So between lots of stressful family stuff this weekend I was very happy to have some garage time on the side to get some stuff done.

One of the reasons i got the MX5 was to muck around and do some stuff i have wanted to experiment with for a while, but too either chicken to do on the AE86 because of costs, or illegality for IPRA.

The first of these was mucking around with flocking. The old dash was pretty munted with several cracks and actually broke in half when i knocked it on the stand. Thats ok, because MX5 dashes are like $50 for a half decent NA one. So after i fibreglassed the bottom of it to hopefully minimise cracking, i got to work flocking.

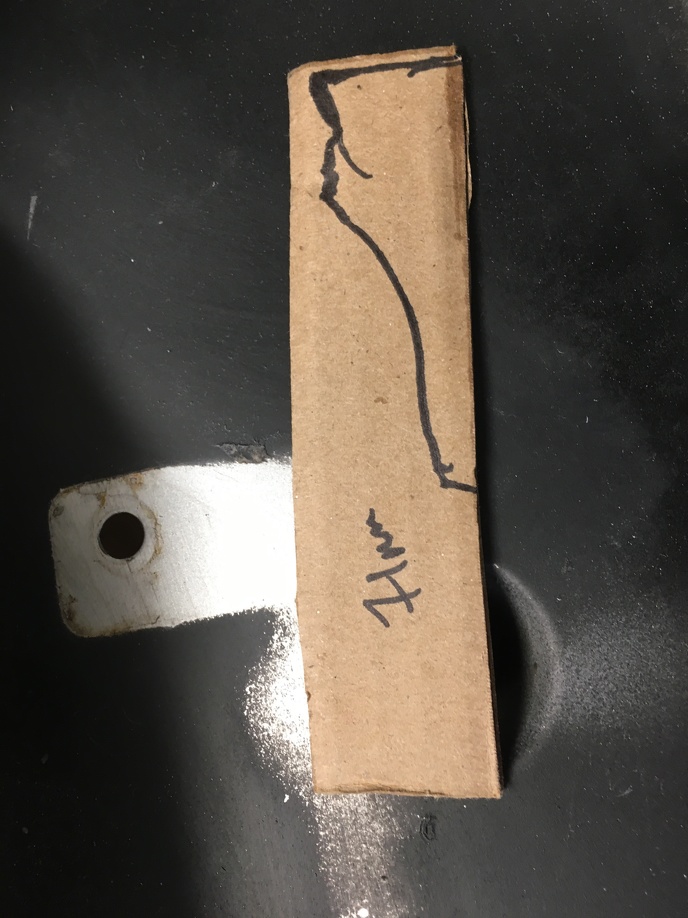

I built this little electrostatic flocking gun from an electric fly swat that i had lying around.

Not recommended TBH, it would have been better with a pressurised unit, but works well enough (although not for how much effort it was to make).

Nevertheless, it does a half decent job and the dash ended up like this:

You can see it looks a little lumpy occasionally though:

Still looks good in car:

Also jammed an NB heater core in there that needed a little bit of reshaping of the outlets, but that was easy as with the old shifter trick

Another thing i have been interested in recently is 3d printing, and given that this is the first build i have done since i built my 3D printer, i figured it was time to knock up some little plugs to seal up the AC box

And also knocked up a mounting bracket for the washer bottle:

Realised afterwards when i was looking on Beavis' site that it is very similar to what he has done for his setup. Turns out we think alike in engineering terms.

I then started looking around for other things to 3d print, and remembered that my rear valance has a big crack in it and a chunk taken out. So as a second attempt at transferring an irregular pattern to digital and then plastic i figured why not.

First bit is getting the shape:

Then scanned it in, processed the photo, then converted the image into a vector image, and finally extruded it in Fusion with a little flange lip for attachment. Giving

Worked a treat.

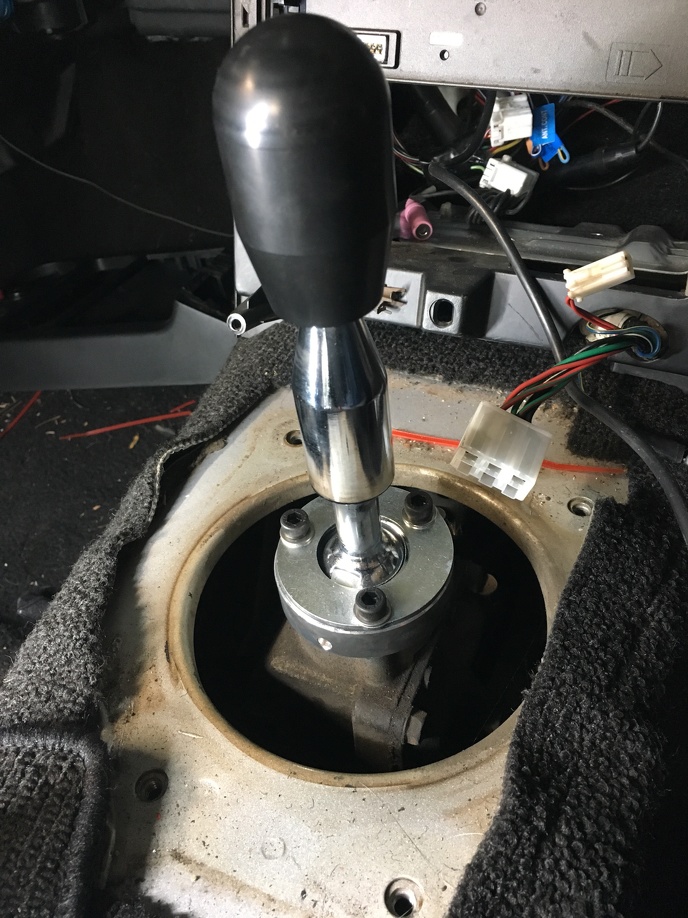

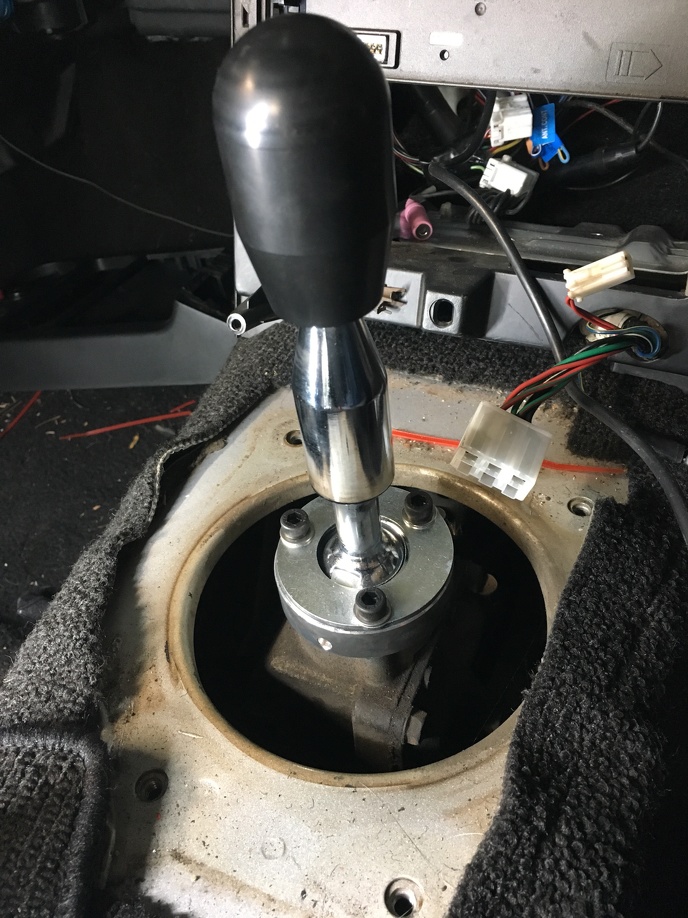

Then i went to turn the car around in the garage and hit a snag. Went to put it into first and ripped the entire shifter knob off and tore a chunk of flesh out of my arm. Some previous owner had installed one of those shift knobs with a grub screw, and it had torn up all the thread.

They had then put the stock shifter back in with a hammer. I kind of already knew about this, which is why i had bought a new one already. But still a painful reminder of previous crappy mods.

So short shifter went in:

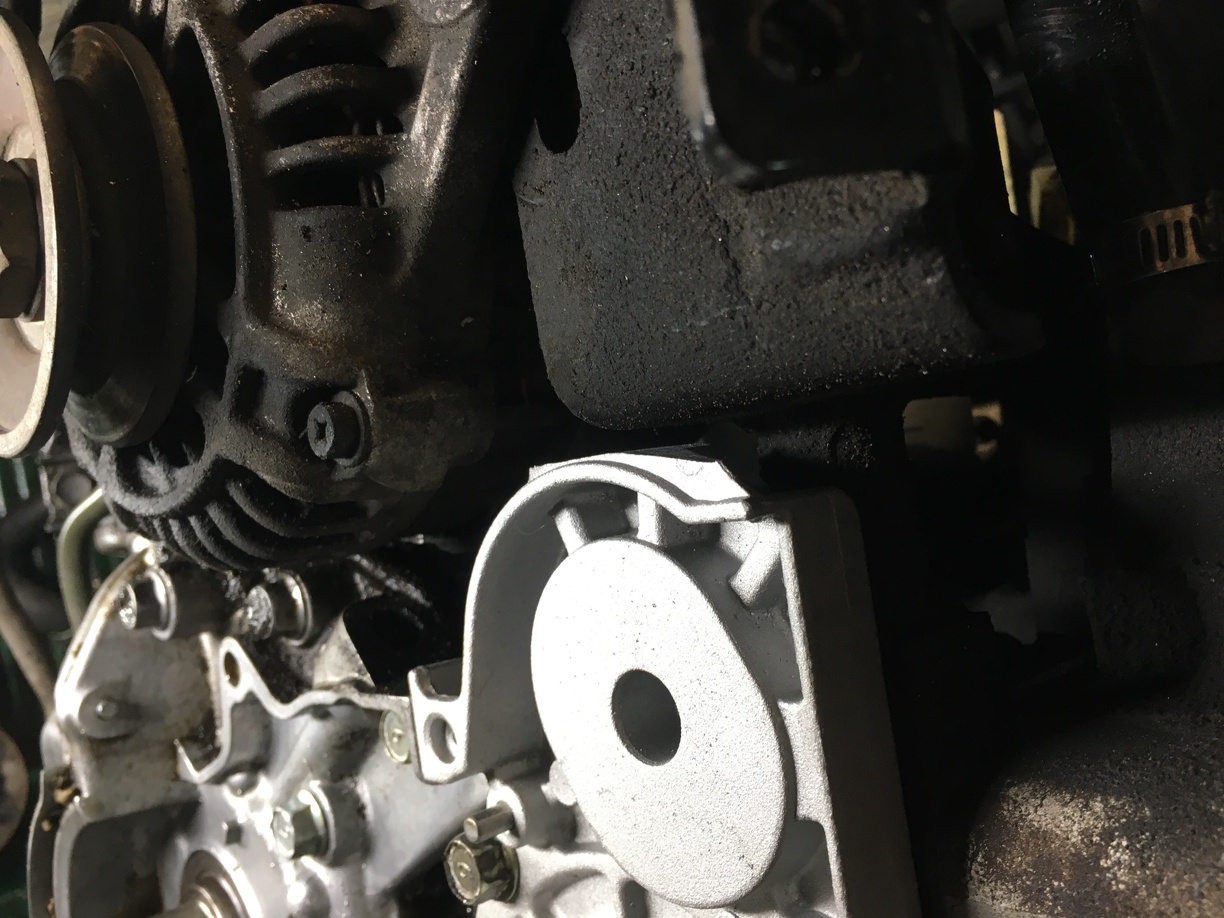

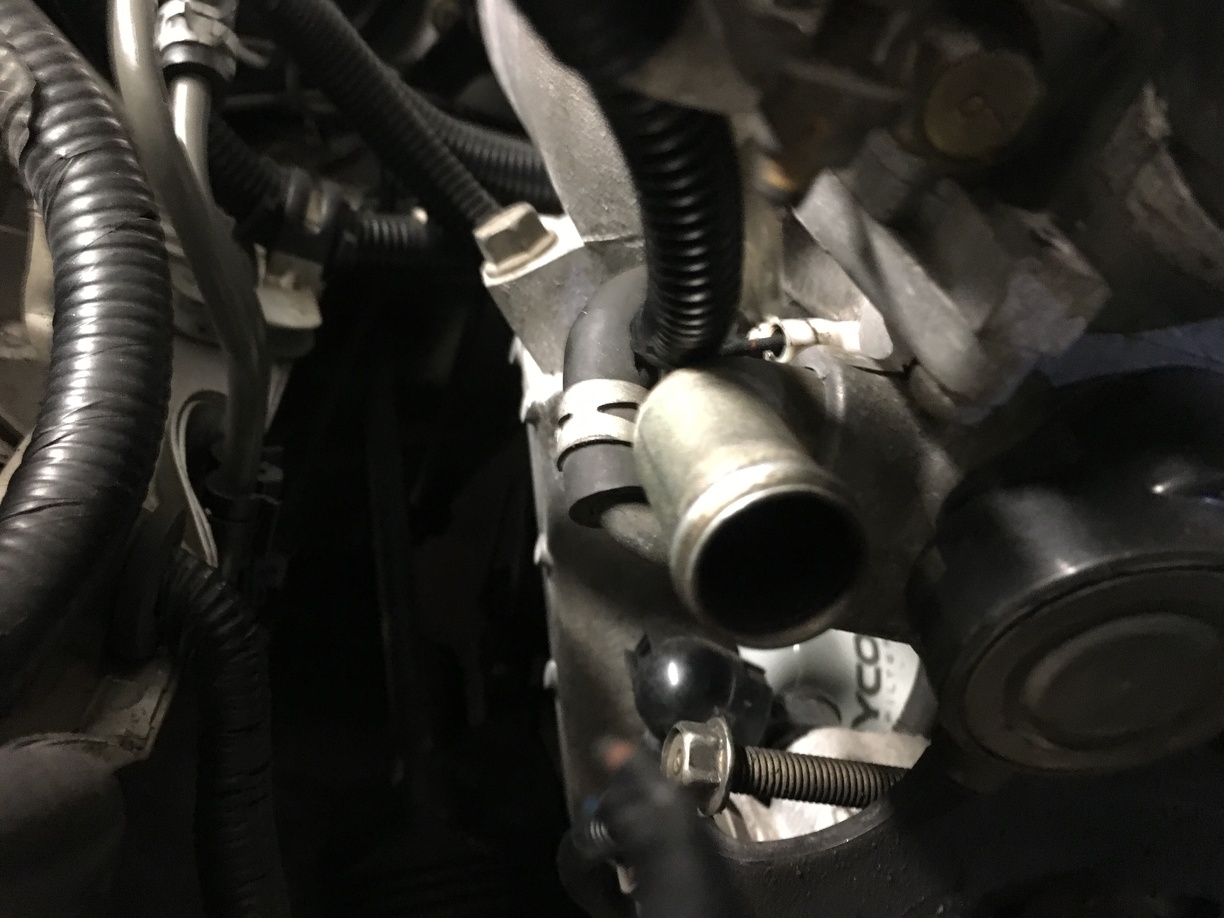

Finally i turned the car around, and then got to work on pulling the water pump out and changing the timing belt

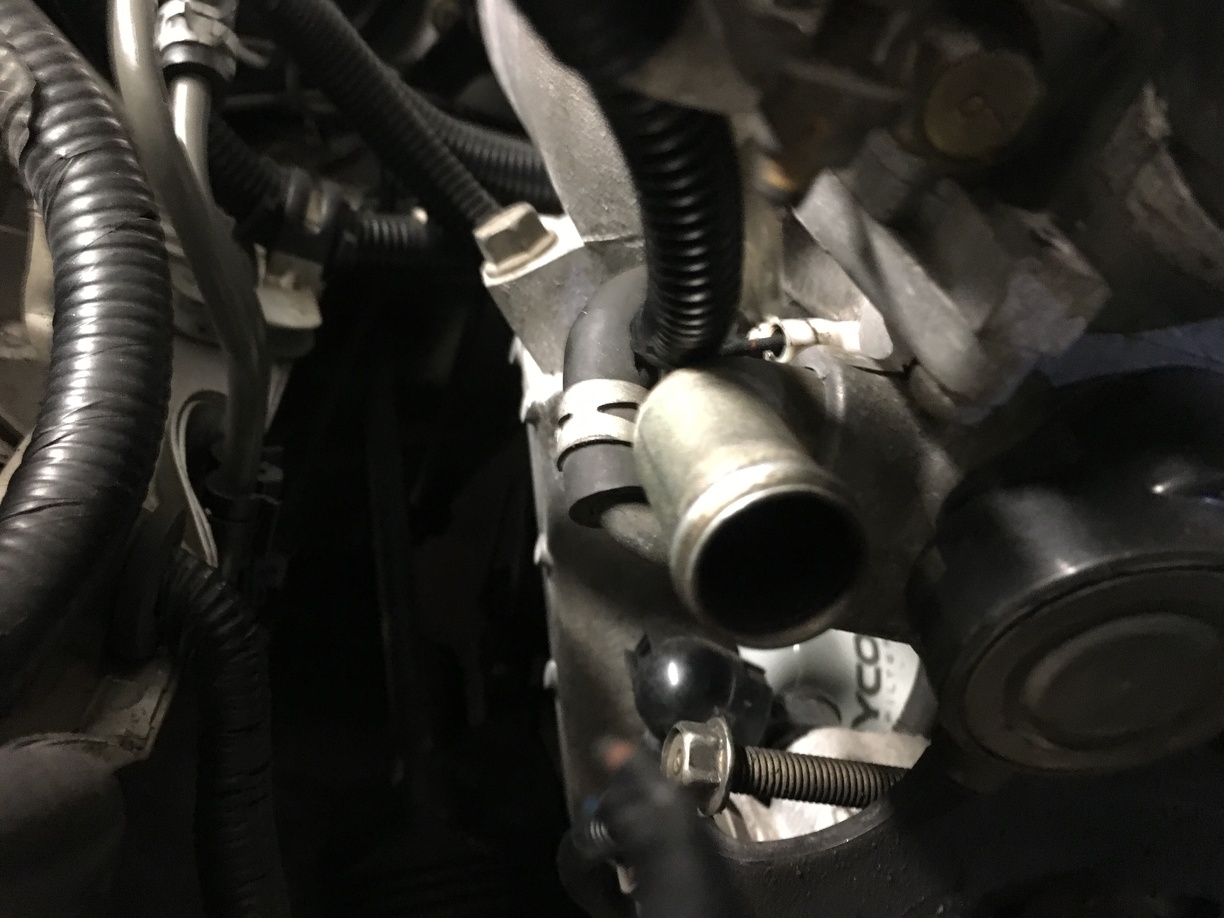

Had forgotten how annoying it can be working on road cars again, and with all of these fiddly little water hoses for random intake junk, its a pain in the bunghole

This one looks like some form of intake heater, wonder if i can delete it

While this one looks like an IACV

Probably need that one for the moment i guess.

Thats about it for this weekend, should be able to do most of the other stuff on the engine bay area this week or next weekend, but its going well.