BP performance build - pic heavy

Posted: Sun Aug 21, 2016 10:34 pm

I'm rebuilding a NA8 engine - with some mods on the way. Acquired some parts, its a budget build so Im taking my time getting it sorted. Will be a street engine with hopefully a happy level of compromise between driveability and power.

Id appreciate any advice of the rebuild and choice of parts.

Ive already ground off the lettering off the cam cover, and will likely cut the face of the cover for access the cam gears. Unsure if I should paint or polish the cover, polish would look great but difficult to maintain. COPS mounting plate already made.

Headers are 4-1 stainless - not racingbeat but similar.

I bought the complete long engine a while ago -

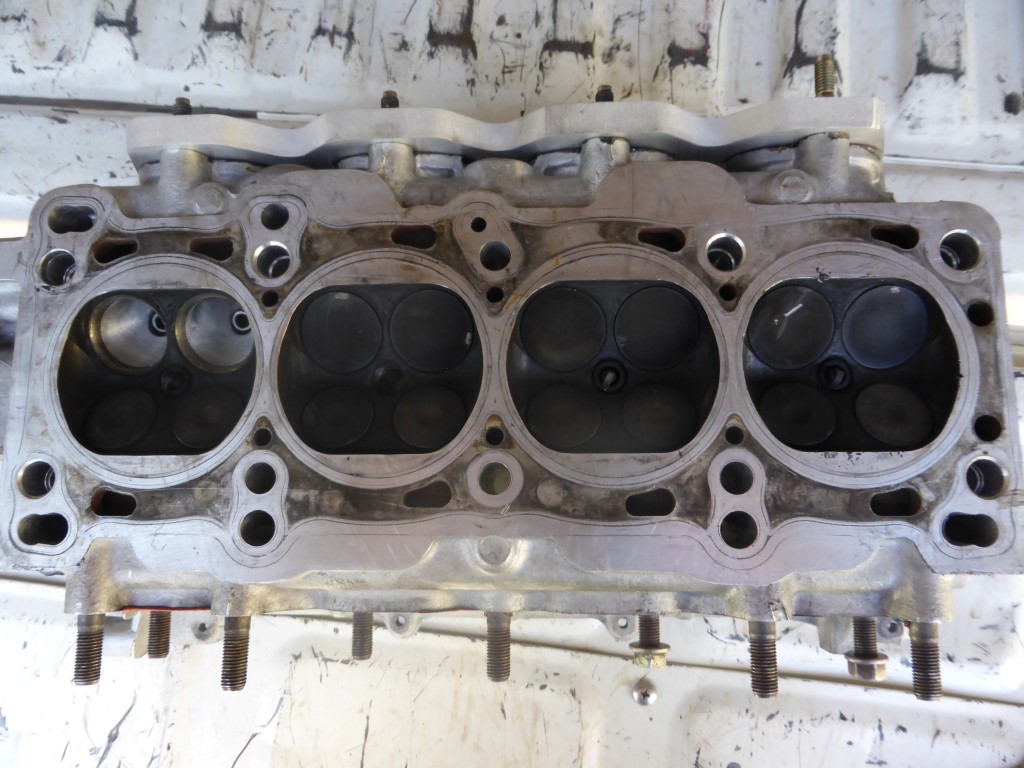

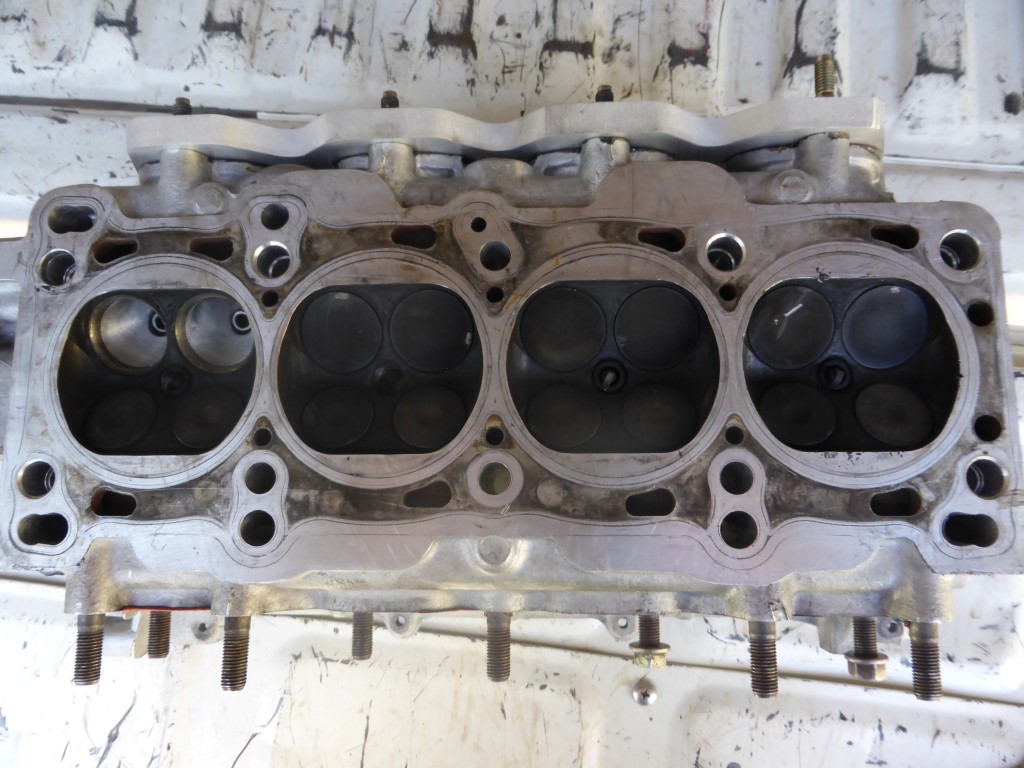

The head was purchased separately, and has had backcut +1 oversized valves,porting and duel valve springs.

The block is original na8- with over 150000kms on it, slight ridge on top of bores.

Clutch and flywheel combo- flywheel is a lightweight chromoly one about 3.5kg and the clutch is a exedy with inorganic cushioned button plate.

2 X na8 exhaust cams (one wrapped up ready to send to regrinders) and a adjustable cam gear set. After regrinding both the exhaust cams, I'll do the ex inlet mod.

The valves are very long compared to standard at 117mm. Looks like the underside of the buckets have been machined to suit the valves and perhaps the previous owner ground the valve to get the correct length without using shims.

Testing with the standard 36mm base circle cam it seems the base circle would have to be reduced to 32-33mm for this to work.

Anyone know if I can grind/cut the the valve stem 2-4mm and use SUB shims? Do stainless valves have 'hardened' ends or is it ok to cut them?

I've been quoted $250 to get the block rebored, but was thinking about hunting around for a low kms block that doesn't need a rebore and only a hone.

Thoughts at the moment are to:

1 Get the cams reground to 270degree(220-230 at .050) with 10mm lift.

2 Shave head - it has marks in one cylinder that a shave would clean up.

3 Relap the valves. Fit cams with SUB shims- easier to write then do.

4 Use 10:1 pistons in a newer block or rebored this one.(hoping for 11-12:1 CR with head shave)

5 Maybe buy h beam conrods. Maybe buy new oil pump.

6 rebuild with new bearings seals gaskets water pump.

7 Get running with the na8 inlet manifold but replace it soon after with a handmade one with straight runners. Or a honda moded one. See the watercut flange plate already on the engine.

Lots of maybes like:

H beam rods, or are they only for turbo engines.

Is the standard front pulley ok for high revs

Is the std oil pump ok

Oil squirters, keep or remove.

Id appreciate any advice of the rebuild and choice of parts.

Ive already ground off the lettering off the cam cover, and will likely cut the face of the cover for access the cam gears. Unsure if I should paint or polish the cover, polish would look great but difficult to maintain. COPS mounting plate already made.

Headers are 4-1 stainless - not racingbeat but similar.

I bought the complete long engine a while ago -

The head was purchased separately, and has had backcut +1 oversized valves,porting and duel valve springs.

The block is original na8- with over 150000kms on it, slight ridge on top of bores.

Clutch and flywheel combo- flywheel is a lightweight chromoly one about 3.5kg and the clutch is a exedy with inorganic cushioned button plate.

2 X na8 exhaust cams (one wrapped up ready to send to regrinders) and a adjustable cam gear set. After regrinding both the exhaust cams, I'll do the ex inlet mod.

The valves are very long compared to standard at 117mm. Looks like the underside of the buckets have been machined to suit the valves and perhaps the previous owner ground the valve to get the correct length without using shims.

Testing with the standard 36mm base circle cam it seems the base circle would have to be reduced to 32-33mm for this to work.

Anyone know if I can grind/cut the the valve stem 2-4mm and use SUB shims? Do stainless valves have 'hardened' ends or is it ok to cut them?

I've been quoted $250 to get the block rebored, but was thinking about hunting around for a low kms block that doesn't need a rebore and only a hone.

Thoughts at the moment are to:

1 Get the cams reground to 270degree(220-230 at .050) with 10mm lift.

2 Shave head - it has marks in one cylinder that a shave would clean up.

3 Relap the valves. Fit cams with SUB shims- easier to write then do.

4 Use 10:1 pistons in a newer block or rebored this one.(hoping for 11-12:1 CR with head shave)

5 Maybe buy h beam conrods. Maybe buy new oil pump.

6 rebuild with new bearings seals gaskets water pump.

7 Get running with the na8 inlet manifold but replace it soon after with a handmade one with straight runners. Or a honda moded one. See the watercut flange plate already on the engine.

Lots of maybes like:

H beam rods, or are they only for turbo engines.

Is the standard front pulley ok for high revs

Is the std oil pump ok

Oil squirters, keep or remove.