NC 20BPP Time Attack / Track Car - Build Thread

Moderators: timk, Stu, -alex, miata, StanTheMan, greenMachine, ManiacLachy, Daffy, zombie, Andrew, The American, Lokiel

- zero00

- Speed Racer

- Posts: 3248

- Joined: Mon Apr 12, 2010 6:54 pm

- Vehicle: NB8A

- Location: Sunshine Coast Queensland

Re: NC Track Car - Build Thread

Thanks Danny, I will dust off the TV and watch!

Roger D-SUNSHINE COAST

2000 NB8A-LP 69.1248|QR Clubman 71.9235|QR Sprint 68.1412

1989 NA6 B-SPEC #77|Toyota GTS86 MT

2000 NB8A-LP 69.1248|QR Clubman 71.9235|QR Sprint 68.1412

1989 NA6 B-SPEC #77|Toyota GTS86 MT

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - Build Thread

zero00 wrote:Thanks Danny, I will dust off the TV and watch!

T minus 3 hours (Brisbane time).

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - Build Thread

The last 14 days leading up to patting rear the bumper of the NC and sending it south to WTAC 2014 were nothing short of organised chaos.

Lucky for me, my friends and workmates were just as committed as me to reaching the goal!

As such I would like to thank the following people and businesses who all assisted in some way:

* Automotive Plus

- Jeff Mason

- Dave Avenell

- Jason Furness

- Dave Crelley

- Deanne Curd

* Australian Diversified Engineering

- Clive Gray

- Matt Gray

- Ben Crisp

- Adam Byster

- Daniel Kirk

- Chris Finn

- Mark Dale

- Raynor Kennerley

* GT Auto Garage

- Dave Johnson

- David Lenthall

- Tim Hung

* AMB Aero

- Andrew Brilliant

* Ultimate Big Boys Toyz

- Rob Sabo

- Wayne Power

- Dan Nicholls

* Gold Rush Composites

- Max Buhner

- Steve Griffith

- Matt Griffith

* Custom Race Electrics

- Greg Walsh

- Steve Ford

* Engineering Precision Solutions

- Ron Julius

* Mayne Paint and Panel

- Eric Johns

- Glen Dorahy

* BRMD

- Brett Rogers

* MR Tuning

- Michael Flanders

- Daniel Ensor

- Leigh Geyer

- Andy McElrea

and last, but by no means least, Ian Baker for putting on the biggest Time Attack event in the world!

Cheers,

Danny

Lucky for me, my friends and workmates were just as committed as me to reaching the goal!

As such I would like to thank the following people and businesses who all assisted in some way:

* Automotive Plus

- Jeff Mason

- Dave Avenell

- Jason Furness

- Dave Crelley

- Deanne Curd

* Australian Diversified Engineering

- Clive Gray

- Matt Gray

- Ben Crisp

- Adam Byster

- Daniel Kirk

- Chris Finn

- Mark Dale

- Raynor Kennerley

* GT Auto Garage

- Dave Johnson

- David Lenthall

- Tim Hung

* AMB Aero

- Andrew Brilliant

* Ultimate Big Boys Toyz

- Rob Sabo

- Wayne Power

- Dan Nicholls

* Gold Rush Composites

- Max Buhner

- Steve Griffith

- Matt Griffith

* Custom Race Electrics

- Greg Walsh

- Steve Ford

* Engineering Precision Solutions

- Ron Julius

* Mayne Paint and Panel

- Eric Johns

- Glen Dorahy

* BRMD

- Brett Rogers

* MR Tuning

- Michael Flanders

- Daniel Ensor

- Leigh Geyer

- Andy McElrea

and last, but by no means least, Ian Baker for putting on the biggest Time Attack event in the world!

Cheers,

Danny

- zero00

- Speed Racer

- Posts: 3248

- Joined: Mon Apr 12, 2010 6:54 pm

- Vehicle: NB8A

- Location: Sunshine Coast Queensland

Re: NC Track Car - Build Thread

Great post Danny

Roger D-SUNSHINE COAST

2000 NB8A-LP 69.1248|QR Clubman 71.9235|QR Sprint 68.1412

1989 NA6 B-SPEC #77|Toyota GTS86 MT

2000 NB8A-LP 69.1248|QR Clubman 71.9235|QR Sprint 68.1412

1989 NA6 B-SPEC #77|Toyota GTS86 MT

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - Build Thread

zero00 wrote:Great post Danny

Thanks Roger.

About a month out from WTAC 2014 I reviewed the composite component manufacturing schedule and it was pretty obvious we would be pushing sh1t up hill to fully execute the aero package as design by AMB Aero in good time. So a compromise was in order...

(1) Use the aluminium front splitter/diffuser I had designed before contracting AMB Aero's services to develop a complete package.

(2) Fabricate an aluminium rear diffuser.

(3) Laser cut new aluminium end plates for the rear wing.

(4) Make a fibre glass nose cone from a one shot mould.

(5) A fibreglass duct was used to go between the heat exchangers and the bonnet outlet.

(6) Use the rather heavy OEM hardtop.

All of the above components will be replaced with composite components over the next 3-6 months. So there is still quite a bit of R&D/track testing to be done before WTAC 2015. This exercise will see a fair bit of weight come out of the car.

The next series of posts will document a day by day summary of the 14 days that lead to the NC's venture south.

1st October - Wednesday

Firstly, the OEM hardtop was sent out to Mayne Paint & Panel to be painted the body colour.

The modified front cross-member was almost finished and ready for painting.

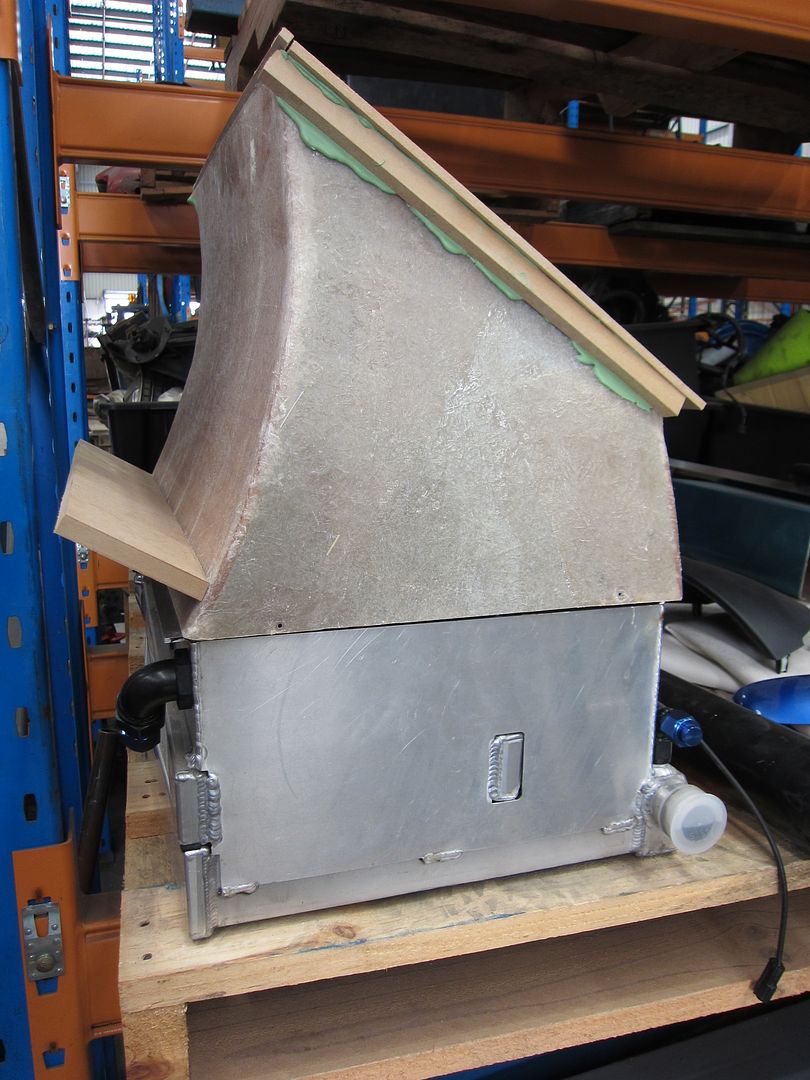

Trial fitting the temporary fibre glass heat exchanger to bonnet duct on the heat exchanger assembly.

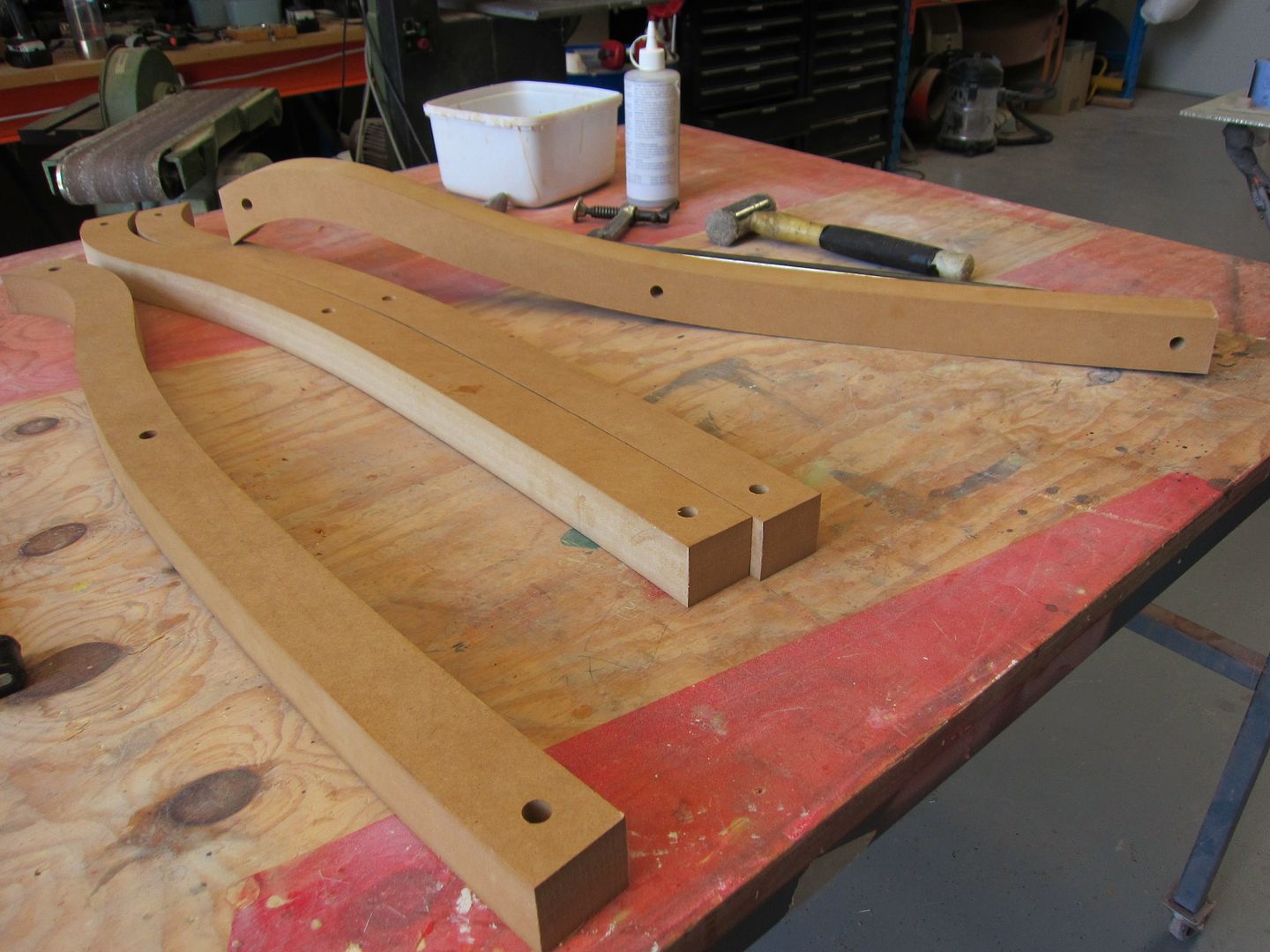

Bits pieces for the rear diffuser plug that we won't be using just yet.

The bonnet plug all flanged up in anticipation of the tooling to be sprayed (first step in making the mould).

The top layer of carbon fibre twill laid in the door outer skin mould.

The inner door mould all ready for vacuum and resin infusion.

The rear clip mould ready for bagging.

2nd October - Thursday

Buggered if I can remember....didn't take any photos but would have been doing something.

Cheers,

Danny

- beavis

- Forum sponsor

- Posts: 1405

- Joined: Mon Feb 02, 2009 12:31 pm

- Vehicle: NB8B - Turbo

- Location: Melbourne

Re: NC Track Car - Build Thread

That looks like a McLaren F1 in the background, only not quite..... I wonder what it is?

Turbo NB Build Thread | BeavisMotorsport.com | YouTube.com/bbeavis | Cars: NA6, NA8-VVT, NB-Turbo, ND-2L

- Regie

- Speed Racer

- Posts: 4259

- Joined: Thu May 15, 2008 3:02 pm

- Vehicle: NC - V8

- Location: Sydney

Re: NC Track Car - Build Thread

Yeah Danny what is that. It looks very similar to a F1. Perhaps the rare whale tail version?? or at least a body of it

MY07 NC, Mazdaspeed Body, Ohlins, Full GWR Exhaust, 17x9 RPF1's, 4.1FGR and lots lots more

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - Build Thread

beavis wrote:That looks like a McLaren F1 in the background, only not quite..... I wonder what it is?

Regie wrote:Yeah Danny what is that. It looks very similar to a F1. Perhaps the rare whale tail version?? or at least a body of it

It is a McLaren F1 replica.

- 16bit

- Speed Racer

- Posts: 2346

- Joined: Wed Nov 29, 2006 1:51 pm

- Vehicle: NB8A - Supercharged

- Location: Brisbane Southside

Re: NC Track Car - Build Thread

mercedes are crushing replicas of their cars, i would not be putting that on the internets. ron dennis may come looking for it!

98 evo gold - rotrexed and loving it.

This post has been printed using recycled pixels

This post has been printed using recycled pixels

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - Build Thread

16bit wrote:mercedes are crushing replicas of their cars, i would not be putting that on the internets. ron dennis may come looking for it!

I've got no idea whose it is or where it is now.

- 16bit

- Speed Racer

- Posts: 2346

- Joined: Wed Nov 29, 2006 1:51 pm

- Vehicle: NB8A - Supercharged

- Location: Brisbane Southside

Re: NC Track Car - Build Thread

me either!

98 evo gold - rotrexed and loving it.

This post has been printed using recycled pixels

This post has been printed using recycled pixels

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - Build Thread

3rd October - Friday

Shazam!

A bonnet mould appeared!!

The heat exchanger duct all smoothed out and flanged at each end.

The front plug was progressing well...but still some time away from being ready to have a mould taken and product made.

4th October - Saturday

Finally some carbon that I can play with...This is straight out of the moulds with only trimming and gluing done.

So the completed (but empty) carbon door shell weighed in at a hefty.....

A fully assembled NC door with some of the door card trimmed and speaker removed weighs in at....

5th October - Sunday

So my next trick was to transfer all of the OEM powered glass, quarter glass, inner & outer door seals, latches and mechanism into the carbon door. In no less than 7 hours (per door) it was completed.

There was a massive amount of holes to drill just for the door seal clips alone.

These tapped alloy plates were glued in for the door hinges to attach.

....and weighed in at....

The fitting of all the OEM gear was just an exercise in proving that the carbon doors could indeed replace a standard steel door cosmetically. in the not too distant future the glass and powered window mechanism will be removed. Hope fully this will get the door weight down to between 5 and 6 kg.

Sunday is to be continued....

Cheers,

Danny

Shazam!

A bonnet mould appeared!!

The heat exchanger duct all smoothed out and flanged at each end.

The front plug was progressing well...but still some time away from being ready to have a mould taken and product made.

4th October - Saturday

Finally some carbon that I can play with...This is straight out of the moulds with only trimming and gluing done.

So the completed (but empty) carbon door shell weighed in at a hefty.....

A fully assembled NC door with some of the door card trimmed and speaker removed weighs in at....

5th October - Sunday

So my next trick was to transfer all of the OEM powered glass, quarter glass, inner & outer door seals, latches and mechanism into the carbon door. In no less than 7 hours (per door) it was completed.

There was a massive amount of holes to drill just for the door seal clips alone.

These tapped alloy plates were glued in for the door hinges to attach.

....and weighed in at....

The fitting of all the OEM gear was just an exercise in proving that the carbon doors could indeed replace a standard steel door cosmetically. in the not too distant future the glass and powered window mechanism will be removed. Hope fully this will get the door weight down to between 5 and 6 kg.

Sunday is to be continued....

Cheers,

Danny

- beavis

- Forum sponsor

- Posts: 1405

- Joined: Mon Feb 02, 2009 12:31 pm

- Vehicle: NB8B - Turbo

- Location: Melbourne

Re: NC Track Car - Build Thread

Im suprised the stock door was that light at 24kg. Thats the same as a factory NB door.

That said, im suprised at how heavy the carbon door was, 4kg seems high, but then I suppose it has a fully moulded inner skin which is overkill for race application but makes sense if you want to sell them for road/track use.

I am still running steel doors in my car, and they are the same weight as your cf doors, albeit mine dont have electric windows.

That said, im suprised at how heavy the carbon door was, 4kg seems high, but then I suppose it has a fully moulded inner skin which is overkill for race application but makes sense if you want to sell them for road/track use.

I am still running steel doors in my car, and they are the same weight as your cf doors, albeit mine dont have electric windows.

Turbo NB Build Thread | BeavisMotorsport.com | YouTube.com/bbeavis | Cars: NA6, NA8-VVT, NB-Turbo, ND-2L

- orx626

- Forum sponsor

- Posts: 1774

- Joined: Thu Sep 23, 2004 8:26 am

- Vehicle: NC - Rotary

- Location: Brisbane - Northside

- Contact:

Re: NC Track Car - Build Thread

beavis wrote:Im suprised the stock door was that light at 24kg. Thats the same as a factory NB door.

At a guess you could add another 4-5kg for the speaker and the remainder of the door card that was removed. So that would take it closer to 30kg,

beavis wrote:That said, im suprised at how heavy the carbon door was, 4kg seems high, but then I suppose it has a fully moulded inner skin which is overkill for race application but makes sense if you want to sell them for road/track use

You're spot on Beavis. This was purely an exercise in creating an OEM spec composite door (sans side intrusion). So I can tick that box now. A new door pair will be done without the complex and heavy inner skin. So you never know...4kg with "glass" may be achievable.

Cheers,

Danny

- lightyear

- Infinity & Beyond

- Posts: 2331

- Joined: Mon Jun 02, 2008 7:54 pm

- Vehicle: NA6 - Turbo

- Location: s.e. melbourne

Re: NC Track Car - Build Thread

I love your updates. My door shells are a bit under 2.0kg's from memory. That's with an inner and outer layer of 180-200gsm cloth, and 1.5mm Soric core. What did you use on yours?

My doors have a full flat "door skin" on the inside.

Next time I make door moulds, i want the inside door trim to sink right in. Will upload a pic to explain.

My NA door moulds are Oem shape on the inner half. Like you said there are so many holes to cut, meaning so many holes to fill when it comes to moulding.

I prefer to see build/progress pics, than seeing the final thing. Always have.

My doors have a full flat "door skin" on the inside.

Next time I make door moulds, i want the inside door trim to sink right in. Will upload a pic to explain.

My NA door moulds are Oem shape on the inner half. Like you said there are so many holes to cut, meaning so many holes to fill when it comes to moulding.

I prefer to see build/progress pics, than seeing the final thing. Always have.

NA8B - P.I 1:50.1 Wntn1:38.0 Sand1:27.6 Wntn S1:08 Bfrd1:06.9 Cldr1:08.5 Wak1:10.4

"SE" - P.I 1:43.8 Wntn1:32.9 Sand1:22.0 Bfrd1:05.3

"SE" - P.I 1:43.8 Wntn1:32.9 Sand1:22.0 Bfrd1:05.3

Who is online

Users browsing this forum: No registered users and 6 guests