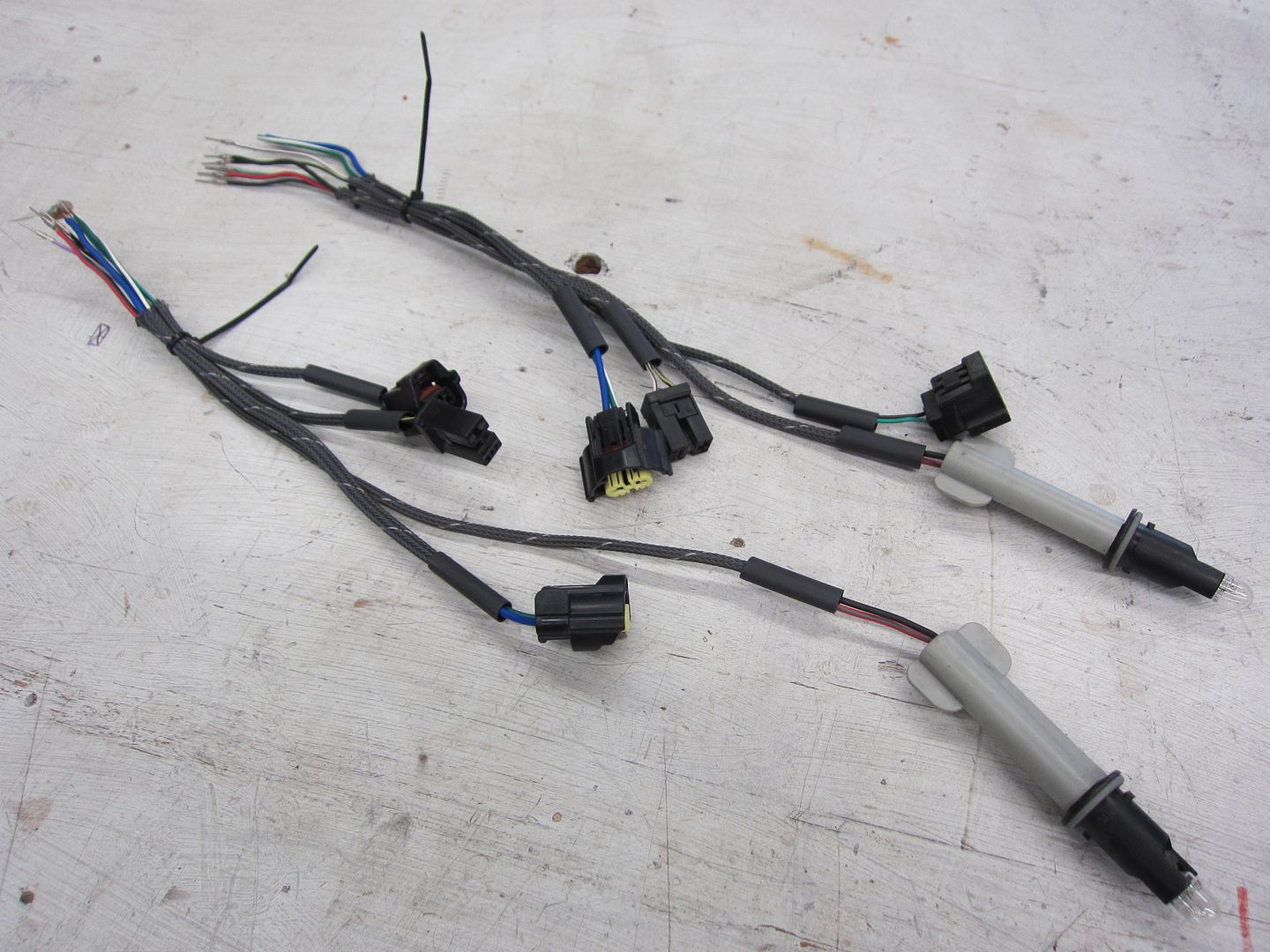

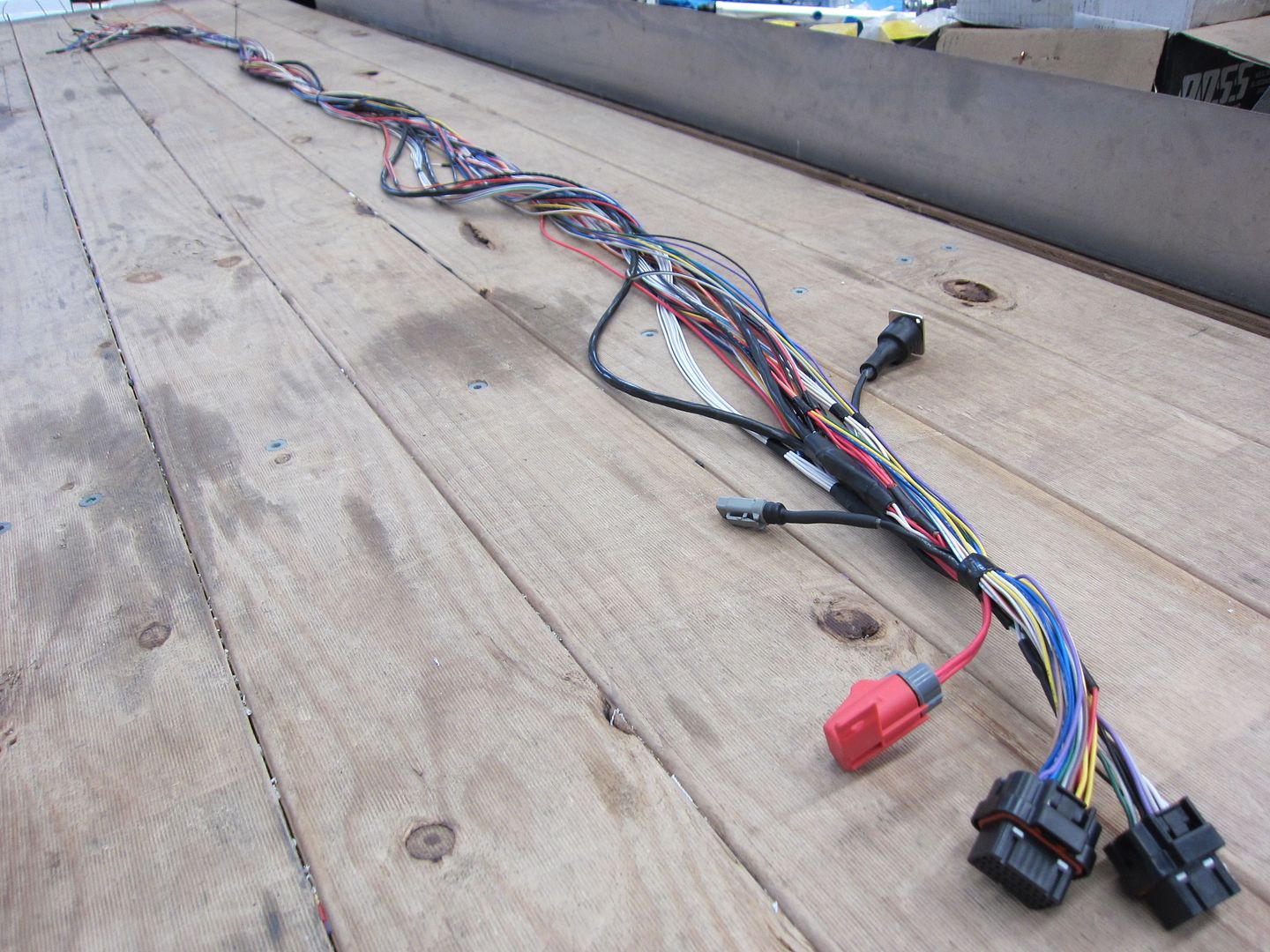

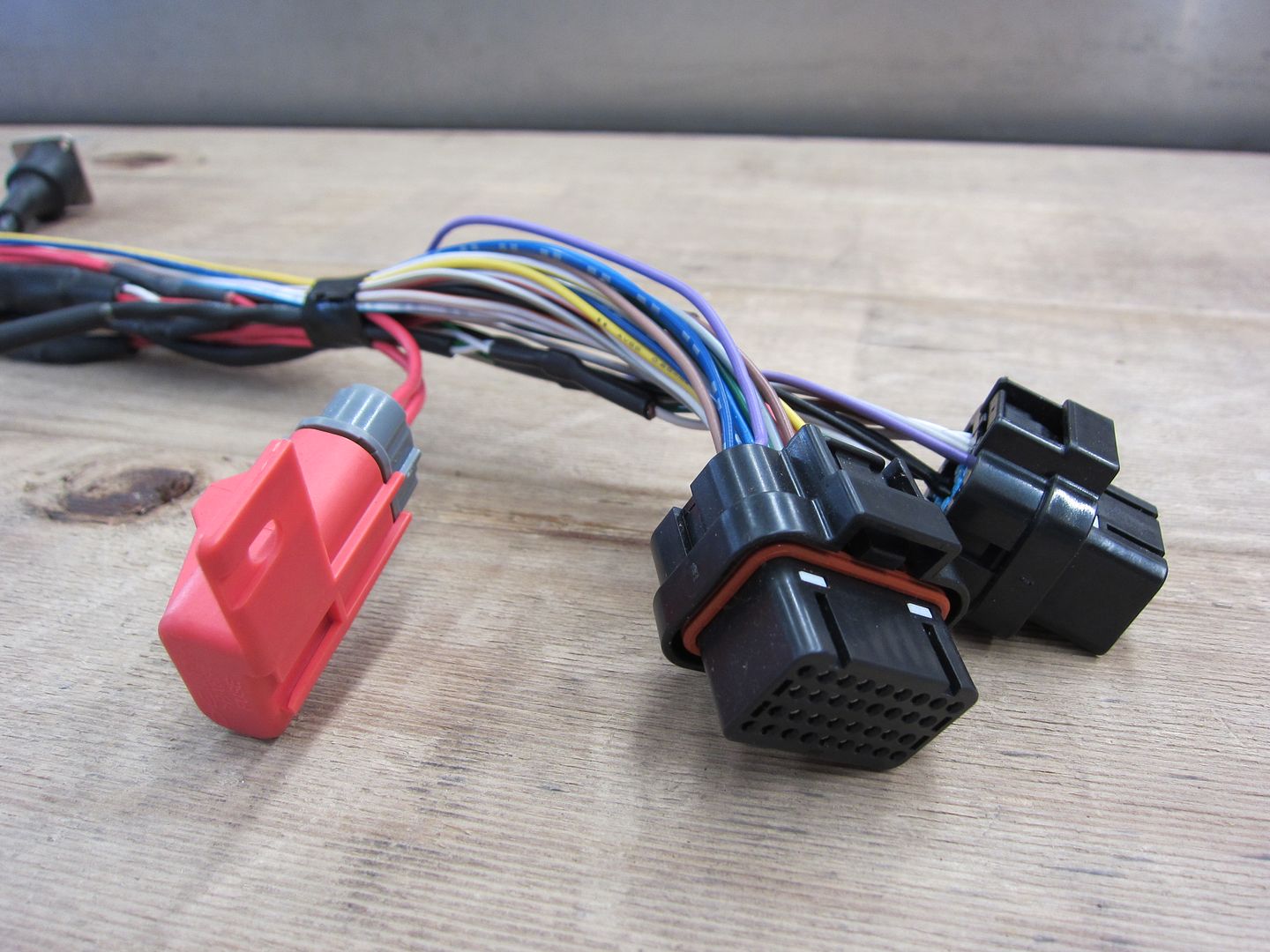

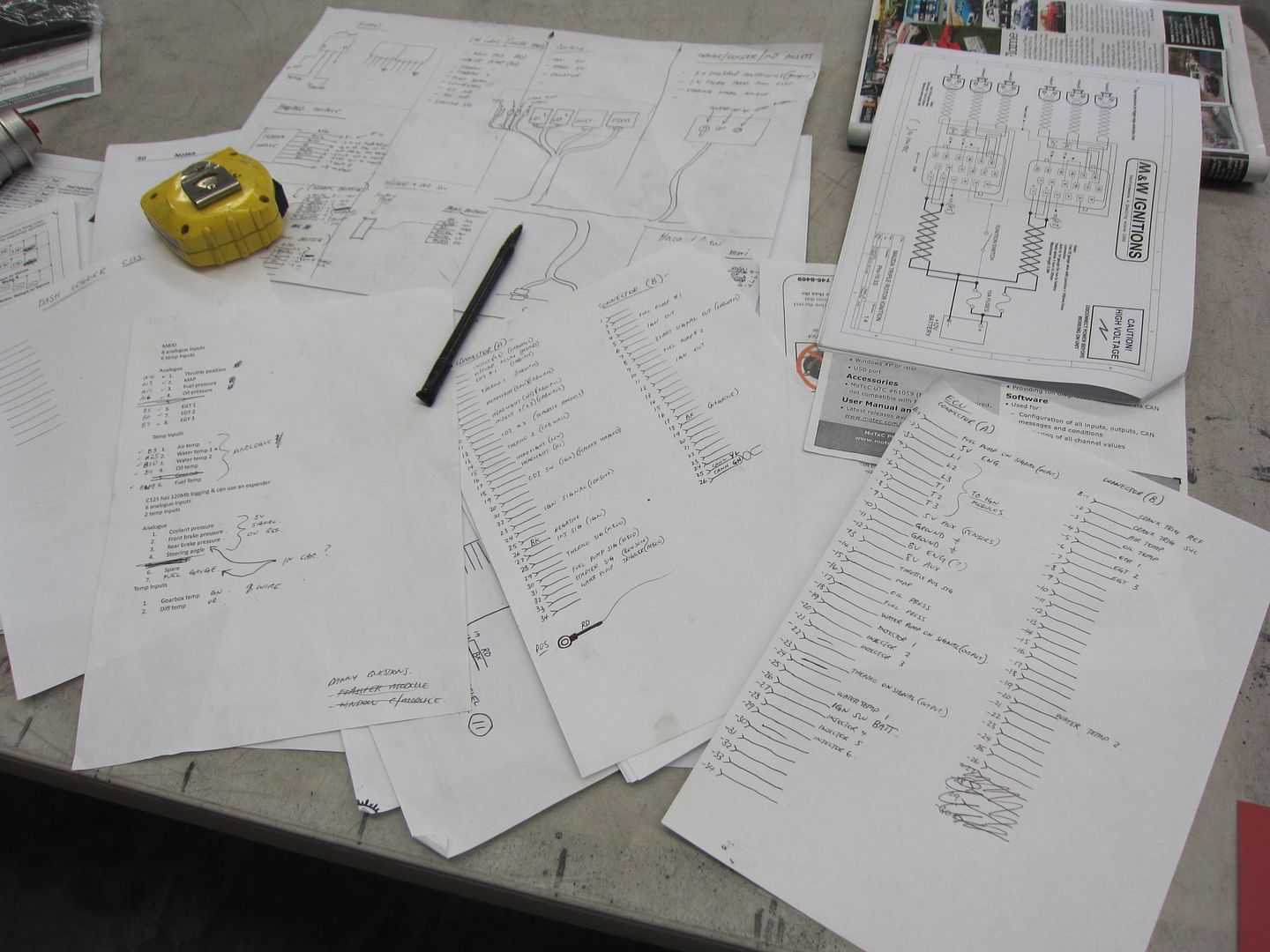

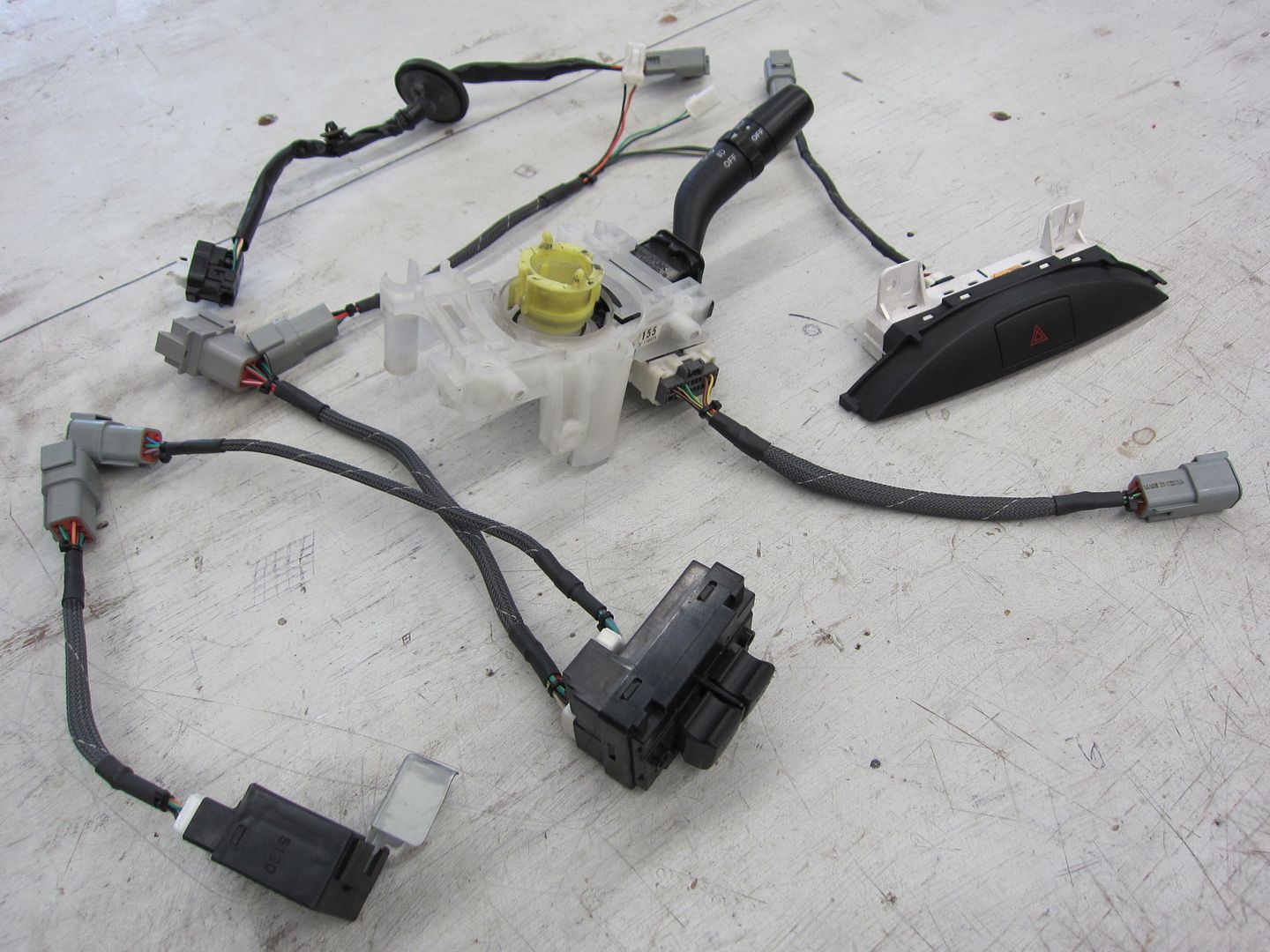

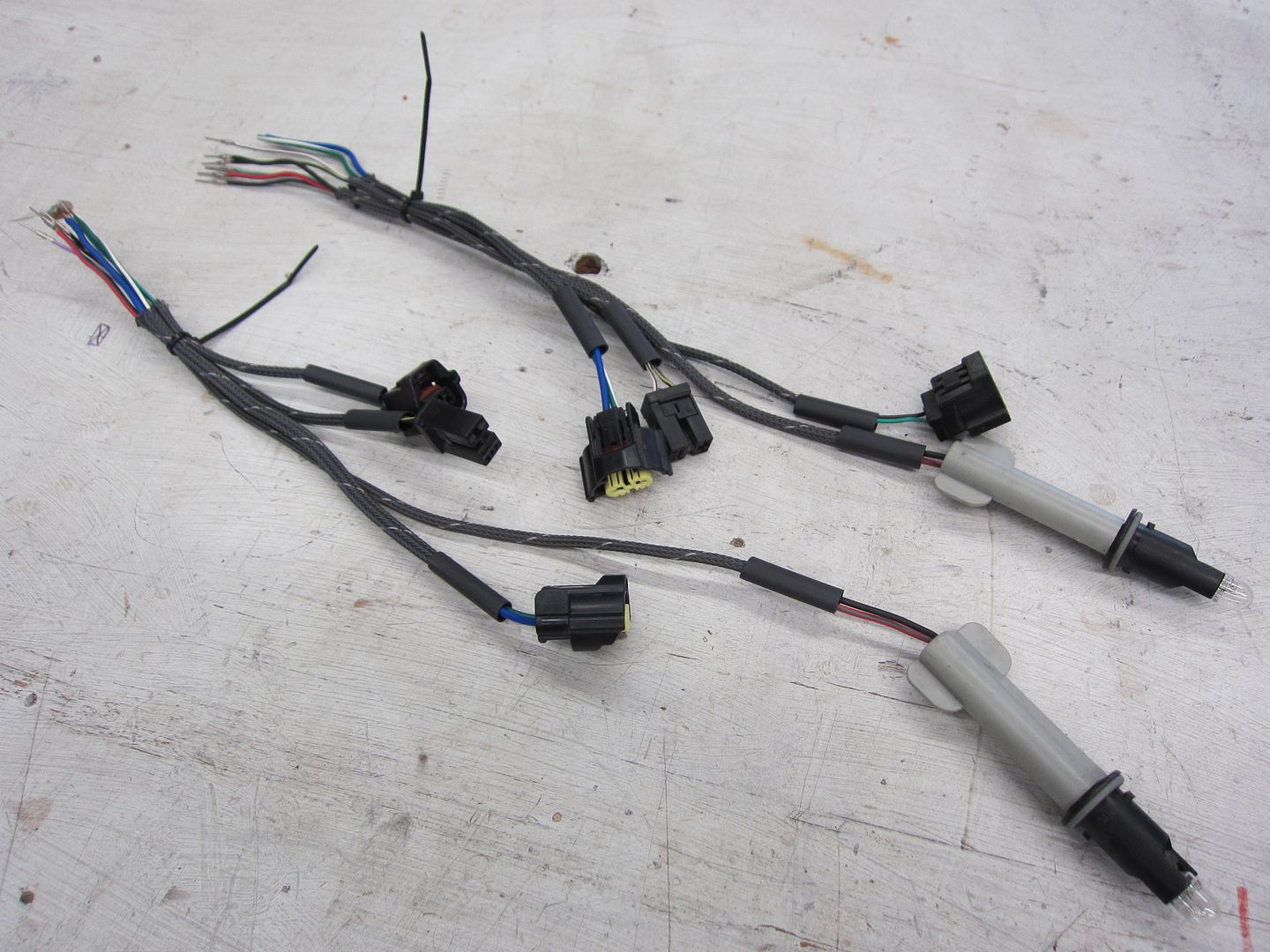

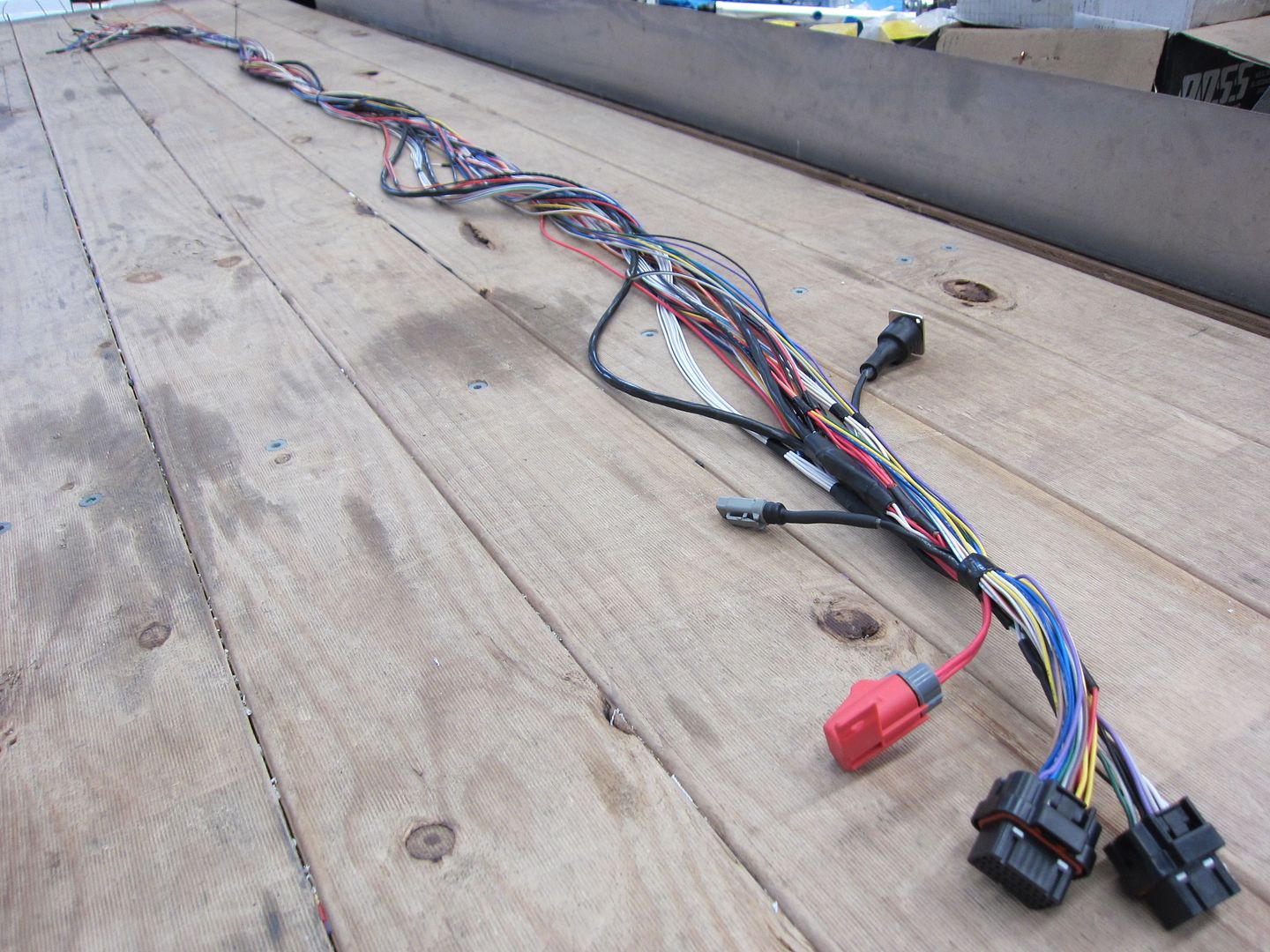

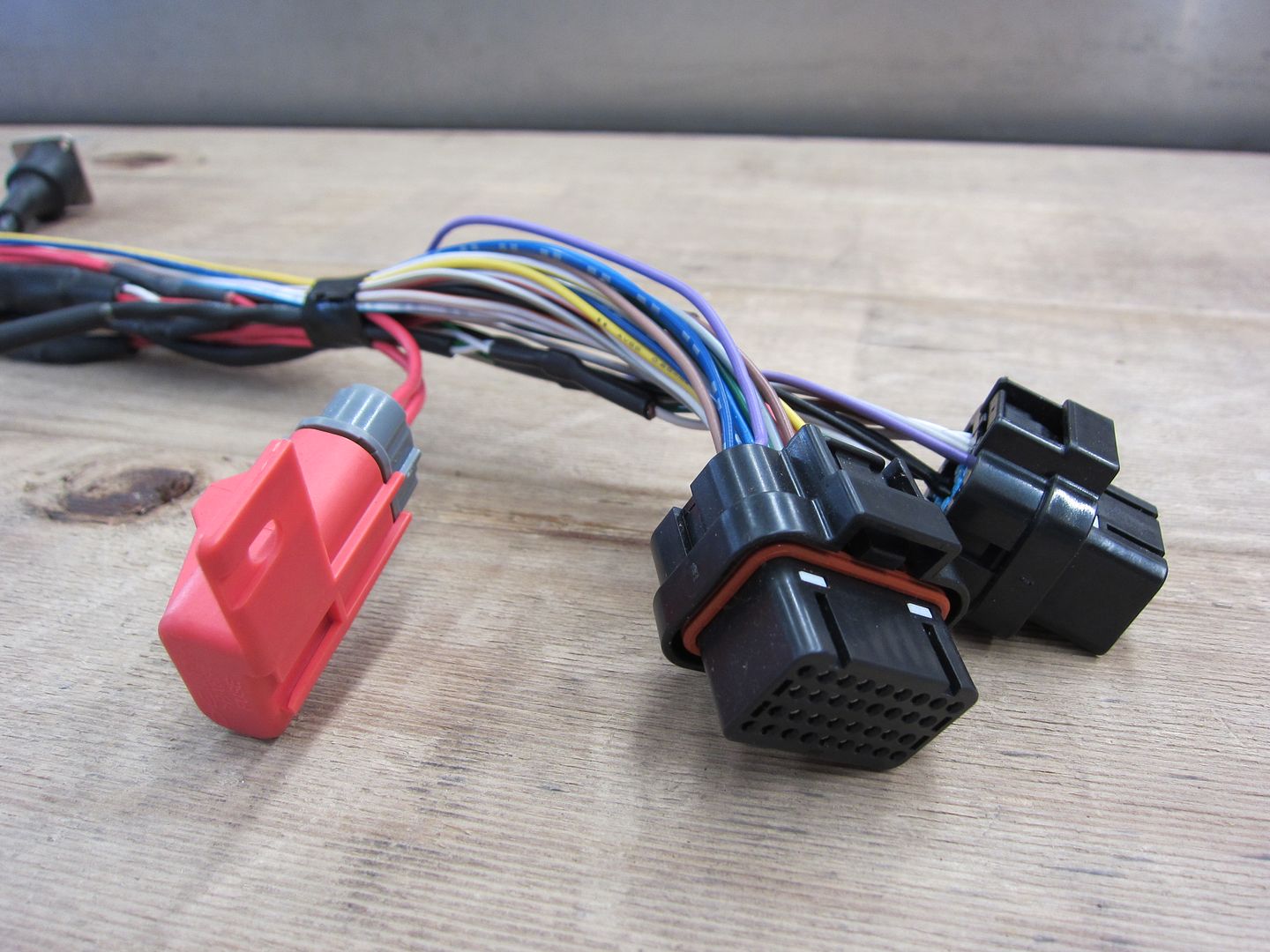

In the mean time progress on the wiring has gone forward in leaps and bounds. A whole new loom is being made for the car to simplify the electrical system and to remove any unneccessary wiring loom sections and electrical components.

Where OEM electrical components are being re-used, short loom tails were terminated and plugged.

This is the main chassis loom. Once layed out in the car it will be shortened and terminated accordingly.

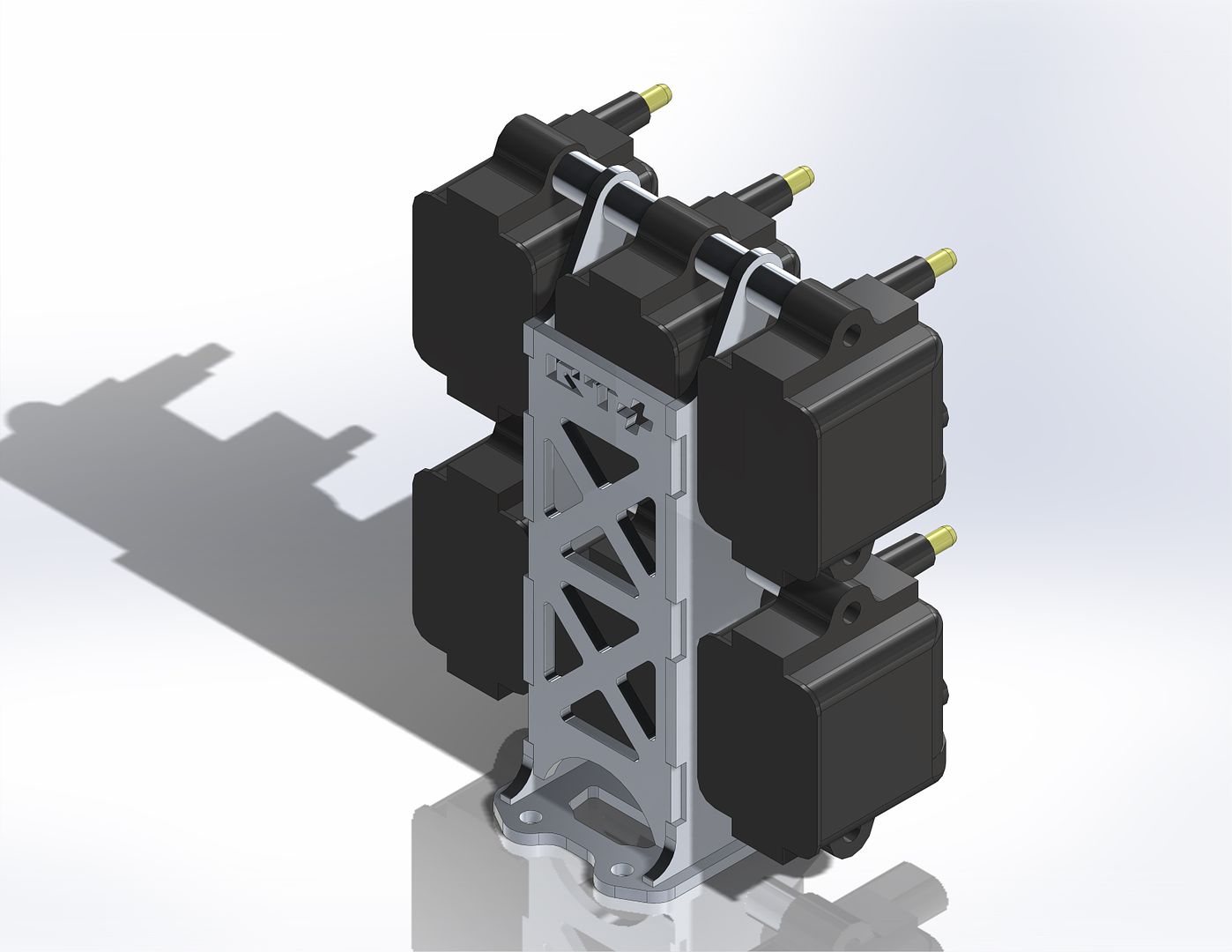

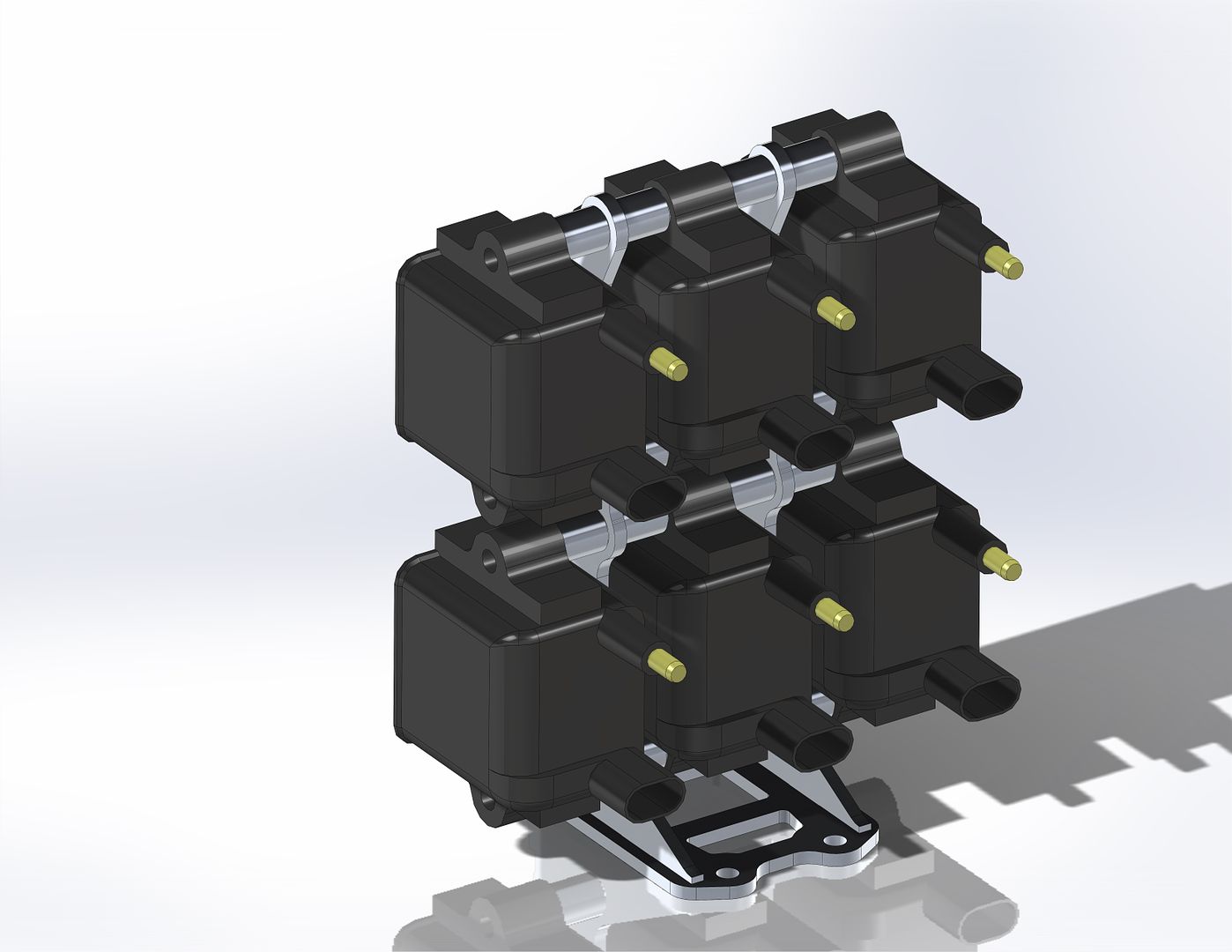

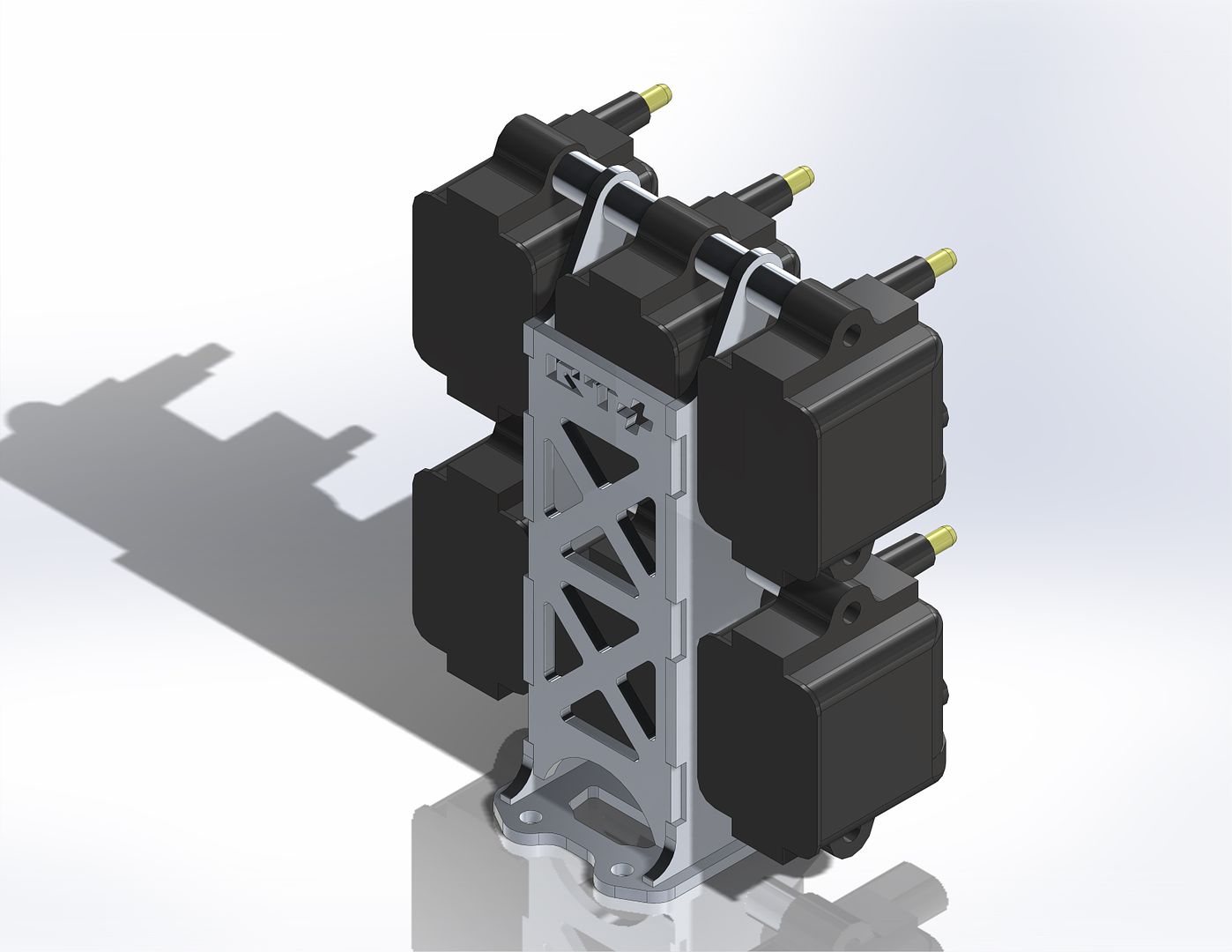

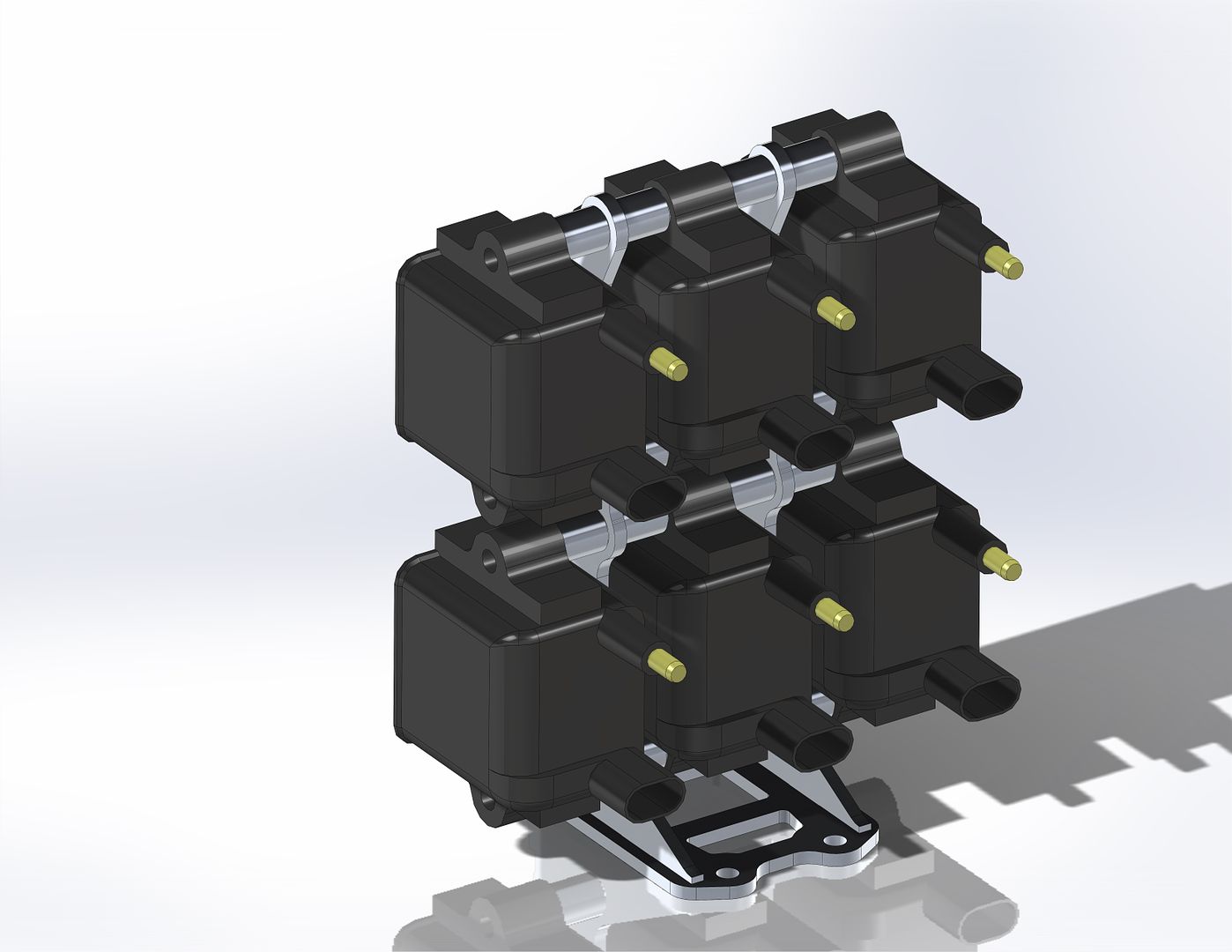

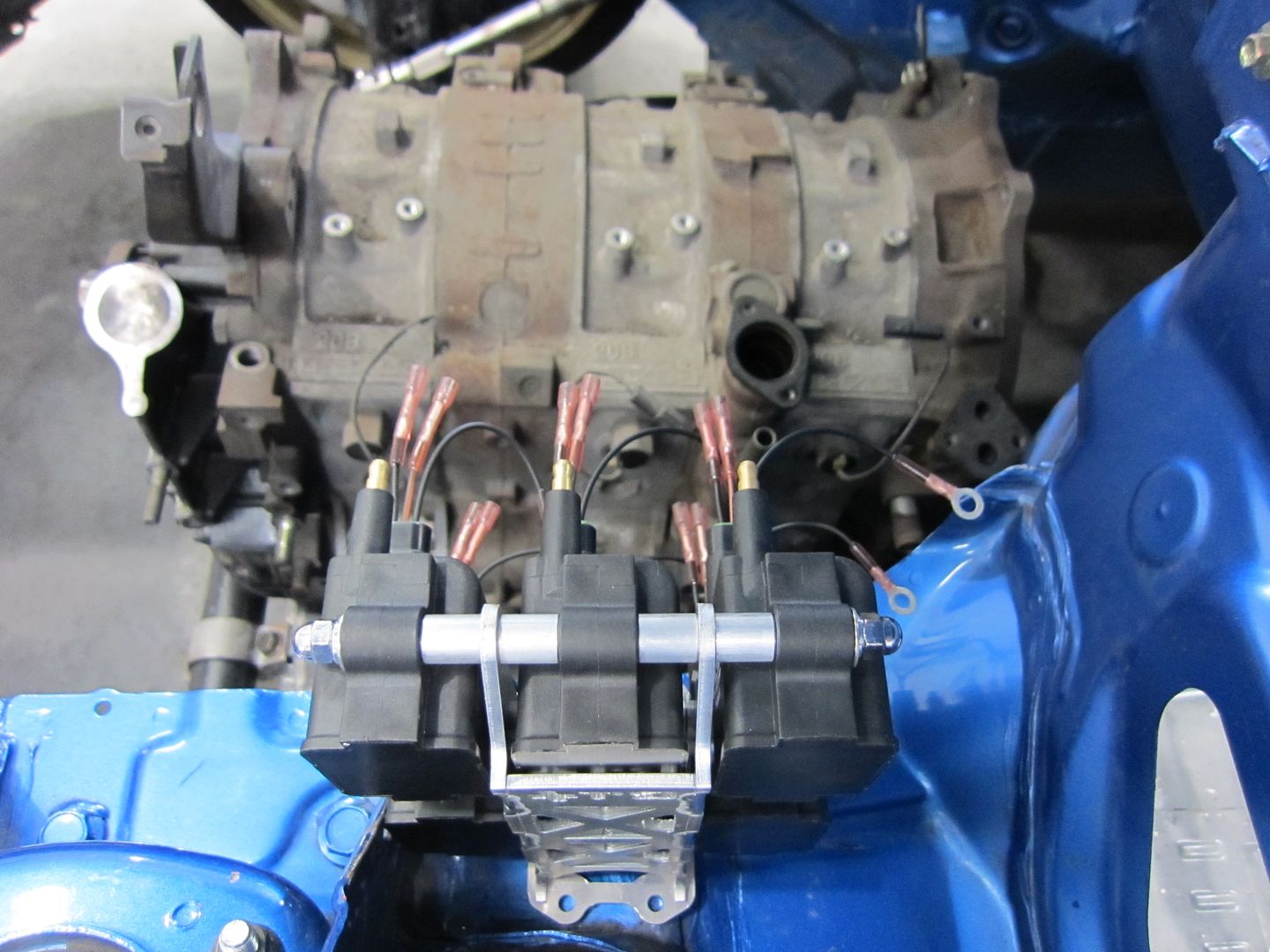

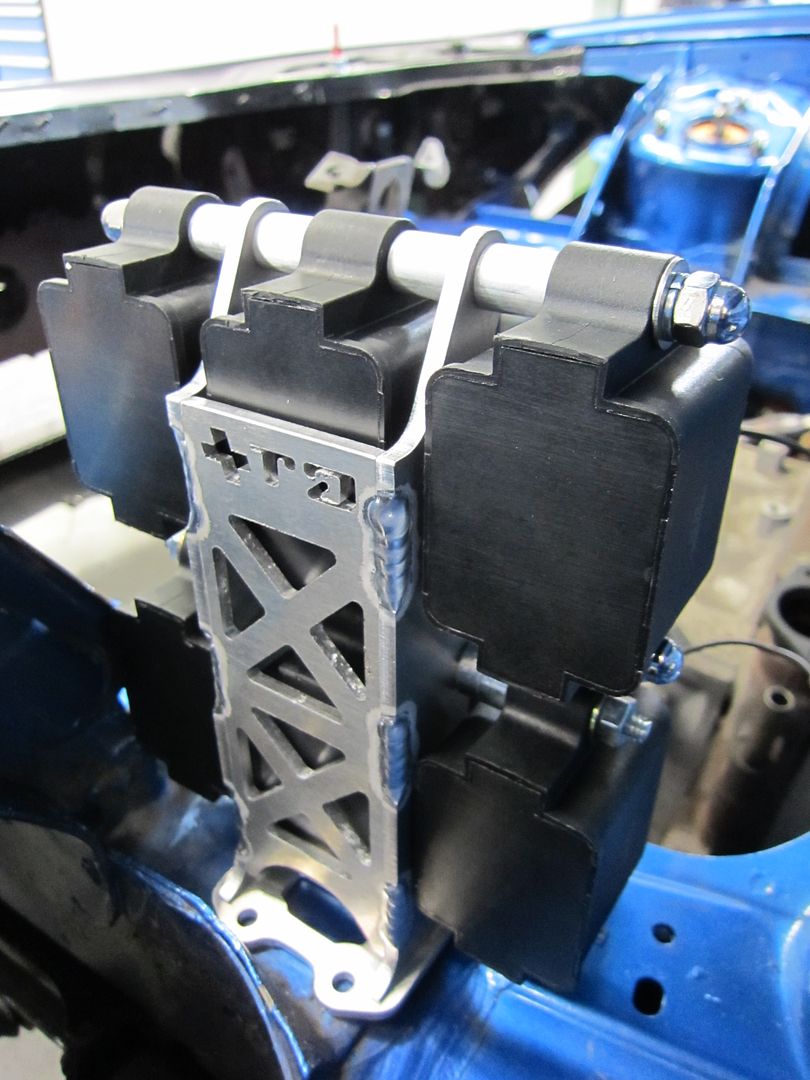

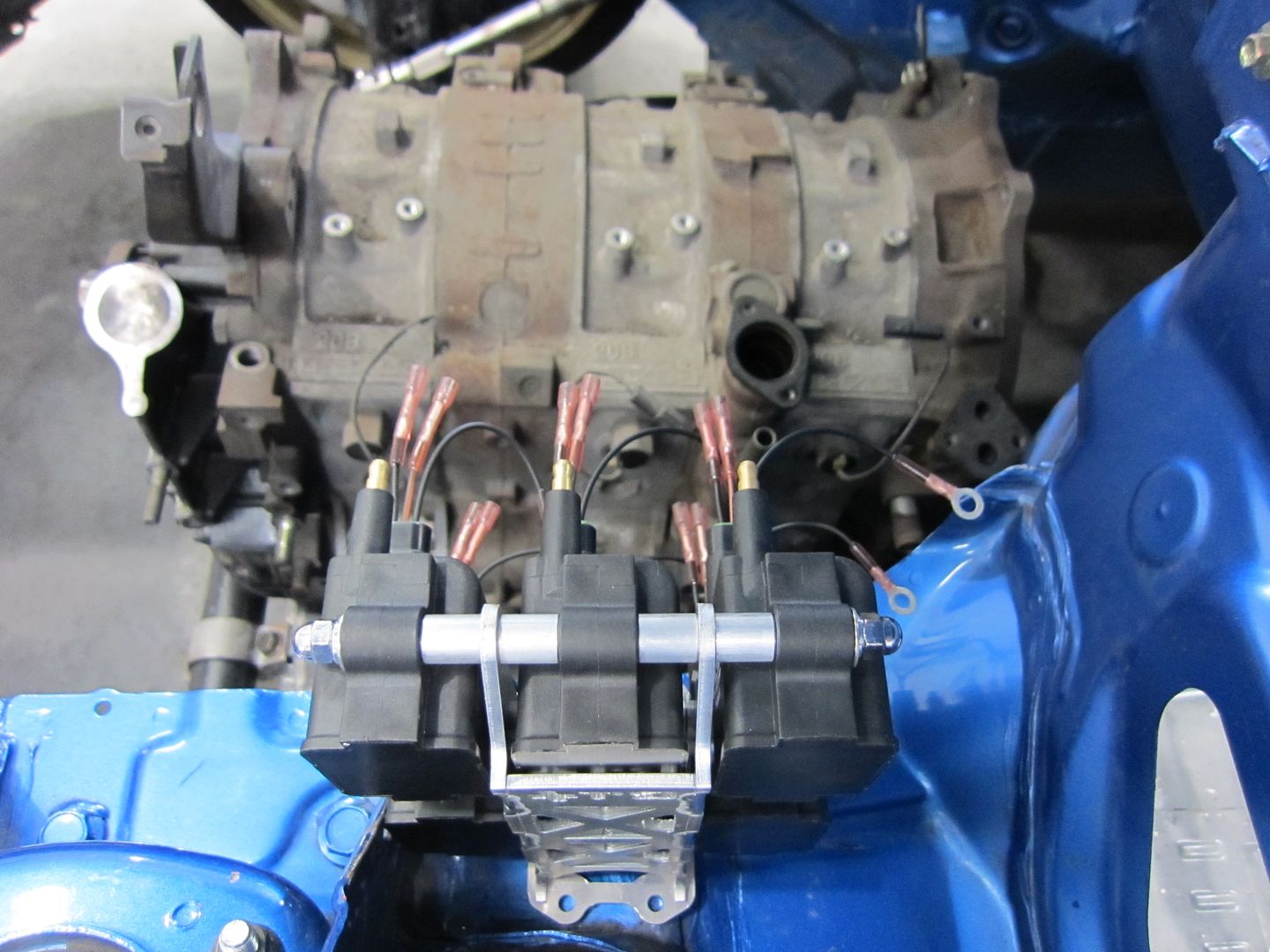

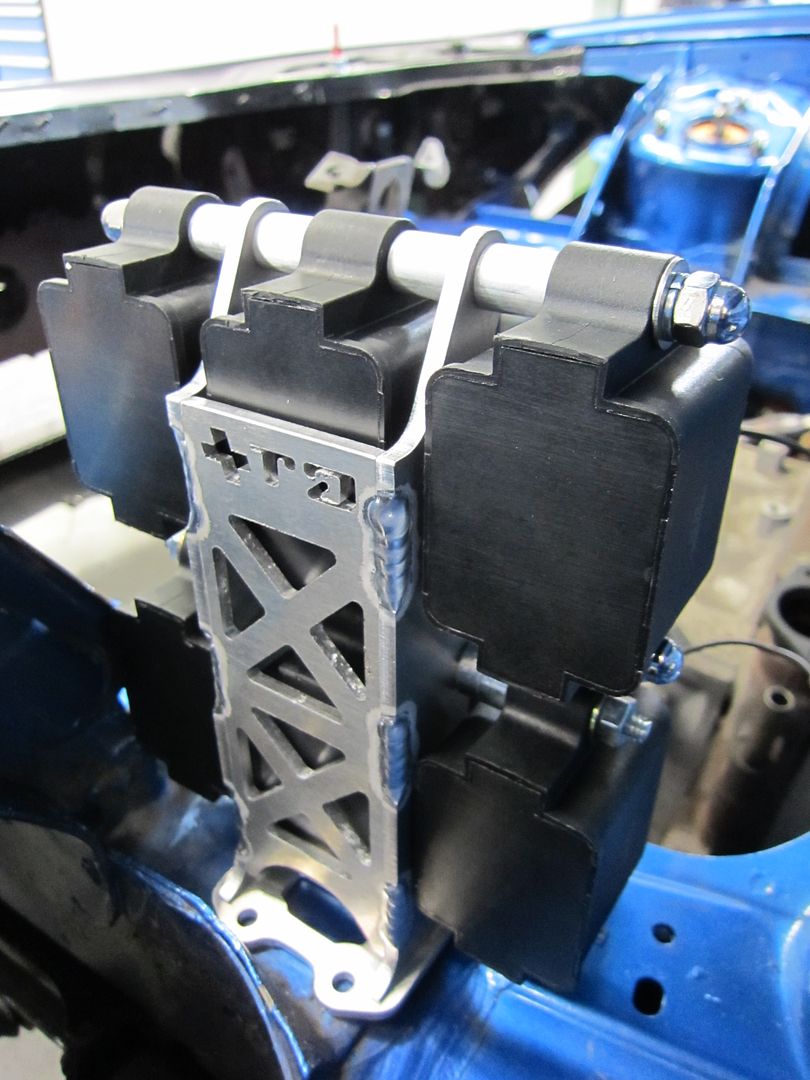

The coil bracket has also been completed....and yes the backing plate was welded on back to front! I'll knock another one up before the car is finished.

I'll knock another one up before the car is finished.

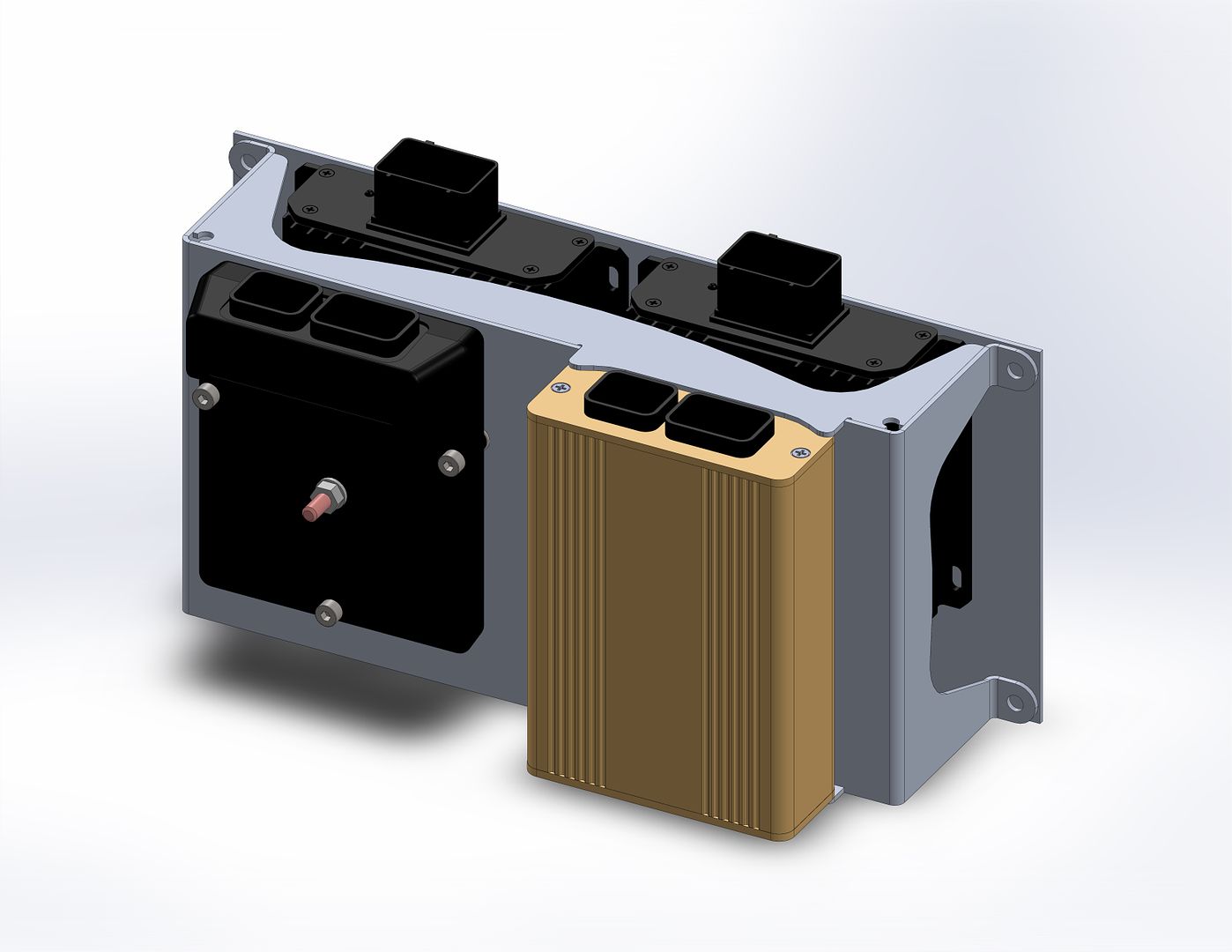

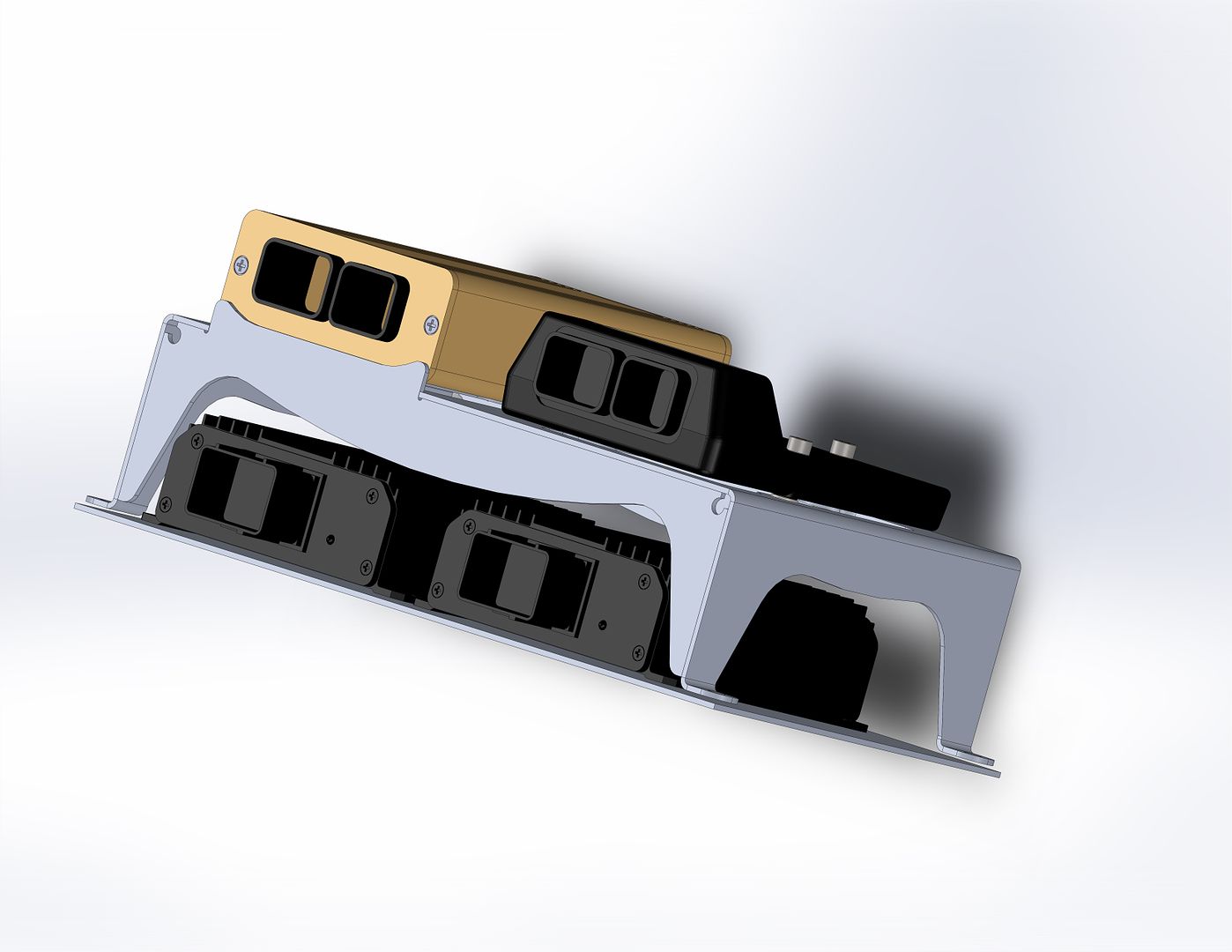

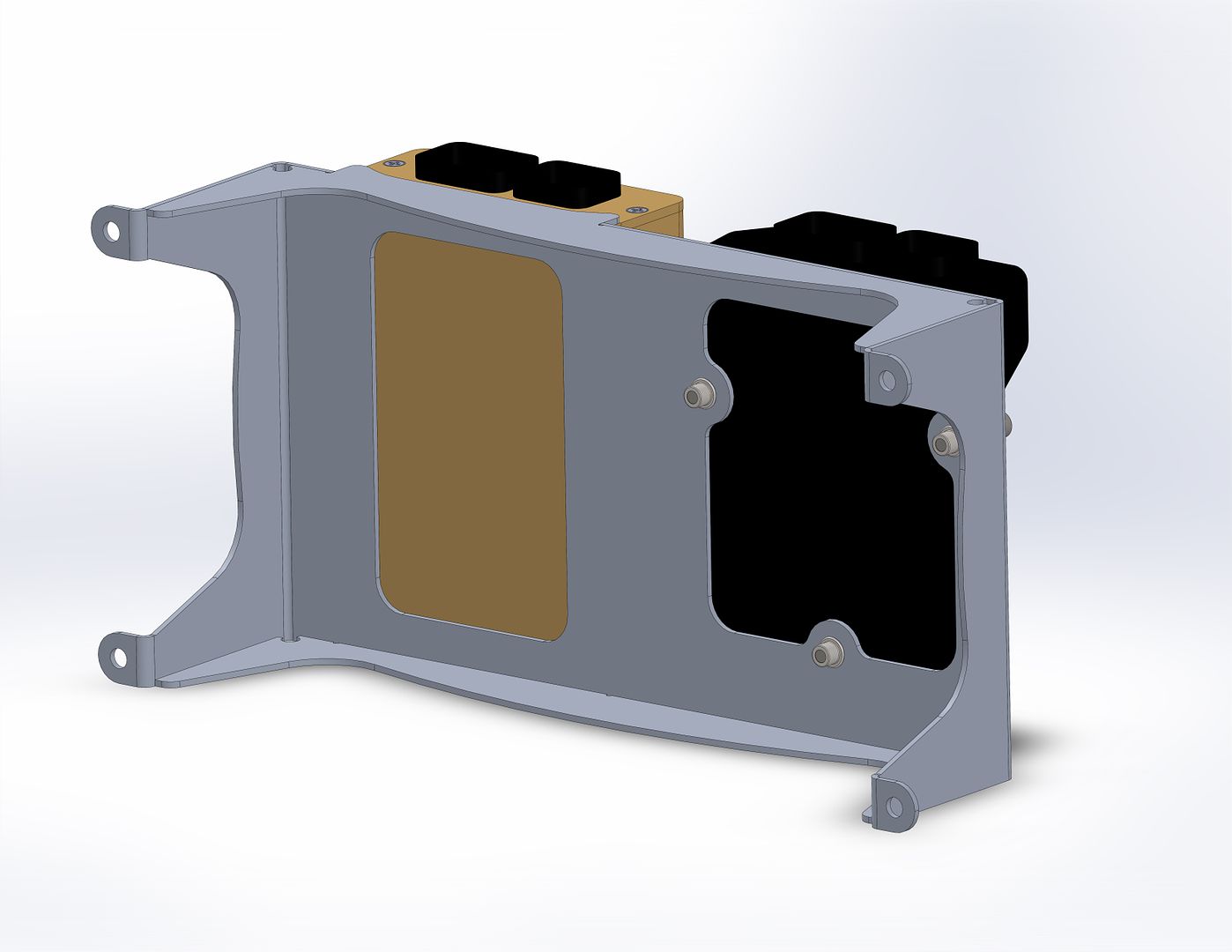

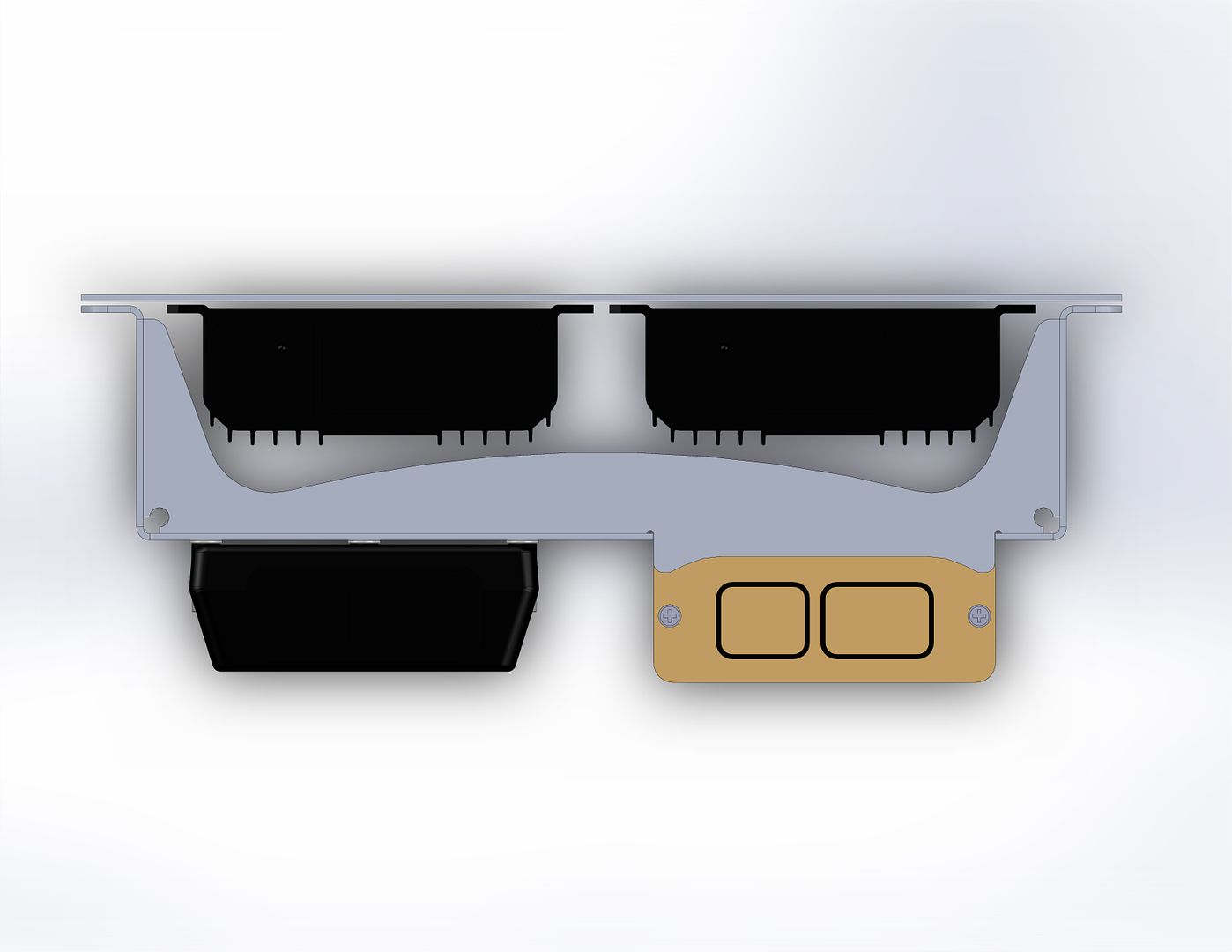

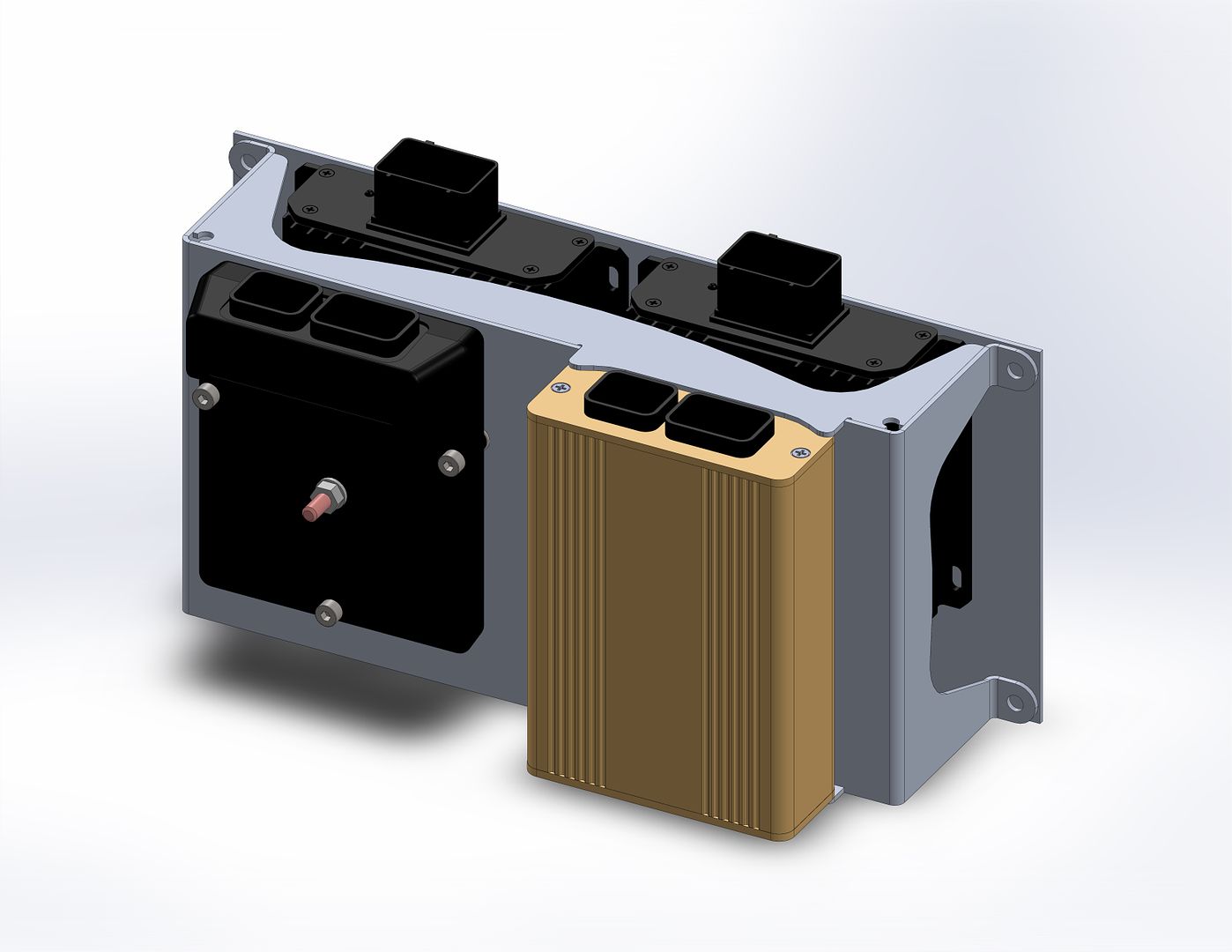

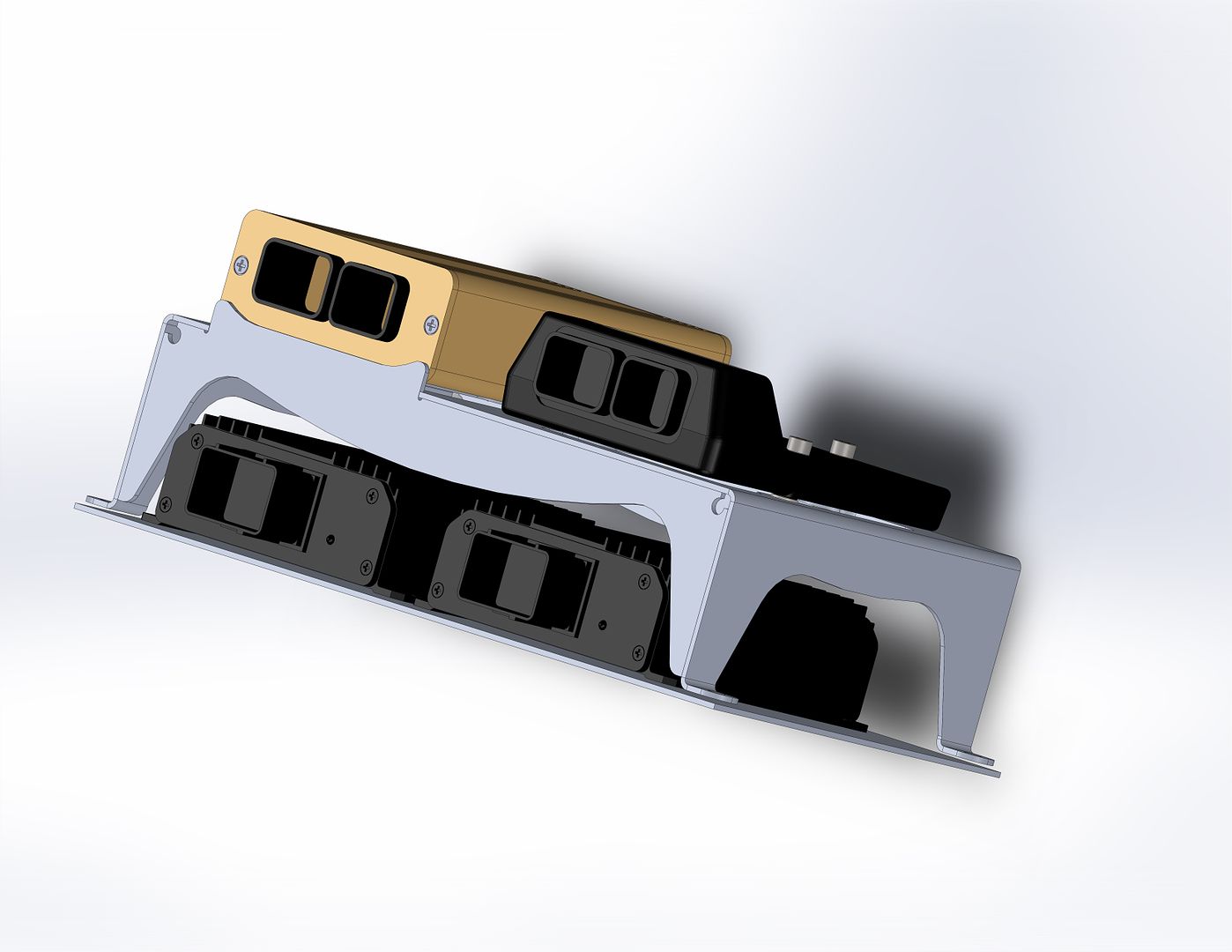

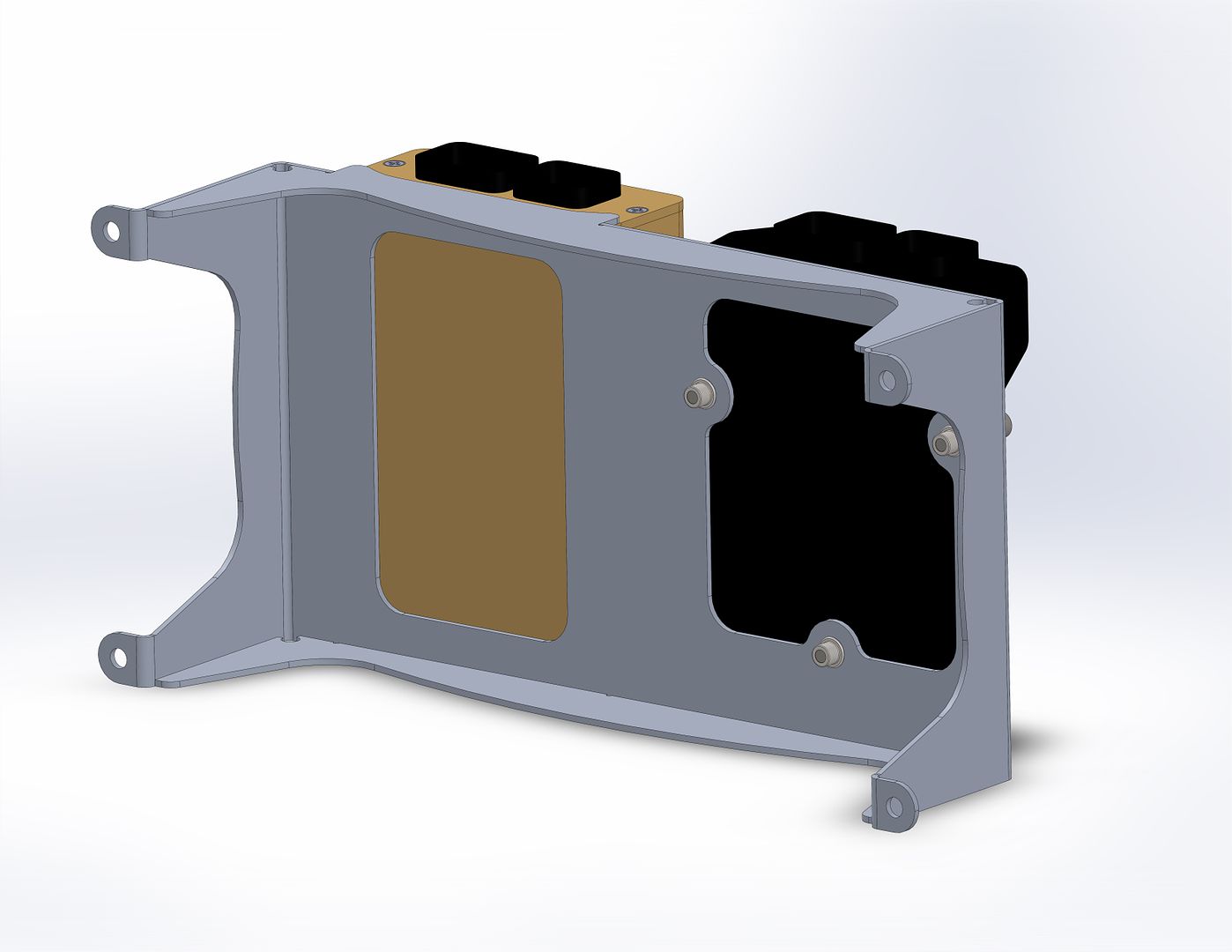

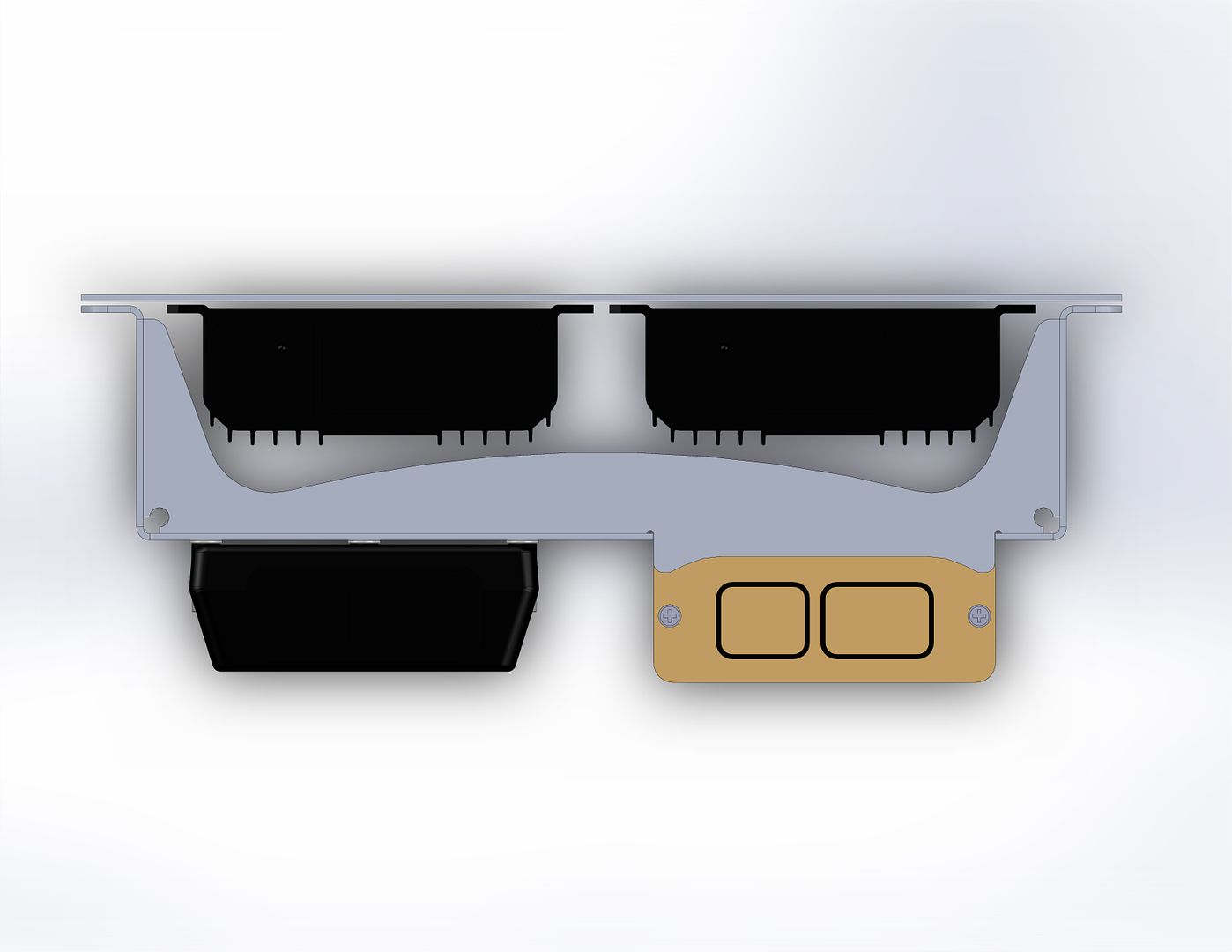

I've also spent some time drawing up the mount assembly for the Motec M800, Motec PDM15 and the two M&W Pro-16's. I'm still to finalise the attachment of the assembly on the firewall above the passenger side footwell. This will be done once I've got the whole lot together and physically in the car.

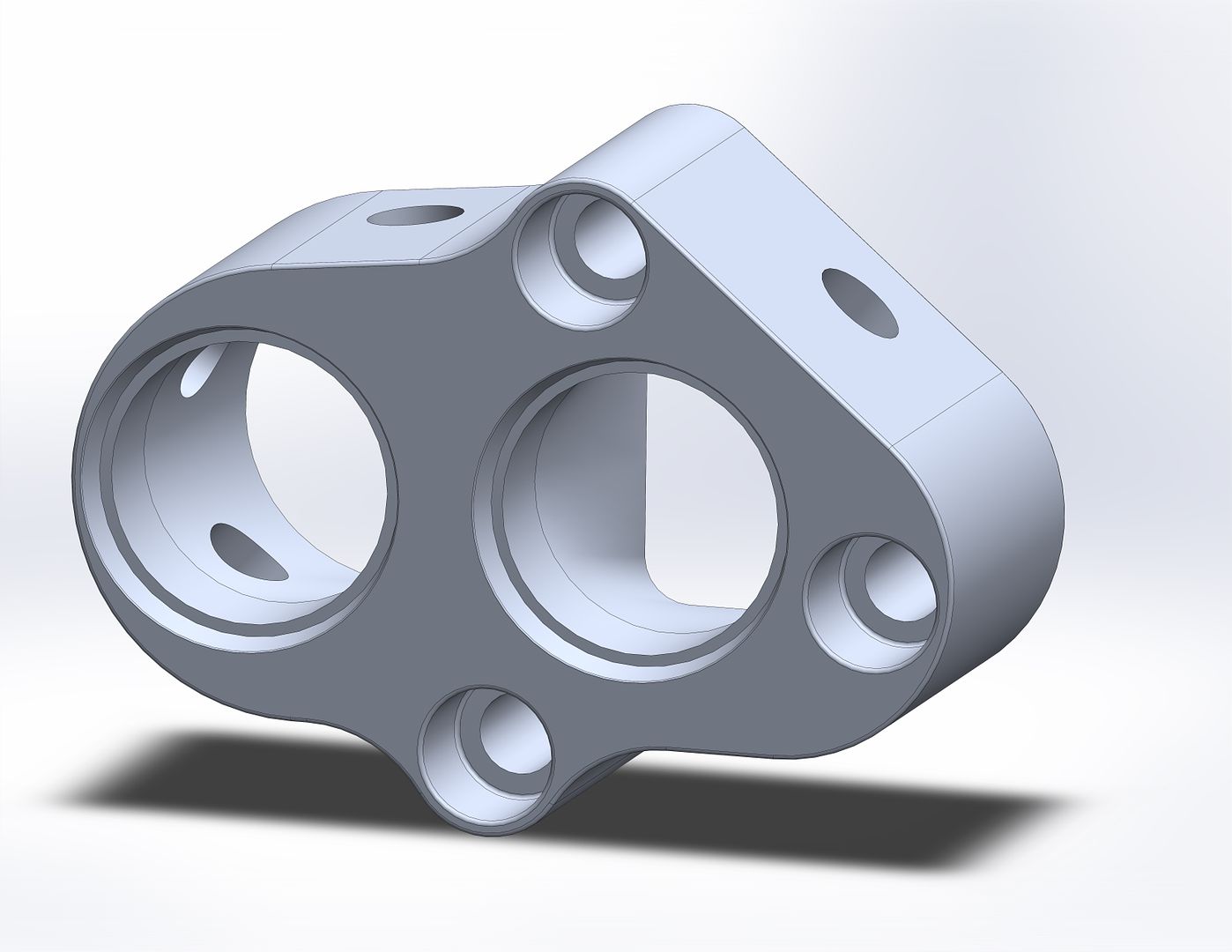

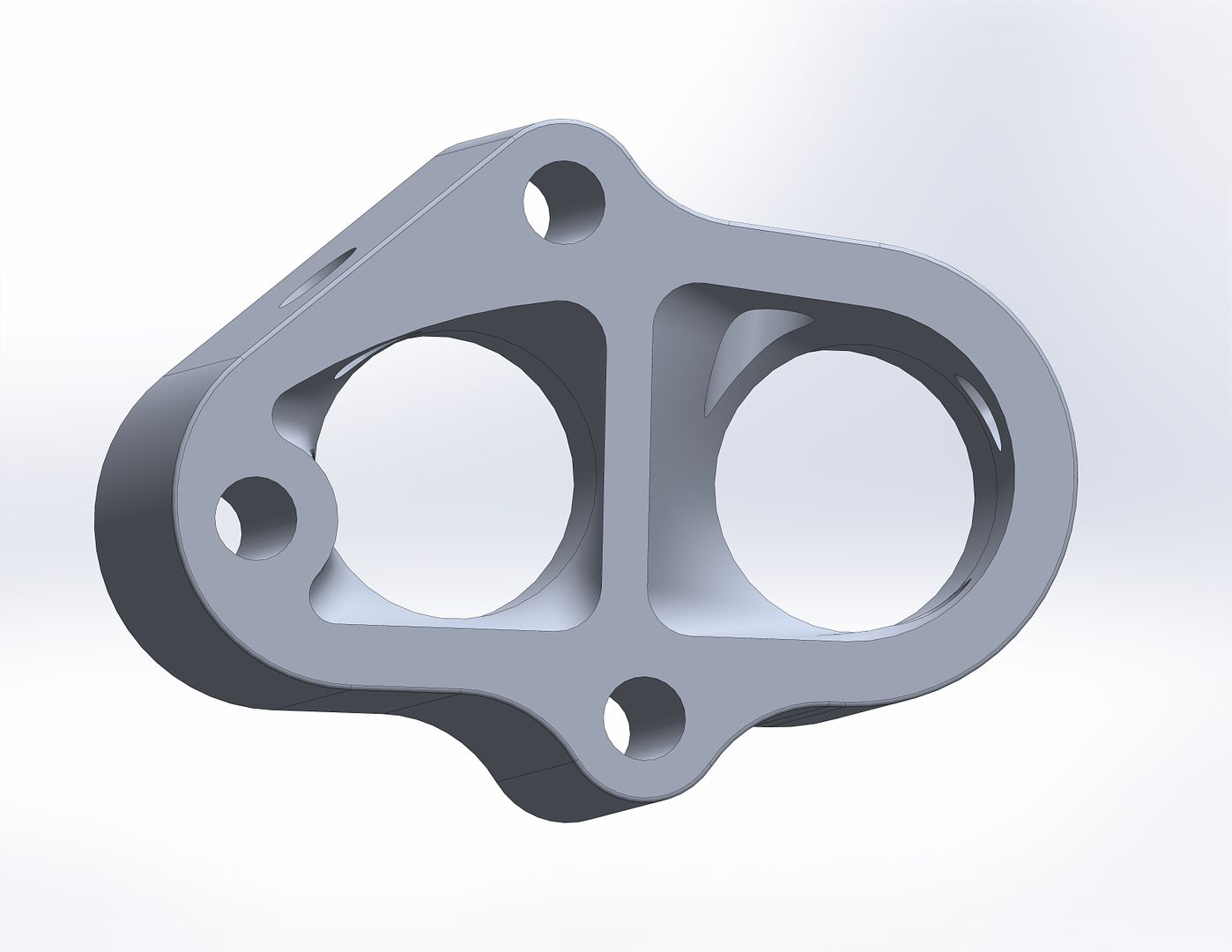

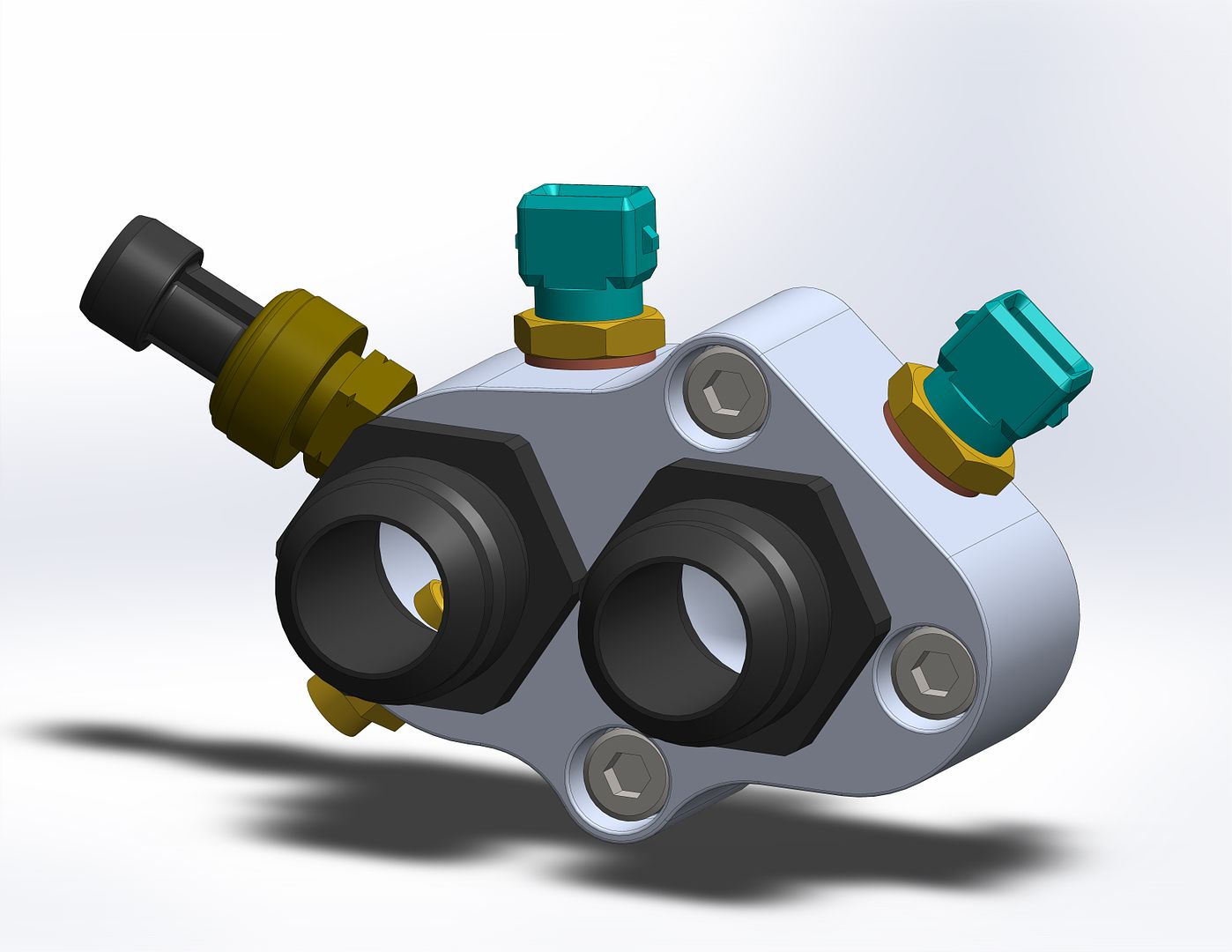

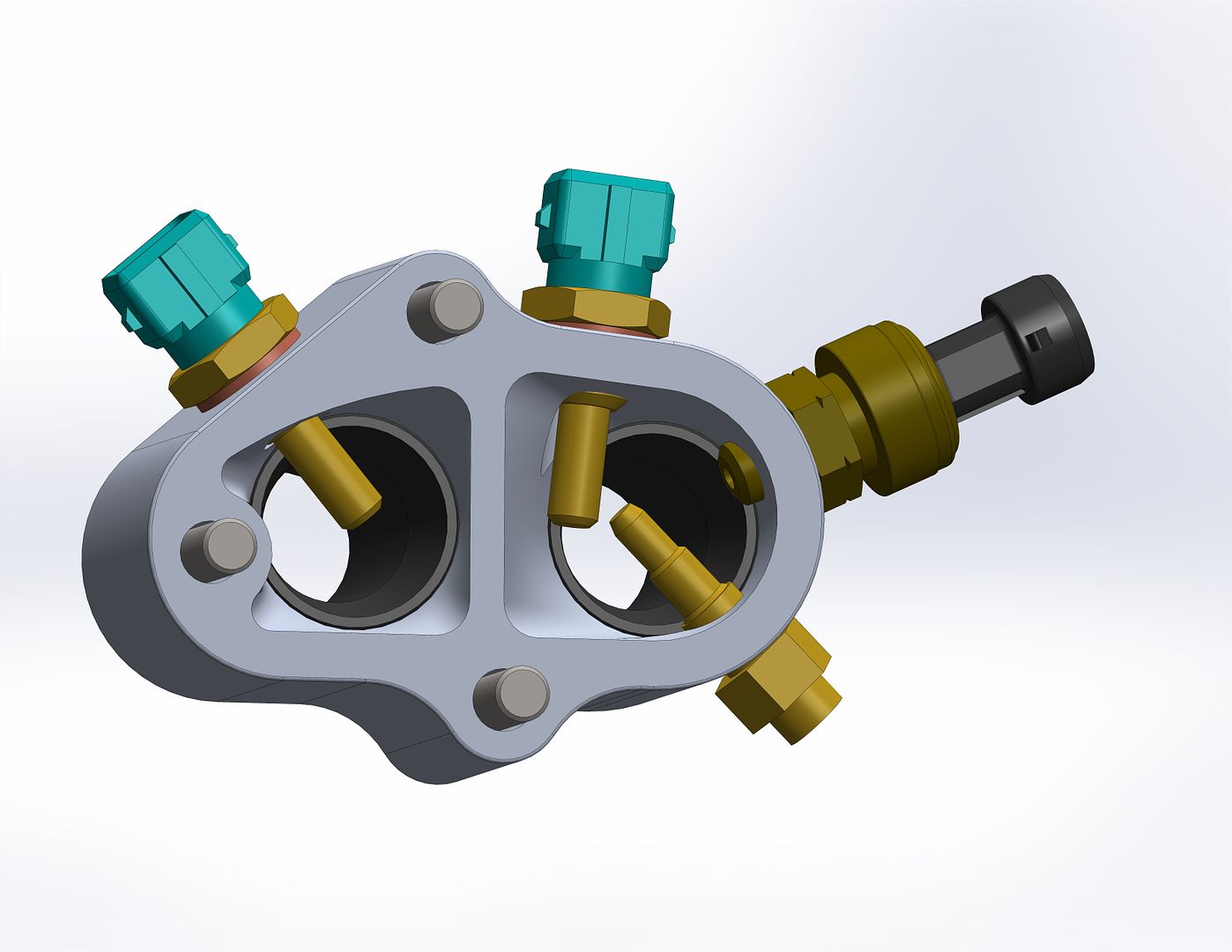

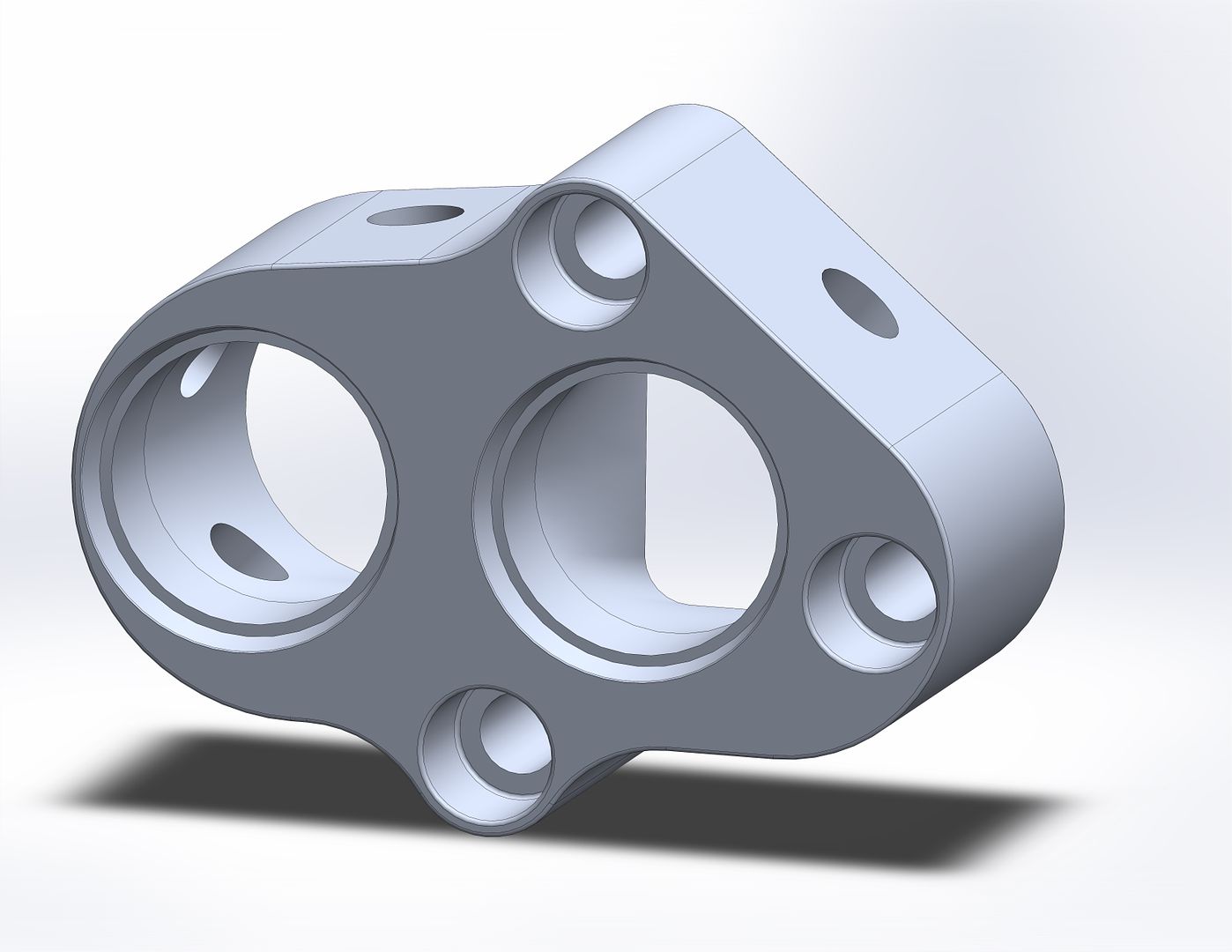

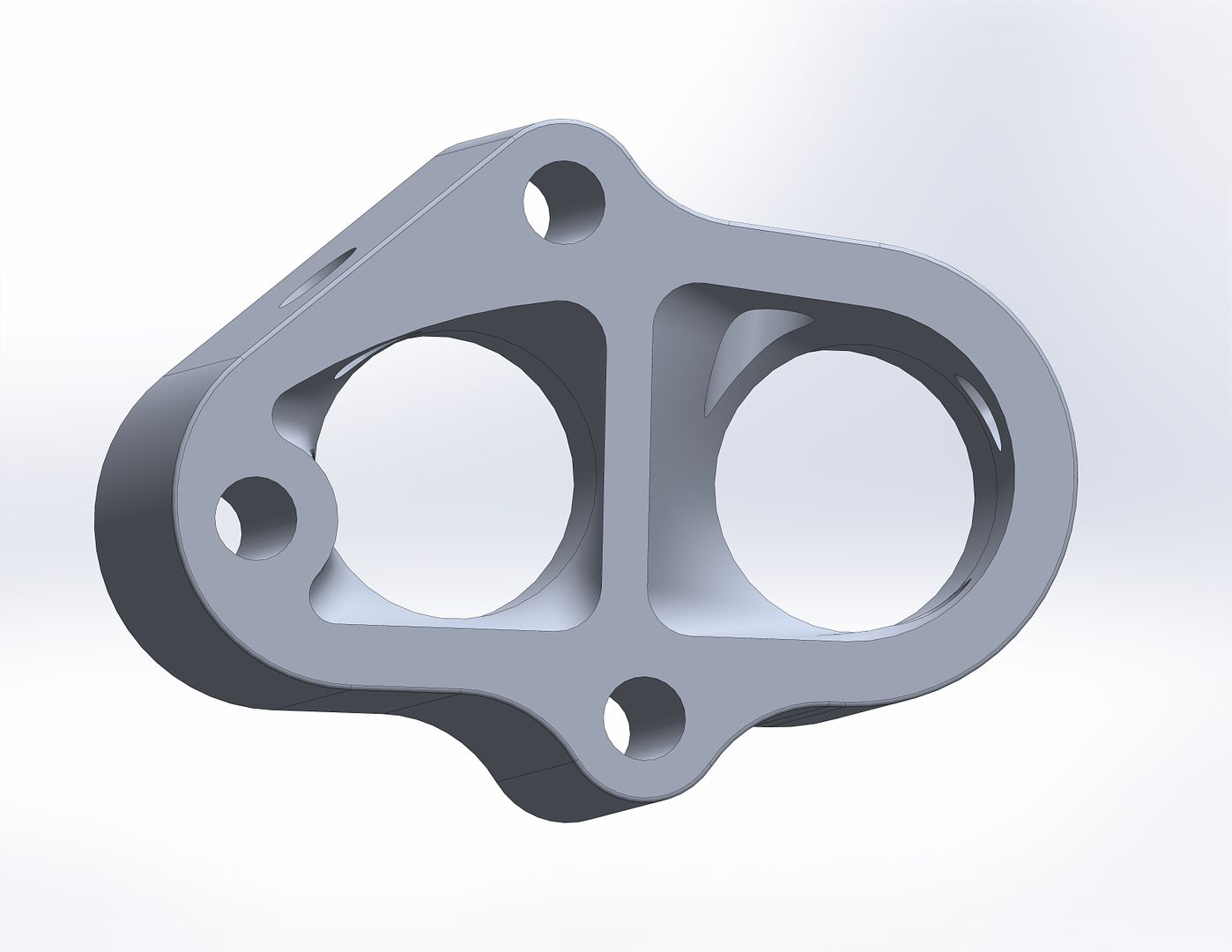

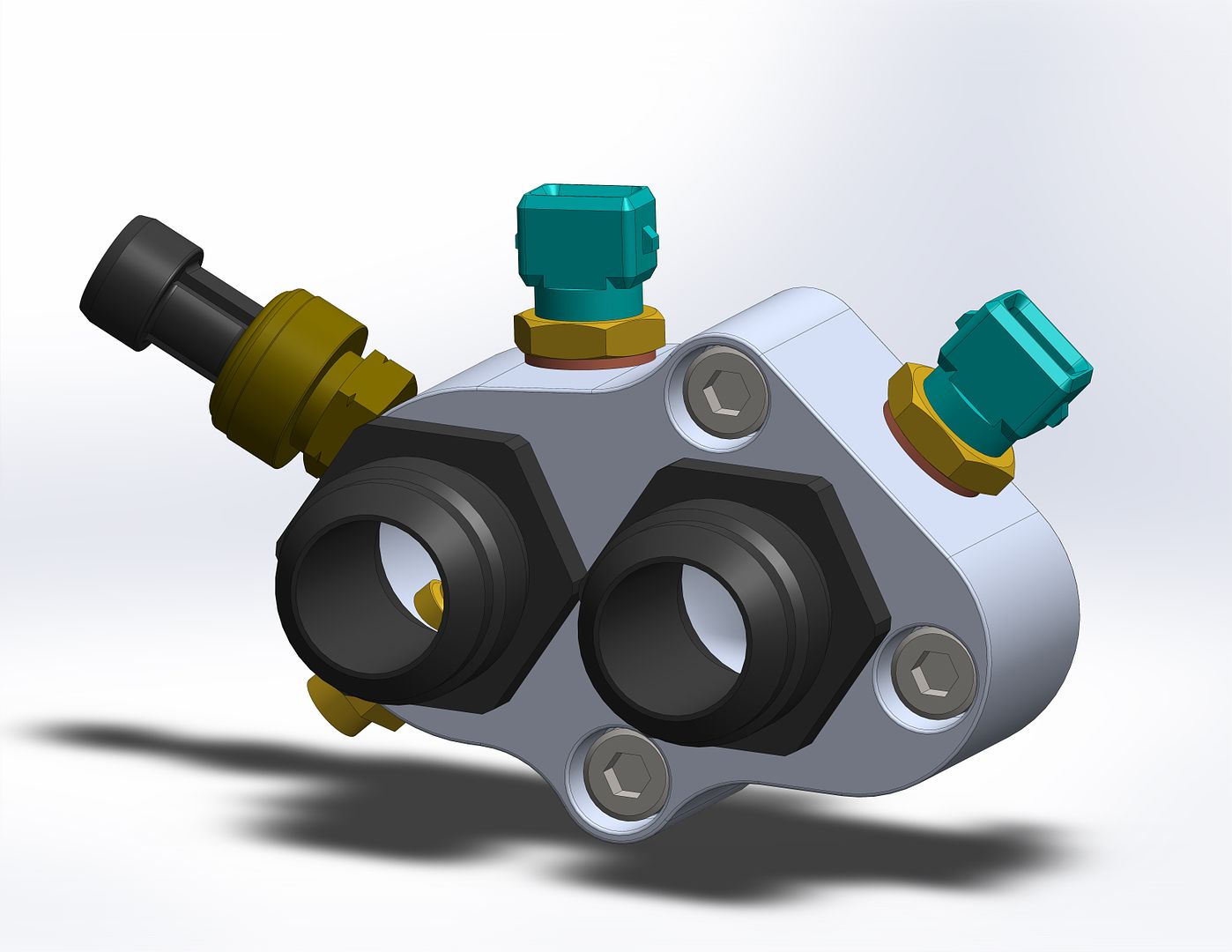

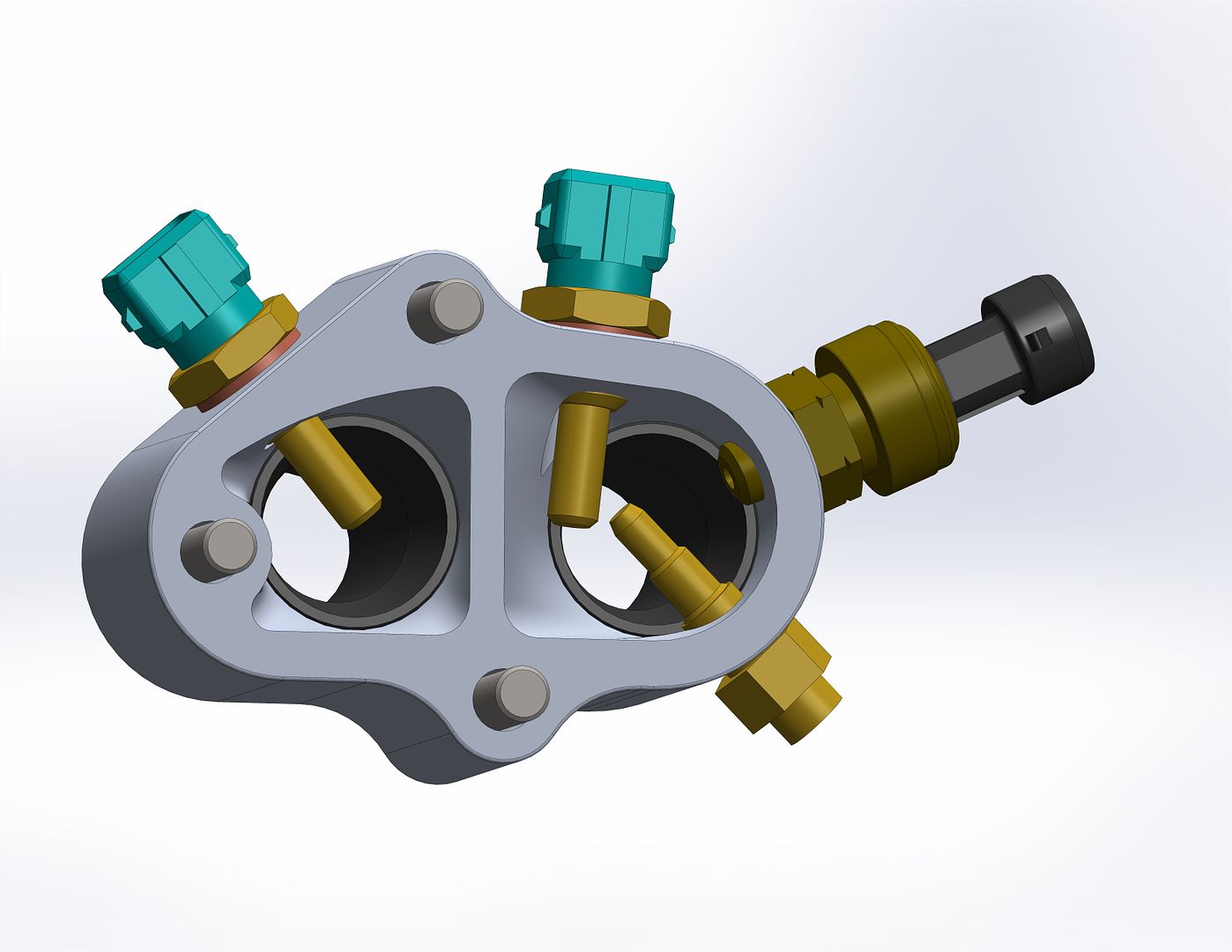

Time has also been put into the cooling system take-off point at the front of the engine (where the OEM water pump and thermostat housing once resided).

The fittings are dash 16 and provision has been made for the following sensors.

(1) Coolant Inlet Temp - Motec datalogger

(2) Coolant Outlet Temp - Motec datalogger

(3) Coolant Outlet Temp - Defi Gauge (for redundancy)

(4) Cooling System Pressure - Motec datalogger

With the sensors, fittings and fasteners in position.

With any luck this month will see the engine assembled and back in the car for the second last time.

Cheers,

Danny

In the mean time progress on the wiring has gone forward in leaps and bounds. A whole new loom is being made for the car to simplify the electrical system and to remove any unneccessary wiring loom sections and electrical components.

Where OEM electrical components are being re-used, short loom tails were terminated and plugged.

This is the main chassis loom. Once layed out in the car it will be shortened and terminated accordingly.

The coil bracket has also been completed....and yes the backing plate was welded on back to front!

I've also spent some time drawing up the mount assembly for the Motec M800, Motec PDM15 and the two M&W Pro-16's. I'm still to finalise the attachment of the assembly on the firewall above the passenger side footwell. This will be done once I've got the whole lot together and physically in the car.

Time has also been put into the cooling system take-off point at the front of the engine (where the OEM water pump and thermostat housing once resided).

The fittings are dash 16 and provision has been made for the following sensors.

(1) Coolant Inlet Temp - Motec datalogger

(2) Coolant Outlet Temp - Motec datalogger

(3) Coolant Outlet Temp - Defi Gauge (for redundancy)

(4) Cooling System Pressure - Motec datalogger

With the sensors, fittings and fasteners in position.

With any luck this month will see the engine assembled and back in the car for the second last time.

Cheers,

Danny

Who is online

Users browsing this forum: No registered users and 4 guests