Bigdog's SP Engine Rebuild (not 56K friendly)

Posted: Sun Jul 26, 2009 5:55 pm

The story so far....

As some of you know my SP's clutch started slipping badly a while back. As I had a leaking exhaust manifold that required removing all the turbo stuff and the manifold to fix it, I thought I would pull the engine and give it a freshen up with some forged rods and pistons which I had ordered on spec from Les in WA. Note that the car was running perfectly, so there was no great need to do all this, just the convenience of having the engine out to do the other jobs. It was also due for a timing belt change in another 20K.

Unfortunately there were some delays getting the rods and pistons, and after suffering withdrawal symptoms from lack of booooost, I said stuff it and dropped it to the local clutch shop for a new button clutch, with the engine pull postponed for 20K.

Next day I got the call to say that having removed the gearbox and clutch they found that the sump had been leaking into the bell housing around the rear of the crank and oil had got to the clutch. Not only that but the sump was leaking around the front of the crank as well. Sooo, out comes the engine, and project rebuild is on again.

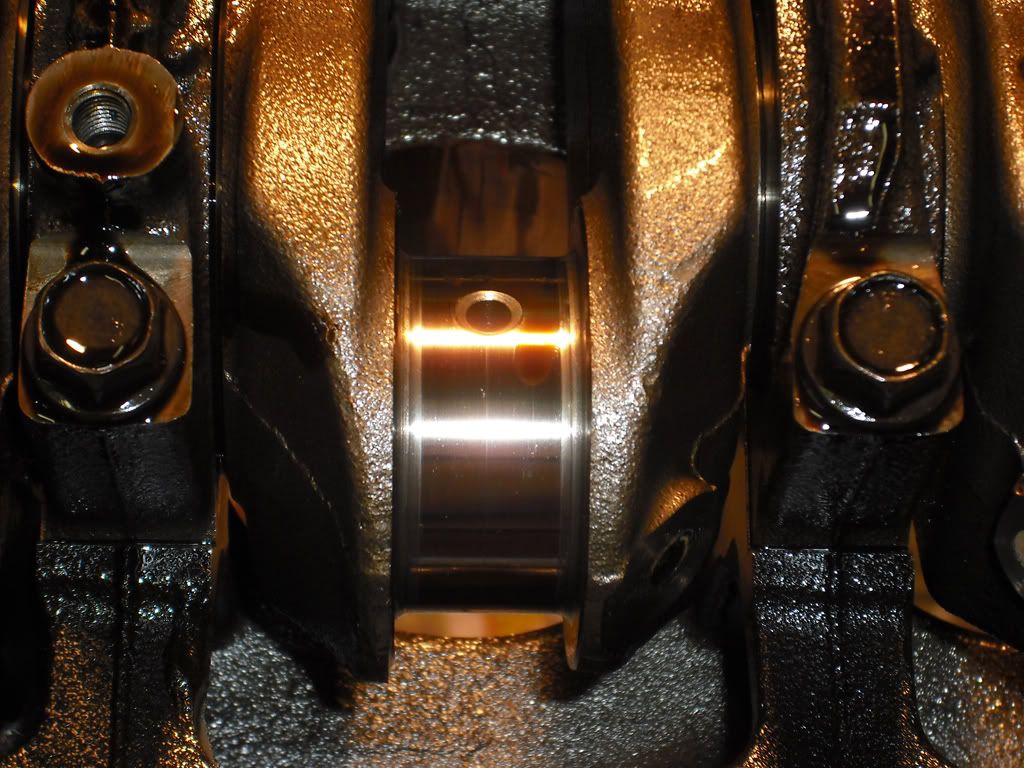

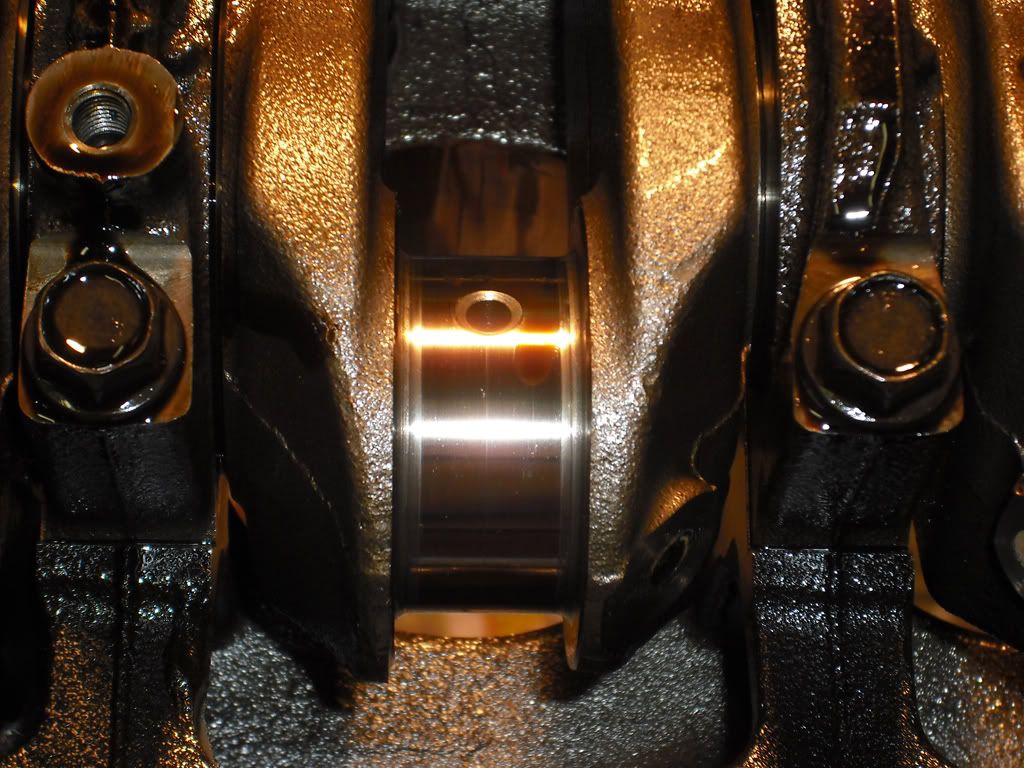

Today I stripped it down and was very pleased with my findings. Basically everything inside is spotless. No bent rods (I told you guys!!), clean bearing shells and perfect bores. The only negative was the heavy carbon build up on the pistons, which points to the very rich setup on the SP, and would possibly have resulted in stuck rings in the future, so my timing is good. The engine has done 170K, and would probably have done another 170K trouble free. Now all I need is my rods and pistons to arrive so I can get the machining done and screw it all back together. Here are some pics of the beast:

you can see the exhaust leak around the top stud

Straight rods!

Carbon build up

Clean bores

Clean crank

As some of you know my SP's clutch started slipping badly a while back. As I had a leaking exhaust manifold that required removing all the turbo stuff and the manifold to fix it, I thought I would pull the engine and give it a freshen up with some forged rods and pistons which I had ordered on spec from Les in WA. Note that the car was running perfectly, so there was no great need to do all this, just the convenience of having the engine out to do the other jobs. It was also due for a timing belt change in another 20K.

Unfortunately there were some delays getting the rods and pistons, and after suffering withdrawal symptoms from lack of booooost, I said stuff it and dropped it to the local clutch shop for a new button clutch, with the engine pull postponed for 20K.

Next day I got the call to say that having removed the gearbox and clutch they found that the sump had been leaking into the bell housing around the rear of the crank and oil had got to the clutch. Not only that but the sump was leaking around the front of the crank as well. Sooo, out comes the engine, and project rebuild is on again.

Today I stripped it down and was very pleased with my findings. Basically everything inside is spotless. No bent rods (I told you guys!!), clean bearing shells and perfect bores. The only negative was the heavy carbon build up on the pistons, which points to the very rich setup on the SP, and would possibly have resulted in stuck rings in the future, so my timing is good. The engine has done 170K, and would probably have done another 170K trouble free. Now all I need is my rods and pistons to arrive so I can get the machining done and screw it all back together. Here are some pics of the beast:

you can see the exhaust leak around the top stud

Straight rods!

Carbon build up

Clean bores

Clean crank